Mathata a ho sebetsa ka Titanium

(1) Coefficient ea deformation e nyane:

Ena ke tšobotsi e batlang e totobetse ho machining ea lisebelisoa tsa alloy titanium. Nakong ea ho itšeha, sebaka sa ho kopana pakeng tsa chip le sefahleho sa rake se seholo haholo, 'me leqeba la chip holim'a sefahleho sa sesebelisoa se seholo ho feta sa lisebelisoa tse akaretsang. Ho tsamaea ho joalo ka nako e telele ho tla baka ho roala lisebelisoa tse tebileng, 'me Friction e boetse e etsahala nakong ea ho tsamaea, e leng ho eketsang mocheso oa sesebelisoa.

(2) Mocheso o phahameng oa ho itšeha:

Ka lehlakoreng le leng, coefficient e nyenyane ea deformation e boletsoeng ka holimo e tla lebisa karolong ea ho eketseha ha mocheso. Ntho e ka sehloohong ea mocheso o phahameng oa ho itšeha ka mokhoa oa ho itšeha oa titanium ke hore mocheso oa mocheso oa motsoako oa titanium o monyenyane haholo, 'me bolelele ba ho kopana pakeng tsa chip le sefahleho sa rake sa sesebelisoa bo khutšoanyane.

Tlas'a tšusumetso ea lintlha tsena, mocheso o hlahisoang nakong ea ho itšeha ke Ho thata ho o fetisetsa ka ntle, 'me haholo-holo o bokella haufi le ntlha ea sesebelisoa, e leng se etsang hore mocheso oa sebaka o be o phahameng haholo.

(3) Thermal conductivity ea titanium alloy e tlase haholo:

Mocheso o hlahisoang ke ho khaola ha o qhaloe habonolo. Ts'ebetso ea ho fetoha ha titanium alloy ke ts'ebetso ea khatello e kholo le khatello e kholo, e tla hlahisa mocheso o mongata, 'me mocheso o phahameng o hlahisoang nakong ea ts'ebetso o ke ke oa hasana ka katleho. Lehareng, mocheso o nyoloha haholo, lehare le kokobela, 'me ho roala ha sesebelisoa ho potlakisa.

Matla a khethehileng a lihlahisoa tsa alloy titanium a phahame haholo har'a lisebelisoa tsa mohaho oa tšepe. Matla a eona a ka bapisoa le a tšepe, empa boima ba eona ke 57% feela ea tšepe. Ntle le moo, li-alloys tsa titanium li na le litšobotsi tsa matla a khoheli a manyane, matla a phahameng a mocheso, botsitso bo botle ba mocheso le ho hanyetsa kutu, empa lisebelisoa tsa alloy tsa titanium li thata ho li khaola ebile li na le ts'ebetso e tlase ea ts'ebetso. Ka hona, mokhoa oa ho hlola bothata le ts'ebetso e tlase ea ts'ebetso ea alloy ea titanium esale e le bothata bo potlakileng bo lokelang ho rarolloa.

Re romelle molaetsa oa hau:

-

Aluminium CNC Machining likarolo

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining likarolo

-

Likarolo tse entsoeng ke CNC bakeng sa Italy

-

CNC Machining Aluminium likarolo

-

Auto Parts Machining

-

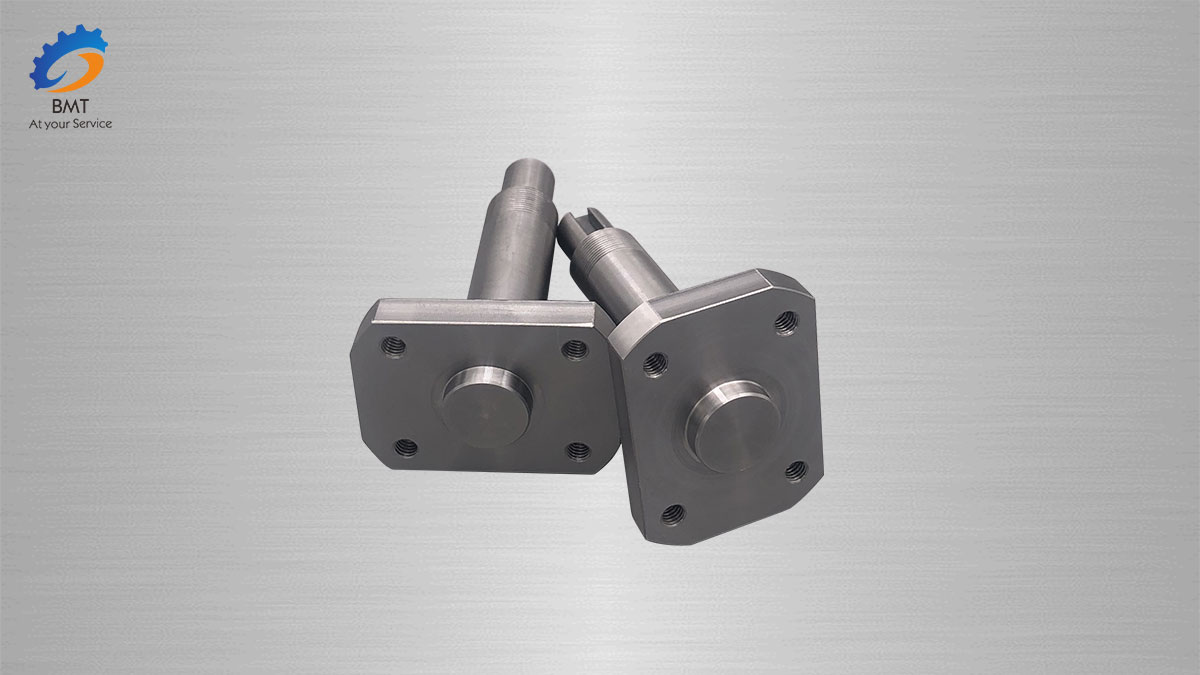

Lisebelisoa tsa Titanium Alloy Forgings

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes