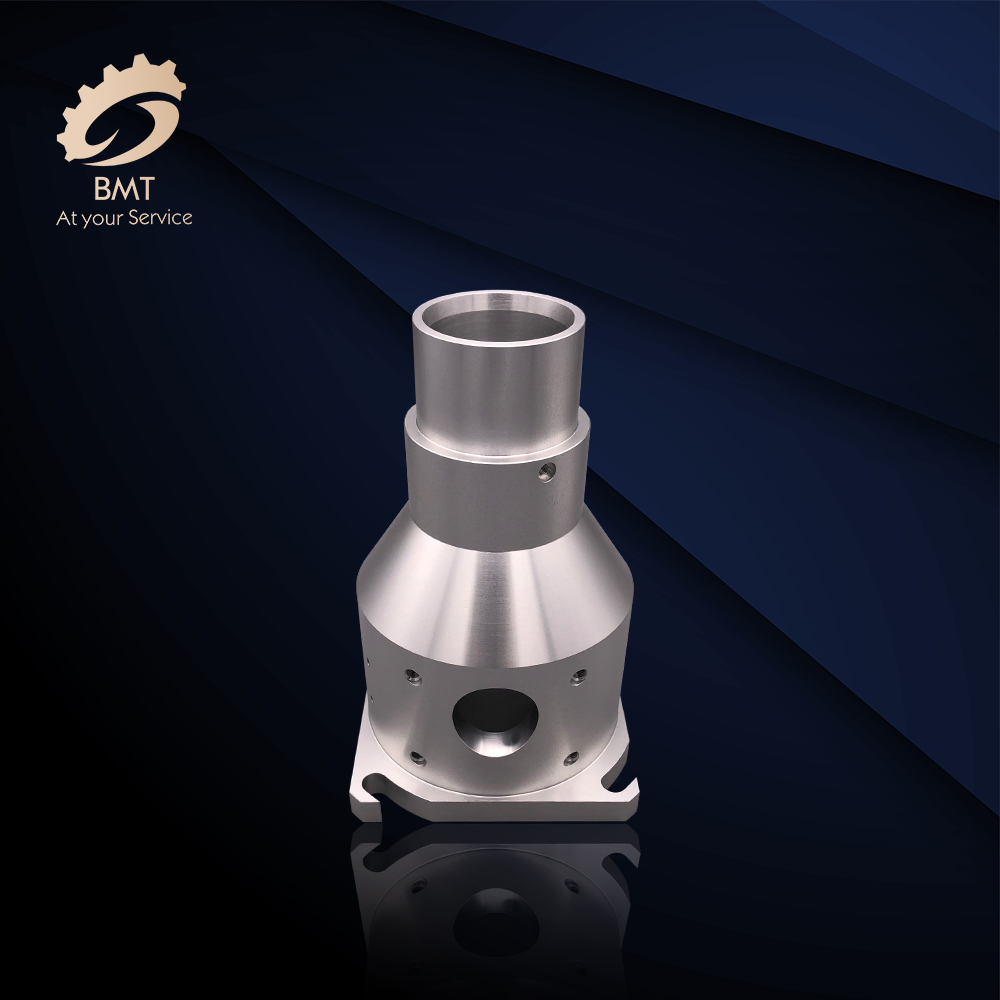

Premium Line ea Customized CNC Machining Parts

Khamphani ea rona, re motlotlo haholo ho fa bareki ba ronalihlahisoa tsa boleng bo holimotse etselitsoeng ho fihlela litlhoko tsa tsona tse khethehileng. Ka likarolo tsa rona tsa machining tsa CNC, u ka se lebella letho ho feta ho nepahala, ho tšoarella le ho ts'epahala. Se etsang hore likarolo tsa rona tsa mochini oa CNC li arohane le tse ling kaofela ke boitlamo ba rona ba ho iketsetsa. Rea utloisisa hore morero o mong le o mong o ikhethile 'me o hloka sete e fapaneng ea litlhaloso. Ke ka lebaka leo re fanang ka mefuta e mengata ea likhetho ho netefatsa hore likarolo tsa rona li lumellana hantle le litlhoko tsa hau. Hore na o hloka litekanyo tse ikhethileng, lisebelisoa, kapa liphetho, re mona ho tla fana ka eona.

Sehlopha sa rona sa lienjiniere tse nang le litsebo le litsebi li sebelisa maemo a morao-raoMechini ea CNCho hlahisa likarolo ka nepo le botsitso bo ikhethang. Re tsetetse theknoloji ea morao-rao ho netefatsa hore bokhoni ba rona ba ho sebetsa ha bo bapisoa le bo bong. Sena se re nolofalletsa ho etsa likarolo tse rarahaneng tse nang le lintlha tse rarahaneng, liqapi tse rarahaneng habonolo le ka nepo. Ha ho tluoa tabeng ea lisebelisoa, re fana ka mefuta e mengata ea likhetho tseo u ka khethang ho tsona. Hore na o hloka likarolo tse entsoeng ka tšepe ea carbon, tšepe e sa hloekang, aluminiamo, koporo, kapa thepa e sa tloaelehang, re u koahetse. Khetho ea rona e felletseng ea lisebelisoa e netefatsa hore o ka fumana e loketseng kopo ea hau, ho sa tsotelehe hore na e batloa hakae.

Ha re fane feela ka likhetho tsa ho itlhophisa bakeng sa boholo le lisebelisoa, empa re boetse re etelletsa pele liphetho tseo u li batlang. Mechini ea rona e tsoetseng pele ea CNC e khona ho fihlela liphetho tse fapaneng, ho kenyeletsoa polishe ea seipone, satin, brushed, anodized, le phofo e tlotsitsoeng. Ho sa tsotelehe litlhoko tsa botle kapa ts'ebetso, re ka fana ka sephetho se lumellanang hantle le litlhoko tsa hau. E 'ngoe ea melemo ea bohlokoa ea likarolo tsa rona tsa mochini oa CNC ke lebelo leo re ka li hlahisang ka lona. Ka lebaka la ts'ebetso e ntle ea mechini ea rona ea CNC le ts'ebetso ea rona e ntlafalitsoeng, re ka khona ho fihlela linako tse behiloeng ka thata ha re ntse re boloka litekanyetso tsa boleng bo holimo. Boikemisetso ba rona ba ho fana ka ts'ebetso ka nako bo netefatsa hore projeke ea hau e lula e le teng 'me e fokotsa tieho efe kapa efe e ka bang teng.

Ka k'hamphani ea rona, o ka itšetleha ka lihlahisoa tsa boleng bo holimo ka linako tsohle. Mekhoa ea rona e tiileng ea taolo ea boleng e netefatsa hore karolo e 'ngoe le e' ngoe e tlohang setsing sa rona e hlahlojoa ka botlalo bakeng sa ho nepahala ha maemo, mamello le boleng ka kakaretso. Re ikemiselitse ho feta litebello tsa hau le ho u fa likarolo tse sa fihlelleng litlhaloso tsa hau feela empa hape li feta maemo a indasteri. Ho tloha ho bofofisi ba lifofane le likoloi ho ea ho indasteri ea lisebelisoa tsa elektroniki le tsa tlhahiso, likarolo tsa rona tsa mochini oa CNC tse ikhethileng li fumana lits'ebetso makaleng a fapaneng. Re iketselitse botumo bo matla har'a bareki ba rona ka bokhoni ba rona ba ho fana ka lihlahisoa tse ikhethang tse ipabolang mafapheng a bona.

Qetellong, haeba u batla maemo a holimo-limoLikarolo tsa mochini oa CNCe etselitsoe litlhoko tsa hau hantle, 'me ha e shebahale ho feta k'hamphani ea rona. Ka theknoloji ea rona ea morao-rao, khetho e kholo ea thepa, le boitlamo ba ho sebetsa hantle, re balekane ba phethahetseng ba ho phethahatsa litlhoko tsohle tsa hau tsa mochini oa CNC. Ikopanye le rona kajeno ho buisana ka morero oa hau le ho bona hore na re ka fetola pono ea hau joang hore e be ea nnete.

Re romelle molaetsa oa hau:

-

Axis High Precision CNC Machining likarolo

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes

-

Aluminium CNC Machining likarolo

-

Auto Parts Machining

-

Likarolo tsa CNC Auto Likarolo tse entsoeng

-

Lisebelisoa tsa mochini oa CNC

-

Aluminium Sheet Metal Fabrication

-

Indasteri ea Likoloi

-

Ho Sila ho se Setsi

-

CNC Machining Melemo

-

CNC Machining Aluminium likarolo