Mekhoa e Tloaelehileng ea ho Etsa Metal Metal

Custom Sheet Metal Fabrication e bonahala e rarahane hanyane kaha e ka hahuoa ka mefuta eohle ea libopeho, empa tsoelo-pele eohle ea tlhahiso e ka khaoloa ka mehato e meraro joalo ka tlase.

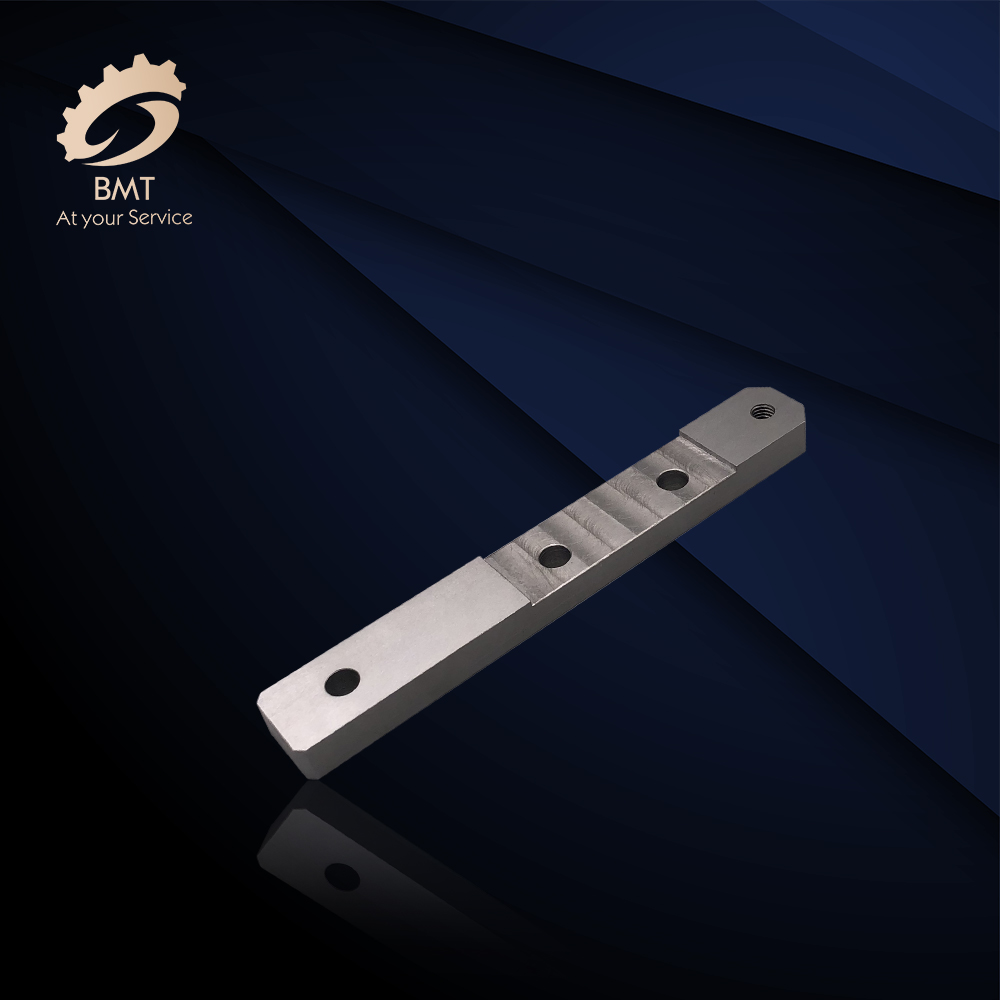

Ea pele ke tsoelo-pele ea ho khaola e boetse e bitsoa tsoelo-pele ea ho tlosa thepa. Khatelo-peleng ena, ho na le mekhoa e mengata e fapaneng e kenyelletsang ho itšeha ka laser, ho itšeha ka jete ea metsi, ho itšeha ka plasma, le ho itšeha ka litebele. Har'a tsona kaofela, ho itšeha ka laser ho kenyelletsa tšebeliso ea laser bakeng sa ho fumana maqeba a nepahetseng ka tšepe ea letlapa. E nepahetse ebile e sebetsa hantle ho feta mekhoa e meng ea ho itšeha ka boholo bo boholo 'me e nahana ka thepa ea letlapa la tšepe, e leng mokhoa o atileng haholo fekthering ea rona.

Punch cutting, ka lehlakoreng le leng, ke tsela e 'ngoe e tloaelehileng ebile e loketse ho sebelisoa ho sebelisoa ka boholo bo nyane.

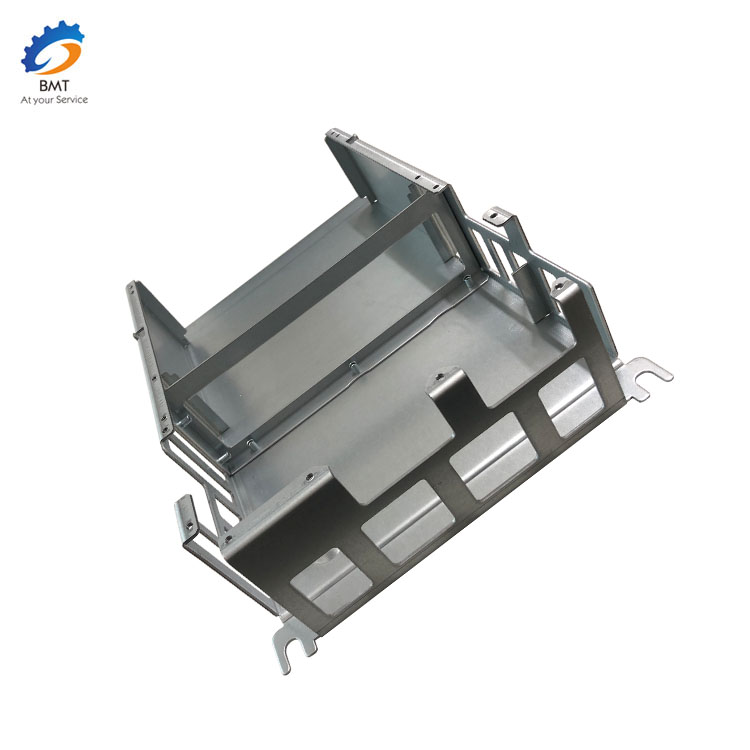

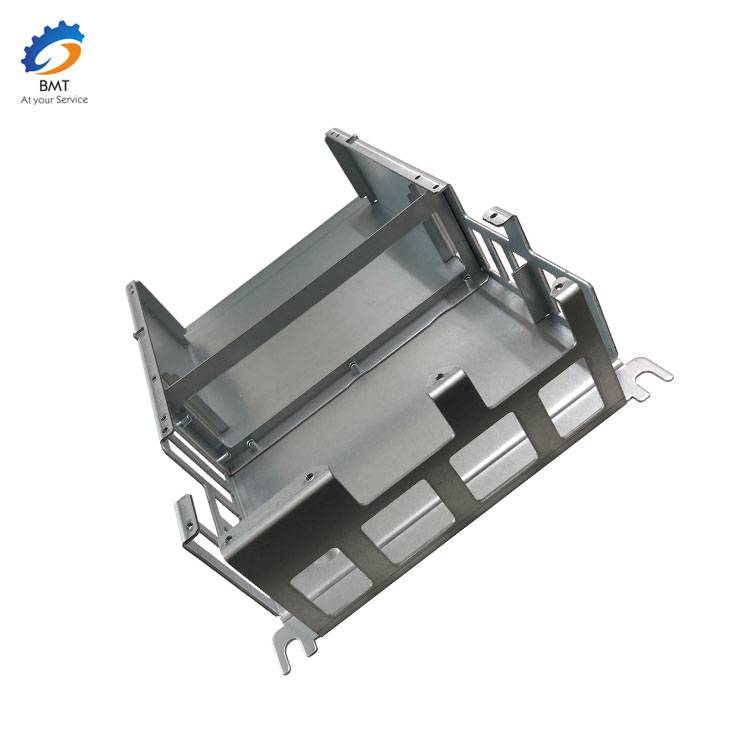

Ka mor'a ho itšeha, re na le sebopeho seo hape se bitsoang deformation ea lintho tse bonahalang. Ho na le mekhoa e 'maloa ea ho theha e kenyelletsang ho bilika, ho ohla, ho kobeha, ho hatakela le ho cheselletsa.

Qetellong, e ea phetheha. Sena se bua ka likarolo tsa prototype tse bentšoang ka abrasive ho felisa matheba a makukuno le ho fumana tšobotsi e boreleli. Kamora ts'ebetso ena, hangata e kenyelletsa tsoelo-pele ea ho qetela joalo ka ho penta le anodizing.

Mefuta ea Boqapi ke Efe?

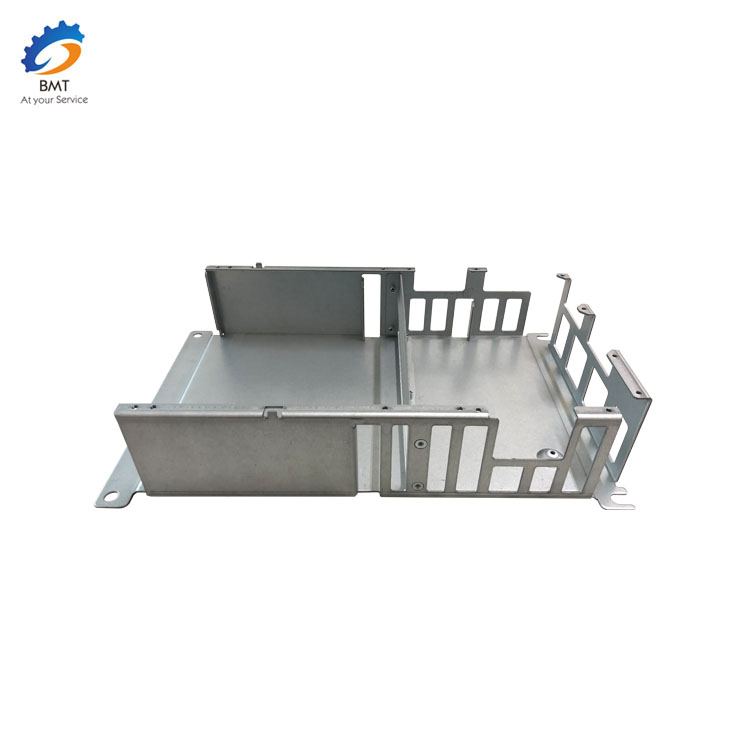

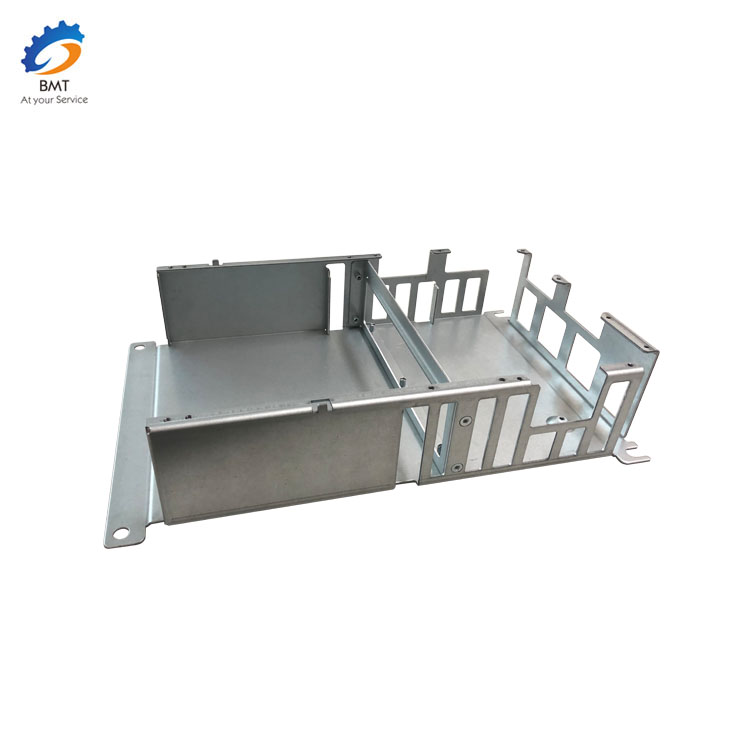

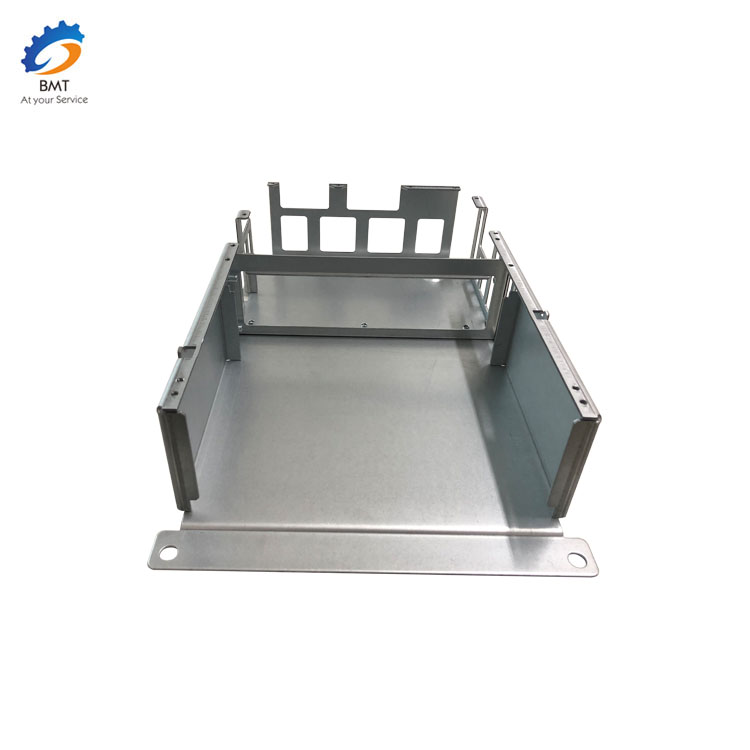

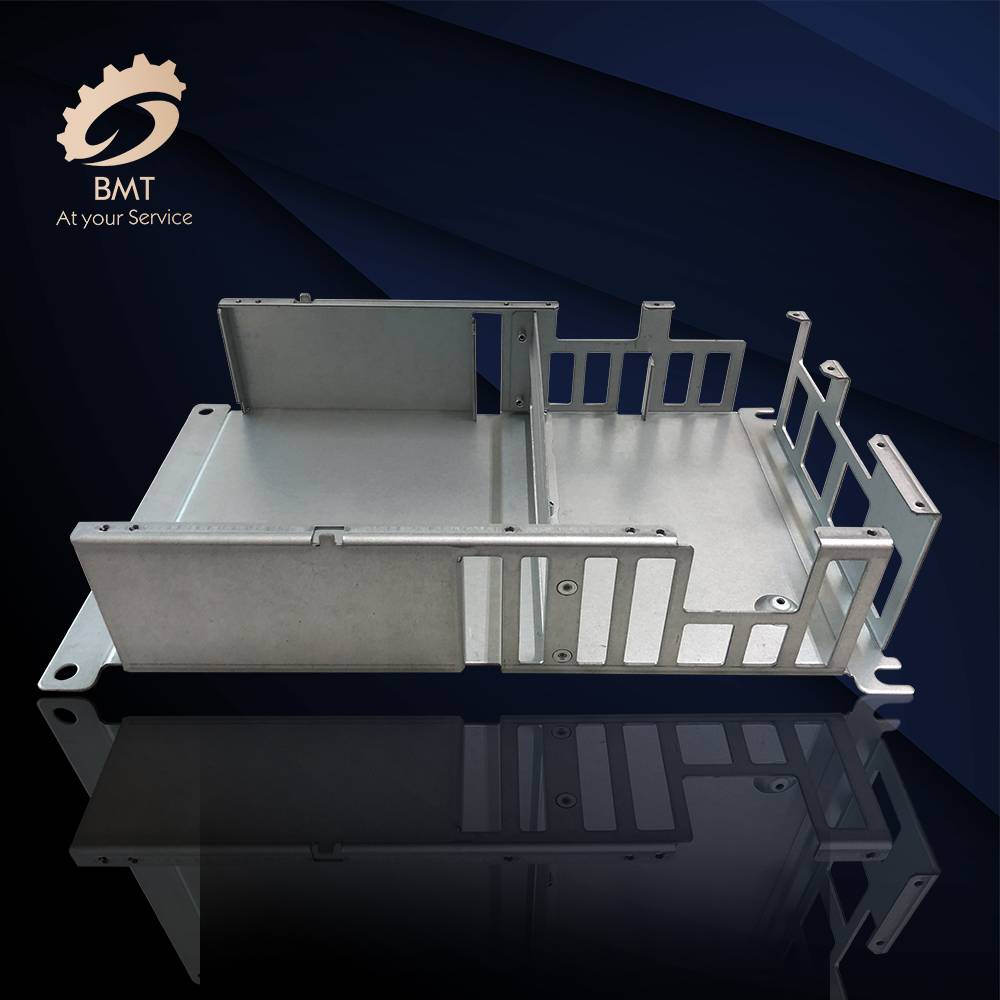

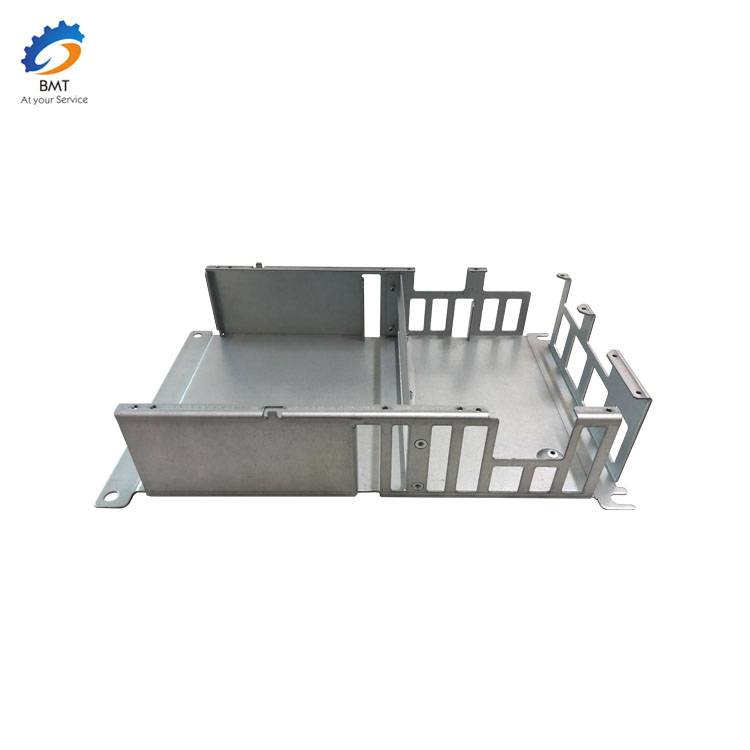

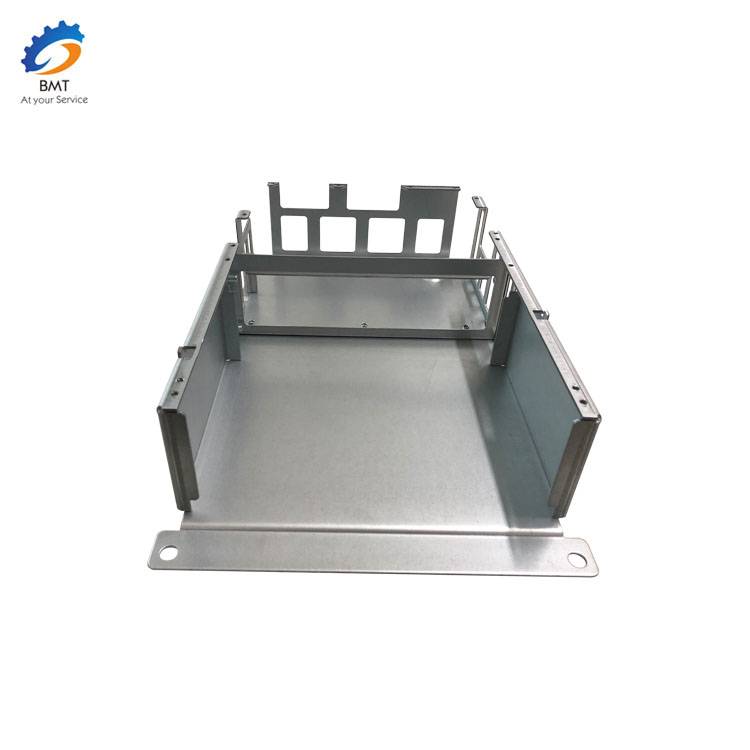

Ho na le mefuta e mengata e fapaneng ea mekhoa ea ho etsa tšepe. Har'a tsona, tse atileng haholo li kenyelletsa Ho Seha, ho mena, ho etsa, ho phunya, ho hatakela, ho cheselletsa le ho bentša. Ho etsa karolo e le 'ngoe, re ka hloka ts'ebetso e le' ngoe kapa tse 'maloa ka holimo tse itšetlehileng ka moralo oa karolo. Mohlala, re ka hloka feela mokhoa oa ho itšeha bakeng sa karolo e le 'ngoe ea letlapa le bataletseng. Empa re kanna ra tlameha ho sebelisa lits'ebetso tsohle tse kaholimo bakeng sa sehlahisoa se seholo sa khabinete.

The Sheet Thickness Range Of Metal Fabrication ke Eng?

Ntle le haeba re kopanya likotoana tse peli sekotong se le seng, botenya ba thepa ea lakane bo lokela ho lula bo tsitsitse. Ntle le moo, mefuta e fapaneng ea litšepe e fumaneha, 'me botenya ba lakane bo ka tloha ho lisenthimithara tse 0,02 ho isa ho 0,25.

Ke bokae ho Custom Sheet Fabrication ea Metal?

Ho ipapisitse le. Litsenyehelo tse akaretsang tsa karolo ea tšepe e tloahelehileng li ipapisitse le likarolo tse 'maloa tse kenyelletsang boholo ba karolo ea tšepe, thepa, ho rarahana, le bongata ba ho reka.

Ka mantsoe a mang, litšenyehelo tse fokolang tsa thepa le nako e fokolang ea ho etsa thepa e thehiloeng ho MOQ e tšoanang, litšenyehelo li tlaase. E le ho rarolla mathata a hau a ho etsa tlhahiso, ikopanye le rona hona joale 'me re tlosa bohloko ho uena. Re tiile bakeng sa CNC Machining le Sheet Metal.

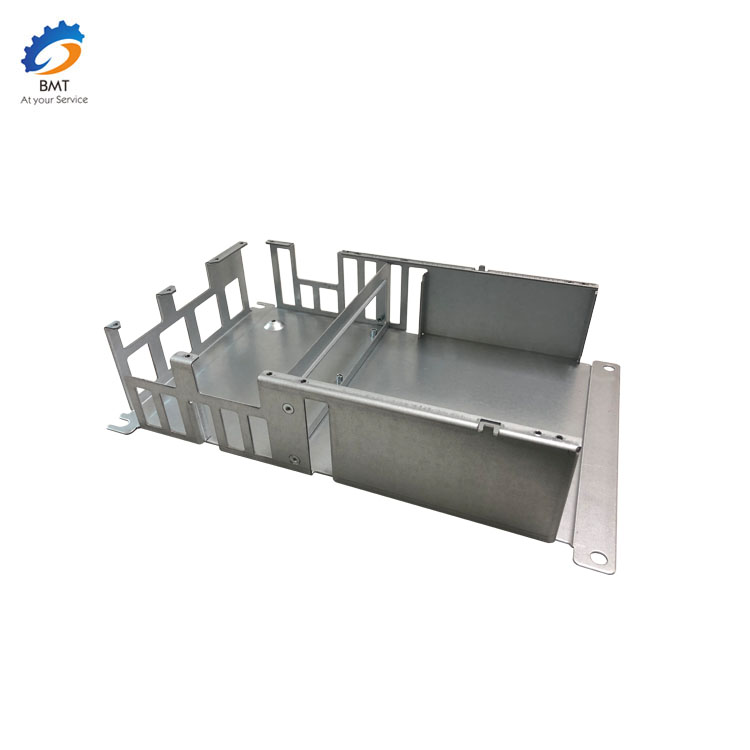

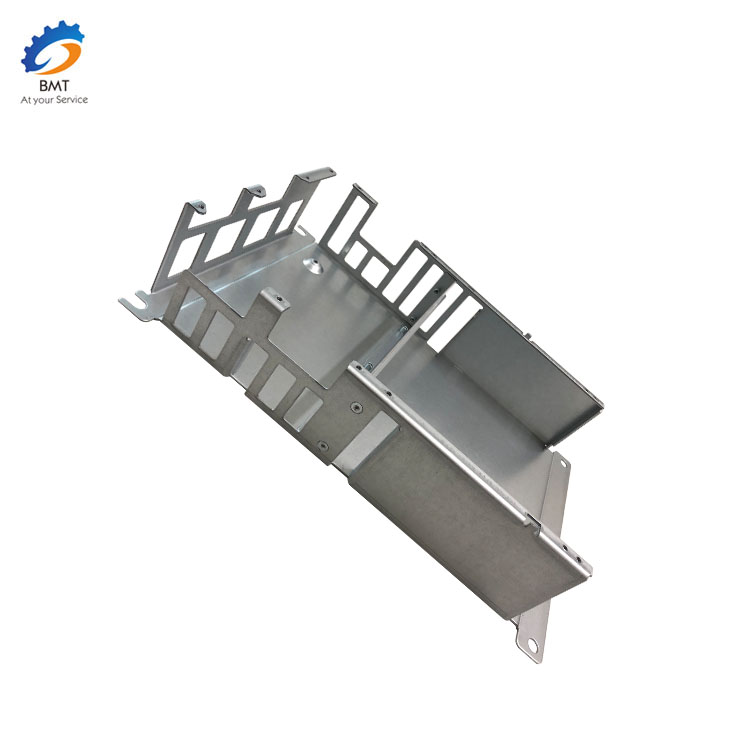

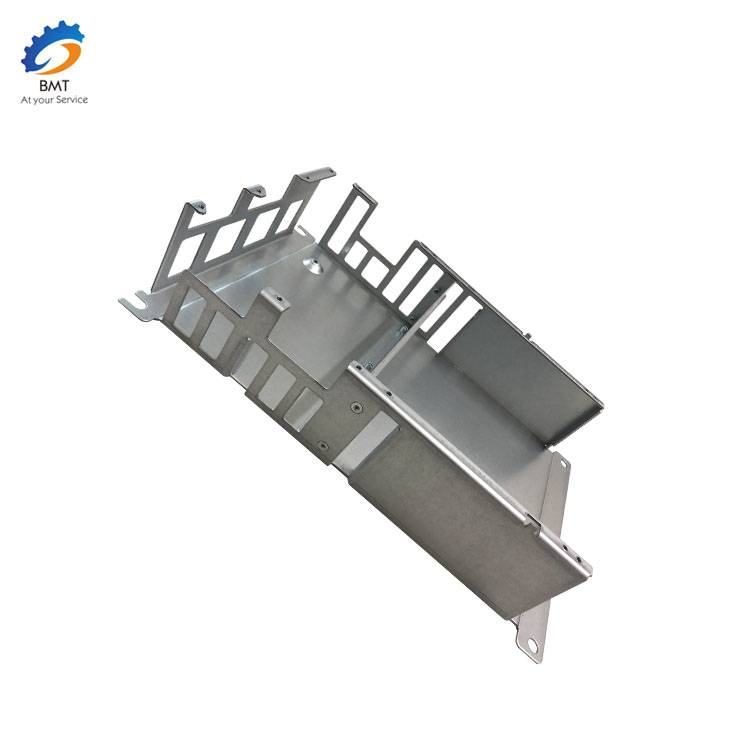

Ho etsoa ha tšepe ea pampiri ke mokhoa oo ka oona u ka fetolang lipampiri tse bataletseng tsa tšepe kapa lisebelisoa tse ling hore e be lihlahisoa kapa u li fe sebopeho, ka ho seha, ho khumama le ho kopanya. Letlapa la tšepe le ka etsoa hoo e batlang e le sebōpeho leha e le sefe, seo hangata se etsoang ka ho khaola le ho koba tšepe.

Resistance Welding, Atolosa Metal, ho kobeha, Laser Cutting, Shrinking, Ho otlolla, ho otla ka litebele, ho hatakela, joalo-joalo ke mekhoa ea bohlokoa ka ho fetisisa lits'ebetsong tsa tšepe. U lokela ho etsa bonnete ba hore k'hamphani eo u sebetsang le eona e na le bokhoni bo ka holimo 'me e u fa tšebeletso e molemo ka ho fetisisa ntle le ho tsilatsila, le haeba litheko tsa tsona li le holimo hanyenyane, empa u ka fumana seo u se batlang ka boleng bo phethahetseng le likarabo tse khotsofatsang.

Tlhaloso ea Sehlahisoa