Moetsi oa likarolo tsa Mold Machining

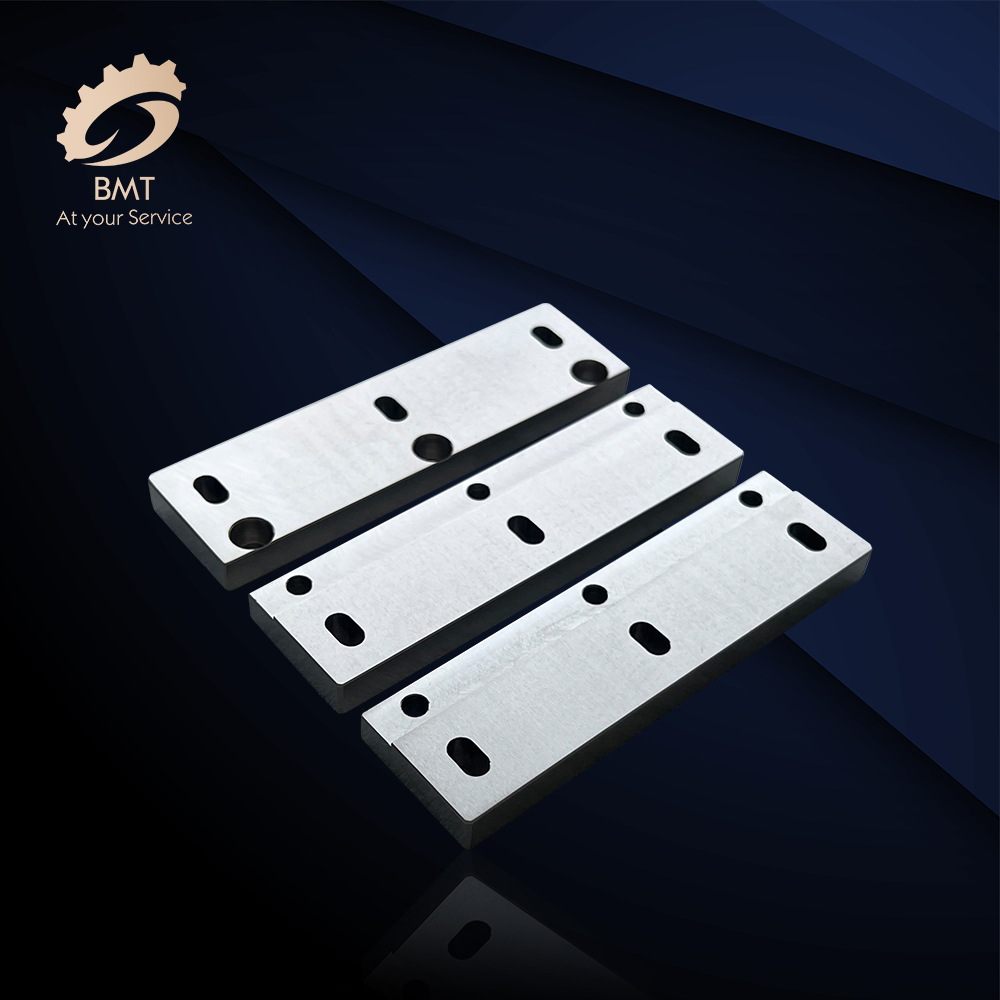

Ho hlahisa ronaboleng bo phahamengLikarolo tsa Mold Machining, tse etselitsoeng ho fihlela litlhoko tsa boenjiniere bo nepahetseng le tlhahiso. Likarolo tsa rona tsa Mold Machining li entsoe ka nepo le ka hloko ho lintlha, ho netefatsa hore li kopana le lintlha tse hlokahalang bakeng sa hlobo e sebelisoang liindastering tse fapaneng joalo ka likoloi, sefofane le thepa ea bareki. Likarolo tsa rona tsa Mold Machining li etsoa ho sebelisoa mahlale a morao-rao le mekhoa, ho netefatsa hore karolo ka 'ngoe e entsoe ka nepo le ka nepo. Re utloisisa bohlokoa ba ho nepahala ha mochini oa hlobo, 'me likarolo tsa rona li etselitsoe ho finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng le tshebetso.

Ea ronaLikarolo tsa Mold Machiningli entsoe ka thepa ea boleng bo holimo, ho netefatsa hore li tšoarella ebile li tšoarella nako e telele. Hore na o hloka li-core pins, ejector pins, kapa likarolo life kapa life tsa mochini oa hlobo, o ka tšepa hore lihlahisoa tsa rona li tla kopana le ho feta litebello tsa hau. E 'ngoe ea likarolo tsa bohlokoa tsa likarolo tsa rona tsa Mold Machining ke ho nepahala le ho nepahala ha tsona. Re etsa bonnete ba hore karolo e 'ngoe le e' ngoe e etsoa ka mokhoa o tiileng ka ho fetisisa, ho etsa bonnete ba hore e lumellana hantle le ho sebetsa ka mokhoa o se nang sekoli ka har'a hlobo ea hau. Boemo bona ba ho nepahala bo bohlokoa bakeng sa ho netefatsa boleng le botsitso ba lihlahisoa tse ntseng li etsoa ho sebelisoa hlobo ena.

Ntle le ho nepahala ha bona, likarolo tsa rona tsa Mold Machining le tsona li etselitsoe ho sebelisoa habonolo le tlhokomelo. Re utloisisa hore nako ke ea bohlokoa hoindasteri ea tlhahiso, 'me likarolo tsa rona li etselitsoe ho ba bonolo ho kenya le ho li boloka, ho fokotsa nako ea ho fokotsa nako le ho eketsa tlhahiso. Likarolo tsa rona tsa Mold Machining li boetse li etselitsoe hore li feto-fetohe le maemo, ho netefatsa hore li ka sebelisoa mefuteng e mengata ea hlobo le litlhophiso. Hore na o sebetsa ka hlobo ea ente, hlobo kapa li-compress hlobo, o ka ts'epa hore likarolo tsa rona li tla fihlela litlhoko le litlhaloso tsa hau.

Re motlotlo haholo ka boleng ba Mold Machining Parts ea rona mme re ikemiselitse ho fa bareki ba rona lihlahisoa tse ntle ka ho fetisisa le tšebeletso e ka khonehang. Sehlopha sa rona sa lienjiniere tse nang le litsebo tse phahameng le litsebi li ikemiselitse ho netefatsa hore karolo ka 'ngoe e etsoa ka maemo a holimo, 'me re lula re leka ka matla ho ntlafatsa le ho qapa lihlahisoa tsa rona ho finyella litlhoko tse tsoelang pele tsa indasteri.

Ha ho tluoa tabeng ea ho lokisa hlobo, ho nepahala le boleng ke tsa bohlokoa ka ho fetisisa. Ka likarolo tsa rona tsa Mold Machining, o ka tšepa hore o fumana lihlahisoa tse ntle ka ho fetisisa tse fumanehang. Ho sa tsotellehe hore na u moetsi oa hlobo, sesebelisoa le moetsi oa lefu, kapa mookameli oa tlhahiso, u ka itšetleha ka likarolo tsa rona ho u thusa ho finyella litlhoko tsa hau tsa tlhahiso le ho finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng le katleho.

Re romelle molaetsa oa hau:

-

Axis High Precision CNC Machining likarolo

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes

-

Aluminium CNC Machining likarolo

-

Auto Parts Machining

-

Likarolo tsa CNC Auto Likarolo tse entsoeng

-

Lisebelisoa tsa mochini oa CNC

-

Aluminium Sheet Metal Fabrication

-

Indasteri ea Likoloi

-

Ho Sila ho se Setsi

-

CNC Machining Melemo

-

CNC Machining Aluminium likarolo