Titanium Alloy CNC Machining

Ha boima ba alloy ea titanium bo le boholo ho feta HB350, ho khaola ho thata haholo, 'me ha e le ka tlase ho HB300, ho bonolo ho khomarela thipa' me ho thata ho khaola. Ka hona, bothata ba ho sebetsana le titanium bo ka rarolloa ho tloha lehare. Ho roala ha groove ea ho kenya mochine ha ho etsoa li-alloys tsa titanium ke ho apara sebakeng sa morao le ka pele ho ea ka botebo ba sehiloeng, seo hangata se bakoang ke lera le thata le siiloeng ke mochine o fetileng.

Boitšoaro ba lik'hemik'hale le ho hasana ha sesebelisoa le lisebelisoa tsa mosebetsi ka mocheso oa ho sebetsa o fetang 800 ° C le tsona ke tse ling tsa mabaka a ho thehoa ha groove wear. Hobane nakong ea ts'ebetso ea machining, limolek'hule tsa titanium tsa workpiece li bokella ka pel'a lehare 'me li "welded" ho ea moeling oa lehare tlas'a khatello e phahameng le mocheso o phahameng, ho etsa moeli o hahiloeng.

Ha moeli o hahelletsoeng o hula moeling oa ho itšeha, o tlosa seaparo sa carbide sa ho kenya, kahoo machining a titanium a hloka lisebelisoa tse khethehileng tsa ho kenya le li-geometri.

.

Ho bohlokoa ho bolela hore kaha li-alloys tsa titanium li hlahisa mocheso o phahameng nakong ea ts'ebetso, palo e kholo ea mokelikeli o nang le khatello e phahameng e tlameha ho fafatsoa ka mokhoa o nepahetseng le o nakong ho tlosa mocheso kapele. Ho boetse ho na le meaho e ikhethileng ea li-milling cutters tse sebelisoang ka ho khetheha bakeng sa ts'ebetso ea alloy ea titanium 'marakeng kajeno, tse loketseng hantle ts'ebetso ea titanium alloy.

Hajoale, linaha tsohle li nts'etsapele li-alloys tse ncha tsa titanium ka theko e tlase le ts'ebetso e phahameng, 'me li leka ka matla ho etsa hore li-alloys tsa titanium li kene sebakeng sa indasteri ea sechaba se nang le monyetla o moholo oa mmaraka. naha ea heso e boetse e qenehela boiteko bo matla ho tsoela pele tšimong ena.

Ho lumeloa hore ka boiteko bo kopanetsoeng ba litsebi tsohle tsa indasteri, ts'ebetso ea li-alloys tsa titanium ha e sa tla hlola e e-ba bothata nakong e tlang, empa e tla fetoha lehare le bohale bakeng sa nts'etsopele ea indasteri ea tlhahiso ea naha ea heso, ho hlōla litšitiso bakeng sa tsoelo-pele ea indasteri eohle.

Re romelle molaetsa oa hau:

-

Aluminium CNC Machining likarolo

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining likarolo

-

Likarolo tse entsoeng ke CNC bakeng sa Italy

-

CNC Machining Aluminium likarolo

-

Auto Parts Machining

-

Lisebelisoa tsa Titanium Alloy Forgings

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

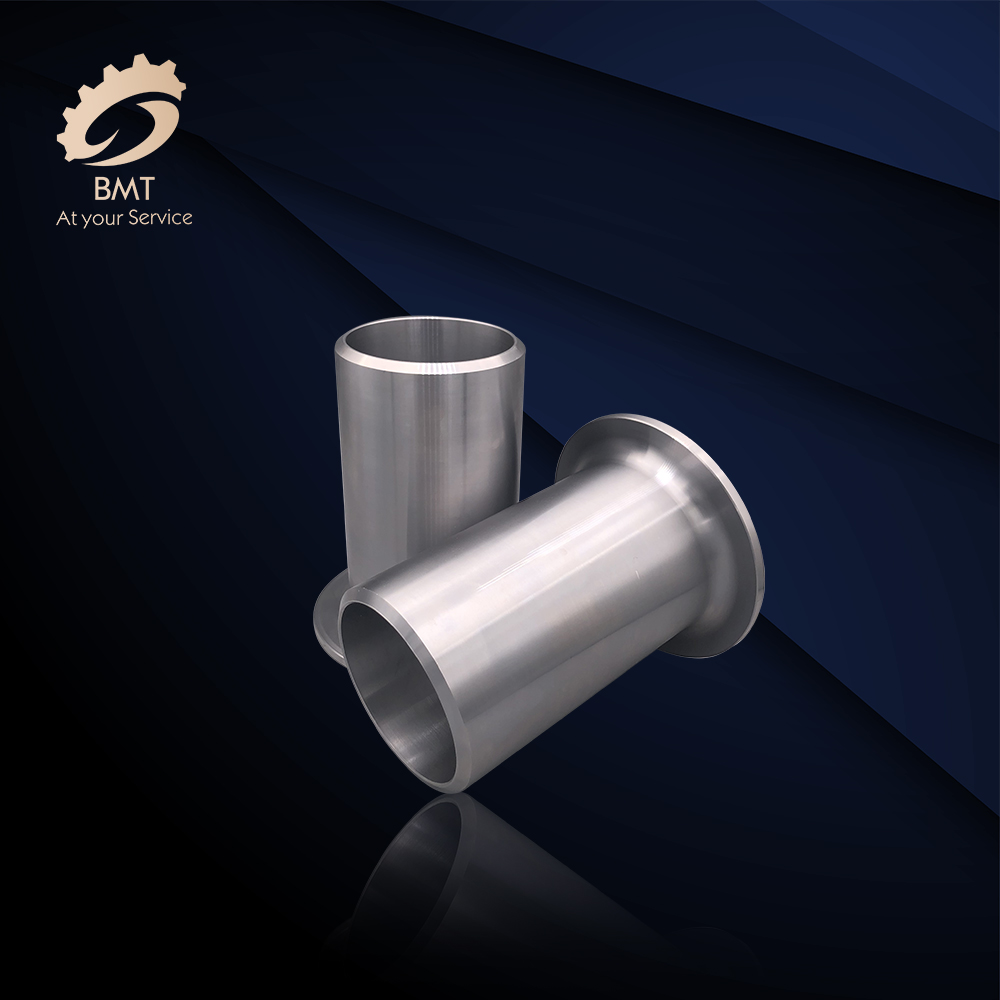

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes