Moetsi oa hau oa Precision Machining

POTLAKO MACHINA

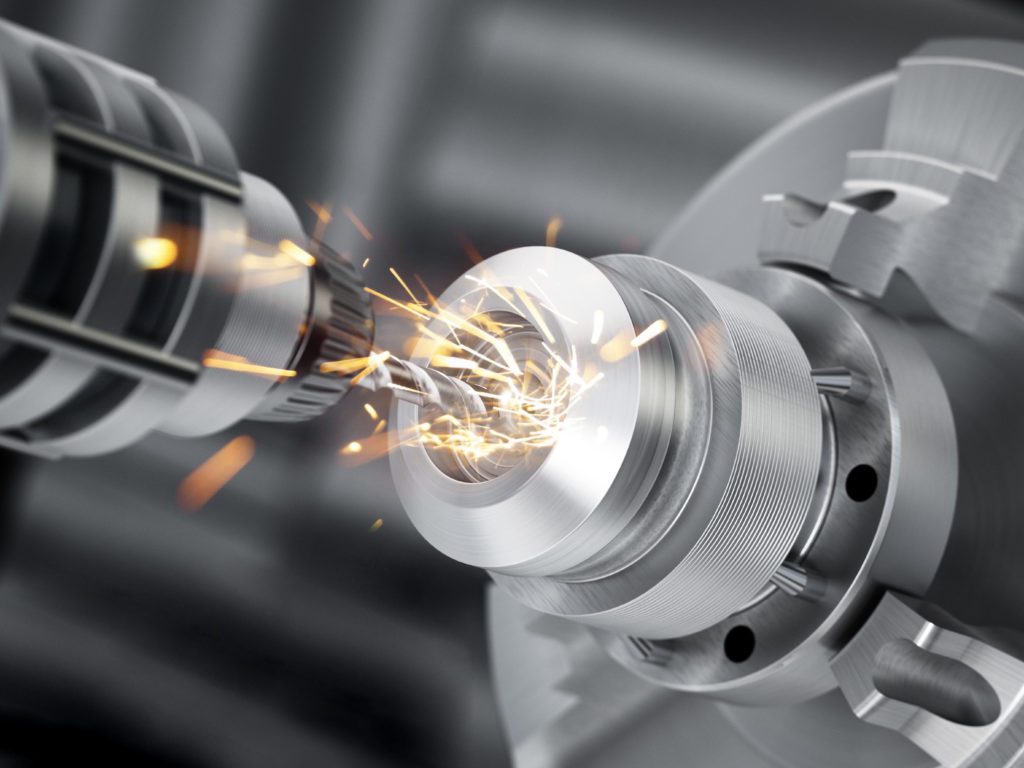

Precision machining ke ts'ebetso eo ho eona sebopeho kapa ts'ebetso ea mochini o sebetsang e fetoloang ka mochini o sebetsang.Ho ea ka boemo ba mocheso oa workpiece e lokelang ho sebetsoa, e arotsoe ka ts'ebetso e batang le ts'ebetso e chesang.Ka tloaelo, ho sebetsa ka mocheso oa kamore, 'me ha ho bake liphetoho tsa lik'hemik'hale kapa tsa mohato oa workpiece, e bitsoa ho sebetsa ha serame.Ka kakaretso, ho sebetsa ka holimo kapa ka tlase ho mocheso o tloaelehileng ho tla baka phetoho ea lik'hemik'hale kapa karolo ea mosebetsi, e bitsoang ho sebetsa ha mocheso.Ts'ebetso e batang e ka aroloa ka ts'ebetso ea ho itšeha le ts'ebetso ea khatello ho latela phapang ea mekhoa ea ts'ebetso.Ts'ebetso ea mocheso hangata e kenyelletsa kalafo ea mocheso, ho forging, casting le welding.

Ho sebetsa likarolo tsa likoloi ke karolo e etsang likarolo tsohle tsa koloi le lihlahisoa tse sebeletsang ho lokisa likarolo tsa koloi.E le motheo oa indasteri ea likoloi, likarolo tsa likoloi ke lintlha tse hlokahalang ho ts'ehetsa nts'etsopele e tsitsitseng le e phetseng hantle ea indasteri ea likoloi.Haholo-holo, tsoelo-pele e ikemetseng ea hona joale le mekhoa e mecha ea indasteri ea likoloi e ntseng e etsoa ka matla le ka ho feletseng e hloka tsamaiso e matla ea likarolo ho e tšehetsa.Mefuta e ikemetseng ea likoloi le boqapi ba thekenoloji e hloka likarolo le likarolo e le motheo, 'me ntlafatso e ikemetseng ea likarolo le likarolo e na le matla a matla a ho nts'etsapele indasteri ea likoloi.Ba susumetsa le ho sebelisana le ba bang.Ha ho mofuta o ikemetseng oa likoloi tse felletseng, le sistimi e matla ea likarolo.Bokhoni ba R&D le boqapi ba k'hamphani bo thata ho phatloha, 'me ntle le ts'ehetso ea sistimi e matla ea likarolo, ho tla ba thata hore lihlahisoa tse ikemetseng li be kholo le ho ba matla.

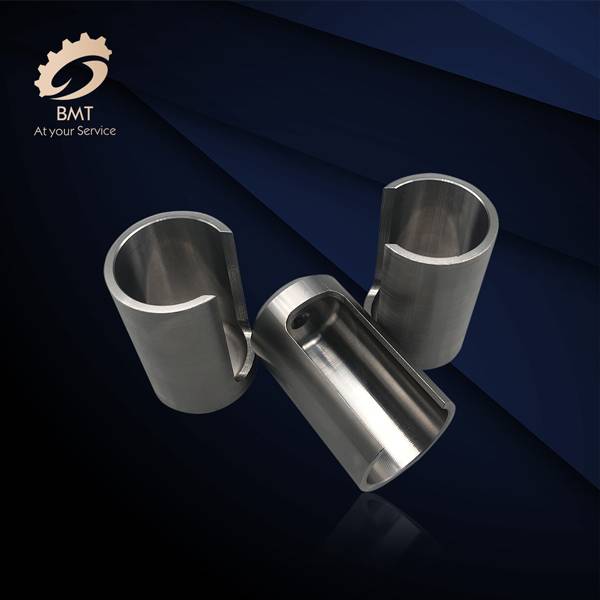

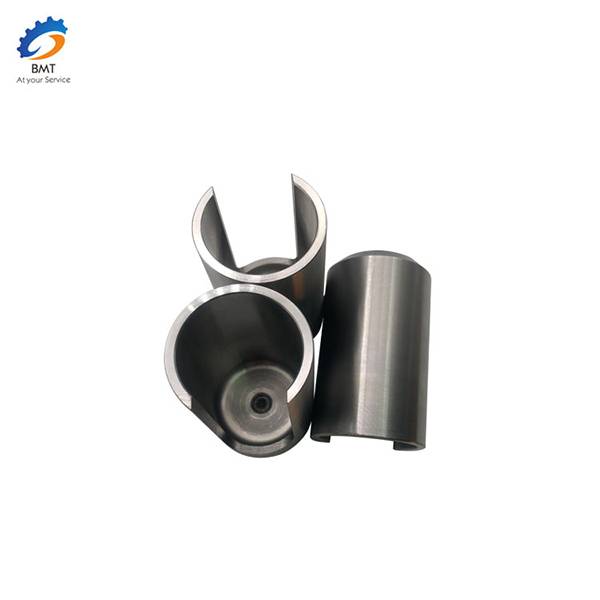

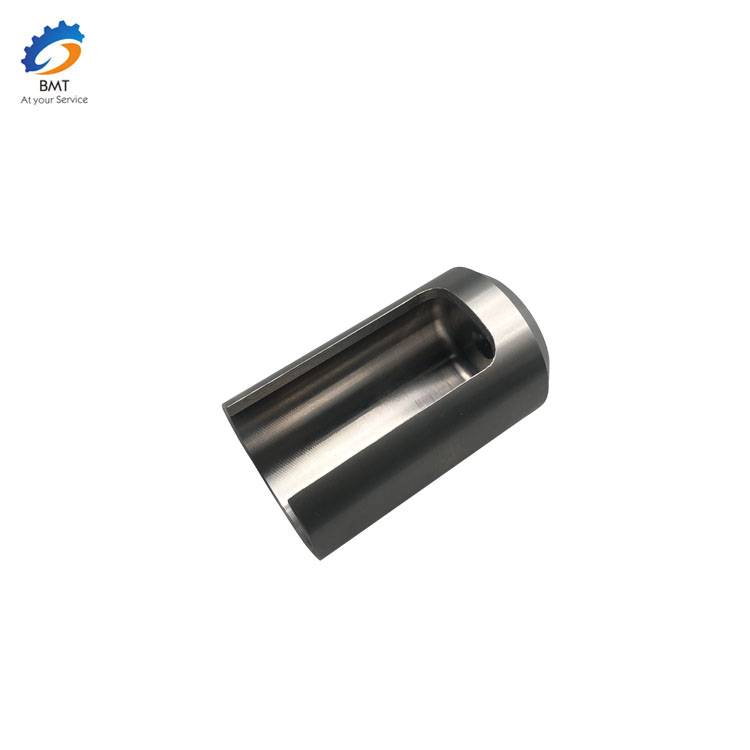

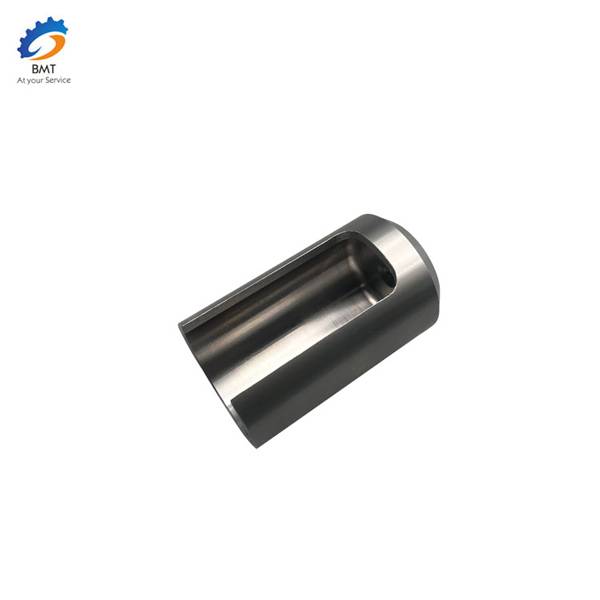

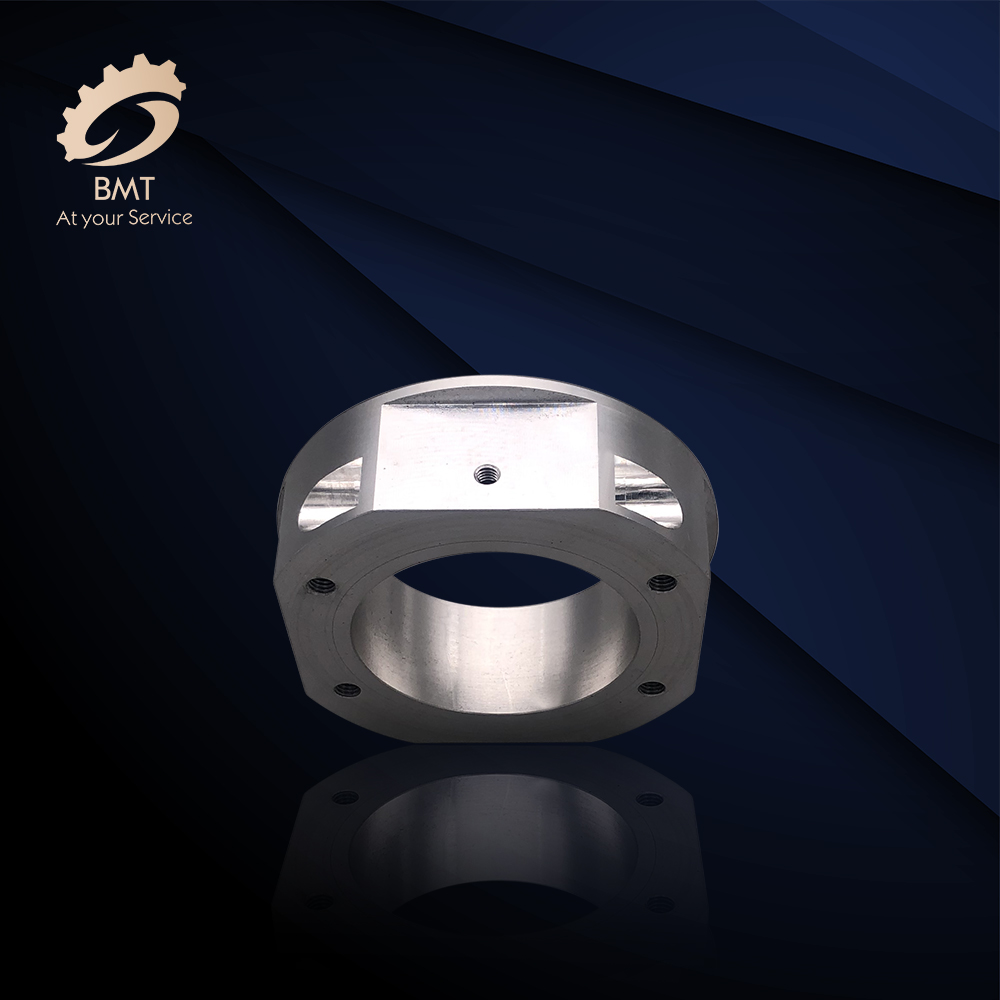

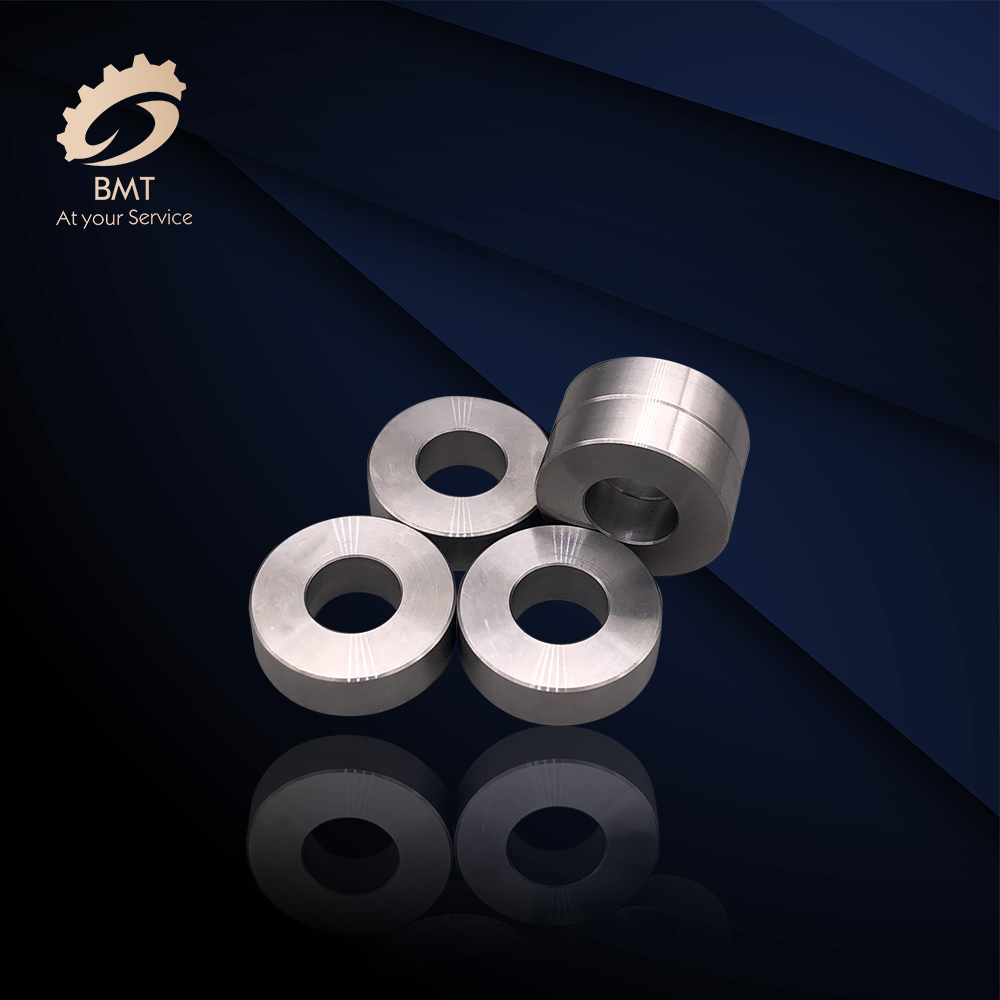

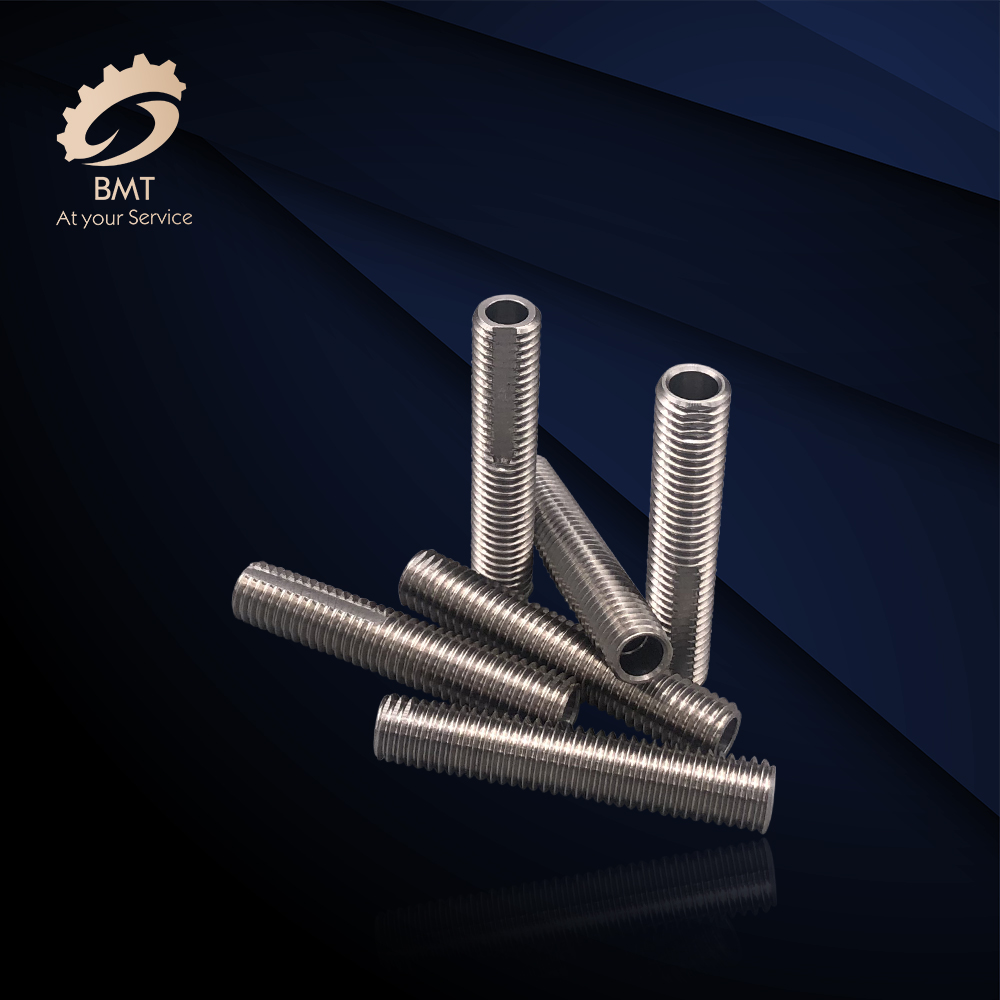

Likarolo li bua ka likarolo tse ikemetseng tse ke keng tsa aroloa ka mochini.Ke likarolo tsa mantlha tsa mochini le yuniti ea mantlha ts'ebetsong ea tlhahiso ea mochini.Ts'ebetso ea tlhahiso ka kakaretso ha e hloke ts'ebetso ea kopano.Tse kang li-sleeve, lihlahla, linate, li-crankshafts, li-blades, li-gear, likamera, lihlopha tsa molamu tse kopanyang, lihlooho tsa molamu tse kopanyang, joalo-joalo Bakeng sa machining a rona a nepahetseng, ts'ebetso e thata haholo, 'me mekhoa ea ho sebetsa e kenyelletsa ho khaola le ho tsoa.Ho na le litlhoko tse khethehileng tsa boholo le ho nepahala, tse kang 1mm plus minus micrometers, joalo-joalo Haeba boholo bo le boholo haholo, bo tla senyeha.Ka nako ena, ho tšoana le ho tsosolosa, ho ja nako le ho sebetsa ka thata, 'me ka linako tse ling esita le thepa eohle e entsoeng e tlosoa.Sena se bakile keketseho ea litšenyehelo, 'me ka nako e ts'oanang, likarolo ha li na thuso.

Lisebelisoa tse ling tse tloaelehileng ha li khone ho qeta ho sebetsa ha hlobo, joalo ka li-cavities tse nang le li-angles tse nyenyane tsa R;li-electrode li sebetsoa ka sekhahla sa motlakase.Hangata tsena li entsoe ka koporo kapa graphite.Tsoelo-pele e potlakileng ea theknoloji ea tlhahiso ea hlobo e fetohile karolo ea bohlokoa ea theknoloji ea morao-rao ea tlhahiso.Theknoloji ea sejoale-joale ea tlhahiso ea hlobo e ntse e tsoela pele molemong oa ho potlakisa tlhahiso ea tlhahisoleseling, ho ntlafatsa maemo a bonolo a tlhahiso, tlhahiso e potlakileng le kopanyo ea sistimi.E bonahatsoa ka ho khetheha ho thekenoloji ea CAD/CAM ea hlobo, theknoloji ea laser e potlakileng ea prototyping ea hlobo, theknoloji ea ho etsa ka mokhoa o nepahetseng oa hlobo, le theknoloji ea ultra-precision processing ea hlobo.Moralo oa hlobo o sebelisa mokhoa oa finite element le mokhoa oa elemental oa moeli ho etsa phallo, ho pholisa le ho fetisa mocheso.Theknoloji ea ketsiso e matla, thekenoloji ea hlobo ea CIMS, theknoloji e tsoetseng pele ea tlhahiso e kang thekenoloji ea hlobo ea DNM le thekenoloji ea taolo ea lipalo e ntlafalitsoe.