Likarolo tsa Precision Machining le likarolo tsa Metal tsa Sheet

Re hlahisa likarolo tsa rona tsa Precision Machining le Lihlahisoa tsa Metal tsa Sheet, tse etselitsoeng ho finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng le tshebetso. Lihlahisoa tsa rona li entsoe ka boqhetseke ho sebelisa mekhoa e tsoetseng pele ea tlhahiso le theknoloji ea morao-rao ho netefatsa ho nepahala, ho tšoarella le ho ts'epahala.

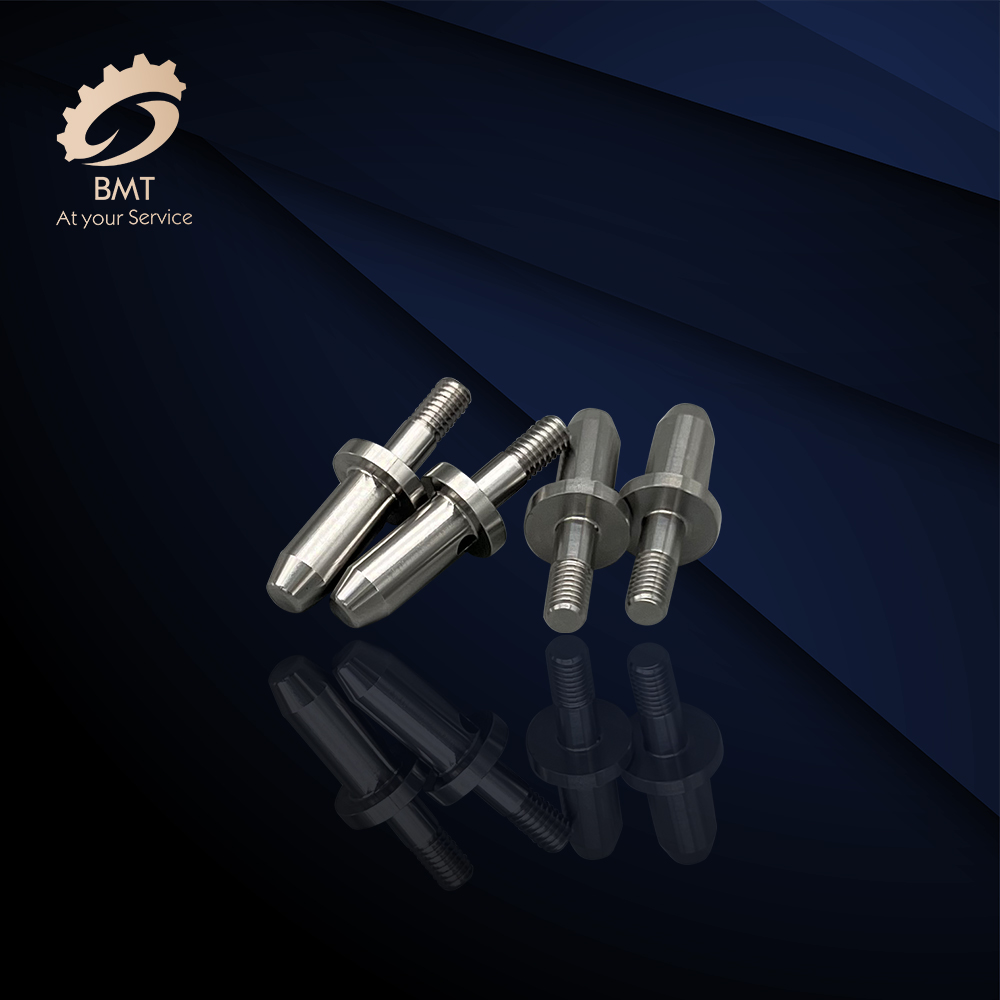

Likarolo tsa mochini:Ea ronalikarolo tsa mochinili etselitsoe ho fana ka ho nepahala le ho tsitsa ho ikhethang, ho li etsa tse loketseng mefuta e mengata ea lits'ebetso tsa indasteri. Hore na o hloka lisebelisoa tse rarahaneng bakeng sa sefofane, likoloi, lisebelisoa tsa bongaka, kapa indasteri efe kapa efe, likarolo tsa rona tsa mochini li etselitsoe ho fihlela litlhoko tsa hau tse ikhethileng. Re sebelisa lisebelisoa tsa morao-rao tsa mochini oa CNC 'me re hira litsebi tse hloahloa ho hlahisa likarolo tse nang le mamello e thata le lijeometri tse rarahaneng. Ho tloha ho li-prototype ho isa ho tlhahiso e phahameng haholo, re na le bokhoni ba ho fana ka likarolo tsa machining tse nepahetseng tse fetang tebello ea hau.

Sheet Metal:

Ea ronalihlahisoa tsa tšepeli entsoe ka mokhoa o nepahetseng le ho ela hloko lintlha, li fana ka tharollo e fapaneng bakeng sa litlhoko tse fapaneng tsa ho etsa. Hore na o hloka lintho tse koaletsoeng, masakana, liphanele, kapa likarolo tse ling tsa tšepe, re na le boiphihlelo ba ho fana ka lihlahisoa tsa boleng bo holimo tse fihlelang litlhoko tsa hau hantle. Re sebetsa ka mefuta e fapaneng ea thepa, ho kenyeletsoa tšepe e sa hloekang, aluminium, le tšepe ea k'habone, 'me e khona ho amohela mefuta e mengata ea botenya le boholo. Ts'ebetso ea rona ea ho etsa lesela la tšepe e kenyelletsa ho seha, ho koba, ho tjheseletsa le ho qeta, ho netefatsa hore lihlahisoa tsa ho qetela li finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng le boqapi.

Netefaletso ea boleng:

Setsing sa rona, boleng bo ka pele ho tsohle tseo re li etsang. Re kentse ts'ebetsong mehato e thata ea taolo ea boleng ho pholletsa le ts'ebetso ea tlhahiso ho netefatsa hore sehlahisoa se seng le se seng se finyella litekanyetso tse phahameng ka ho fetisisa tsa bokhabane. Ho tloha tlhahlobong ea thepa e tala ho isa tekong ea ho qetela ea sehlahisoa, re latela litataiso tse tiileng tsa boleng ho netefatsa ts'epahalo le ts'ebetso ea likarolo tsa rona tsa mochini le lihlahisoa tsa tšepe. Boitlamo ba rona ba boleng bo bonahala ka khotsofalo ea bareki ba rona le katlehong ea ho kopanya lihlahisoa tsa rona liindastering tse fapaneng.

Boikemisetso:

Rea utloisisa hore morero o mong le o mong o na le litlhoko tse ikhethang, ke ka lebaka leo re fanang ka likhetho tsa ho iketsetsa ho etsa hore lihlahisoa tsa rona li lumellane le litlhoko tsa hau tse khethehileng. Hore na o hloka likarolo tsa machining tsa tloaelo tse nang le lijeometri tse rarahaneng kapa lihlahisoa tsa tšepe tse nang le litekanyo tse ikhethileng le liphetho, sehlopha sa rona se ikemiselitse ho sebetsa haufi-ufi le uena ho etsa hore pono ea hau e phele. Re na le boitseanape le ho feto-fetoha ha maemo ho amohela likopo tsa moetlo le ho fana ka lihlahisoa tse tsamaellanang le litlhaloso tsa hau hantle.

Qetello:

Ka ronalikarolo tse nepahetseng tsa machiningle lihlahisoa tsa sheet metal, o ka tšepa hore o fumana likarolo tsa boleng bo holimo tse etselitsoeng ts'ebetso le bophelo bo bolelele. Hore na o hloka likarolo tsa machining tse nepahetseng bakeng sa lits'ebetso tsa bohlokoa kapa lihlahisoa tsa tšepe tse ikhethileng bakeng sa litlhoko tsa hau tsa ho etsa, re na le bokhoni le boiphihlelo ba ho fana ka liphetho tse ikhethang. Ikopanye le rona kajeno ho ithuta haholoanyane ka lihlahisoa tsa rona le kamoo re ka tšehetsang litlhoko tsa hau tsa tlhahiso.

Re romelle molaetsa oa hau:

-

Axis High Precision CNC Machining likarolo

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes

-

Aluminium CNC Machining likarolo

-

Auto Parts Machining

-

Likarolo tsa CNC Auto Likarolo tse entsoeng

-

Lisebelisoa tsa mochini oa CNC

-

Aluminium Sheet Metal Fabrication

-

Indasteri ea Likoloi

-

Ho Sila ho se Setsi

-

CNC Machining Melemo

-

CNC Machining Aluminium likarolo