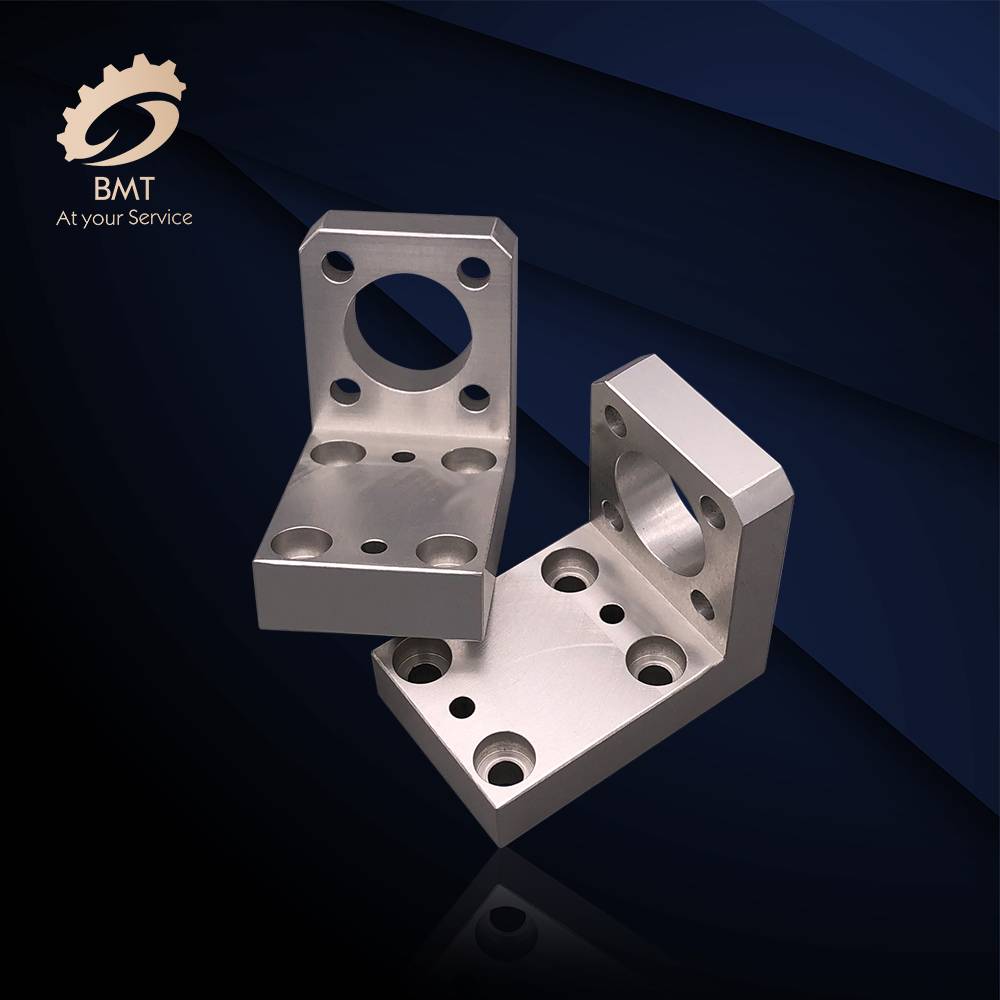

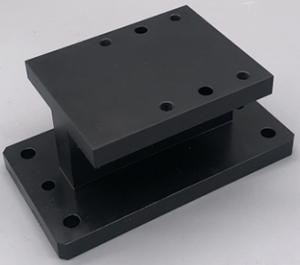

BMT CNC Machining Surface Treatment

Ka linako tse ling, Bareki ba khetha lits'ebeletso tsa kalafo ea tšepe ka mor'a ho sebetsa BMT ho ntlafatsa ponahalo ea likarolo, ho fumana bokaholimo bo boreleli, le ho fihlela ho hanyetsa kutu, joalo-joalo Ka boiphihlelo ba lilemo tse fetang 10 ka likarolo tsa CNC Precision Machining mme ba ithutile ho tsoa ho bareki, bareki ba rona. hangata khetha Oxide Blacking, polishing, Carburizing, Anodize, Chrome Plating, Zinc Plating, Nickel Plating, Sandblasting, Laser engraving, Mocheso kalafo, Powder Coated, joalo-joalo Phapang ke efe pakeng tsa liphekolo tsee holim'a metsi?

| Electroplating | Ts'ebetso ea ho sebelisa motlakase ho fokotsa li-cations tsa tšepe tse qhibilihisitsoeng e le hore li thehe mokelikeli o mosesaane o kopantsoeng oa tšepe holim'a electrode, ho fetola thepa ea holim'a tšepe kapa ho haha botenya bakeng sa likarolo tse fokolang. |

|

| Ho benya | Mokhoa oa ho hohla bokaholimo ba likarolo kapa ho sebelisa ketso ea lik'hemik'hale ho hlahisa bokaholimo bo boreleli le bo benyang, ho etsa hore bokaholimo bo be le ponahalo e ikhethang kapa ho fokotsa ponahalo e pharalletseng linthong tse ling. |

|

| Ho penta | E bua ka mokhoa o fetohang oa ho qetela, ho fafatsa pente, pigment kapa 'mala sebakeng se tiileng e le lera le sireletsang,' me e ka etsoa ka tšepe kapa likarolo tse seng tsa tšepe tsa CNC tsa libopeho leha e le life, hangata li sebelisoa ka aluminium, tšepe e sa hloekang le. likarolo tsa tšepe tsa tšepe.Sepheo ke ho ntlafatsa ponahalo ea botle le ho thibela ho bola kapa oxidation. |

|

| Boikemisetso | Mokhoa o tloaelehileng oa phekolo ea holim'a lik'hemik'hale bakeng sa tšepe le tšepe e sa hloekang, ho tlosa litšila tse nang le ferrous kapa ho sebelisa seaparo se bobebe sa thepa e sireletsang ho etsa khetla bakeng sa ho matlafatsa ho hanyetsa ha kutu kapa ho fokotsa ts'ebetso ea lik'hemik'hale. |

|

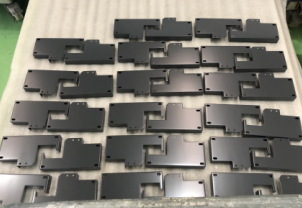

| Ho roala ka phofo | Qetello e sebetsang le e khabisitsoeng, e sebelisoang e le phofshoana e sa lefelloeng, e omeletseng, e sebelisa electrostatically ebe e phekoloa tlas'a mocheso, ho etsa qetello e thata e thata ho feta pente e tloaelehileng.Lisebelisoa tsa mantlha tse kenyelletsang lisebelisoa tsa ntlo, li-extrusions tsa aluminium, lisebelisoa tsa meropa, koloi, lithuthuthu le likarolo tsa baesekele. |

|

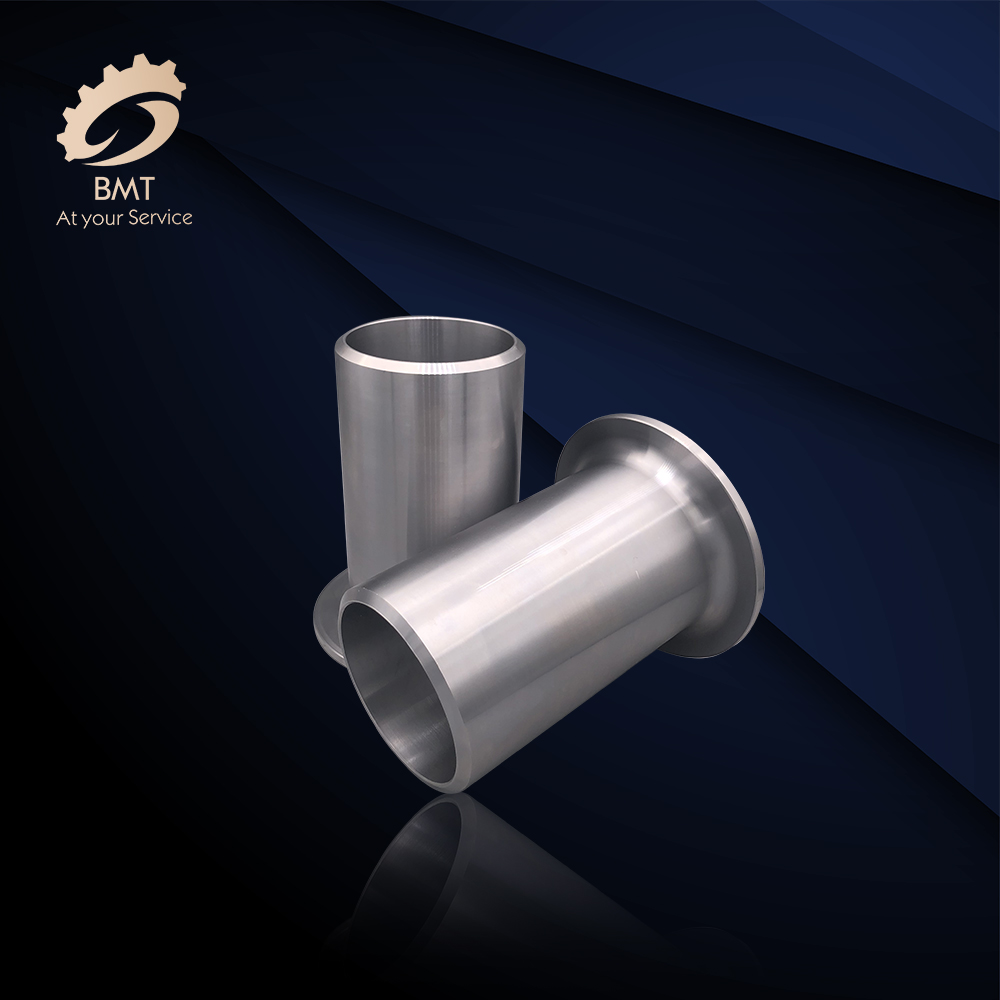

| Anodizing | Ts'ebetso ea electrolytic passivation ea ho etsa lesela le tšesaane la aluminium oxide ka ntle ho likarolo tse entsoeng ka aluminium CNC ho eketsa botenya ba lera la oxide ea tlhaho le ho sireletsa tšepe, kaha lera le na le kutu e phahameng le ho hanyetsa abrasion ho feta aluminium. |

|

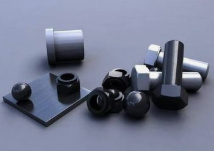

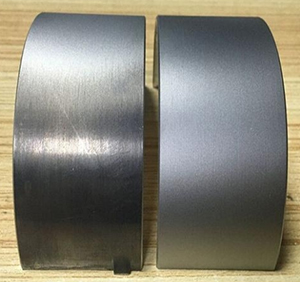

| oxide e ntšo | Ts'ebetso ea lik'hemik'hale ea ho etsa lesela le letšo la phetoho holim'a tšepe e sa hloekang, li-alloys tsa koporo le koporo, zinki, tšepe e phofshoana, solder ea silevera le lisebelisoa tsa ferrous, ho ntlafatsa ho hanyetsa kutu le ho fokotsa khanya ea leseli. |  |

| Ho phatloha ho matla/ Ho qhomisa lehlabathe | Ts'ebetso kapa ts'ebetso ea ho tsamaisa leqhubu la lintho tse hlabang tse entsoeng ka likaroloana tsa boholo ba lehlabathe la lebelo le phahameng khahlano le bokaholimo ba tšepe tlas'a khatello e matla e nang le lisebelisoa tse phatlohang joalo ka sistimi ea khatello ea moea, ho tlosa litšila tse holim'a metsi, litšepe tse hloekileng kapa ho eketsa sebopeho, ebe o fetola boreledi kapa ho ba makgwakgwa bokahodimo. |

|

| Phosphating | Ts'ebetso ea lik'hemik'hale bakeng sa ho phekola holim'a tšepe, moo likarolo tsa tšepe-phosphate tse sa qhibilihang li thehoa holim'a thepa ea motheo.Likarolo tse entsoeng li na le li-porous, tse monyang 'me li loketse joaloka lera la phetoho bakeng sa ho roala phofo e latelang ntle le phekolo e eketsehileng. |  |

BMT e boetse e fana ka ts'ebeletso ea ho sila, ea liindasteri, le ts'ebeletso e eketsehileng ea ho qeta litšepe bakeng sa ho hlahisa phello e ntle ea karolo ea hau.Re bolelle feela seo u se hlokang 'me re tla hlokomela tse ling kaofela!

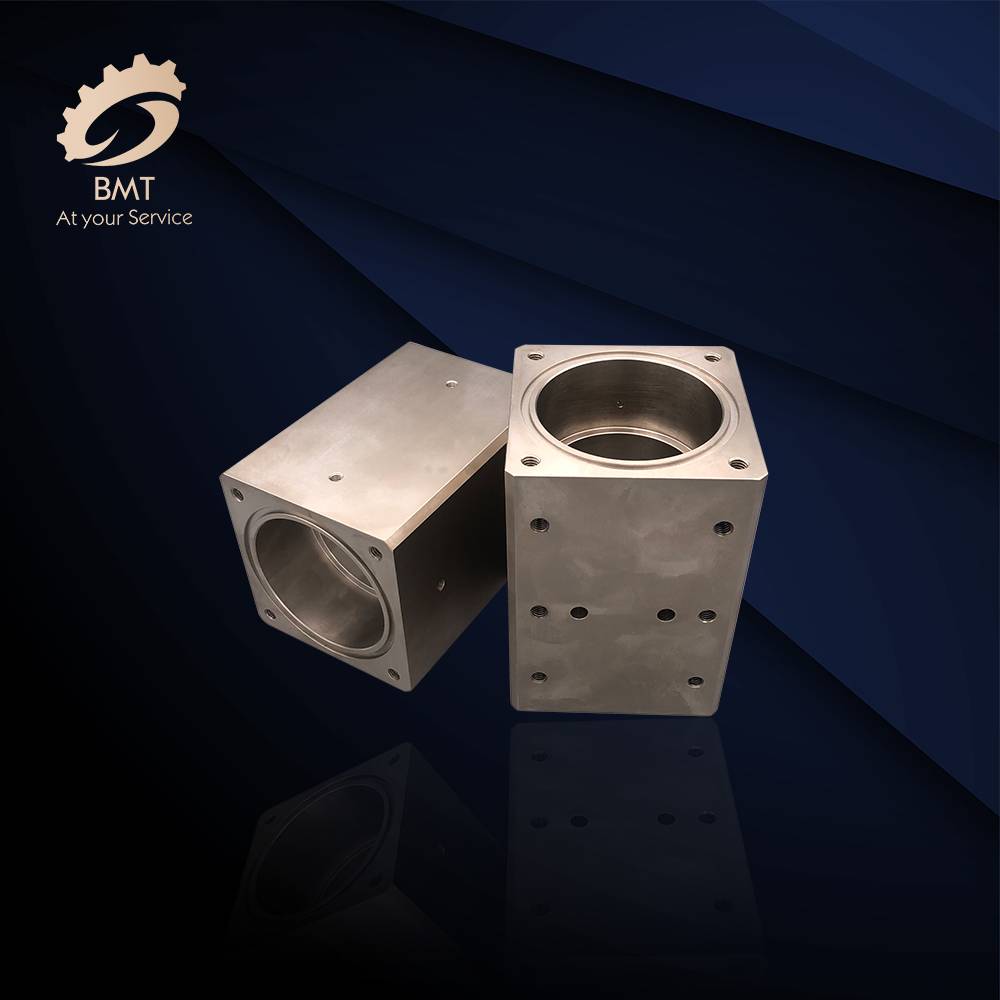

Tlhaloso ea Sehlahisoa