Lits'ebeletso tsa Mechining ea Boemo ba Naha

Re hlahisa lits'ebeletso tsa rona tsa "State-Of-The-Art Machining Services", moo ho nepahala ho kopanang le ts'ebetso e nepahetseng. Bokhoni ba rona ba ho etsa mochini ha bo bapisoe, bo fana ka likarolo tsa boleng bo holimo le likarolo tsa mefuta e mengata ea liindasteri. Ho tloha sebakeng sa sefofane ho ea ho likoloi, tsa bongaka hosesole, tharollo ea rona ea machining e etselitsoe ho fihlela litlhoko tse ikhethang tsa moreki e mong le e mong. Ts'ebetso ea rona ea machining e qala ka software ea morao-rao ea CAD/CAM, e re lumellang ho etsa meralo e qaqileng, e nepahetseng bakeng sa bareki ba rona. Hang ha meralo e phethetsoe, sehlopha sa rona sa baenjiniere ba nang le boiphihlelo le bo-machini ba sebelisa mechini e tsoetseng pele ea CNC ho fetola meralo hore e be ea nnete.

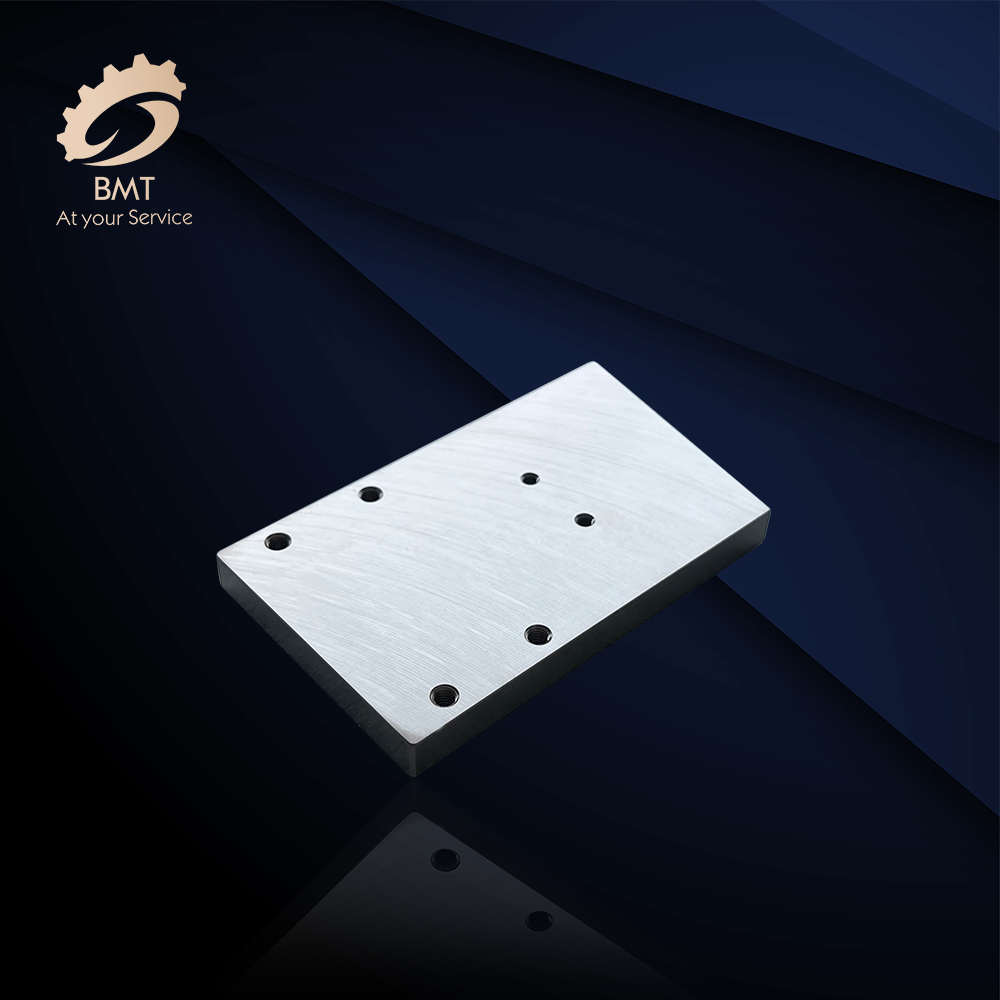

Ka botsebi ba rona hoho sila, ho reteleha, ho phunya, le ho sila, re ka hlahisa likarolo tse rarahaneng tse nang le mamello e thata le li-geometri tse rarahaneng. E 'ngoe ea likarolo tsa bohlokoa tsa lits'ebeletso tsa rona tsa mochini ke boitlamo ba rona ba boleng. Re khomarela mehato e tiileng ea taolo ea boleng ho pholletsa le ts'ebetso eohle, ho netefatsa hore karolo e 'ngoe le e' ngoe e finyella litekanyetso tse phahameng ka ho fetisisa. Ho tloha khethong ea lisebelisoa ho isa tlhahlobong ea ho qetela, re etelletsa pele ho nepahala le ho nepahala likarolong tsohle tsa ts'ebetso ea rona ea mochini. Ntle le boleng, lits'ebeletso tsa rona tsa machining li boetse li tsebahala ka lebelo le ts'ebetso ea tsona.

Ka ronamechine e tsoetseng pelele dithulaganyo streamlined, re ka potlako hlahisa meqolo e khōlō ea likarolo ntle le sehlabelo boleng. Sena se re fa monyetla oa ho kopana le linako tse behiloeng tse tiileng le ho fana ka likarolo ka nako, ho thusa bareki ba rona ho lula pele ho tlholisano ea bona. Litšebeletso tsa rona tsa machining li na le mefuta e mengata ebile lia fetoha, li khona ho sebetsana le mefuta e mengata ea thepa. Hore na ke aluminium, tšepe, titanium, kapa li-alloys tsa kantle ho naha, re na le boiphihlelo le lisebelisoa tsa ho sebetsana le thepa efe kapa efe habonolo. Re boetse re fana ka mefuta e mengata ea li-finishing le li-coatings ho fihlela litlhoko tse khethehileng tsa botle le ts'ebetso. Ho feta moo, lits'ebeletso tsa rona tsa mochini ha li felle feela tlhahisong ea bongata. Re na le bokhoni ba ho sebetsana le litaelo tsa molumo o phahameng le o tlase, ho re etsa balekane ba loketseng bakeng sa likhoebo tsa mefuta eohle.

Ebang ke prototype bakeng sa sehlahisoa se secha kapa tlhahiso e kholo ea tlhahiso, re ka sebetsana le eona ka mokhoa o ts'oanang oa ho nepahala le ho ela hloko lintlha. Litšebeletso tsa rona tsa mochini li feta feela ho hlahisa likarolo. Re boetse re fana ka lits'ebeletso tse kenyellelitsoeng boleng joalo ka kopano, ho paka, le kitting, ho fana ka tharollo e felletseng bakeng sa bareki ba rona. Sena se ba lumella ho fokotsa chelete ea bona ea phepelo le ho fokotsa litšenyehelo tsa bona tsa tlhahiso ka kakaretso. Ka boinehelo ba rona ho bokhabane le khotsofalo ea bareki, re itlhomme re le balekane ba tšepahalang bakeng sa litlhoko tsa machining. Bareki ba rona ba itšetlehile ka rona bakeng sa boleng bo tsitsitseng, linako tsa phetoho e potlakileng, le tšebeletso e ikhethang ea bareki. Re motlotlo ka ho aha likamano tse tšoarellang nako e telele le bareki ba rona, ho utloisisa litlhoko tsa bona tse ikhethang, le ho fana ka litharollo tse ntle ka ho fetisisa tse ka khonehang.

Qetellong, ea ronalits'ebeletso tsa mochinike motsoako o phethahetseng oa ho nepahala, ho sebetsa hantle le ho ts'epahala. Ka theknoloji ea rona e tsoetseng pele, basebetsi ba nang le boiphihlelo, le boitlamo bo sa thekeseleng ba boleng, re khetho e nepahetseng bakeng sa litlhoko tsohle tsa machining. Ebang ke prototype e nyane kapa tlhahiso e kholo ea tlhahiso, re na le boiphihlelo le bokhoni ba ho etsa hore meralo ea hau e phele. Ikopanye le rona kajeno ho ithuta haholoanyane ka lits'ebeletso tsa rona tsa machining li ka u thusang ho isa khoebo ea hau boemong bo bong.

Re romelle molaetsa oa hau:

-

Axis High Precision CNC Machining likarolo

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes

-

Aluminium CNC Machining likarolo

-

Auto Parts Machining

-

Likarolo tsa CNC Auto Likarolo tse entsoeng

-

Lisebelisoa tsa mochini oa CNC

-

Aluminium Sheet Metal Fabrication

-

Indasteri ea Likoloi

-

Ho Sila ho se Setsi

-

CNC Machining Melemo

-

CNC Machining Aluminium likarolo