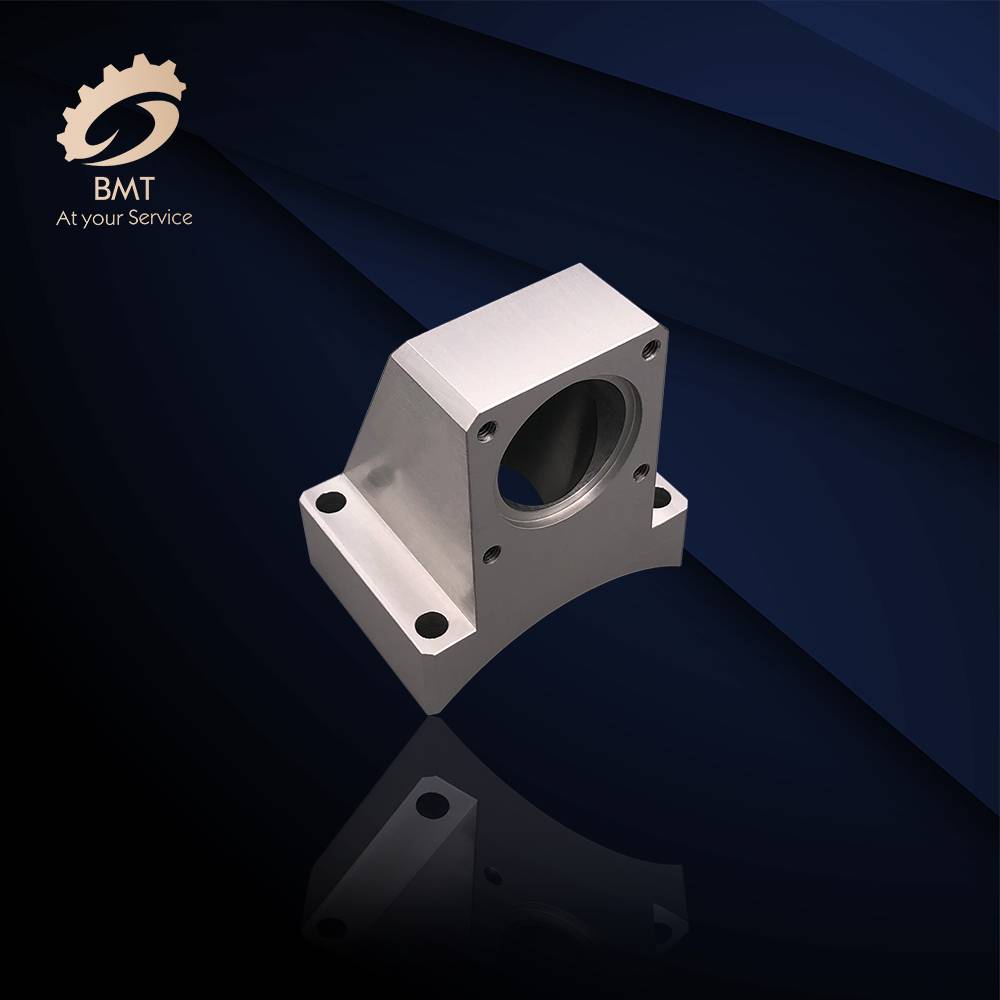

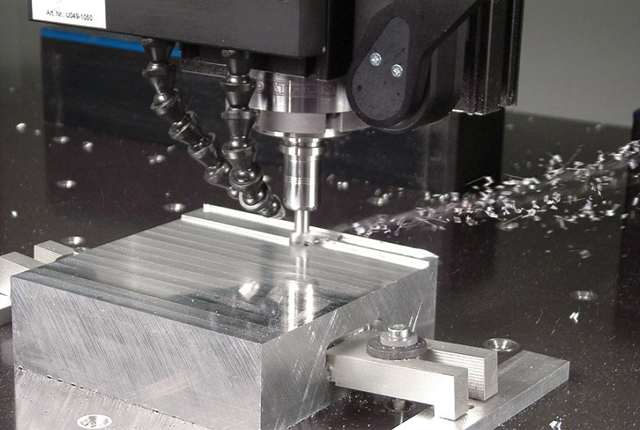

Melemo ea CNC Machining

Melemo ea CNC Machining

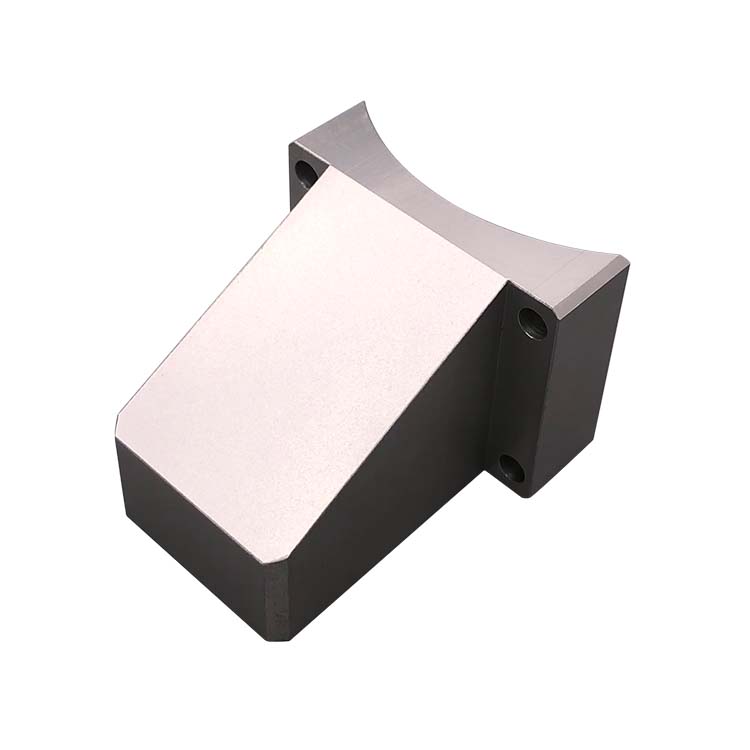

✔ Ho nepahala ho Phahameng, Mamello e Matla;

✔ Thepa e Ntle ea 'Mele;

✔ Litšenyehelo tse Haholo-holo tsa ho Seta;

✔ Thepa e hlophisitsoeng;

✔ Ho Kenngwa Tshebetsong ha Machining ka Potlako.

CNC Machining Lipotso le likarabo

Q1:Ke puo efe e sebelisoang ke mechini ea CNC?

A1:Mechini ea CNC e hlophisitsoe ho sebelisoa G-code le M-code, likhoutu ka bobeli lia amoheleha.

Q2:Na CNC le VMC lia tšoana?

A2:Karabo ke NO.

✔ CNC (E bitsoa taolo ea linomoro tsa komporo) ke boiketsetso ba lisebelisoa tsa mochini ka ts'ebeliso ea likhomphutha tse hlophiselitsoeng ho etsa palo efe kapa efe ea litaelo ho hlahisa likarolo tsa moetlo.Ka mantsoe a mang, k'homphieutha e laola mechine ea CNC.

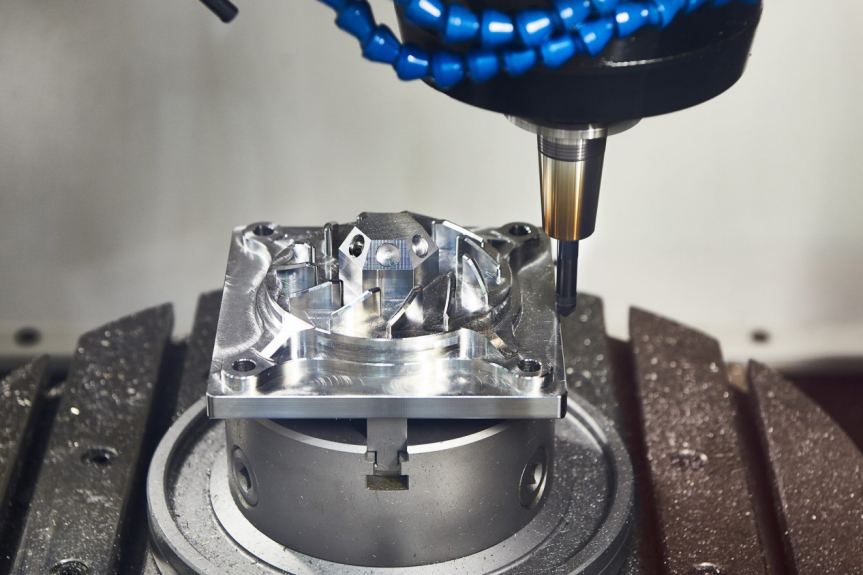

✔ VMC (Seo se bitsoang Vertical Machining Center) ke mofuta oa mochini o ka sebelisoang ho etsa lits'ebetso tse 'maloa tsa machining, joalo ka ho cheka, le mesebetsi ea ho sila.VMC ke mofuta oa mochini oa CNC o sebelisetsoang ho seha litšepe.

Q3:Phapano ke efe lipakeng tsa PLC le CNC?

A3:PLC (Programmable Logic Controller) e na le tatellano, ha CNC e na le maemo.

Q4:Ke mang ea qapileng machining a CNC le bohlokoa ba ona?

A4:John T. Parsons.CNC Machining ke ts'ebetso e fokolang e tlosang thepa ho tloha billet ho sebelisa sesebelisoa sa ho itšeha se chitja, se phethang karolo ea bohlokoa ho theknoloji ea morao-rao ea mechine.

Q5:Bohlokoa ba mochini oa CNC ke bofe?

A5:Ha ts'ebetso e ntse e iketsetsa, e eketsa ts'ebetso, e theola litšenyehelo le ho eketsa ho nepahala.

Q6:Ke lisebelisoa life tse ka sebelisoang mochining oa CNC?

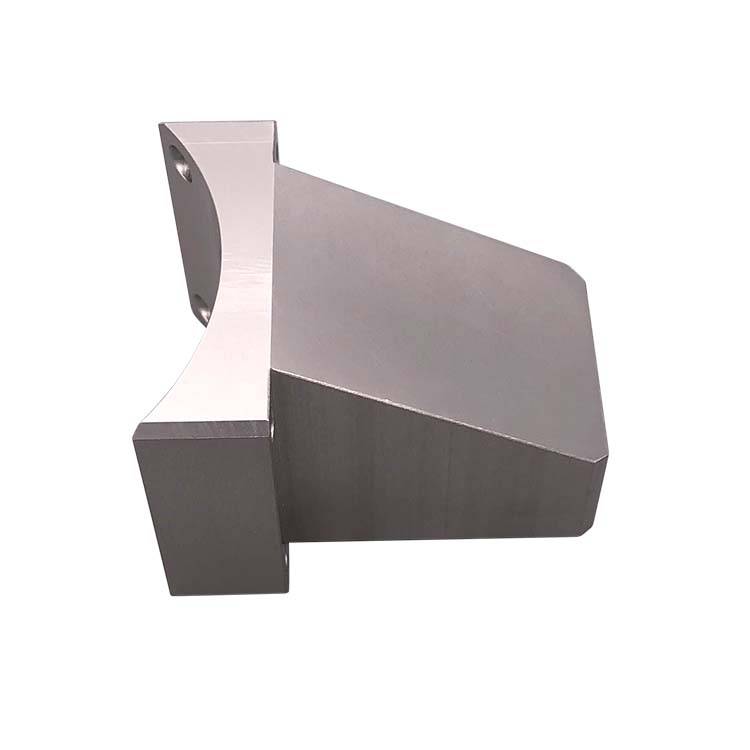

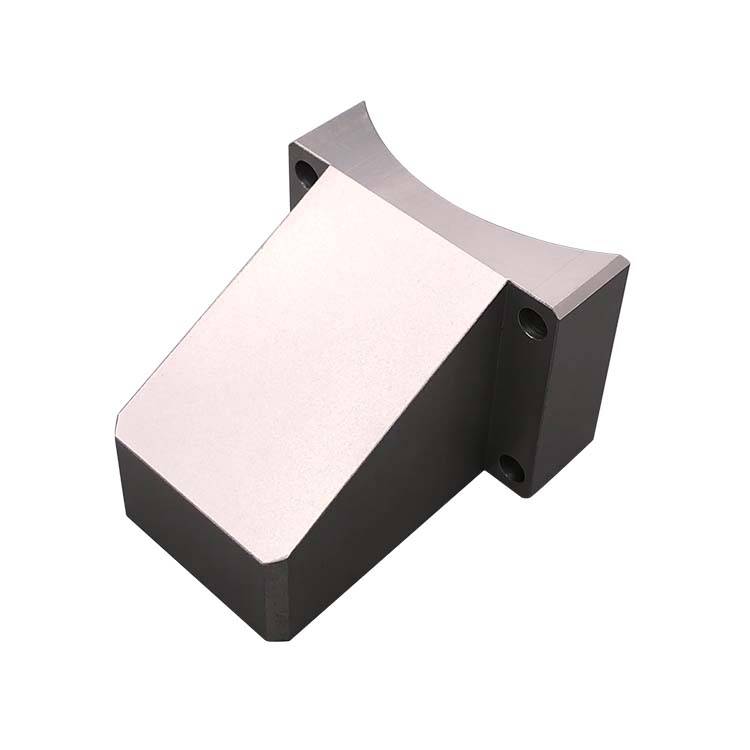

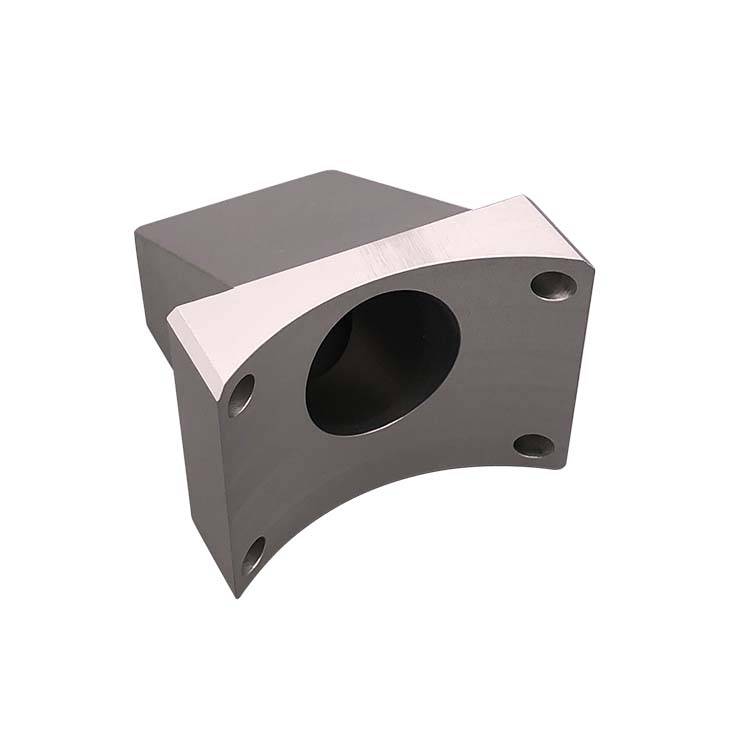

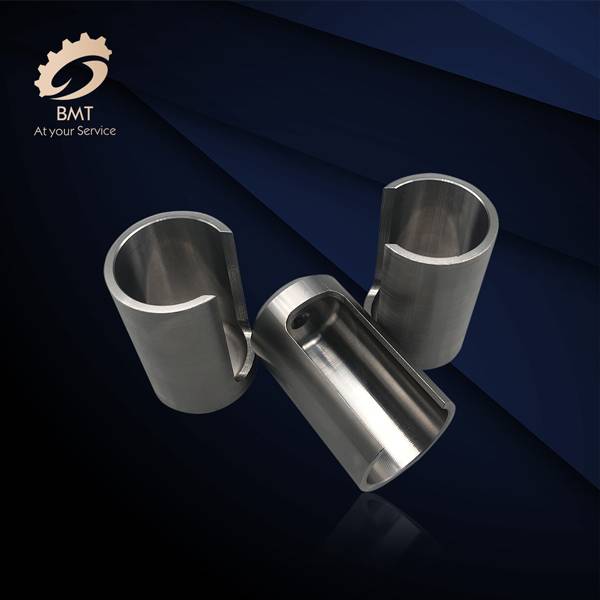

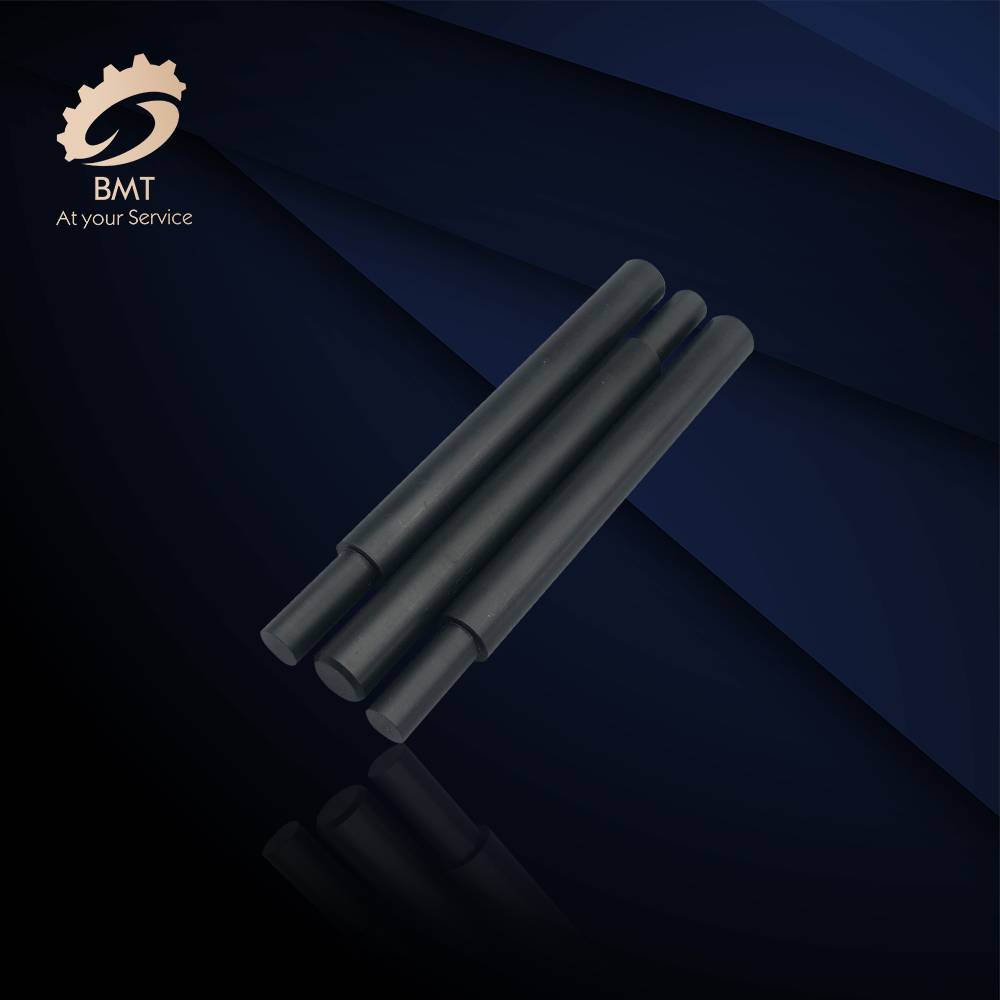

A6:Ho itšetlehile ka likopo.Ka tloaelo, lisebelisoa tse tloaelehileng li kenyelletsa Stainless Steel, Carbon Steel, Copper, Brass, Aluminium, Titanium, Alloy, Polypropylene, ABS, POM, PC le Nylon, joalo-joalo.

Q7:Ke mefuta efe ea mechini ea CNC eo re nang le eona?

A7:Mochini o Tloaelehileng oa Lathe, Mochini oa Lathe oa CNC, Mochini oa ho Hlōla, Mochini oa ho Cheka, Mochini oa ho Cheka Laser, Mochini oa ho Seha Plasma, WEDM, Mochini oa Welding, Mochini oa ho Hōla, joalo-joalo.

Q8:Phapano ke efe lipakeng tsa DNC le CNC?

A8:DNC (E bitsoa Direct Numerical Control) ke sistimi e sebelisang komporo e kholo ho sebetsa mechini e mengata.DNC e bua ka marang-rang a mochini o fetang o le mong oa CNC.

Q9:Mochini oa NC ke eng?

A9:Mechini ea Numerical Control (NC) e fumana litaelo ho tsoa kareteng ea punch, athe mochini oa CNC o fumana litaelo ho tsoa komporong.

Q10:Ke liindasteri life tse sebelisang machining a CNC?

A10:Sepakapaka, sesebelisoa sa bongaka, lifoto, ts'ireletso, lisebelisoa tsa elektroniki, lipalangoang le tse ling.

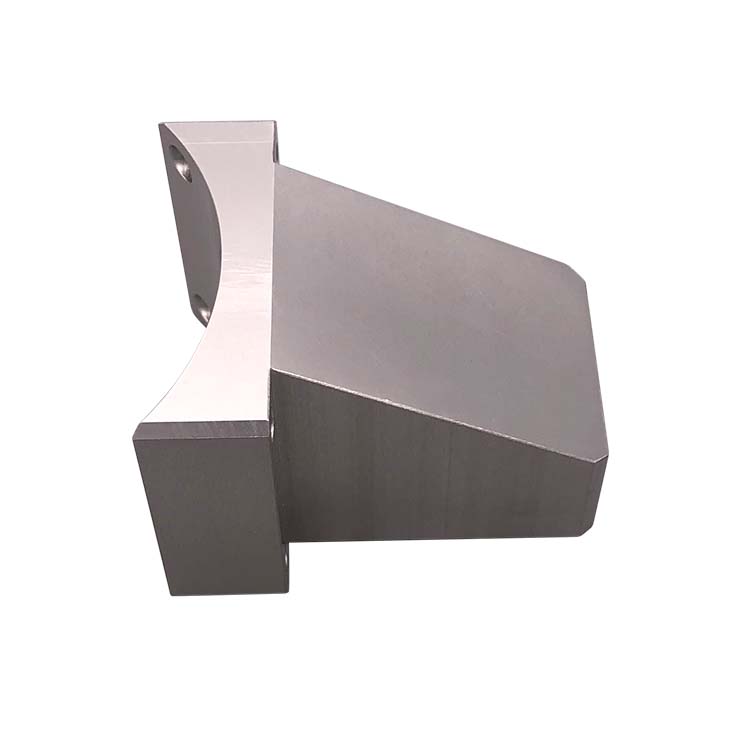

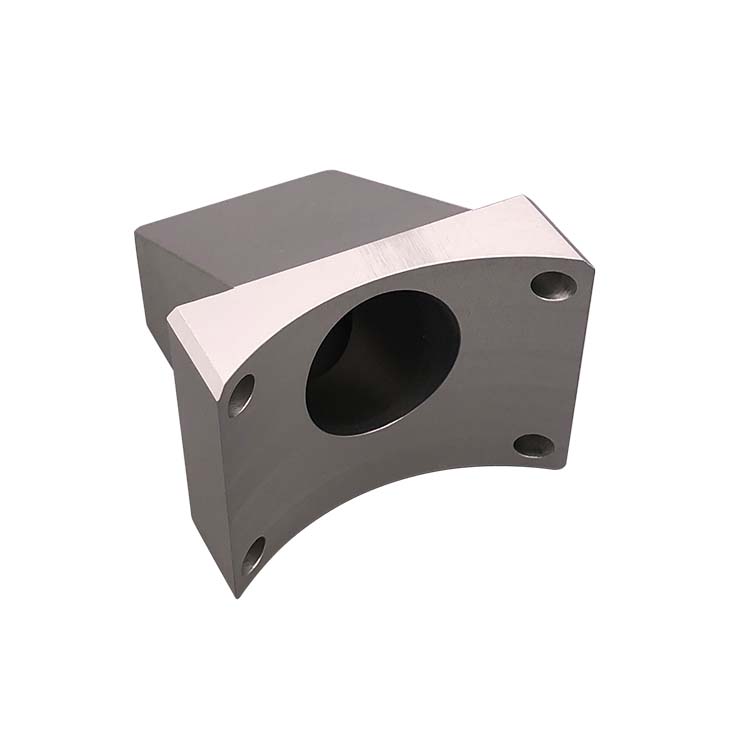

Q11:Ke mofuta ofe oa ho qetela o hlahisoang ke machining a CNC?

A11:Mechini e meng ea CNC, joalo ka leloala la CNC, e ka siea matšoao a sesebelisoa a bonahalang.Ka lebaka la sena, ho ka 'na ha hlokahala mohato o eketsehileng ho qeta karolo, joalo ka ho sila kapa ho bentša.

Q12:Liphetho tse tloaelehileng tsa likarolo tsa CNC ke life?

A12:Ho phatloha ha lifaha, anodized, filimi ea lik'hemik'hale, passivation, ho roala phofo, electro polishing, electro nickel plating, zinki plating, silevera plating le khauta plating, joalo-joalo.