Likarolo tsa Milling Cutters

Ho leka ho matlafatsa ho tiea ha sesebelisoa pele ho sebetsa ho tla tlisa melemo ho tlhahiso ea nako e telele nakong e tlang.Ha e lelefatse bophelo ba sesebelisoa feela, empa hape e ntlafatsa boleng ba holim'a mochini oa mosebetsi le ho fokotsa phoso ea machining.

Ka mokhoa o ts'oanang, khetho e sa nepahalang ea sesebelisoa e tla khutsufatsa bophelo ba sesebelisoa.Ka mohlala, haeba leloala la ho qetela le bophara ba 3.175mm le kenngoa ka har'a mochine oa ho khaola (ho e-na le chuck ea selemo), ka lebaka la ketso ea sekoti se tiisang, lekhalo le loketseng pakeng tsa sehahi le sehahi se leeme ho se seng. lehlakore, 'me setsi sa seha se khelohile.Bohareng ba ho potoloha ha sesebelisoa sa sesebelisoa se eketsa ho phalla ha radial ea seha sehahi nakong ea ts'ebetso, e leng se etsang hore ho be le moroalo o sa leka-lekaneng oa ho khaola leino le leng le le leng la mochine o silang.Boemo bona ba ho itšeha ha bo lokele sesebelisoa, haholo ha ho siloa li-alloys tse thehiloeng ho nickel.

Ka ho sebelisa sesebelisoa sa lisebelisoa se ntlafatsang eccentricity ea ho kenya lisebelisoa, tse kang hydraulic chuck le shrink-fit chuck, ketso ea ho itšeha e ka ba e leka-lekaneng le e tsitsitseng, ho roala lisebelisoa ho fokotseha, 'me boleng ba holim'a metsi bo ntlafatsoa.Ho lokela ho lateloa molao-motheo ha u khetha molamu, ke hore, ho tšoara ho lokela ho ba khutšoanyane ka hohle kamoo ho ka khonehang.Litlhoko tsena tsa lisebelisoa le li-workpiece clamping li sebetsa ha ho siloa thepa efe kapa efe, 'me ha ho siloa li-alloys tse thehiloeng ho nickel, ho hlokahala boiphihlelo bo tsoetseng pele ba machining hohle moo ho khonehang.

Tšebeliso ea Lisebelisoa

Ho sa tsotelehe hore na sesebelisoa se entsoe joang, kapa se entsoe ka lisebelisoa life, moetsi oa lisebelisoa o lokela ho fana ka litekanyetso tsa pele tsa ho itšeha lebelo le ho fepa ka leino ka leng.Haeba lintlha tsena li le sieo, ho lokela ho buisanoe le lefapha la botekgeniki la moetsi.Baetsi ba lokela ho tseba hore na lihlahisoa tsa bona li khona ho kolobisa ka bophara, ho pota-pota, ho thetheha, kapa ho ramping, kaha boholo ba li-milling cutters ha li khone ho sebetsana le mesebetsi ena e mengata.Mohlala, haeba sehaho sa tšilo se se na sekhutlo se lekaneng sa bobeli sa ho koloha, sekhutlo sa bevel bakeng sa ho pota-pota sea fokotseha.

Ho hlakile hore haeba matla a machining a sesebelisoa a fetisitsoe, a tla baka tšenyo ho sesebelisoa.Ho joalo le ka plunge milling.Haeba li-chips li ke ke tsa lelekoa ka tlase ho groove ka nako, li-chips li tla hatelloa 'me sesebelisoa se tla senyeha hamorao.Qetellong, maemo ana a kotsi ho bophelo ba sesebelisoa ha ho siloa li-superalloy.Haeba u ne u nahana hore ho fokotsa sekhahla sa phepelo ho tla eketsa bophelo ba lisebelisoa, ho ile ha bonahala ho fosahetse.Mohlala o tloaelehileng ke ha sehiloeng sa pele se etsoa 'me thepa e fumanoa e le thata haholo.Haeba phepelo e fokotsehile (mohlala, phepelo ea leino le leng le le leng la "milling cutter" e fokotsehile ho 0.025 ho isa ho 0.5 mm), moeli o sehang oa sesebelisoa o tla sila sesebelisoa ka matla, 'me phello e tla ba hore sesebelisoa se tla senyeha. kapele kapa hanghang.Ho ferekana ho ka etsa hore mosebetsi o be thata holim'a sebaka sa mosebetsi.E le ho qoba ho thatafala ha mosebetsi, mojaro o itseng oa ho itšeha (0.15-0.2mm / fepa ka leino) o lokela ho bolokoa ha o seha thipa ea pele.

Re romelle molaetsa oa hau:

-

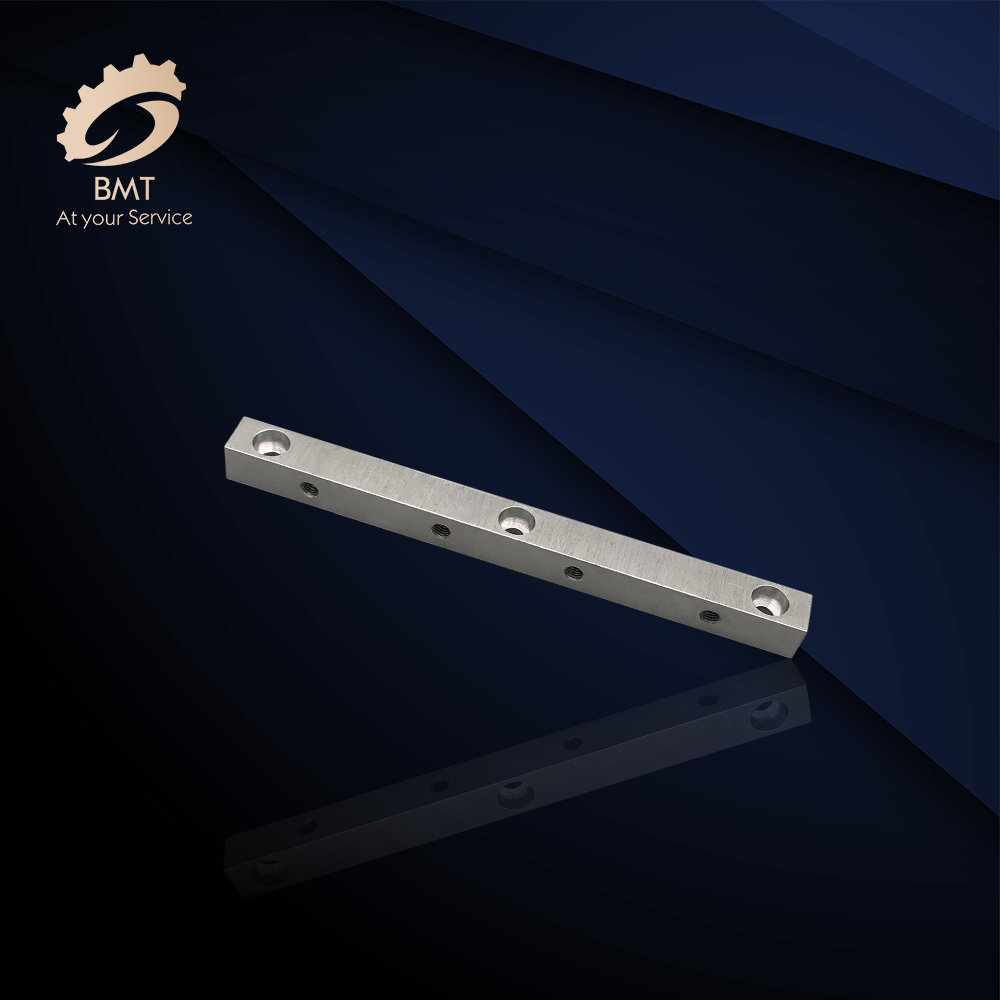

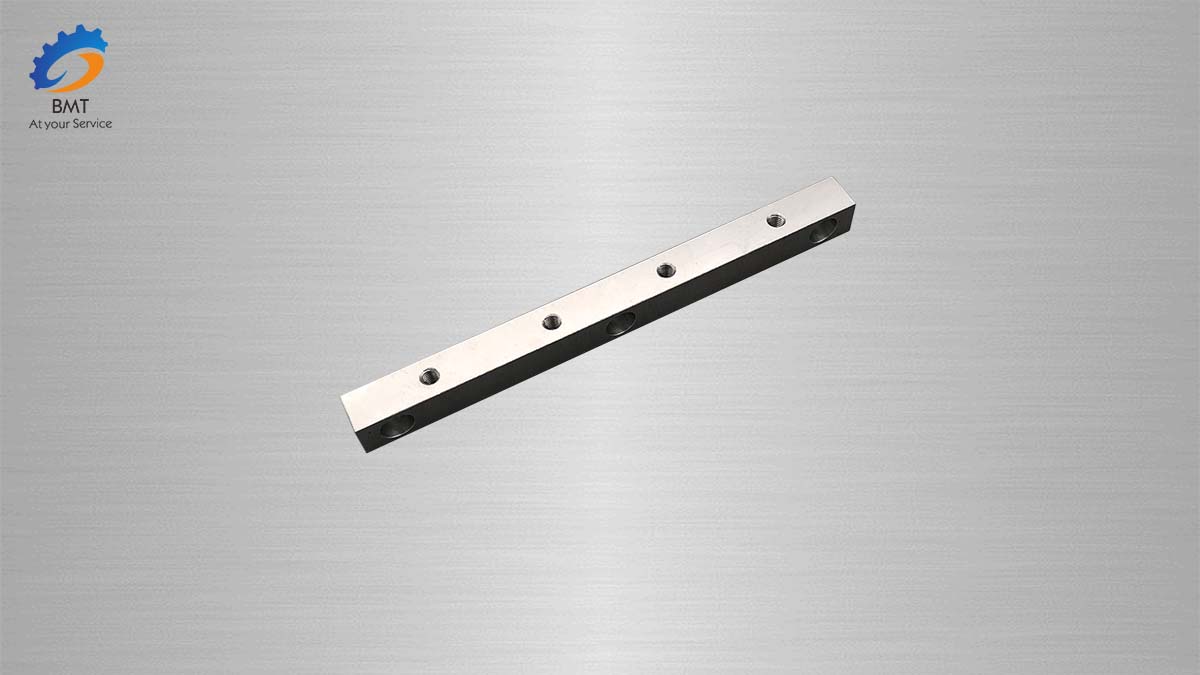

Aluminium CNC Machining likarolo

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining likarolo

-

Likarolo tse entsoeng ke CNC bakeng sa Italy

-

CNC Machining Aluminium likarolo

-

Auto Parts Machining

-

Lisebelisoa tsa Titanium Alloy Forgings

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes