Tharollo ea hau e le 'ngoe bakeng sa Litlhoko tsa Boenjiniere ba Precision

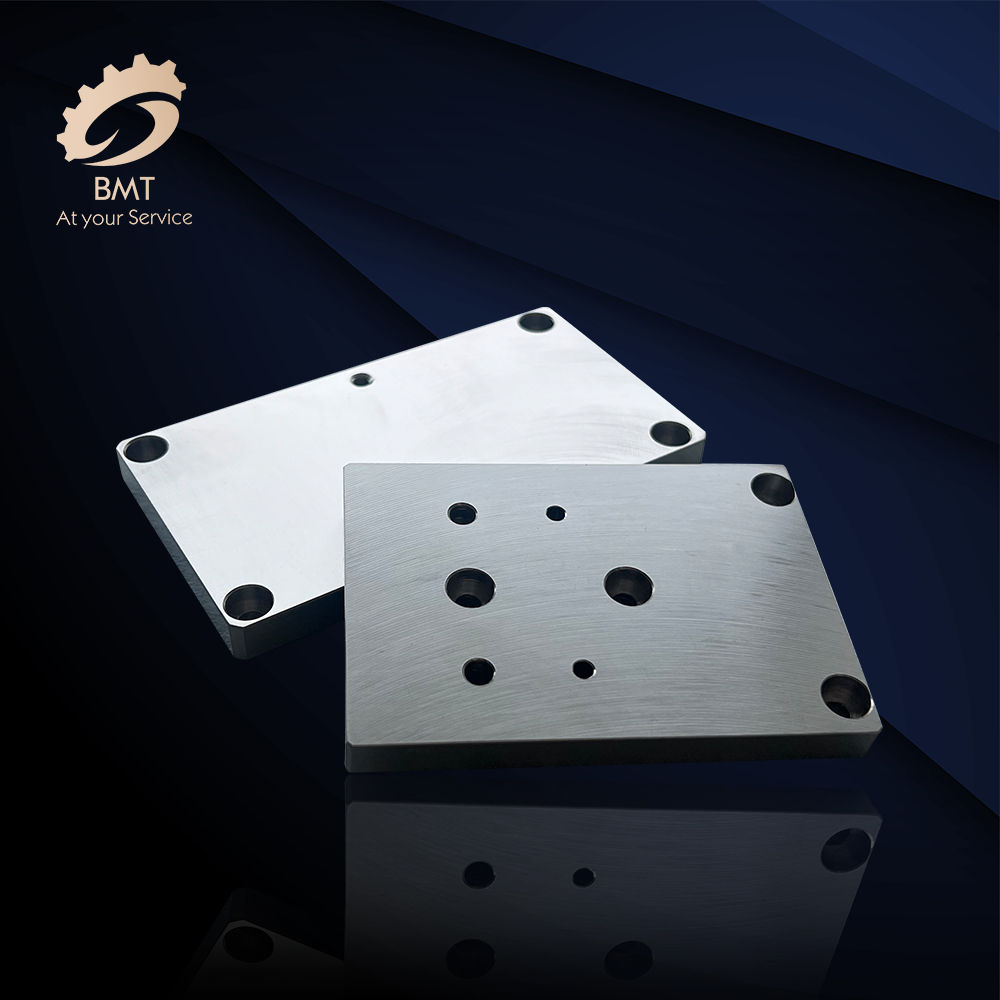

Ho BMT, re motlotlo ka ho ba mofani ea ka sehloohong oa boleng bo holimoHo nepahala ha CNClitharollo tsa machining. Ka lisebelisoa tsa rona tsa morao-rao le sehlopha sa litsebi tse nang le litsebo, re fana ka mefuta e mengata ea litšebeletso tsa boenjiniere tse nepahetseng ho khotsofatsa litlhoko tse fapaneng tsa bareki ba rona. Khamphani ea rona e sebetsa ka ho khetheha ho CNC precision machining, mokhoa o tsoetseng pele oa tlhahiso o sebelisang theknoloji ea taolo ea linomoro tsa komporo (CNC) ho hlahisa likarolo tse rarahaneng le tse rarahaneng ka nepo e ikhethang. Hore na o hloka lisebelisoa tse iketselitsoeng bakeng sa indasteri ea likoloi, lisebelisoa tsa bongaka, lisebelisoa tsa sefofane, kapa lefapha lefe kapa lefe, lits'ebeletso tsa rona tsa mochini o nepahetseng li netefatsa hore litlhoko tsa hau li fihlelleha ka nepo le ka botlalo.

E 'ngoe ea matla a rona a bohlokoa ke bokhoni ba rona ba ho sebetsa ka mefuta e fapaneng ea thepa. Ho tloha ho litšepe tse kang aluminium, tšepe e sa hloekang, titanium, le koporo, ho ea ho lipolasetiki tse tsoetseng pele le lisebelisoa tse entsoeng ka metsoako, re na le tsebo le lisebelisoa tsa ho sebetsana le merero e thata ka ho fetisisa ea machining. Ea ronaCNC bokhoni ba ho sebetsa ka mokhoa o nepahetsengre lumelle ho hlahisa likarolo tse nang le mamello e thata, meralo e rarahaneng, le likhakanyo tse phahameng tsa bokaholimo, ho netefatsa hore litekanyetso tsa boleng bo holimo lia fihlelleha. Ho BMT, re utloisisa bohlokoa ba ho boloka litšenyehelo le linako tse potlakileng tsa phetoho. Mechini ea rona e tsoetseng pele le mekhoa e metle ea tlhahiso e re thusa ho ntlafatsa lebelo la tlhahiso ntle le ho sekisetsa boleng.

Hore na o hloka karolo e nyane ea likarolo kapa tlhahiso ea molumo o phahameng, ho feto-fetoha ha maemo ho re lumella ho fihlela litlhoko tsa hau ha re ntse re latela linako tse thata. Ntle le bokhoni ba rona ba ho sebetsa ka nepo, re boetse re fana ka mefuta e mengata ea litšebeletso tse tlatselletsang ho fana ka tharollo e felletseng ho bareki ba rona. Litšebeletso tsena li kenyelletsa tšehetso ea meralo le boenjiniere, prototyping, kopano, le taolo ea boleng. Ka ho fana ka litharollo tsa ho qetela, re etsa bonnete ba hore bareki ba rona ba fumana ts'ebetso e se nang moeli ho tloha mohopolong ho isa tlhahisong.

Boitlamo ba rona ho khotsofalo ea bareki ha bo thekesele. Re sebelisana haufi-ufi le bareki ba rona, ho netefatsa hore re utloisisa ka botlalo litlhoko tsa bona le ho fana ka litharollo tsa motho ka mong tse lumellanang le litlhoko tsa bona tse ikhethileng. Sehlopha sa rona sa lienjineri tse nang le boiphihlelo le litsebi li sebetsa ka thata ho boloka mehala e bulehileng ea puisano, li fana ka lintlafatso khafetsa ts'ebetsong eohle ea mochini. Ho re khetha ho bolela ho sebelisana le k'hamphani e etelletsang boleng, ho nepahala le ho sebetsa hantle pele. Re ikitlaelletsa ho feta litebello, re fana ka lihlahisoa tse finyellang litlhoko tse boima ka ho fetisisa.

Ka boinehelo ba rona ba ntlafatso e tsoelang pele le matsete a theknoloji ea morao-rao, re lula re le ka pele ho indasteri ea ho etsa machining e nepahetseng, ho netefatsa hore bareki ba rona ba fumana lihlahisoa le litšebeletso tse ntle ka ho fetisisa. Ikopanye le rona kajeno ho buisana le uenaboenjiniere bo nepahetsenglitlhoko. Hore na o hloka prototype kapa tlhahiso e kholo ea tlhahiso, sehlopha sa rona se ikemiselitse ho u fa litharollo tsa boleng bo holimo tsa CNC tsa machining. Tšepa BMT ho fana ka ho nepahala, phetheho le bokhabane nako le nako.

Re romelle molaetsa oa hau:

-

Axis High Precision CNC Machining likarolo

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes

-

Aluminium CNC Machining likarolo

-

Auto Parts Machining

-

Likarolo tsa CNC Auto Likarolo tse entsoeng

-

Lisebelisoa tsa mochini oa CNC

-

Aluminium Sheet Metal Fabrication

-

Indasteri ea Likoloi

-

Ho Sila ho se Setsi

-

CNC Machining Melemo

-

CNC Machining Aluminium likarolo