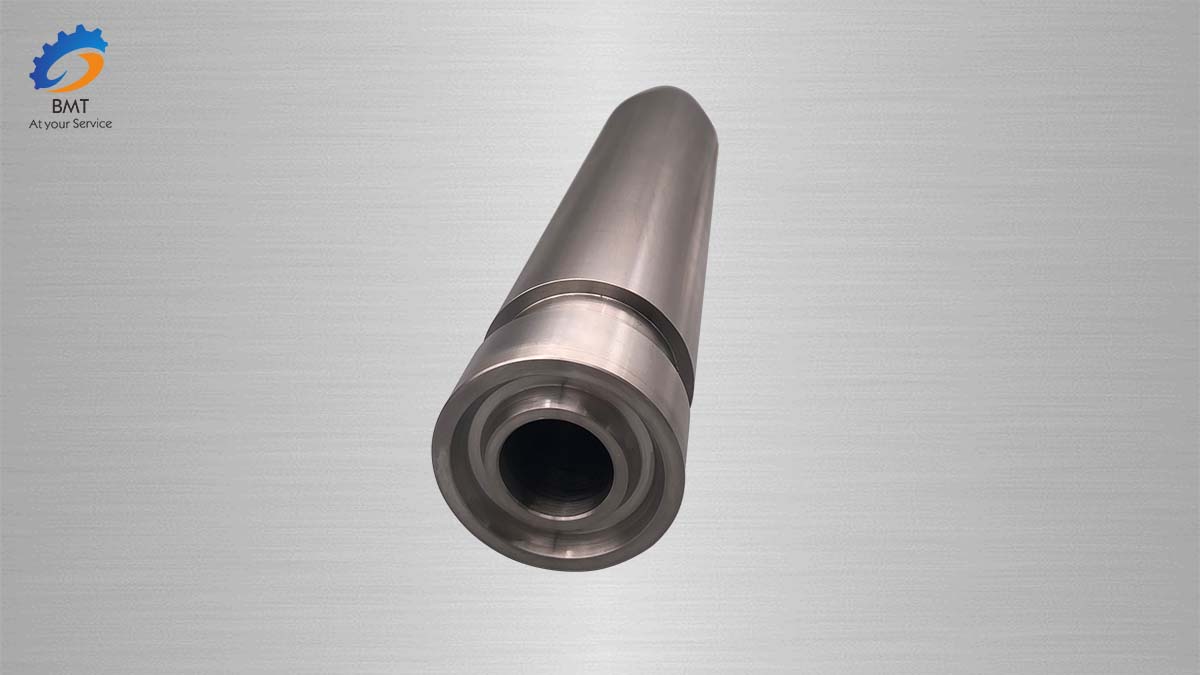

Titanium Alloy CNC Machining

Khatello ea machining ea li-alloys tsa titanium e tšoana haholo le machining a tšepe ho feta litšepe tse se nang ferrous le li-alloys.Mekhoa e mengata ea ts'ebetso ea li-alloys tsa titanium ho forging, ho hatakela molumo le ho hatakela maqephe a haufi le a ts'ebetso ea tšepe.Empa ho na le likarolo tse ling tsa bohlokoa tse lokelang ho eloa hloko ha ho sebetsa li-alloys tsa Chin le Chin.

Le hoja ka kakaretso ho lumeloa hore li-lattice tsa hexagonal tse ka har'a titanium le li-alloys tsa titanium ha li na ductile ha li holofetse, mekhoa e fapaneng ea ho sebetsa ea khatiso e sebelisetsoang litšepe tse ling tsa sebopeho le eona e loketse li-alloys tsa titanium.Karo-karolelano ea ntlha ea lihlahisoa ho moeli oa matla ke e 'ngoe ea matšoao a hore na tšepe e ka mamella deformation ea polasetiki.E kholoanyane karo-karolelano ena, ho mpefala ha polasetiki ea tšepe.Bakeng sa titanium e hloekileng ea indasteri naheng e pholileng, karo-karolelano ke 0.72-0.87, ha e bapisoa le 0.6-0.65 bakeng sa tšepe ea carbon le 0.4-0.5 bakeng sa tšepe e sa hloekang.

Etsa setempe sa molumo, ho forging mahala le lits'ebetso tse ling tse amanang le ts'ebetso ea likarolo tse kholo tsa sefapano le likheo tsa boholo bo boholo sebakeng se futhumetseng (kaholimo ho = yS mocheso oa phetoho).Mocheso oa mocheso oa ho fereka le ho futhumatsa setempe o pakeng tsa 850-1150°C.Lisebelisoa tsa BT;M0, BT1-0, OT4~0 le OT4-1 li na le deformation e khotsofatsang ea polasetiki sebakeng se pholileng.Ka hona, likarolo tse entsoeng ka li-alloys tsena hangata li entsoe ka likheo tse mahareng tse kentsoeng ntle le ho futhumatsa le ho hatakela.Ha motsoako oa titanium o batang o holofetse ka polasetiki, ho sa tsotelehe sebopeho sa eona sa lik'hemik'hale le thepa ea mochini, matla a tla ntlafala haholo, 'me polasetiki e tla fokotseha ka tsela e tšoanang.Ka lebaka lena, kalafo ea annealing lipakeng tsa lits'ebetso e tlameha ho etsoa.

Ho roala ha li-groove tse entsoeng ka machining a li-alloys tsa titanium ke ho apara sebakeng sa morao le ka pele ho ea ka botebo ba sehiloeng, seo hangata se bakoang ke lera le thata le siiloeng ke ts'ebetso e fetileng.Boitšoaro ba lik'hemik'hale le ho hasana ha sesebelisoa le lisebelisoa tsa mosebetsi ka mocheso oa ho sebetsa o fetang 800 ° C hape ke e 'ngoe ea mabaka a ho thehoa ha groove wear.Hobane nakong ea ts'ebetso ea machining, limolek'hule tsa titanium tsa workpiece li bokella ka pel'a lehare 'me li "welded" ho ea moeling oa lehare tlas'a khatello e phahameng le mocheso o phahameng, ho etsa moeli o hahiloeng.Ha moeli o hahiloeng o phunyeletsa moeling oa ho itšeha, seaparo sa carbide sa ho kenya se tlosoa.

Ka lebaka la ho hanyetsa mocheso oa titanium, ho pholisa ho bohlokoa ts'ebetsong ea mochini.Sepheo sa ho pholisa ke ho boloka moeli oa ho itšeha le holim'a lisebelisoa ho tloha mocheso o feteletseng.Sebelisa end coolant bakeng sa ho ntša chip ha u ntse u sila ka mahetla hammoho le lipokotho tsa sefahleho, lipokotho kapa li-grooves tse tletseng.Ha u seha tšepe ea titanium, li-chips li bonolo ho khomarela moeling oa ho itšeha, e leng se etsang hore potoloho e latelang ea sehahi se sehang li-chips hape, hangata se etsa hore moeli oa moeli o fokotsehe.

Sebaka se seng le se seng sa ho kenya se na le lesoba / ente ea sona e pholileng ho rarolla bothata bona le ho ntlafatsa ts'ebetso e sa feleng.Tharollo e 'ngoe e makhethe ke masoba a pholiso a khoele.Li-milling cutters tse telele li na le lintho tse ngata tse kentsoeng.Ho kenya sepholisa lesoba ka leng ho hloka matla a pompo a phahameng le khatello.Ka lehlakoreng le leng, e ka koala masoba a sa hlokahaleng ha ho hlokahala, ka tsela eo e eketsa phallo ho likoti tse hlokahalang.

Re romelle molaetsa oa hau:

-

Aluminium CNC Machining likarolo

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining likarolo

-

Likarolo tse entsoeng ke CNC bakeng sa Italy

-

CNC Machining Aluminium likarolo

-

Auto Parts Machining

-

Lisebelisoa tsa Titanium Alloy Forgings

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes