Mechini ea Boiketsetso

Ho kenyeletsoa li-alloys tse bonolo tsa makenete tse thehiloeng ho nickel, li-alloys tsa nickel-based precision resistance alloys tse thehiloeng ho nickel-electrothermal alloys.Li-alloys tse bonolo tse sebelisoang hangata ke li-permalloys tse nang le hoo e ka bang 80% ea nickel.Ba na le matla a phahameng a phahameng le a pele a permeability le coercivity e tlaase.Ke lisebelisoa tsa bohlokoa tsa mantlha indastering ea elektroniki.Likarolo tsa mantlha tsa li-alloy tse thehiloeng ho nickel ke chromium, aluminium le koporo.

Alloy ena e na le resistivity e phahameng, mocheso o tlase oa mocheso oa resistivity le khanyetso e ntle ea kutu, 'me e sebelisetsoa ho etsa lihanyetsi.Motsoako oa nickel-based electrothermal alloy ke motsoako oa nickel o nang le 20% chromium, e nang le thepa e ntle ea anti-oxidation le anti-corrosion, 'me e ka sebelisoa nako e telele mocheso oa 1000-1100 °C.

Memory Alloy

Nickel alloy e nang le 50 (at)% titanium.Mocheso oa ho hlaphoheloa ke 70 ° C, 'me phello ea mohopolo oa sebopeho e ntle.Phetoho e nyane ho karo-karolelano ea nickel-titanium e ka fetola mocheso oa ho hlaphoheloa ka har'a mefuta e fapaneng ea 30 ho isa ho 100 °C.E sebelisoa haholo ha ho etsoa likarolo tsa sebopeho sa sepakapaka, li-fasteners tse itšebetsang tse sebelisoang indastering ea lifofane, li-motors tsa maiketsetso tsa pelo tse sebelisoang ho biomedicine, jj.

Sebaka sa kopo

Li-alloys tse thehiloeng ho nickel li sebelisoa libakeng tse ngata, tse kang:

1. Leoatle: meaho ea maoatle tikolohong ea leoatle, ho tlosoa ha letsoai metsing a leoatle, temo ea metsi a leoatle, phapanyetsano ea mocheso oa metsi a leoatle, joalo-joalo.

2. Sebaka sa tšireletso ea tikoloho: sesebelisoa sa flue gas desulfurization bakeng sa ho hlahisa matla a mocheso, ho hloekisa metsi a litšila, joalo-joalo.

3. Sebaka sa matla: tlhahiso ea matla a athomo, tšebeliso e felletseng ea mashala, tlhahiso ea matla a maqhubu a leoatle, joalo-joalo.

4. Tšimo ea Petrochemical: ho hloekisa oli, lisebelisoa tsa lik'hemik'hale le tsa lik'hemik'hale, joalo-joalo.

5. Tšimo ea lijo: ho etsa letsoai, ho riteloa ha soy sauce, joalo-joalo Libakeng tse ngata tse ka holimo, tšepe e tloaelehileng e sa hloekang 304 ha e na bokhoni.Masimong ana a khethehileng, tšepe e khethehileng e sa hloekang e bohlokoa ebile e ke ke ea nkeloa sebaka.Lilemong tsa morao tjena, ka tsoelo-pele e potlakileng ea moruo le ntlafatso e tsoelang pele ea boemo ba indasteri ea indasteri, merero e ntseng e eketseha e hloka tšepe e sa hloekang ea boemo bo holimo.Ka kholo ea tlhoko ea li-alloys tse thehiloeng ho nickel liindasteri tse fapaneng.Ka 2011, sekala sa mmaraka oa alloy oa naha ea heso o ile oa fihla ho li-yuan tse libilione tse 23.07, e leng sekhahla sa kholo ea selemo le selemo sa 19.47%.Ka hona, boemo ba nts'etsopele ea indasteri bo ntse bo tsoela pele ho ea holimo.

Katleho e atlehileng ea lisebelisoa tse fapaneng tse kholo tse felletseng e entse hore kaho ea merero e fapaneng ea bohlokoa e khonehe;ho nepahala ha mechini le lisebelisoa ho tsamaisitse indasteri ea microelectronics le indasteri ea likhomphutha.Ho etsoa ha lipotoloho tse kopantsoeng haholo ho entsoe 'me matla a mohopolo a eketsehile habeli;ntshetsopele le tlhahiso ea sepakapaka le libetsa le lisebelisoa tse fapaneng, nts'etsopele ea mahlale le thekenoloji le thuto kaofela li itšetlehile ka tsoelo-pele ea moralo oa mochini le theknoloji ea tlhahiso.

Sena se seholo se holisa tsebo ea mantlha le bokhoni ba ts'ebeliso ea moralo oa mochini le tlhahiso, hammoho le nts'etsopele ea lihlahisoa tse ncha tsa motlakase.

Re romelle molaetsa oa hau:

-

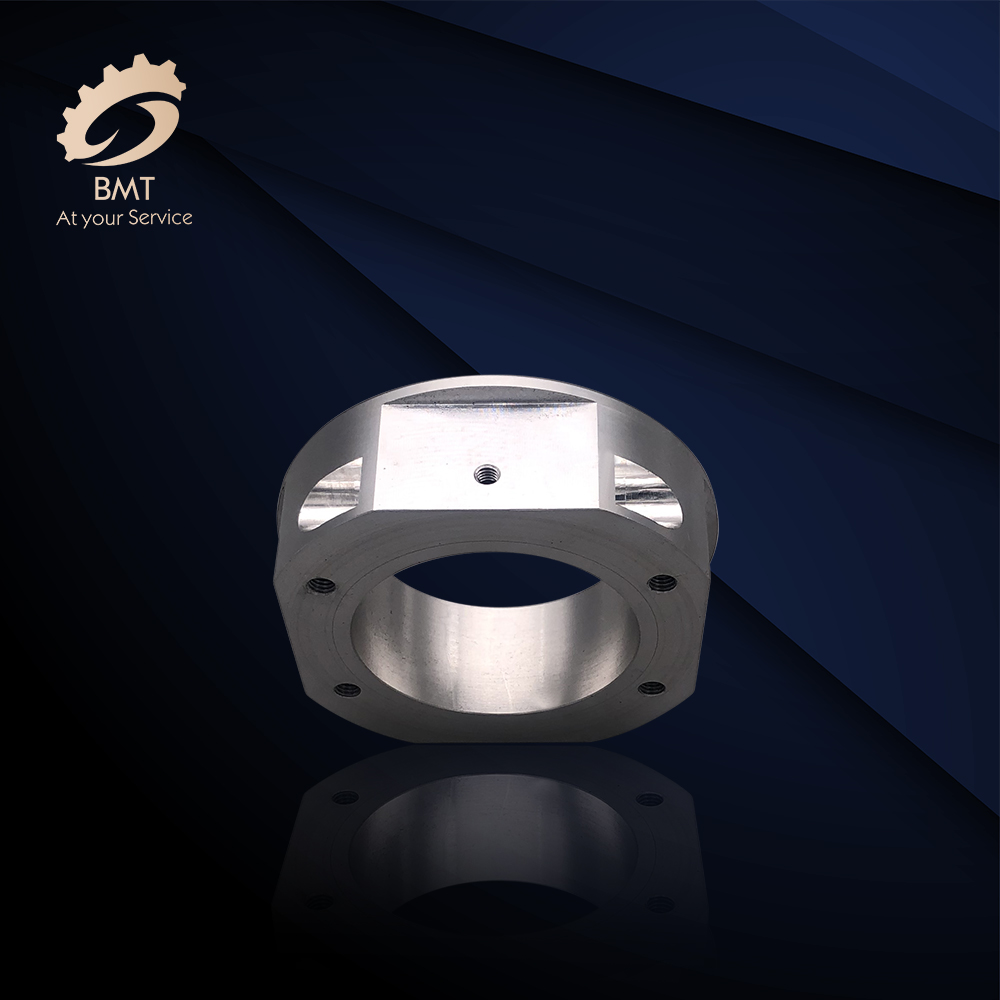

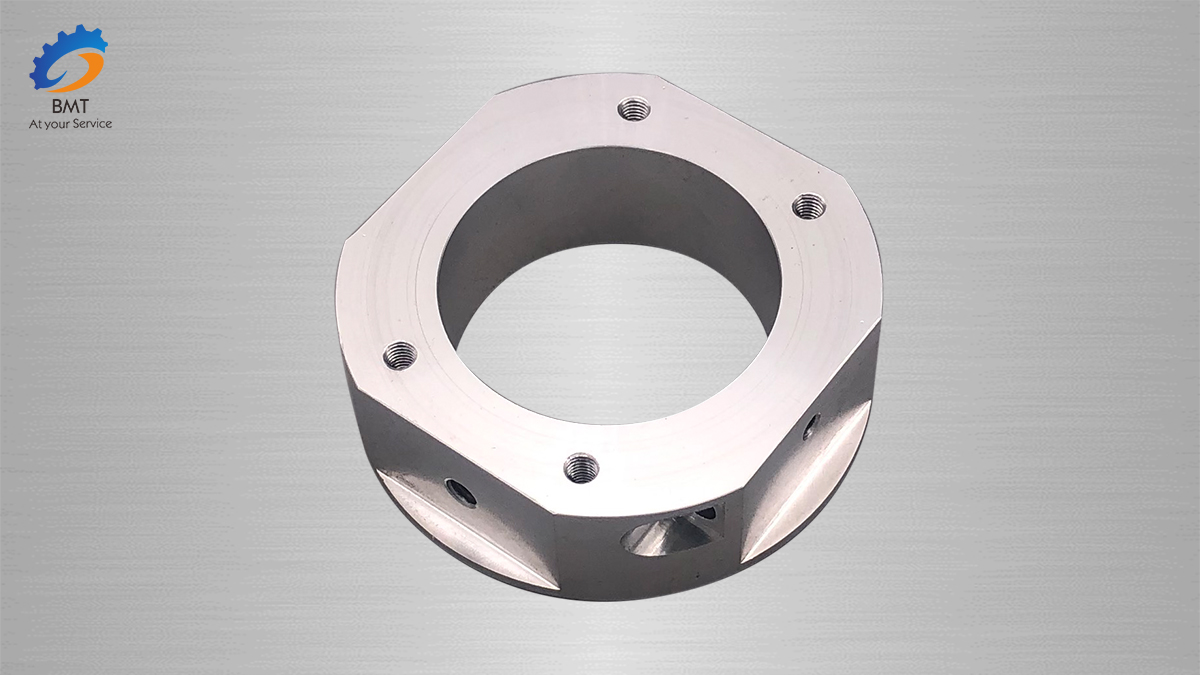

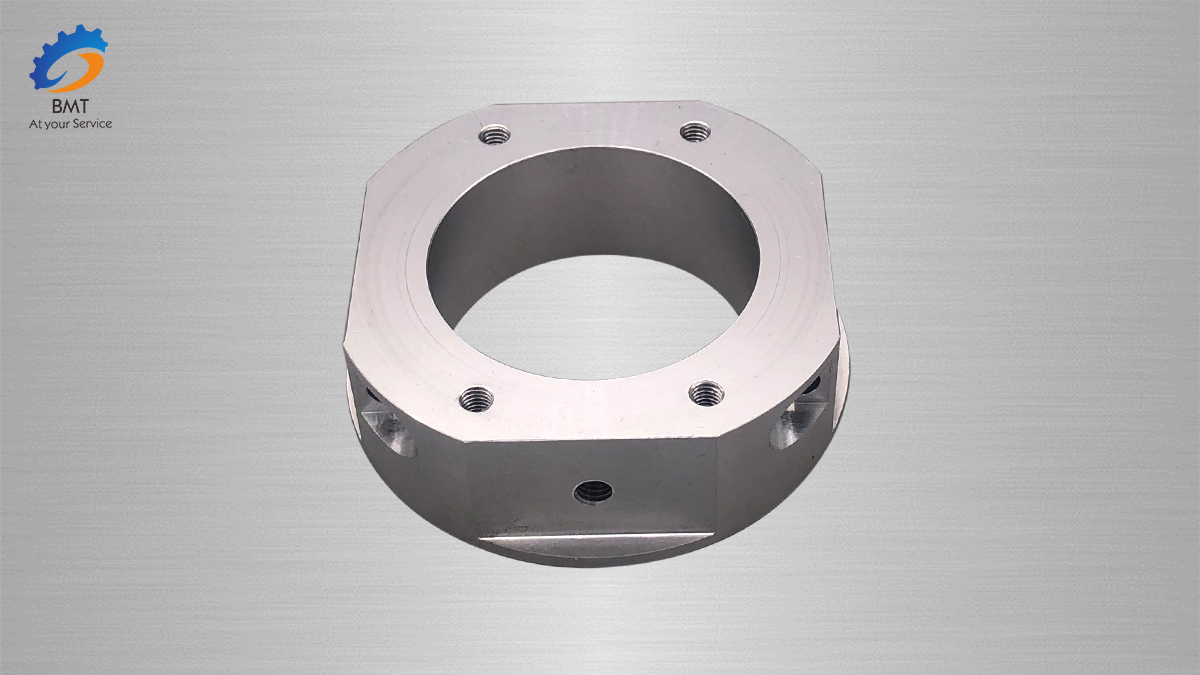

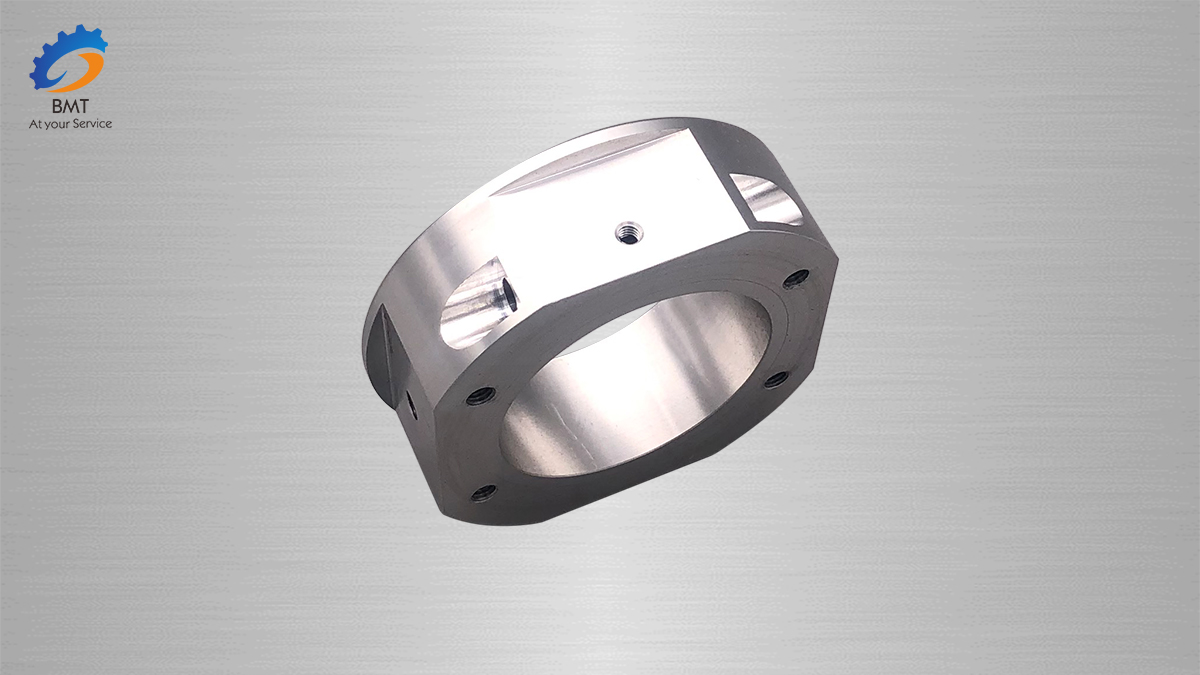

Aluminium CNC Machining likarolo

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining likarolo

-

Likarolo tse entsoeng ke CNC bakeng sa Italy

-

CNC Machining Aluminium likarolo

-

Auto Parts Machining

-

Lisebelisoa tsa Titanium Alloy Forgings

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes