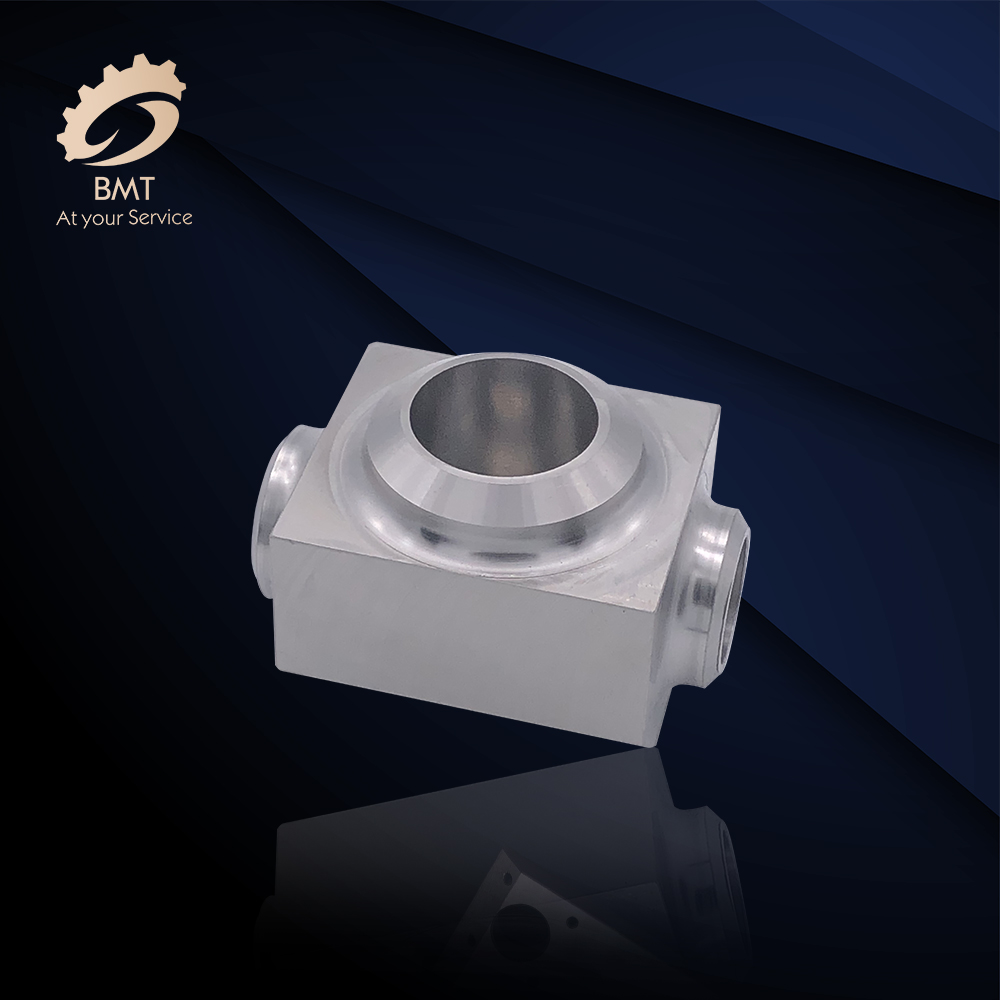

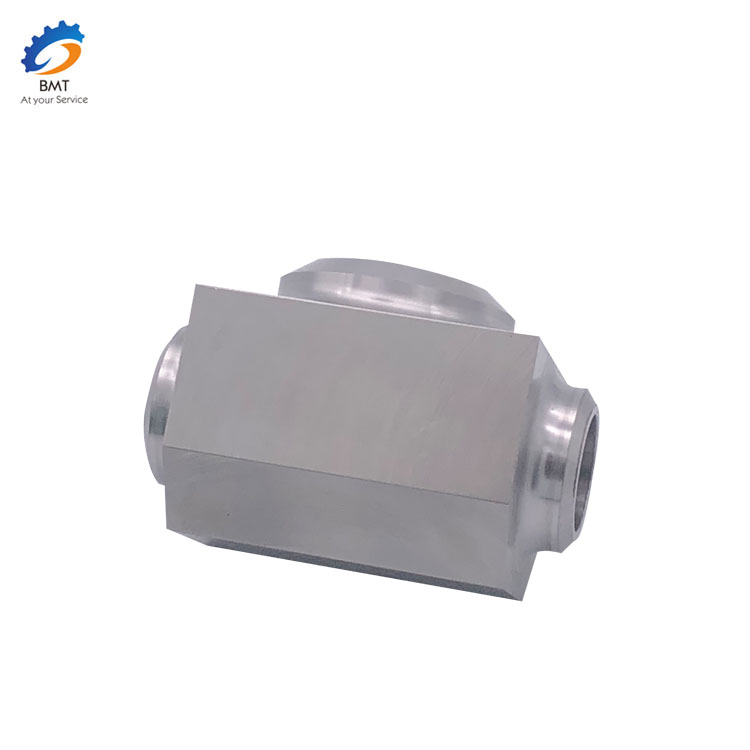

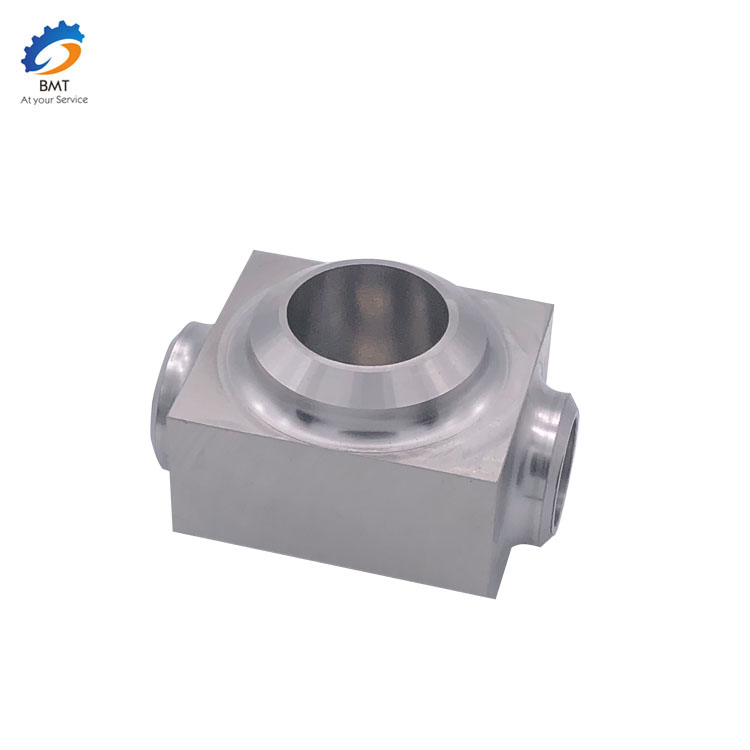

CNC Auto Parts Professional Manufacturer

BMT e sebetsa ka machining ka nepo, ho sebetsa likarolo tse sa tloaheleheng, ho sebetsa likarolo tse ngata tsa CNC, ho sebetsana le likarolo tsa koloi tsa palo, alloy ea batch titanium ka likarolo tse nepahetseng haholo, ts'ebetso ea likarolo tsa shaft, lisebelisoa tsa lisebelisoa tsa semiconductor, joalo-joalo, e na le boiphihlelo bo bongata, bo nang le lisebelisoa. e nang le setsi sa machining sa CNC, lisebelisoa tsa CNC, ho itšeha ka terata, mochini o silang, mochini o silang, o betliloeng, lisebelisoa tse tharo tsa ho lekanya, lisebelisoa tsa ho lekanya bophahamo le lisebelisoa tse ling tse phahameng tsa tlhahiso le lisebelisoa tsa ho lemoha.

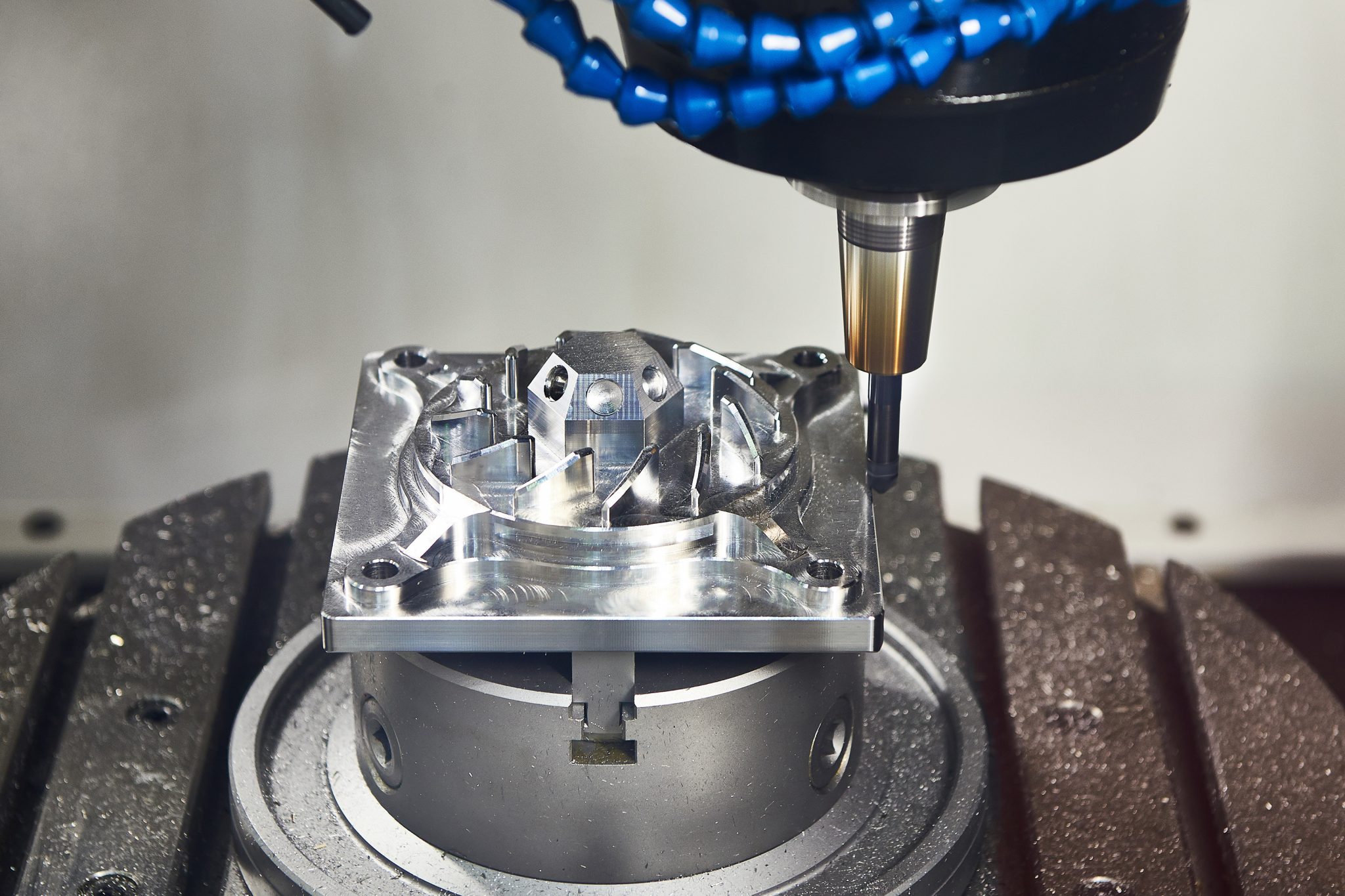

1. Sekaseka litšoantšo tsa ho sebetsa le ho fumana mokhoa oa ho sebetsa

Ho latela lits'oants'o tsa ts'ebetso tse fanoeng ke moreki, basebetsi ba ts'ebetso ba ka sekaseka sebopeho, ho nepahala ha sebopeho, ho hlaka holim'a metsi, lisebelisoa tsa mosebetsi, mofuta o se nang letho le boemo ba kalafo ea mocheso oa likarolo, ebe ba khetha sesebelisoa sa mochini, sesebelisoa, ho tseba hore na sebaka sa ho paka sesebelisoa, mokhoa oa ho sebetsa, tatellano ea ts'ebetso le boholo ba tekanyo ea ho itšeha.Ha ho etsoa qeto ea mokhoa oa ho sebetsa, mosebetsi oa taelo oa mochine oa CNC o lokela ho nahanoa ka botlalo, o fane ka papali e feletseng ho katleho ea mochine oa mochine, e le hore tsela ea ho sebetsa e be e utloahalang, linako tse fokolang tsa thipa le nako e khutšoanyane ea ho sebetsa.

2. Bala boleng ba khokahano ea tsela ea lisebelisoa ka mokhoa o utloahalang

Ho ea ka boholo ba geometri ea karolo ea machining le mokhoa o hlophisitsoeng oa ho hokahanya lenaneo, tsela ea ho sisinyeha ea bohareng ba tsela ea sehahi e baloa, 'me lintlha tsohle tsa boemo ba sehahi li fumanoa.Sistimi e akaretsang ea CNC e na le ts'ebetso ea ho kenella ka mela le ho kenella ka selikalikoe, bakeng sa likarolo tse batlang li le bonolo tsa sebopeho sa polane, joalo ka likarolo tsa machining a line le arc contour, ho hlokahala feela ho bala likarolo tsa geometri tsa ntlha le ntlha ea ho qetela, selikalikoe sa selikalikoe. kapa circular arc radius), ntlha e 'meli ea mateano ea likarolo tsa geometrical kapa litekanyetso tsa khokahanyo tsa lintlha tse tangent.Haeba sistimi ea nc e se na ts'ebetso ea mats'eliso a lisebelisoa, boleng ba khokahano ea trajectory ea setsi sa lisebelisoa bo lokela ho baloa.Bakeng sa likarolo tse nang le sebopeho se rarahaneng (joalo ka likarolo tse entsoeng ka sekhahla se se nang selikalikoe le bokaholimo), hoa hlokahala ho sebelisa karolo e otlolohileng (kapa karolo ea arc) ho lekanya lekhalo kapa bokaholimo ba eona, le ho bala boleng ba khokahano ea eona. nodes ho ya ka bokgabane bo hlokahalang ba machining.

3. Ngola CNC machining lenaneo bakeng sa likarolo

Ho ea ka likarolo tsa tsela ea thipa ho bala lintlha tsa tsela ea lisebelisoa le litekanyetso tsa ts'ebetso li khethiloe le ketso e thusang, basebetsi ba mananeo ba ka lumellana le ts'ebeliso ea tsamaiso ea NUMERICAL e boletsoeng litaelong tsa tshebetso le sebopeho sa lenaneo, karolo ea ho ngola likarolo tsa lenaneo la ho sebetsa.Tlhokomelo e lokela ho lefshoa ho: pele, maemo a ho ngola lenaneo a lokela ho ba bonolo ho hlalosa le ho buisana;Ea bobeli, ts'ebelisong ea ts'ebetso ea sesebelisoa sa mochini oa CNC le litaelo motheong oa ho tseba ka botlalo, taeo ea ts'ebeliso ea litsebo, litsebo tsa mananeo.