Litšobotsi tsa Theknoloji tsa Mechanical Precision Machining

Theknoloji ea sejoale-joale ea ho etsa mechini le mahlale a machining a nepahetseng ke lintlha tsa mantlha tsa ho khothaletsa nts'etsopele e potlakileng le e tsitsitseng ea indasteri ea tlhahiso ea mechini, 'me re hloka ho li hlokomela haholo.Tlas'a semelo sa ho ikopanya ha lichaba tsa moruo, e le ho khothaletsa nts'etsopele ea indasteri ea tlhahiso ea mechini ho fumana sebaka se pharaletseng, re tlameha ho hlahisa, ho ntlafatsa le ho nts'etsapele mahlale a macha a tlhahiso ea mechini ea sejoale-joale le theknoloji e nepahetseng ea machining ka nako e telele, le ho sebetsa indastering ea tlhahiso ea mechini ka mokhoa o utloahalang, ho sebeletsa hamolemo bakeng sa nts'etsopele ea khoebo ea sejoale-joale ea ho etsa le ho lokisa mechini, le ho khothaletsa theknoloji ea rona ea tlhahiso 'marakeng oa machaba oa nts'etsopele e tsitsitseng.

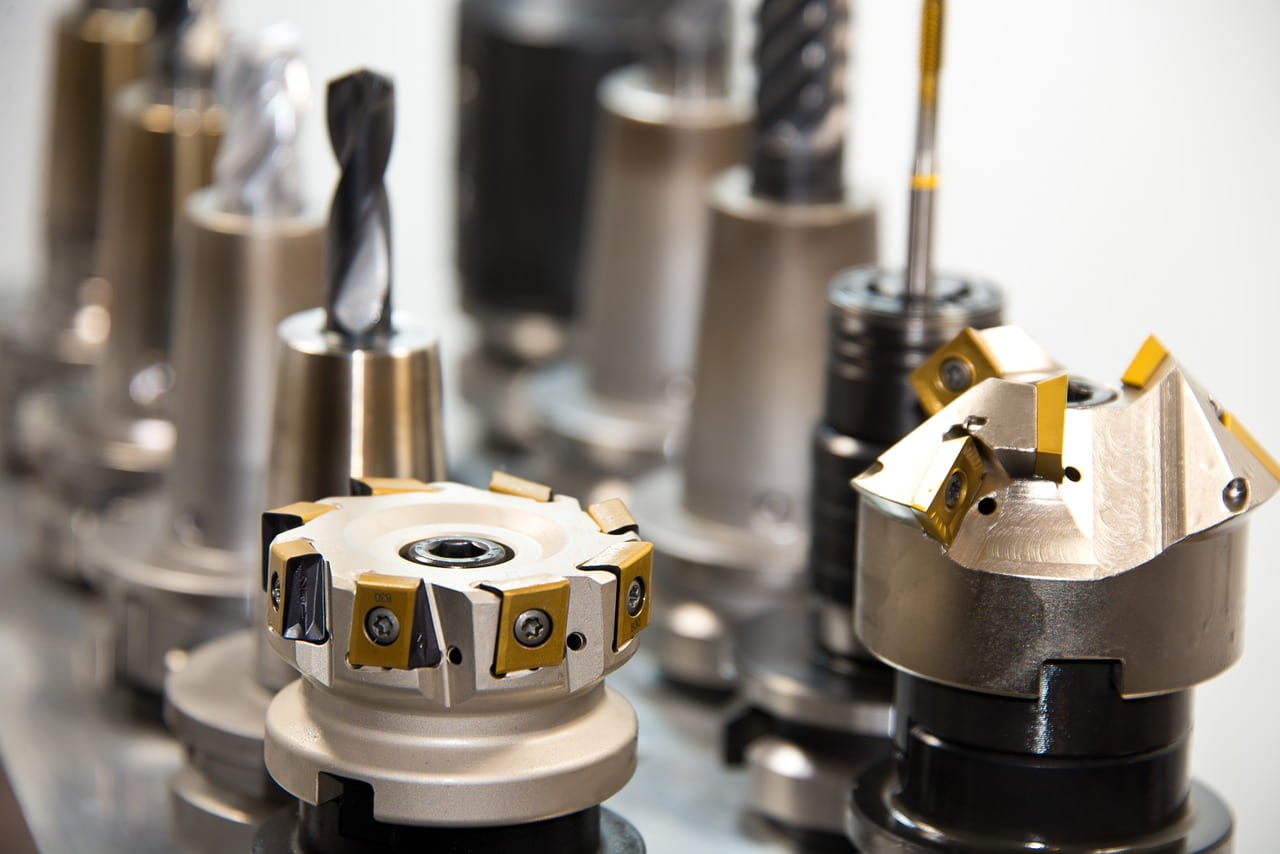

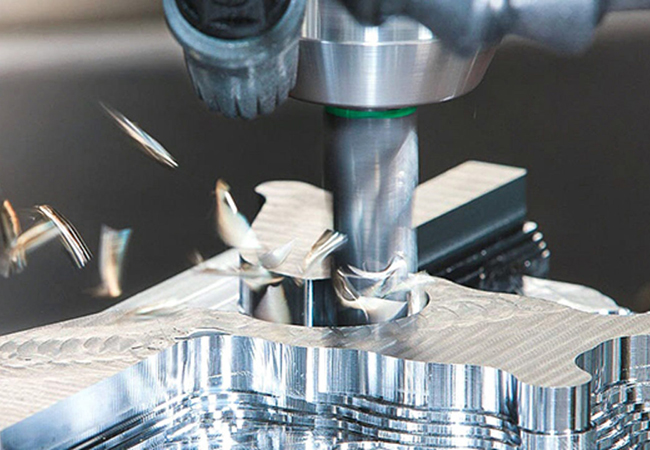

(1) Theknoloji ea Precision Cutting

Ka kakaretso, theknoloji e nepahetseng ea ho itšeha e sebelisa ka ho toba mokhoa oa ho itšeha ho fumana ho nepahala ho phahameng, kahoo e na le litlhoko tse molemo tsa lihlahisoa tsa ho itšeha.Ka mohlala, tlhokahalo ea ho nepahala ho holimo holimo e tlameha ho finyelloa.Empa ke habohlokoa ho hlokomela hore haeba u batla ho sebelisa mokhoa oa ho itšeha ho fumana ho nepahala ho phahameng le boemo bo phahameng ba holimo, u lokela ho qheleloa ka thōko ka mafolofolo tšusumetsong ea lisebelisoa tsa mochine, lisebelisoa, lisebelisoa tsa mosebetsi le lintho tse ka ntle.Ka mohlala, e le hore u tsoele pele ho ntlafatsa ho nepahala le ho nepahala ha mochine oa mochine, ho hlokahala hore u khethe mochine oa mochine o nang le boima bo phahameng, deformation e nyenyane ea mocheso, le ts'ebetso e ntle ea ho hanyetsa ho sisinyeha.

(2) Theknoloji ea ho sila ea Ultra-Precision

Bakeng sa machining, sepheo sa ho fihla ho 1-2mm holim'a mafika, le ts'ebeliso ea boemo ba athomo ho sila sephaphatha sa silicon.Mokhoa o fetileng oa ho sila, oa ho senya, ho bentša le mekhoa e meng ea mekhoa ea setso e ke ke ea finyella litlhoko tsa mosebetsi ona.Ka hona, melao-motheo le mekhoa e mecha e tlameha ho hlahlojoa le ho ithutoa ka botebo.Ke ka lebaka lena moo theknoloji ea ho sila ka mokhoa o nepahetseng haholo e hlahang nakong ea nalane 'me e bapala karolo ea bohlokoa ho feta tekhenoloji e nepahetseng ea mochini.

(1) Bohlokoa ba Theknoloji ea Sejoale-joale ea Tlhahiso ea Mechini le Theknoloji ea Boqapi ba Mechini.

Mabapi le thekenoloji ea tlhahiso, theknoloji ea morao-rao ea tlhahiso ea mechine le theknoloji ea ho sebetsa ka mokhoa o nepahetseng e ameha likarolong tse ngata tsa indasteri ea mechine, joalo ka boenjiniere ba tlhahiso, moralo oa lihlahisoa le nts'etsopele, moralo oa ts'ebetso ea lihlahisoa, ts'ebetso le tlhahiso, thekiso ea lihlahisoa, joalo-joalo Hang ha mathata a etsahala. liindasteri tsena, li tla ama ka ho toba ketane eohle ea boenjiniere.Ka hona, re tlameha ho hokela bohlokoa bo boholo kamanong e teng lipakeng tsa indasteri ea tlhahiso ea mechini ea sejoale-joale le theknoloji e nepahetseng ea machining, e le ho khothaletsa tsoelo-pele le nts'etsopele ea mahlale a mechini.Ka hona, ts'ebetsong, theknoloji ea sejoale-joale ea mochini le theknoloji e nepahetseng ea mochini e tlameha ho kopanngoa ka botlalo ho khothaletsa tsoelo-pele ea mochini le ho fihlela nts'etsopele e potlakileng le tsoelopele ea mahlale.

(2) Mokhoa o hlophisitsoeng oa Theknoloji ea Sejoale-joale ea ho Etsa Mechane le Theknoloji ea ho Etsa Mechane e nepahetseng.

Tlhahiso ea mochini oa sejoale-joale ke mokhoa o rarahaneng oa boenjiniere ts'ebelisong ea mahlale a morao-rao a ho etsa mechini le theknoloji ea ts'ebetso e nepahetseng, joalo ka moralo oa sehlahisoa, tlhahiso le thekiso, e tla kenyelletsa theknoloji ea tlhaiso-leseling ea khomphutha, theknoloji ea sejoale-joale ea kutlo, theknoloji ea tlhahiso ea boiketsetso le mahlale a mang a mangata.Ho phaella moo, ho ka 'na ha e-ba le tlhokahalo ea ho sebelisa lisebelisoa tse ncha, mekhoa e mecha ea tsamaiso, joalo-joalo. Ka hona, ho bua ka kakaretso, theknoloji ea tlhahiso ea indasteri ea mechine e ke ke ea arohanngoa le ts'ebeliso e pharaletseng ea mefuta e sa tšoaneng ea theknoloji ea morao-rao e tsoetseng pele, e hlokang mekhoa ea morao-rao. Theknoloji ea tlhahiso ea mechine le theknoloji ea ho sebetsa ka mokhoa o nepahetseng ho ba le tsamaiso e kholoanyane.

(3) Khokahano ea Lefatše ea Theknoloji ea Mehleng ea Kajeno ea Mechini le Theknoloji ea Precision Machining.

Hajoale, ka nts'etsopele ea ho ikopanya ha lichaba tsa moruo, likarolo tse ngata tsa moruo tsa naha ea rona li hlokometse butle-butle ho kopanya le mokhoa oa machaba.Ho ikopanya ha lichaba tsa lefatše moruong ho hlahisitse mokhoa oa bohlokoa oa ho pota-pota tsoelo-pele ea joale ea sechaba.Ka nako e ts'oanang, tlas'a semelo sa ho ikopanya ha lichaba tsa moruo, tlhōlisano ea 'maraka e ntse e eketseha, indasteri ea tlhahiso ea mechine naheng ea rona e le ho ntšetsa pele tlhōlisano ea likhoebo tsa' maraka oa malapeng le oa machaba, re tlameha ho latela tsoelo-pele ea nako, ka mafolofolo re hlahise mechine ea machaba e tsoetseng pele. Theknoloji ea tlhahiso le theknoloji e nepahetseng ea machining, ho eketsa matsete lipatlisisong tsa ka hare tsa khoebo ho hlaolela basebetsi ba maemo a holimo ba botekgeniki, lipatlisiso le nts'etsopele tumellanong le boemo ba 'nete ba theknoloji ea tlhahiso ea mochini le theknoloji e nepahetseng ea machining, e le ho fihlela nts'etsopele e phetseng hantle le e tsitsitseng ea tlhahiso ea mochini. likhoebo.

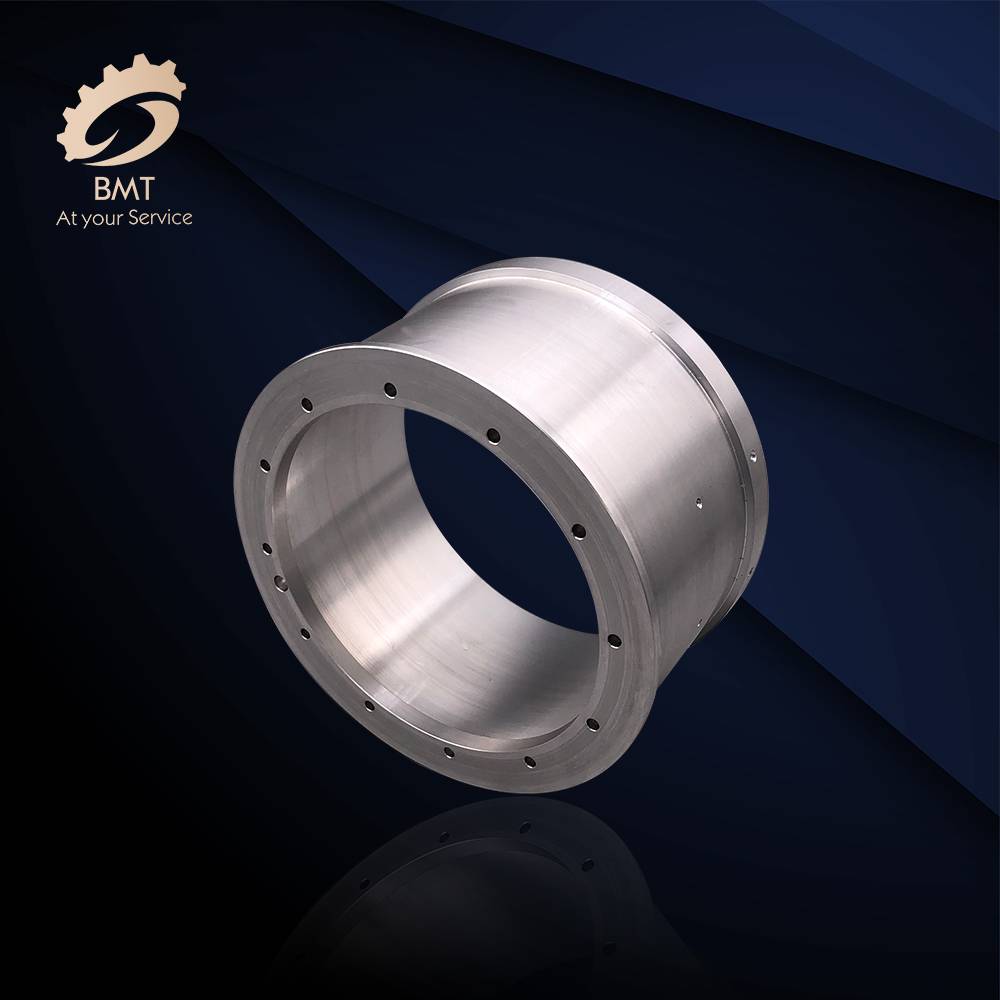

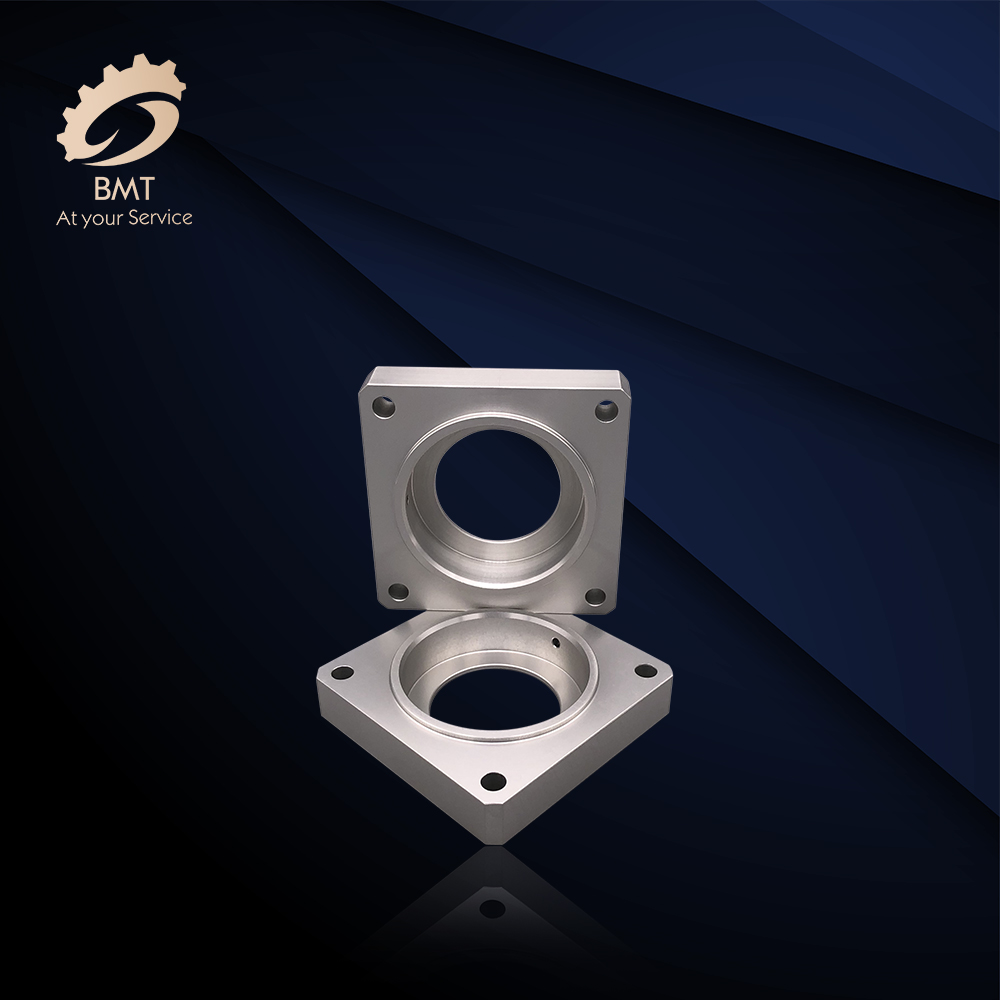

Tlhaloso ea Sehlahisoa