Theknoloji ea ho sebetsa

Ho silae bua ka mokhoa oa ts'ebetso oa ho sebelisa lisebelisoa tsa abrasive le abrasive ho tlosa lisebelisoa tse feteletseng ho tloha mosebetsing.Ho ea ka merero le litlhoko tse fapaneng tsa ts'ebetso, ho na le mefuta e mengata ea mekhoa ea ho sila.E le ho finyella litlhoko tsa nts'etsopele, theknoloji ea ho sila e ntse e tsoela pele ho ea ka mokhoa o nepahetseng, o fokolang, o sebetsang hantle haholo, lebelo le phahameng le ho sila ka mokhoa o itekanetseng.

Ho na le mefuta e mengata eats'ebetso ea ho silamekhoa.Tlhahisong, haholo-holo e bua ka ho sila ka lebili la ho sila.Bakeng sa ho nolofatsa ts'ebeliso le taolo, mekhoa ea ts'ebetso ea ho sila ka kakaretso e arotsoe ka mefuta e mene ho latela liforomo tsa ts'ebetso ea ho sila le lintho tse sebetsang tsa lihlahisoa tsa mochini o silang:

1. Ho ea kaho silaho nepahala, e ka aroloa ka ho sila ka thata, ho sila ka thata, ho sila hantle, ho sila ka seipone le ultra-ho sebetsa hantle;

2. Khaola ka ho sila, ho sila ka longitudinal, creep feed grinding, non-feed sila, khatello e sa khaotseng ea ho sila, le ho sila ka bongata li arotsoe ho latela mokhoa oa ho fepa.

3. Ho ea ka foromo ea ho sila, e ka aroloa ka ho sila ka lebanta, ho sila ho se nang setsi, ho sila ho qetela, ho sila ka mahlakoreng, ho sila ka bophara, ho sila ha profil, ho sila ka mokhoa o tsitsitseng, ho sila ka lebelo le phahameng, ho sila ka matla, khatello e sa khaotseng ea khatello, ho sila ka letsoho, ho omella, ho sila ka metsi, ho sila, ho roala, joalo-joalo

4. Ho ea ka sebaka se entsoeng ka mochine, se ka aroloa ka ho sila ka cylindrical, ho sila ka hare, ho sila ka holim'a metsi le ho sila (ho sila le ho sila ka khoele)

Ho phaella moo, ho na le mekhoa e mengata ea ho khetholla.Ka mohlala, ho ea ka mefuta ea lisebelisoa tsa ho sila tse sebelisoang ha ho sila, li ka aroloa ka: mekhoa ea ho sila bakeng sa lisebelisoa tse tiileng tsa abrasive le lisebelisoa tsa mahala tsa abrasive.Mekhoa ea ho sila bakeng sa lisebelisoa tse tiileng tsa abrasive haholo-holo e kenyelletsa ho sila ha lebili, ho honing, ho sila ka lebanta la abrasive, electrolytic grinding, joalo-joalo;Mekhoa ea machining ea ho sila ea mahala ea abrasive haholo-holo e kenyelletsa ho sila, ho bentša, mochini oa jet, phallo ea abrasive.machining, machining vibration, joalo-joalo Ho ea ka lebelo le melang Vs ea lebili la ho sila, e ka aroloa ka: ho sila ho tloaelehileng Vs<45m/s, ho sila ka lebelo le phahameng Vs<=45m/s, le Ultra-high speed grinding>= 150m/s.Ho ea ka maemo a macha a theknoloji, e ka aroloa ka: ho sila ka matla a khoheli, ho belisoa ha electrochemical, joalo-joalo.

(7) Ha ho etsoa mesebetsi ea matsoho haufi le lebili le silang le potolohang, tse kang lisebelisoa tse silang, lisebelisoa tsa ho hloekisa kapa mekhoa e fosahetseng ea ho lokisa lebili la ho sila, matsoho a basebetsi a ka ’na a tšoara lebili le silang kapa likarolo tse ling tse tsamaeang tsa tšila ’me a tsoa likotsi.

(8) Lerata le phahameng le hlahisoang nakong ea ho sila le ka fihla ho feta 110dB.Haeba ho sa nkuoe mehato ea ho fokotsa lerata, bophelo bo botle le bona bo tla ameha.

Re romelle molaetsa oa hau:

-

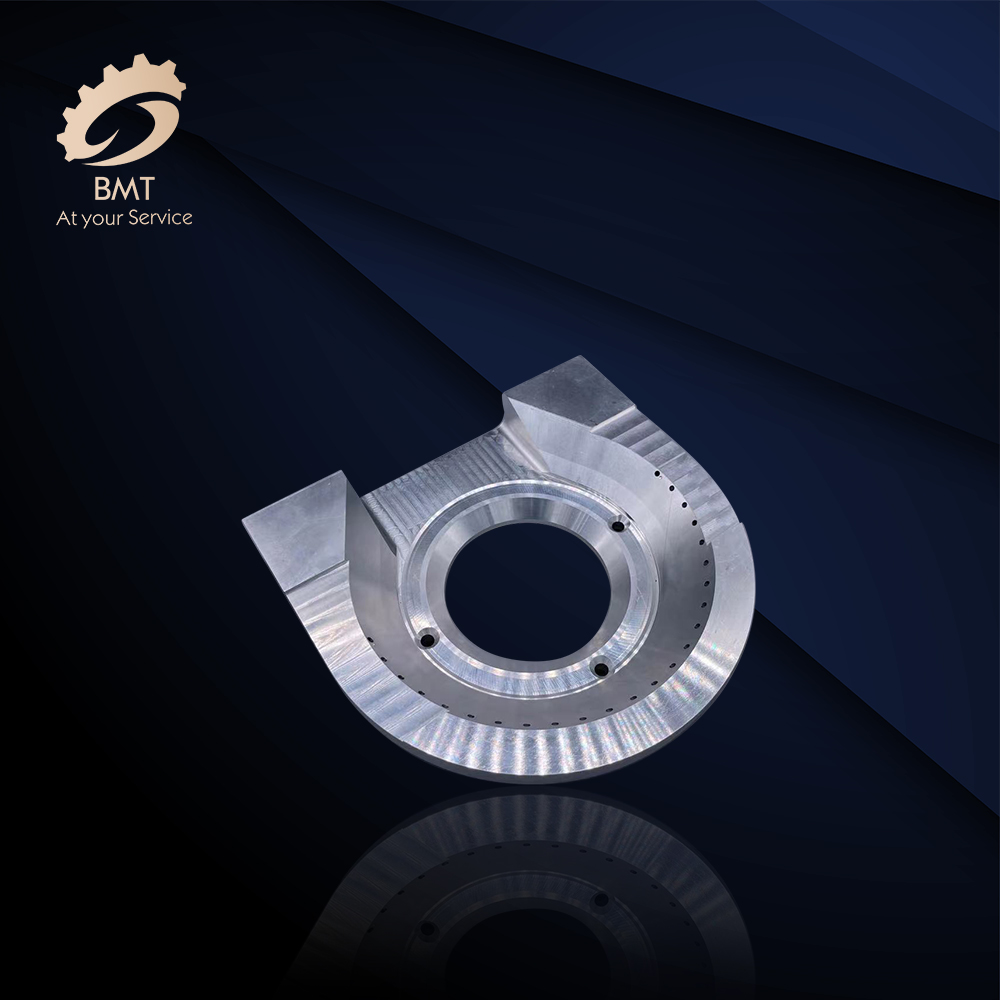

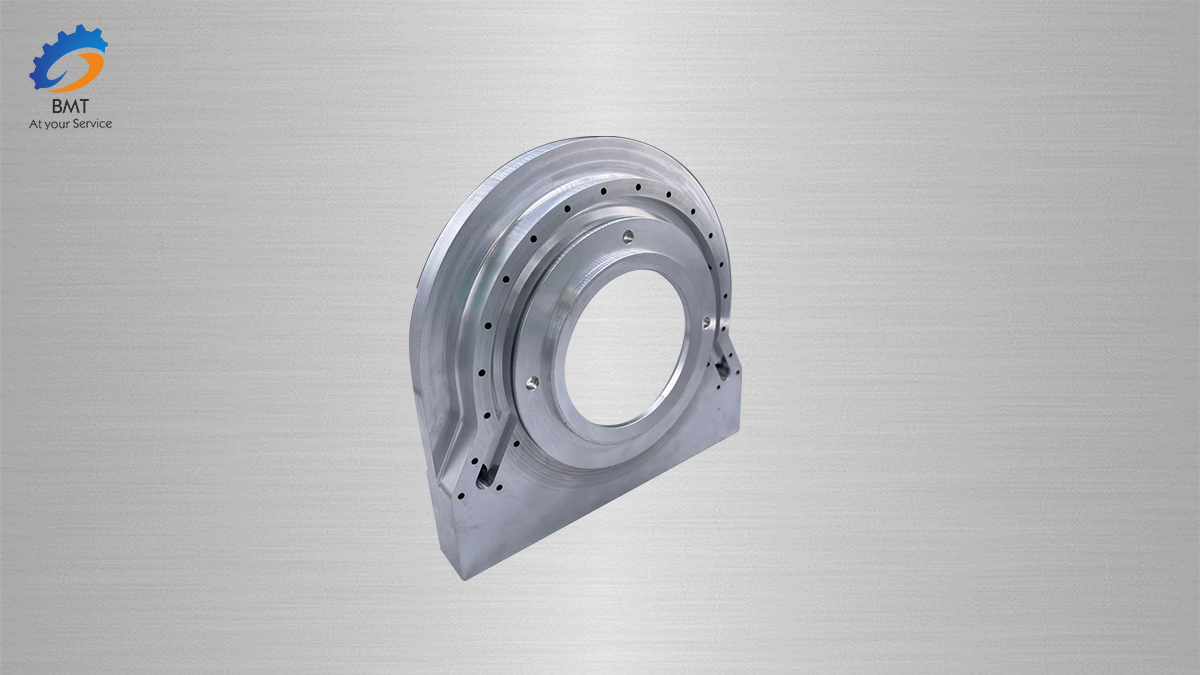

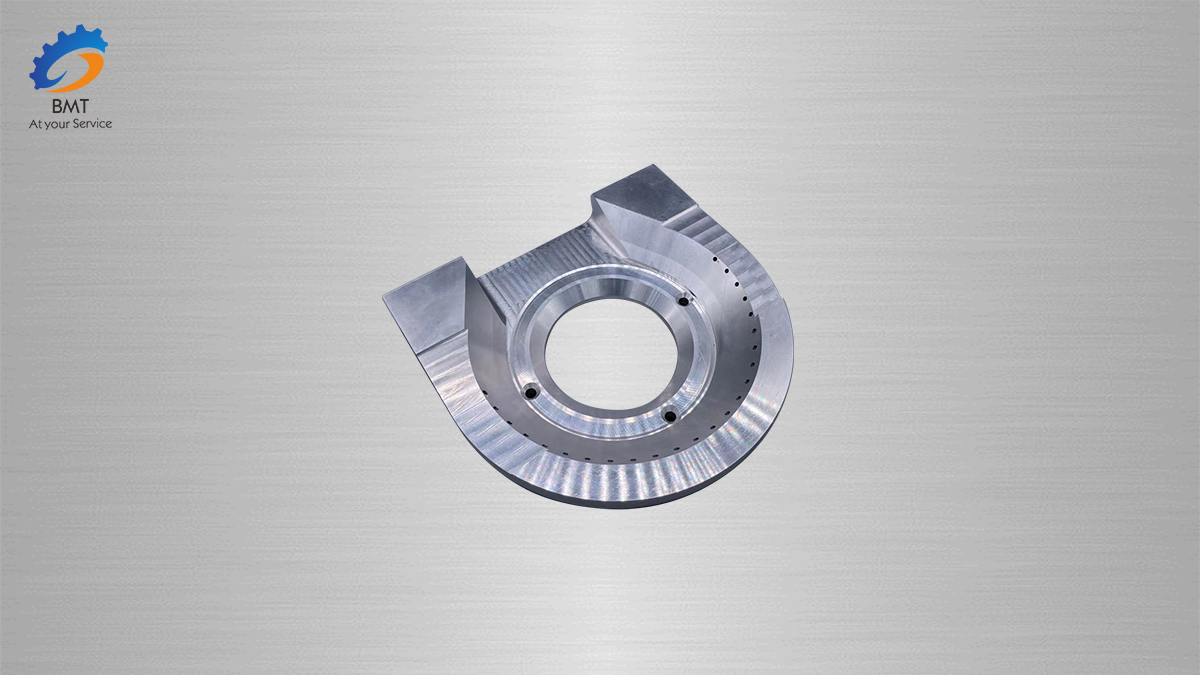

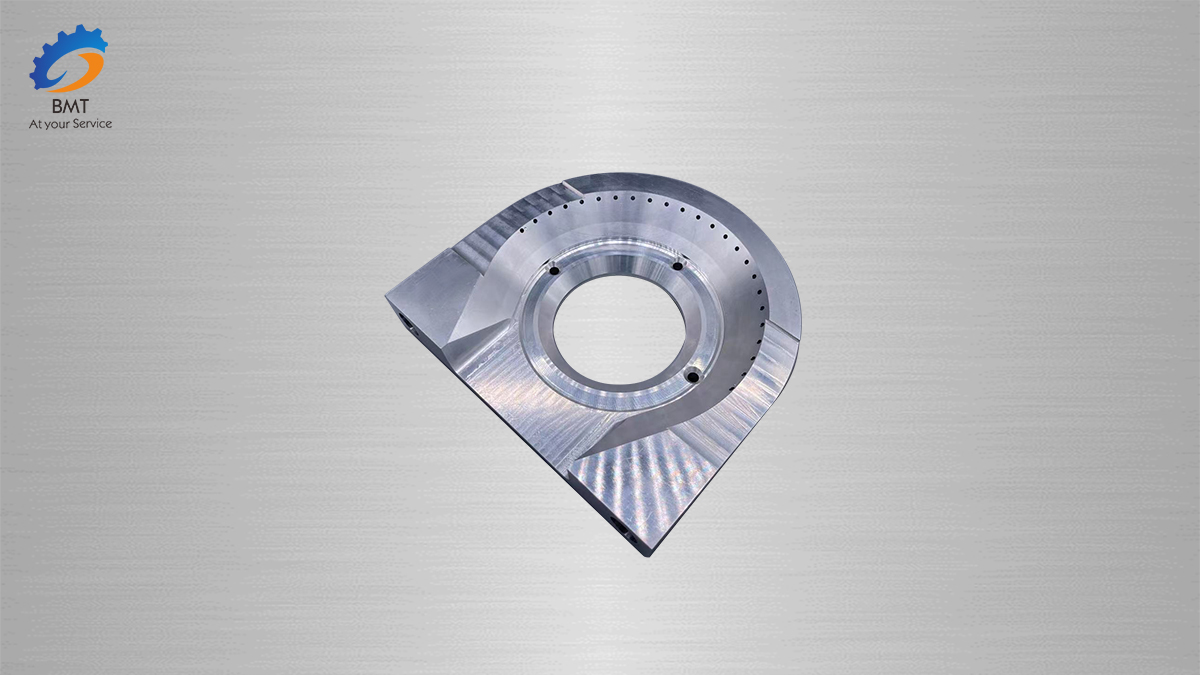

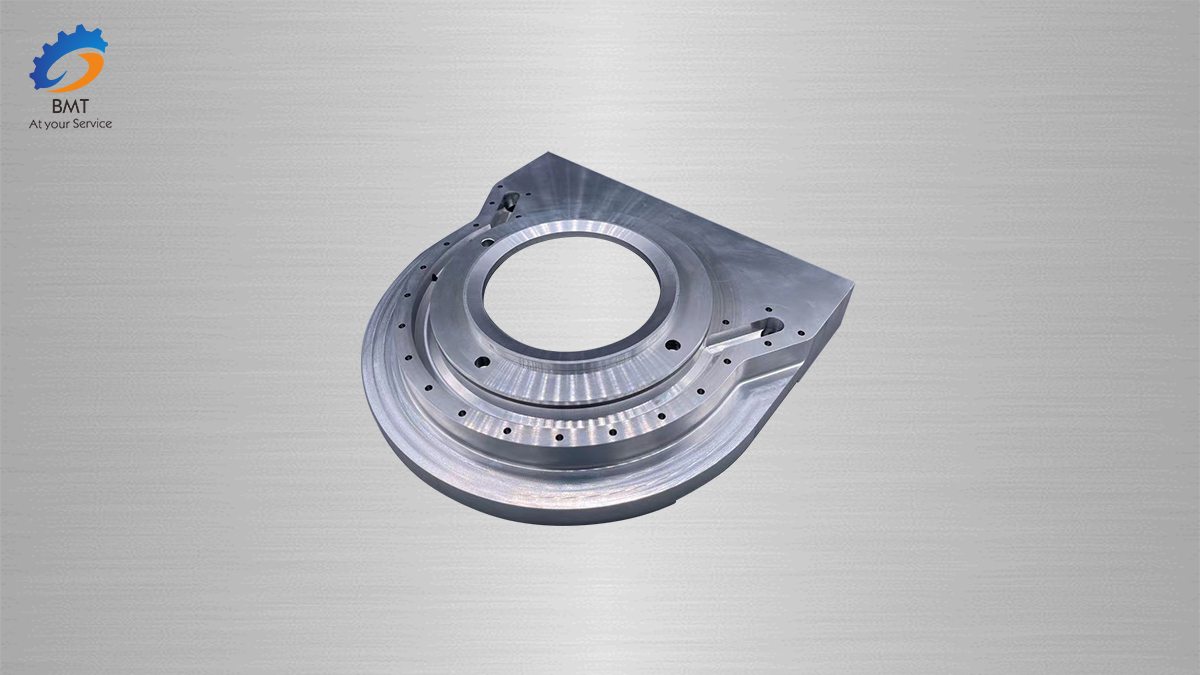

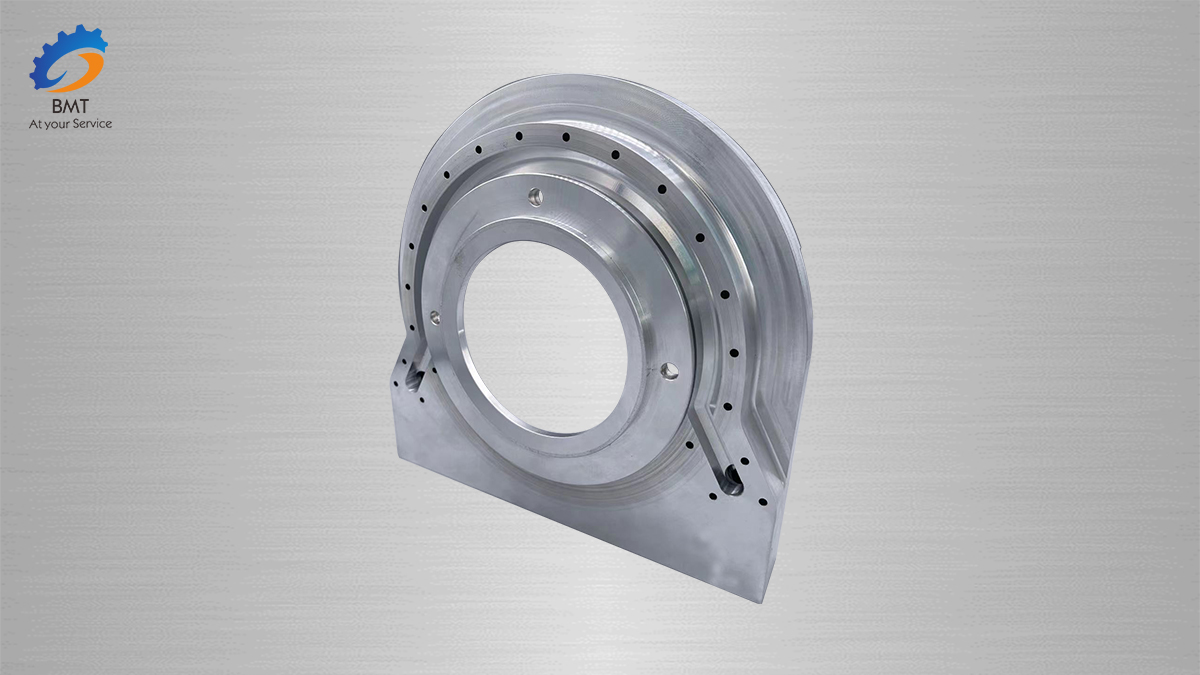

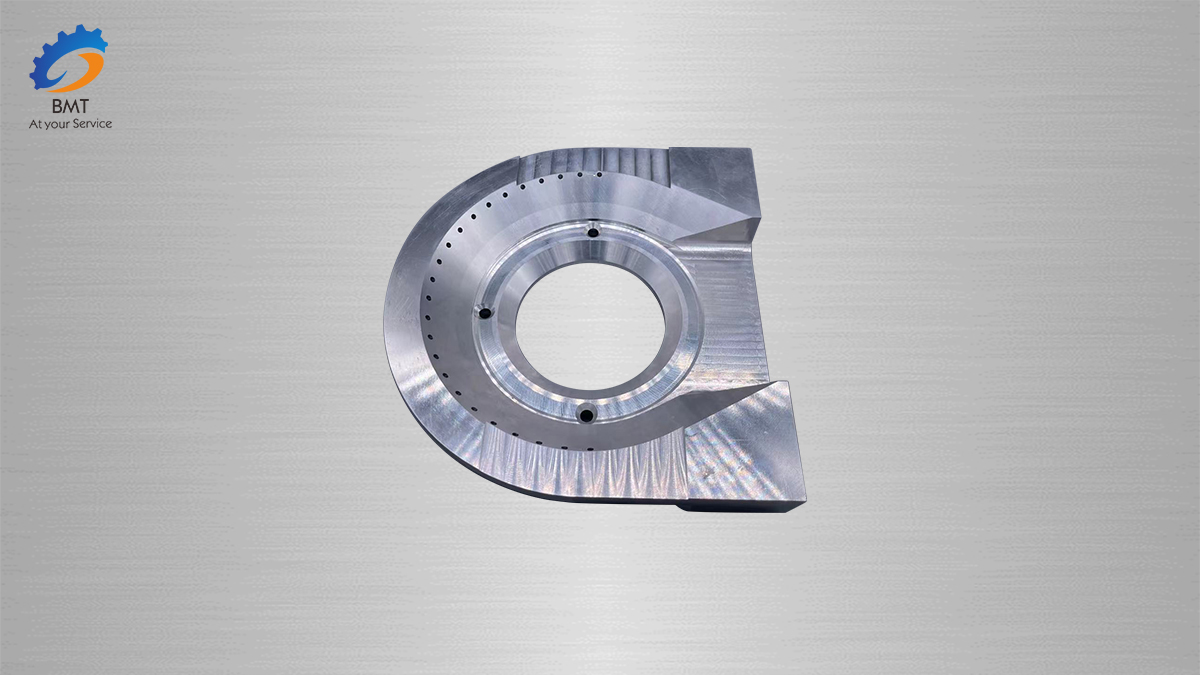

Aluminium CNC Machining likarolo

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining likarolo

-

Likarolo tse entsoeng ke CNC bakeng sa Italy

-

CNC Machining Aluminium likarolo

-

Auto Parts Machining

-

Lisebelisoa tsa Titanium Alloy Forgings

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes