CNC High Precision Machining likarolo

Indastering ea kajeno ea tlhahiso e potlakileng, ho nepahala le ho sebetsa hantle ho bohlokoa hore likhoebo li lule li le tlholisano.Tlhokahalo ea likarolo tsa boleng bo holimo, tse nepahetseng ka linako tsohle, le tse hlahisoang ka potlako e lebisitse ho nts'etsopele ea mahlale a tsoetseng pele a machining.Har'a bona,CNC Machininge hlahella e le e fetolang papali e fetolang tsela eo re atamelang tlhahiso e nepahetseng ka eona.CNC (Computer Numerical Control) Machining ke theknoloji e tsoetseng pele e sebelisang software ea komporo ho laola mochini, ho netefatsa liphetho tse nepahetseng le tse ka phetoang.Ho fapana le mekhoa ea khale ea machining, e itšetlehileng haholo ka mosebetsi oa matsoho le ho kenella ha batho, CNC Machining e tsamaisa mokhoa oa ho etsa lihlahisoa, e fana ka ho nepahala ho ntlafetseng, ho fokotsa liphoso tsa batho, le tlhahiso e eketsehileng.

Pelo ea CNC Machining e holim'a bokhoni ba eona ba ho fetola moralo oa dijithale, o entsoeng ka software e ikhethang, hore e be 'nete ea' mele.Meralo e rarahaneng, libopeho tse rarahaneng, le litekanyo tse mahlonoko tseo pele ho neng ho le thata ho li fihlela ka mekhoa ea setso li se li finyelloa habonolo ka CNC Machining.Ka ho laola hantle motsamao oalisebelisoa tsa ho seha, Mechini ea CNC e ka hlahisa likarolo ka ho nepahala ho ke keng ha bapisoa, mamello e tiileng, le linako tse potlakileng tsa ho fetoha.E 'ngoe ea melemo ea bohlokoa ea CNC Machining ke ho ikamahanya le maemo ho pholletsa le lisebelisoa tse fapaneng.Ebang ke litšepe, lipolasetiki, lehong, kapa metsoako ea eona, CNC Machining e khona ho seha, ho sila, ho phunya le ho bopa lisebelisoa tse fapaneng.Ho feto-fetoha hona ho etsa hore e be khetho ea mantlha bakeng sa liindasteri tse kang sefofane, likoloi, bongaka, lisebelisoa tsa elektroniki, le tse ling tse ngata, moo lintlha tse hlakileng le likhakanyo tsa boleng bo holimo li leng bohlokoa haholo.

Ho feta moo, CNC Machining e ithorisa ka katleho e ikhethang, e lumellang bahlahisi ho ntlafatsa mekhoa ea bona ea tlhahiso le ho fokotsa litšenyehelo.The automation e hlahisitsoeng ke CNC Machining e felisa tlhoko ea ho seta ka letsoho le ho beha leihlo khafetsa, ho lumella basebelisi ho tsepamisa maikutlo mesebetsing e meng ha mochini o sebetsa ka boikemelo.Ts'ebetso ena e potlakisa tlhahiso haholo, e lebisang ho nako e khuts'oane ea ho etella pele le khotsofalo e ntlafalitsoeng ea bareki.Ka nqanetlhahiso ea karolo e nepahetseng, CNC Machining e fana ka melemo e meng e mengata.E matlafatsa bahlahisi ho etsa mohlala ka potlako, ho pheta-pheta meralo ntle le matsapa, le ho ikamahanya le litlhoko tsa 'maraka habonolo.Ka ho sebelisa mananeo a tsoetseng pele a software, mechini ea CNC e ka etsisa lits'ebetso tsa tlhahiso, ea bona liphoso tse ka bang teng, 'me ea ntlafatsa litsela tsa lisebelisoa, e lebisang katlehong e kholo le ho boloka thepa.

Ntle le moo, CNC Machining e khothaletsa botsitso ka ho fokotsa litšila le ho eketsa tšebeliso ea lisebelisoa.Ka ho khetholla ka nepo botebo le metsamao ea lisebelisoa,Mechini ea CNChaholo fokotsa litšila tsa lintho tse bonahalang bapisoa le mekhoa ea setso.Ho feta moo, bokhoni ba ho sebelisa likhechana le tse setseng bakeng sa likarolo tse ling li kenya letsoho molemong oa mokhoa o tsitsitseng oa tlhahiso.Ha ho tluoa ho CNC Machining, ho nepahala, ts'ebetso, ho feto-fetoha ha maemo, le botsitso ke tsona tse susumetsang botumo ba eona bo phatlohileng indastering ea tlhahiso.Ka ho kopanya theknoloji ea morao-rao le tsebo ea basebetsi ba nang le tsebo, CNC Machining e fetotse tsela eo re atamelang karolo e rarahaneng ea tlhahiso, prototyping, le ho feta.

Ka conclusion, CNC Machining e hlahile e le thekenoloji ea ho fetola lipapali, ho fetola sebopeho satlhahisonaha.Ho nepahala ha eona ho ke keng ha bapisoa, bokhoni ba eona ba ho feto-fetoha le maemo, le mekhoa ea tlhahiso e baballang chelete e ngata li etsa hore e be sesebelisoa sa bohlokoa haholo bakeng sa liindasteri lefatšeng ka bophara.Ka ho amohela CNC Machining, likhoebo li ka fihlela litlhoko tse ntseng li eketseha tsa boleng, lebelo, le ho nepahala, ho netefatsa katleho ea tsona 'marakeng oa kajeno oa tlholisano.

Re romelle molaetsa oa hau:

-

Axis High Precision CNC Machining likarolo

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes

-

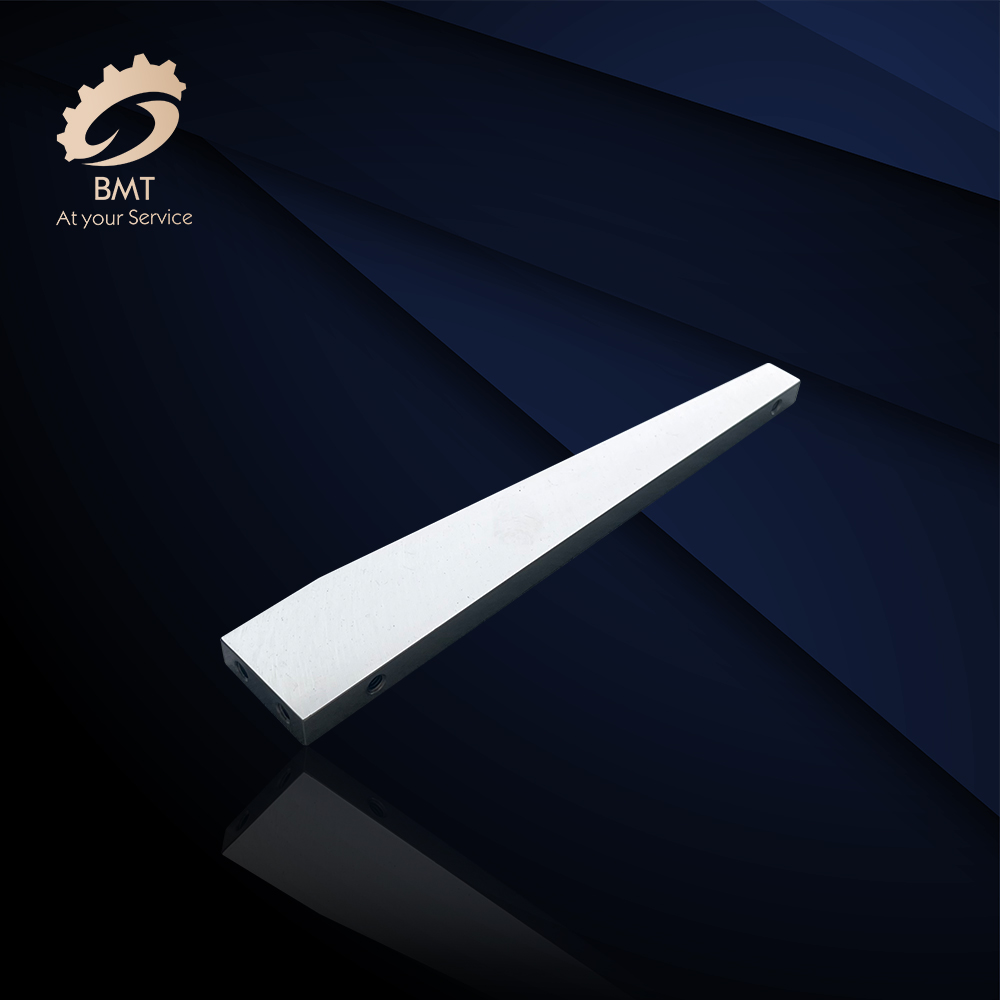

Aluminium CNC Machining likarolo

-

Auto Parts Machining

-

Likarolo tsa CNC Auto Likarolo tse entsoeng

-

Lisebelisoa tsa mochini oa CNC

-

Aluminium Sheet Metal Fabrication

-

Indasteri ea Likoloi

-

Ho Sila ho se Setsi

-

CNC Machining Melemo

-

CNC Machining Aluminium likarolo