Likarolo tsa Machining tse entsoeng ka tloaelo tsa CNC

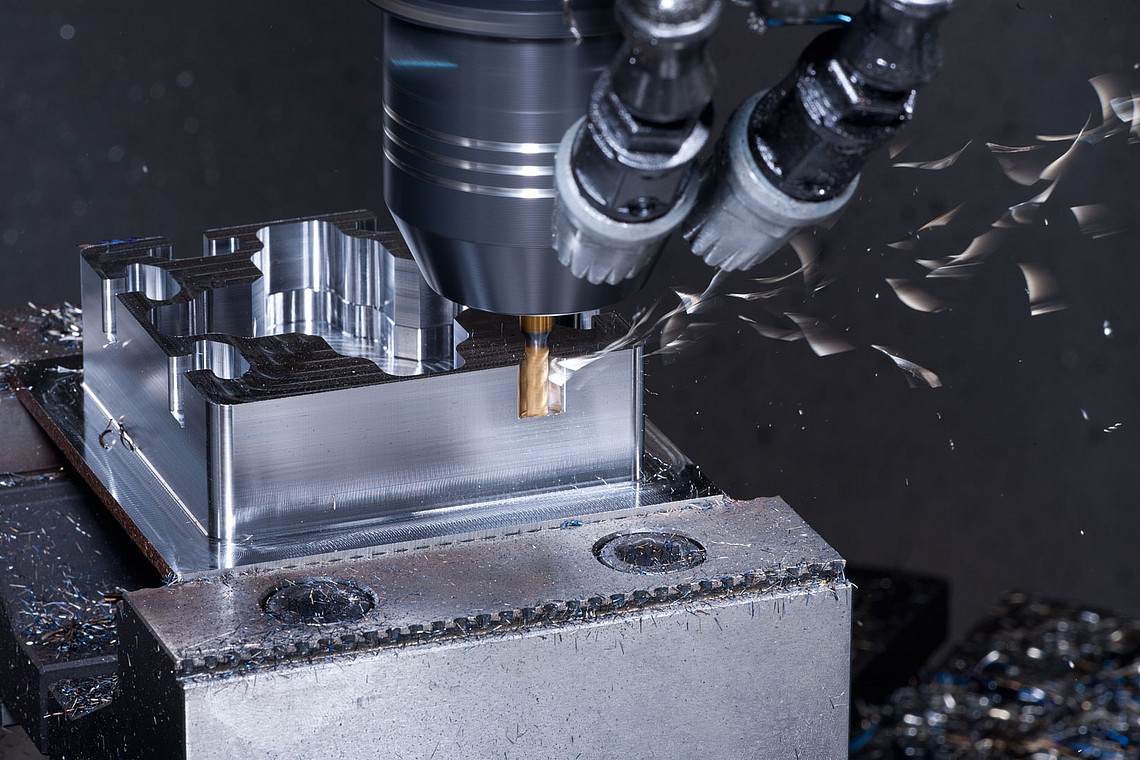

Theknoloji ea ts'ebetso ea likarolo tsa mochini e bolela mokhoa oa ho fetola boholo kapa thepa ea mochini oa mosebetsi ka sesebelisoa sa mochini.Ho ea ka phapang ea mokhoa oa ho sebetsa, e ka aroloa ka ho itšeha le ho sebetsana le khatello.

Mekhoa ea ho sebetsana le likarolo tsa mechine e kenyelletsa haholo-holo: ho reteleha, ho sila, ho rera, ho kenya, ho sila, ho cheka, ho bora, ho phunya, ho sakha le mekhoa e meng.E ka kenyelletsa ho itšeha ka terata, ho lahla, ho forging, electro-corrosion, ho sebetsa ka phofo, electroplating, le kalafo ea mocheso joalo-joalo.

1. Ho reteleha:

Ho na le mochini oa lathe o otlolohileng le mochini o tšekaletseng oa lathe;lisebelisoa tse ncha li na le mochini oa CNC lathe, haholo-holo o sebetsanang le 'mele oa rotary;

2. Ho sila:

Ho na le ho sila tse otlolohileng le tse rapameng;lisebelisoa tse ncha li na le milling ea CNC, e tsejoang hape e le setsi sa machining sa CNC, haholoholo sebaka sa groove le moralo oa sebopeho.Ehlile, e ka boela ea sebetsa camber ka lilepe tse peli kapa lilepe tse tharo tsa CNC Machining Center.

3. Ho rera:

Haholo-holo tshebetso sebopeho moralo sebaka sebakeng.Tlas'a maemo a tloaelehileng, bokaholimo bo thata ha bo phahametse mochini o silang;

4. Ho kenya:

E ka utloisisoa e le moralo o otlolohileng, o loketseng bakeng sa ts'ebetso ea li-circular arc e sa felletseng.

5. Ho sila:

Ho na le ho sila ka sefofane, ho sila ka selikalikoe, ho sila ka har'a lesoba le ka hare, le ho sila lisebelisoa, joalo-joalo. Ho sebetsa ka mokhoa o nepahetseng ka holim'a metsi ho sebetsa hantle, ho hlaka ha workpiece ho phahame haholo;

6. Ho cheka:

Ka tloaelo, ke ho sebetsana le likoti.

7. E tena:

Haholo-holo ke lesoba le boreleli ka har'a lisebelisoa tse tenang kapa lehare, hammoho le ts'ebetso ea bophara bo boholo, lesoba le nepahetseng haholo, le sebopeho se seholo sa mosebetsi.

8. Ho otla:

Haholo-holo e phunya ka mochini oa ho phunya, o ka phunyang lesoba le chitja kapa le nang le sebopeho se ikhethileng.

9. Ho Seha le ho Saha:

Haholo-holo ke ho seha lintho tse bonahalang ka mochine oa ho roka, o atisang ho sebelisoa mosebetsing oa ho koala.

Mochini ofe kapa ofe o entsoe ka likarolo tse ngata tse nepahetseng, ntle le likarolo tsa mochini, mochini ha oa phethahala.Ke ka lebaka leo likarolo tsa mochini li bapalang karolo ea bohlokoa haholo indastering ea mechini.

Ka nts'etsopele ea li-automation, theknoloji ea ho sebetsana le mechine e boetse e qalile ho iketsetsa tataiso ea ho iphetola ha lintho tse tsoelang pele, e tlameha ho phetha karolo ea bohlokoa ho nts'etsopele ea sechaba sa nakong e tlang, ua tseba, matla a ts'ebetso ea mechine ke tsoelo-pele ea moruo oa naha.Ho BMT, re sebelisa theknoloji hantle haholo, e le ho fana ka likarolo tse ntle ka ho fetisisa tsa machining ho bareki ba rona.Haeba ho hlokahala eng kapa eng, ka kopo ikopanye le rona hang-hang.

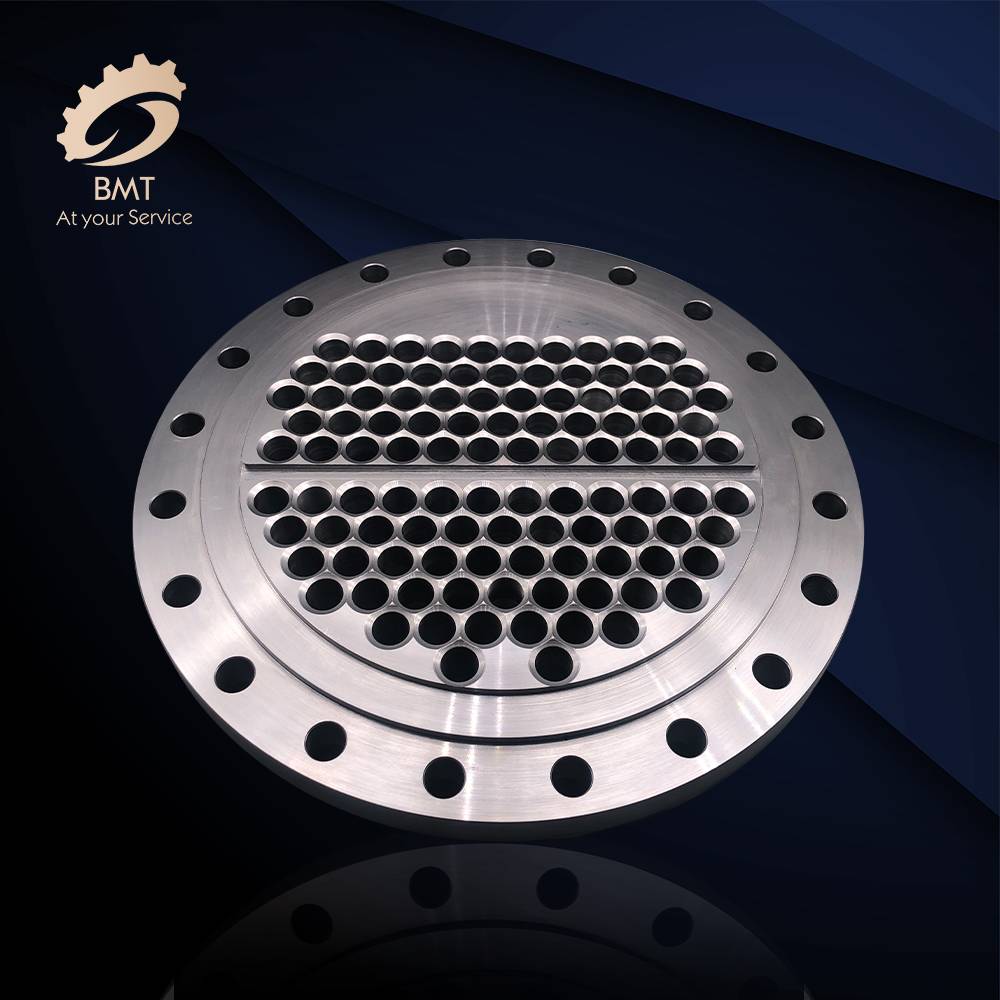

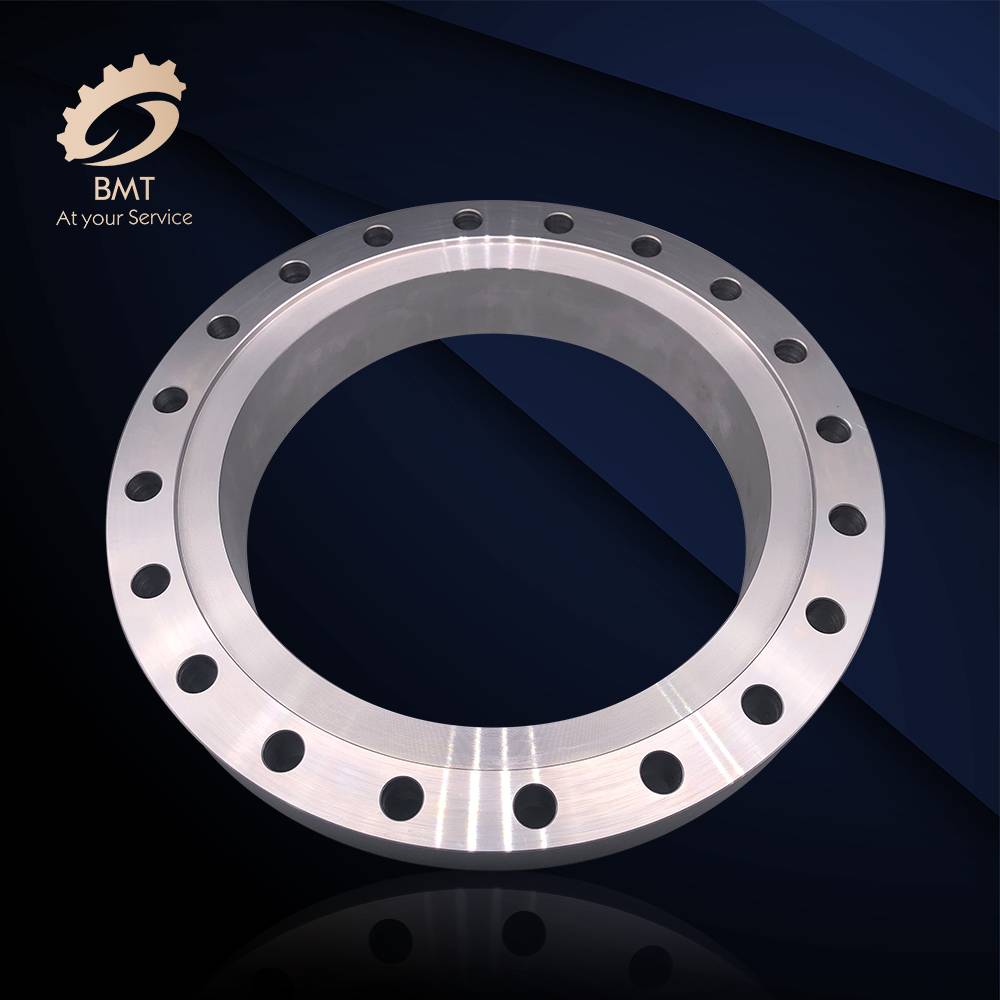

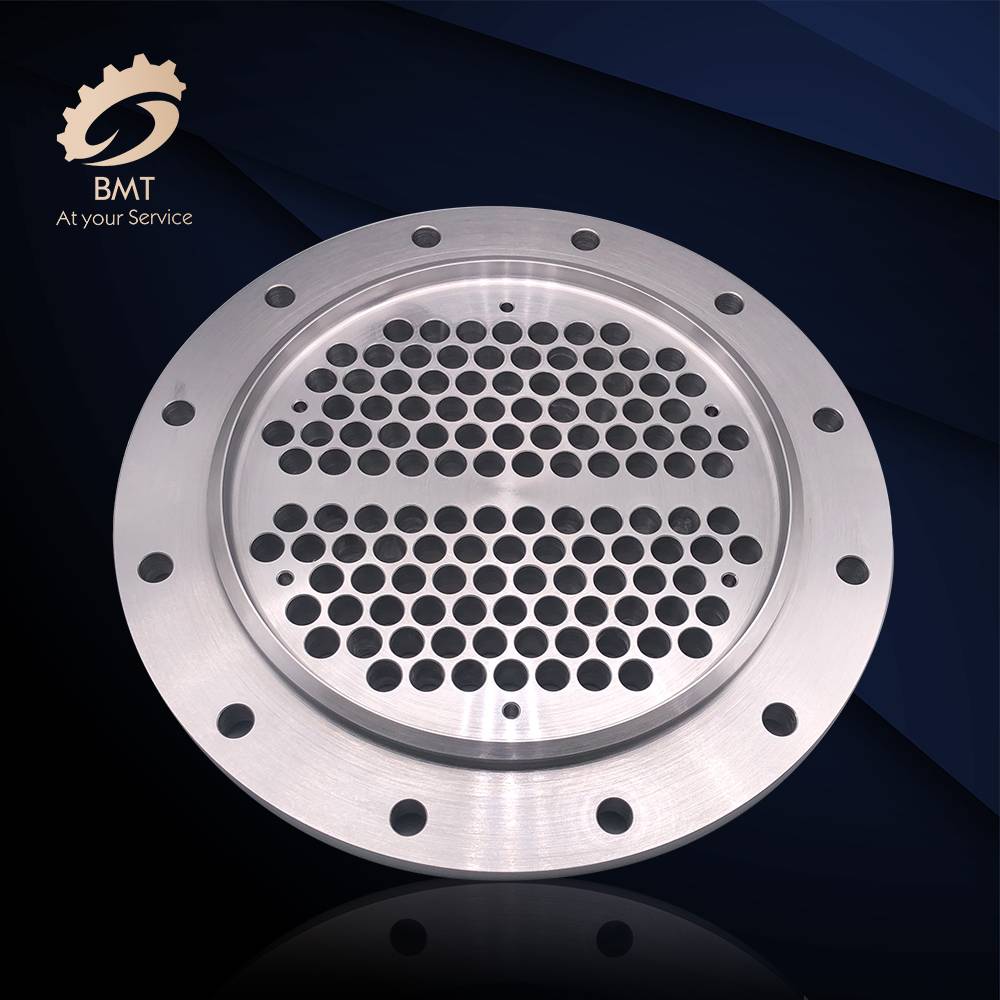

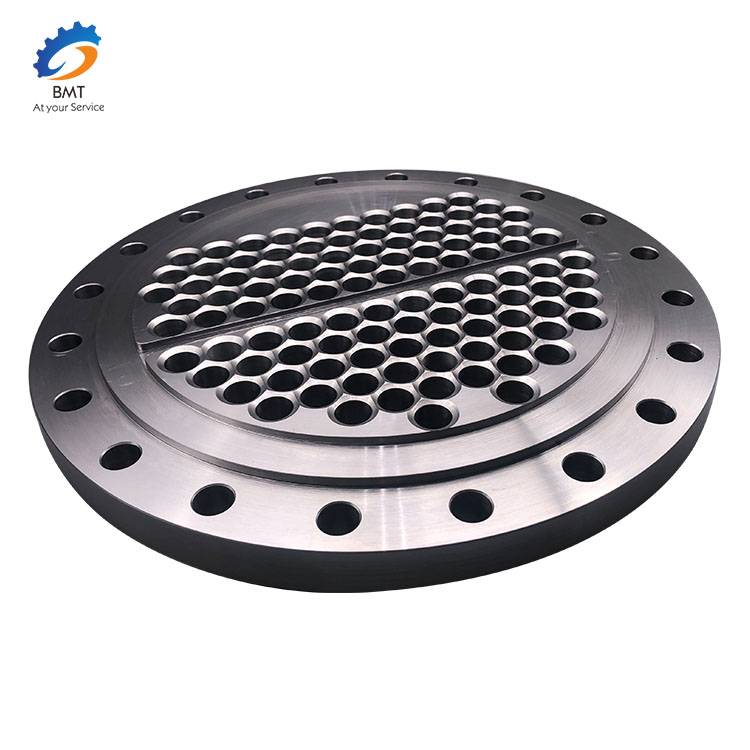

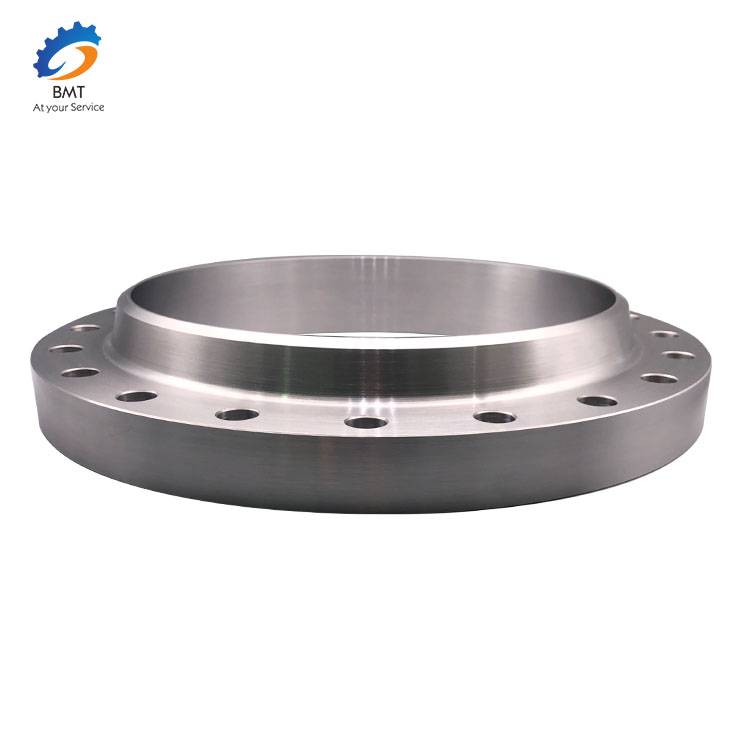

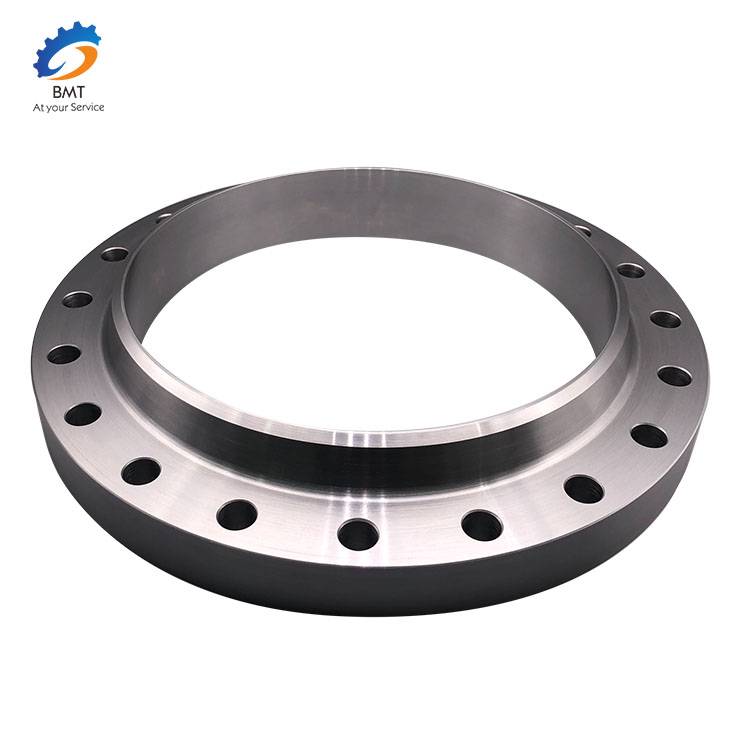

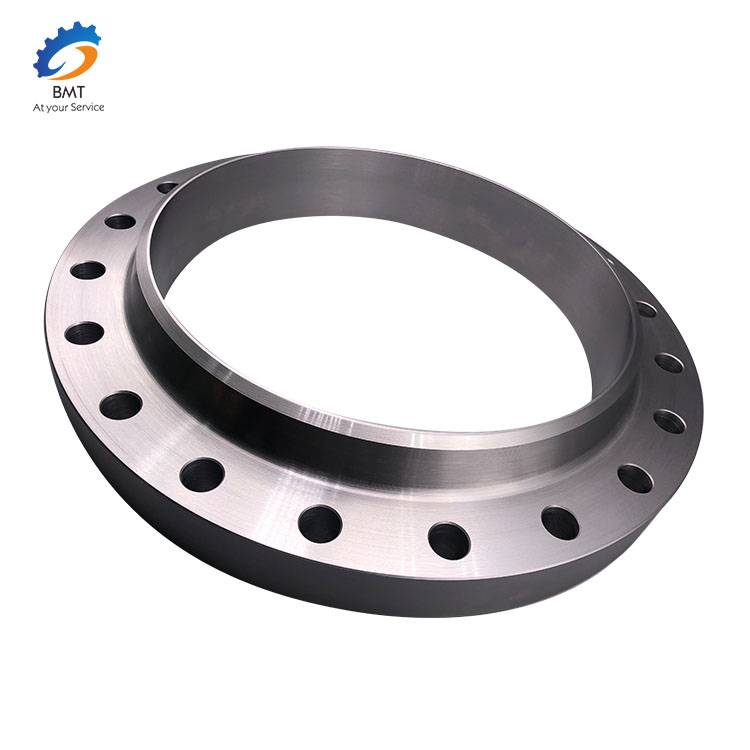

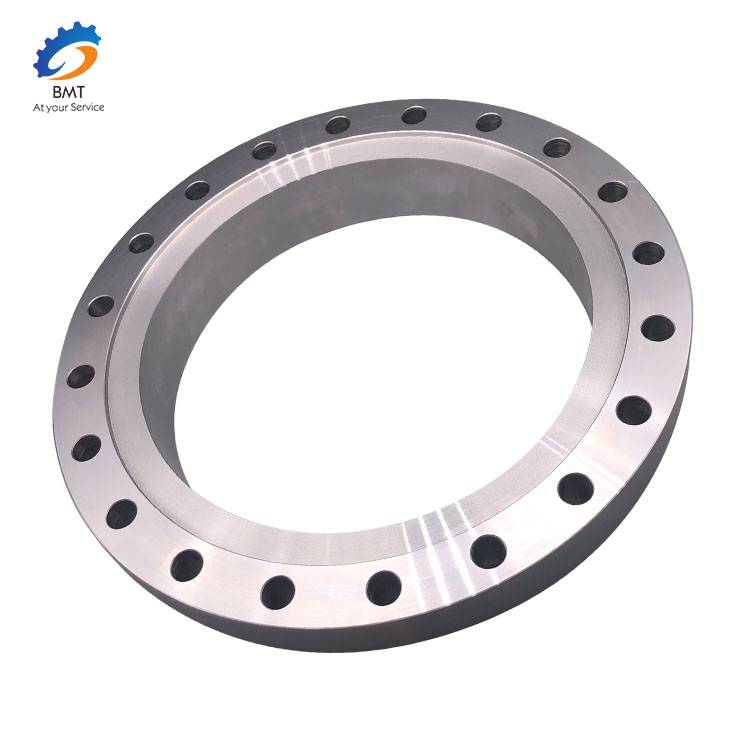

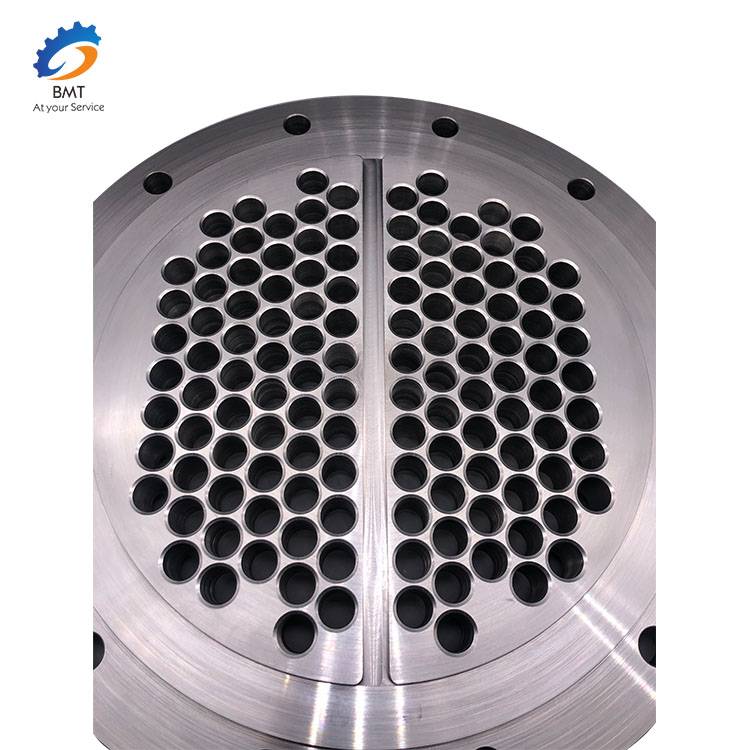

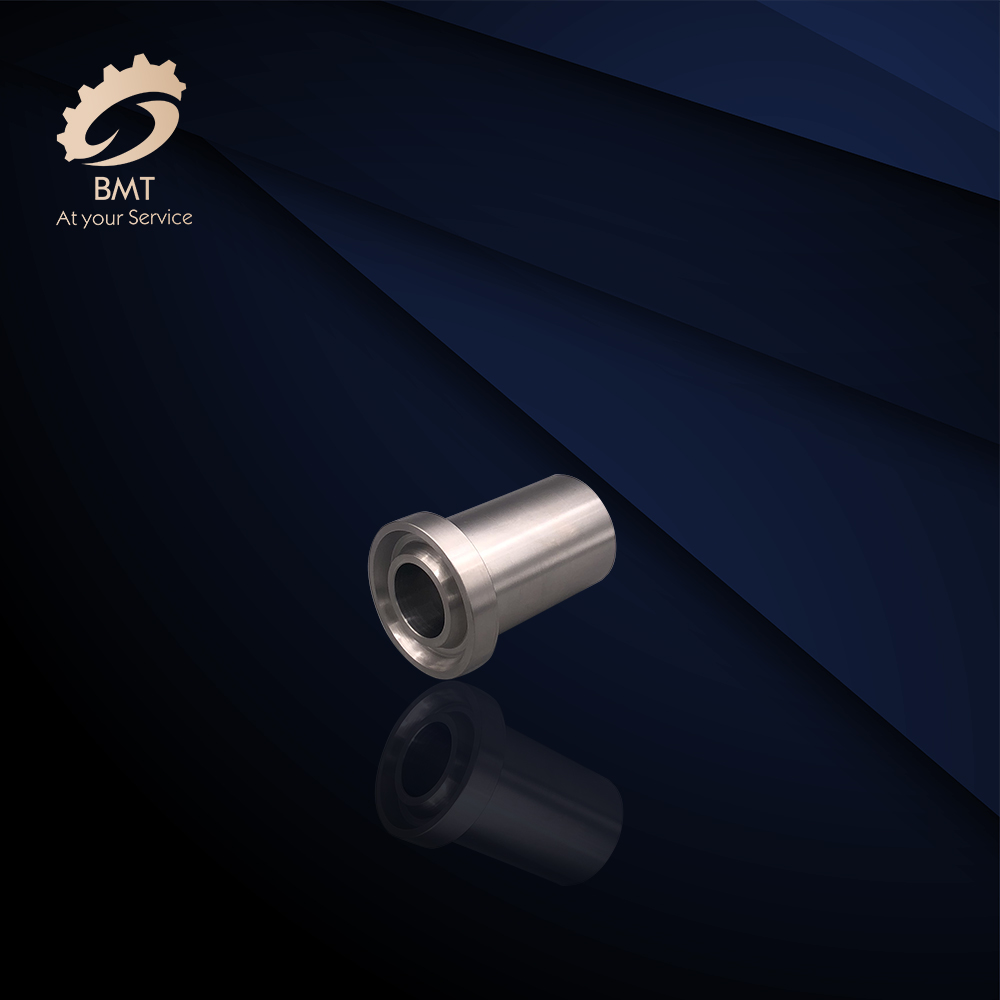

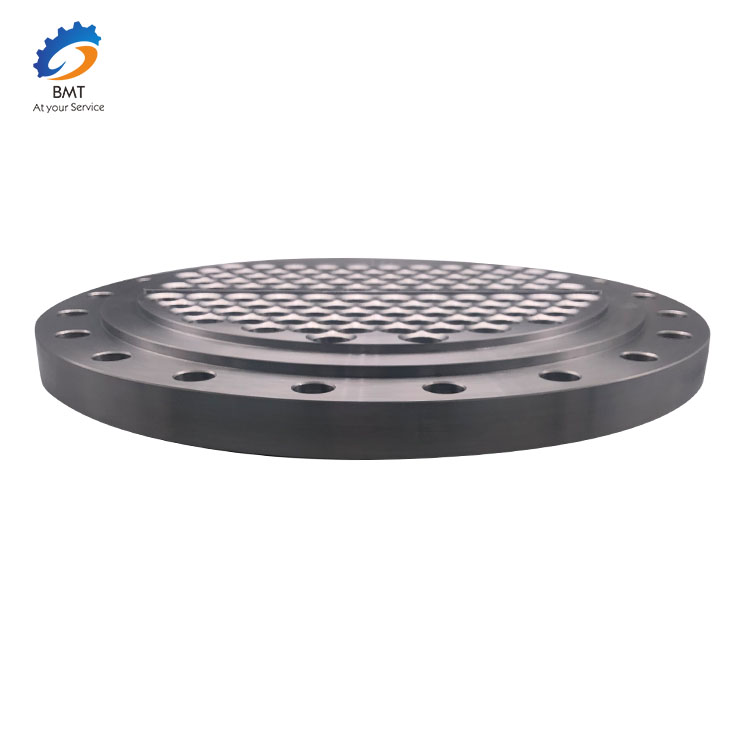

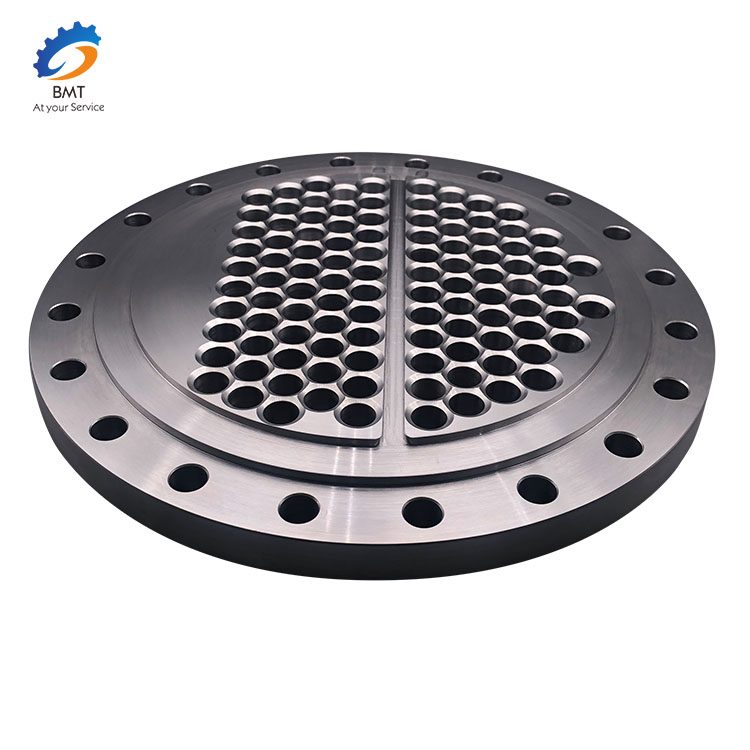

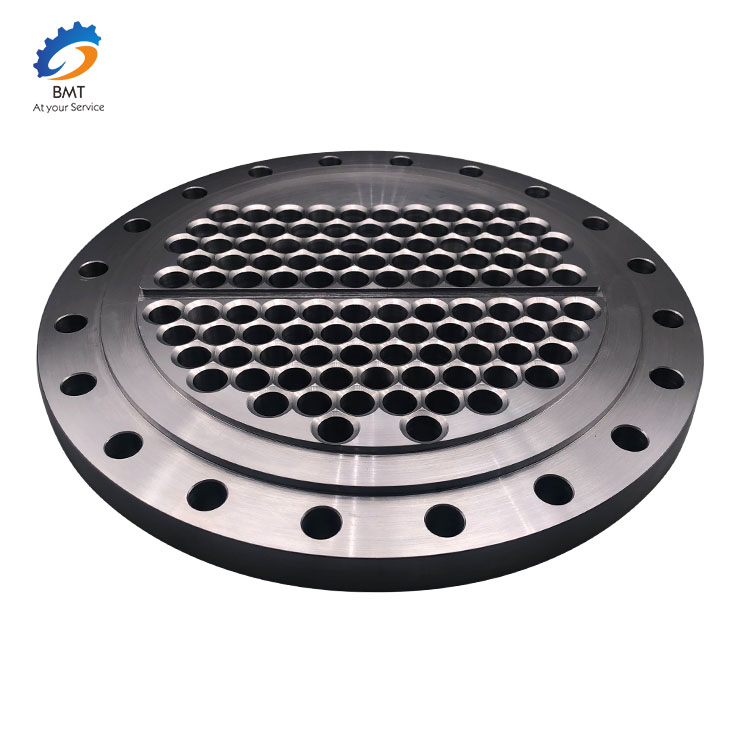

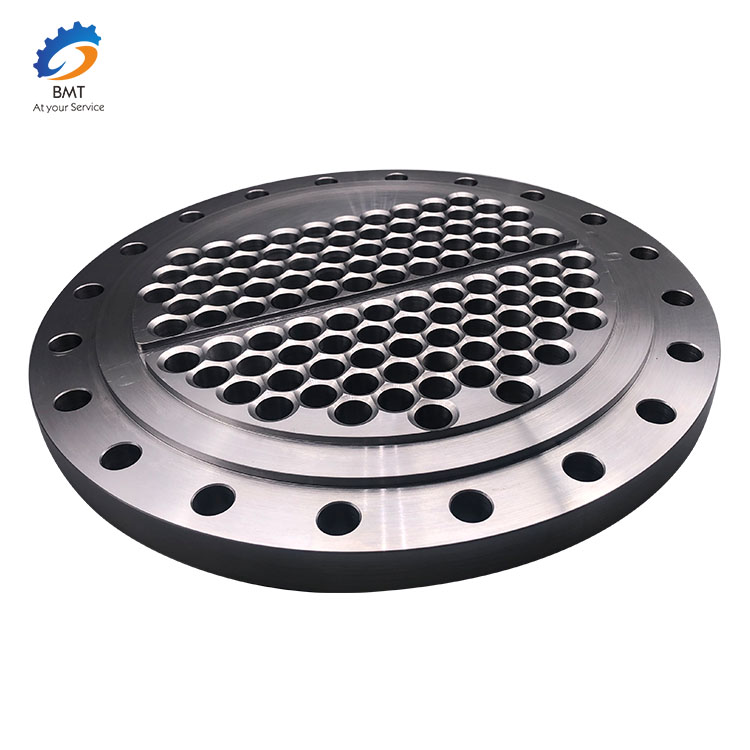

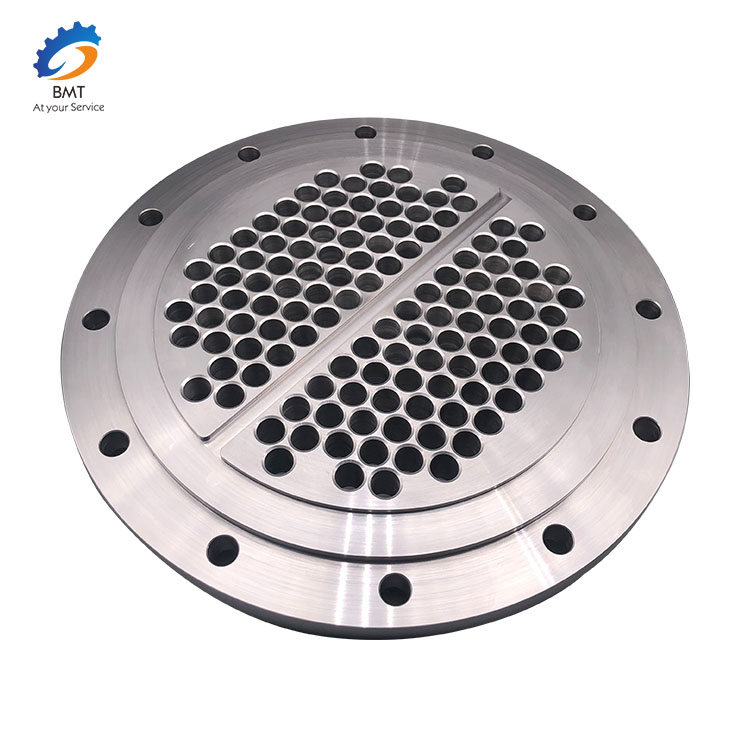

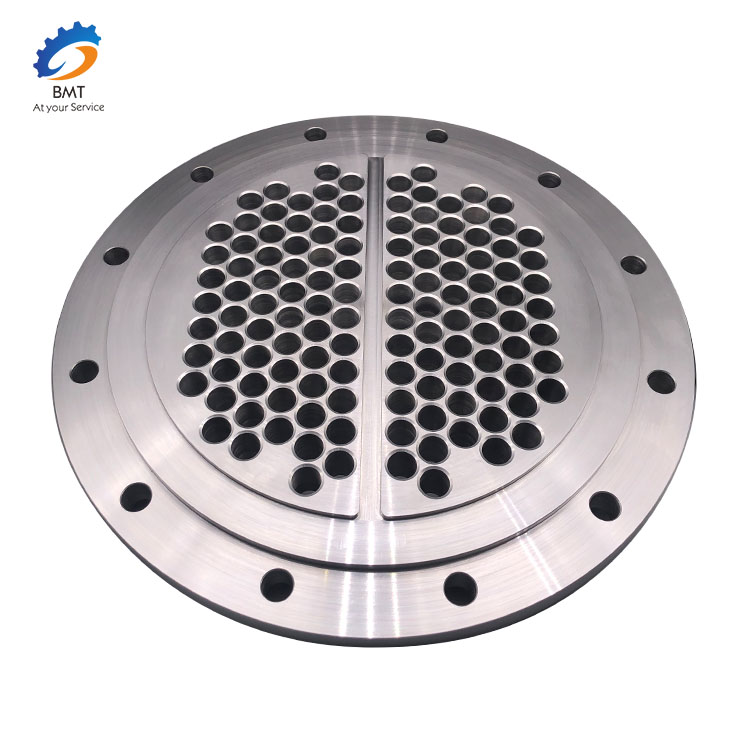

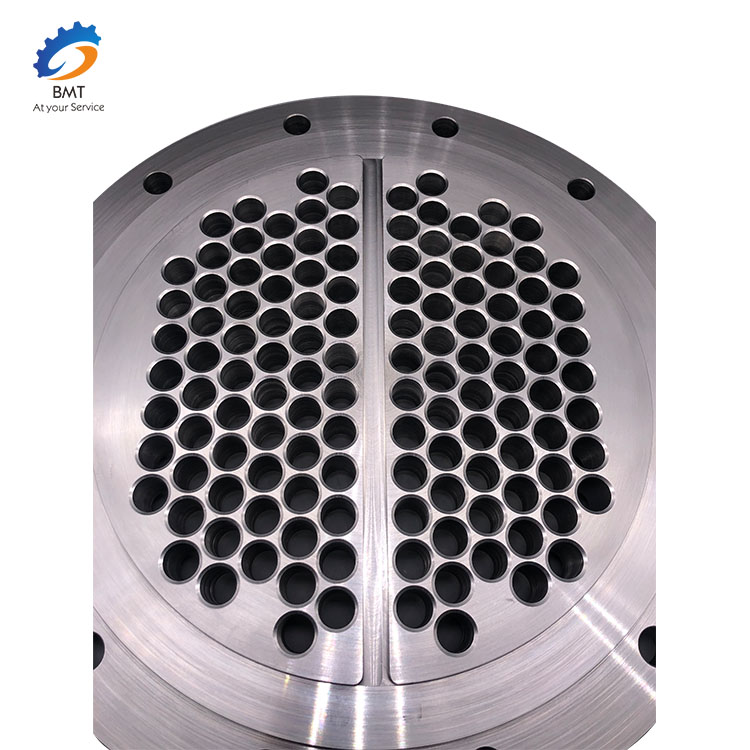

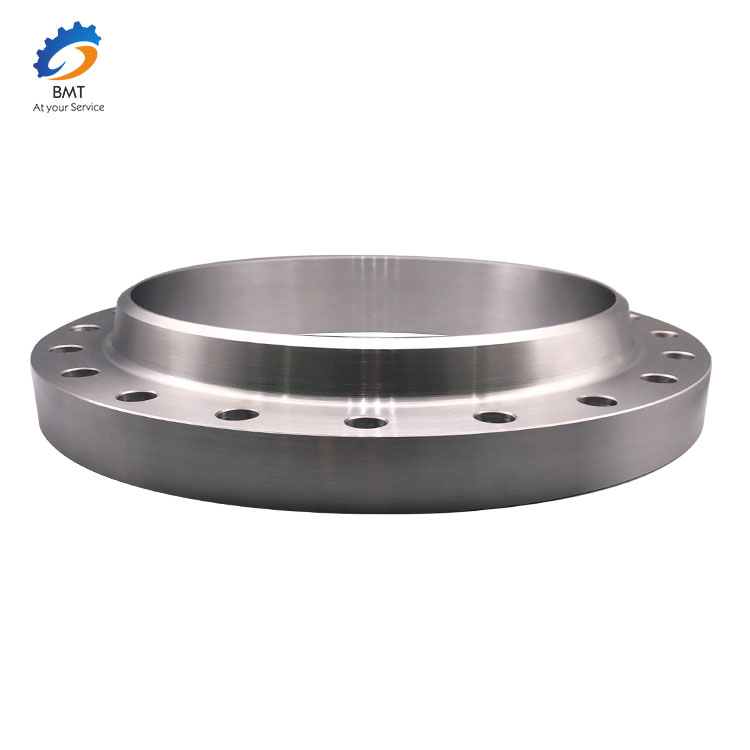

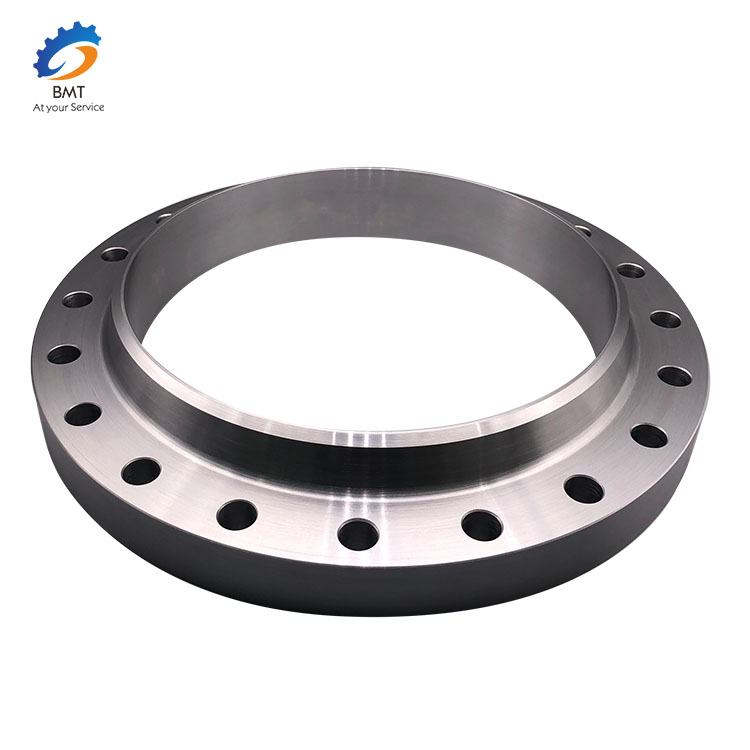

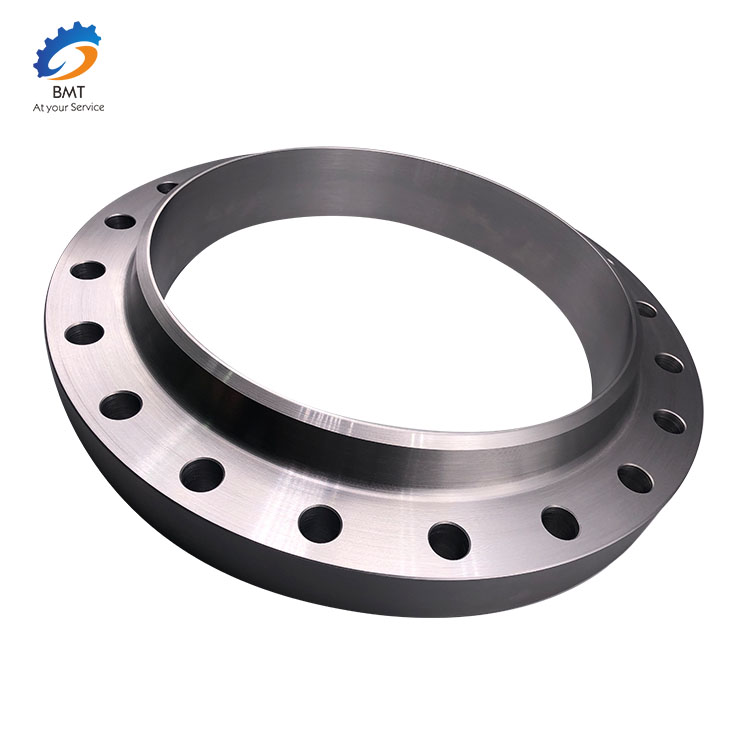

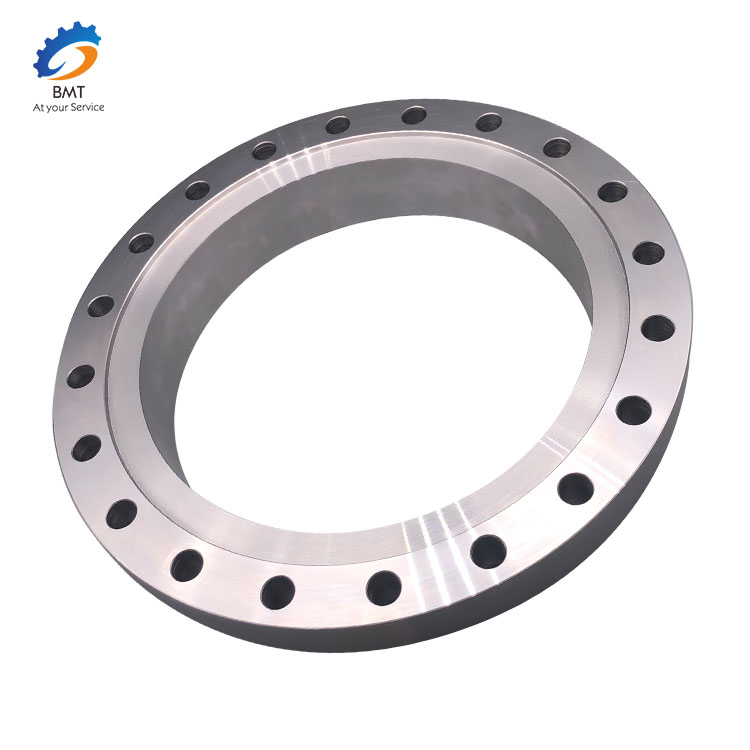

Tlhaloso ea Sehlahisoa

Lihlahisoa tse ling tseo re li entseng