Khutsufatsa potoloho ea hau ea tlhahiso

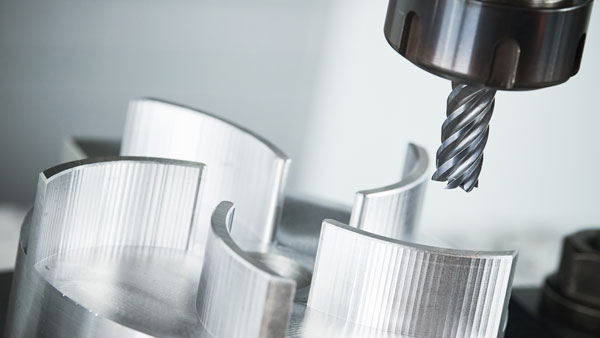

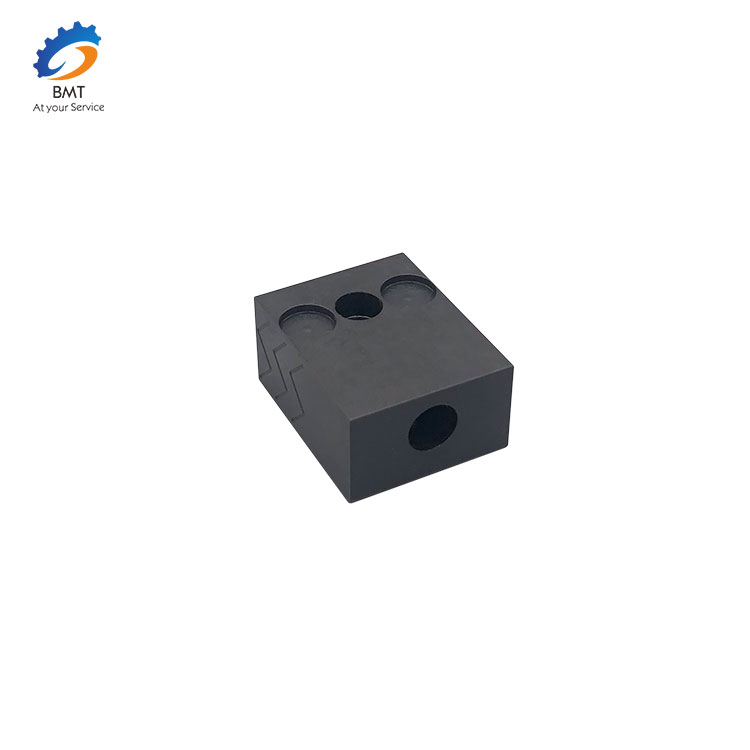

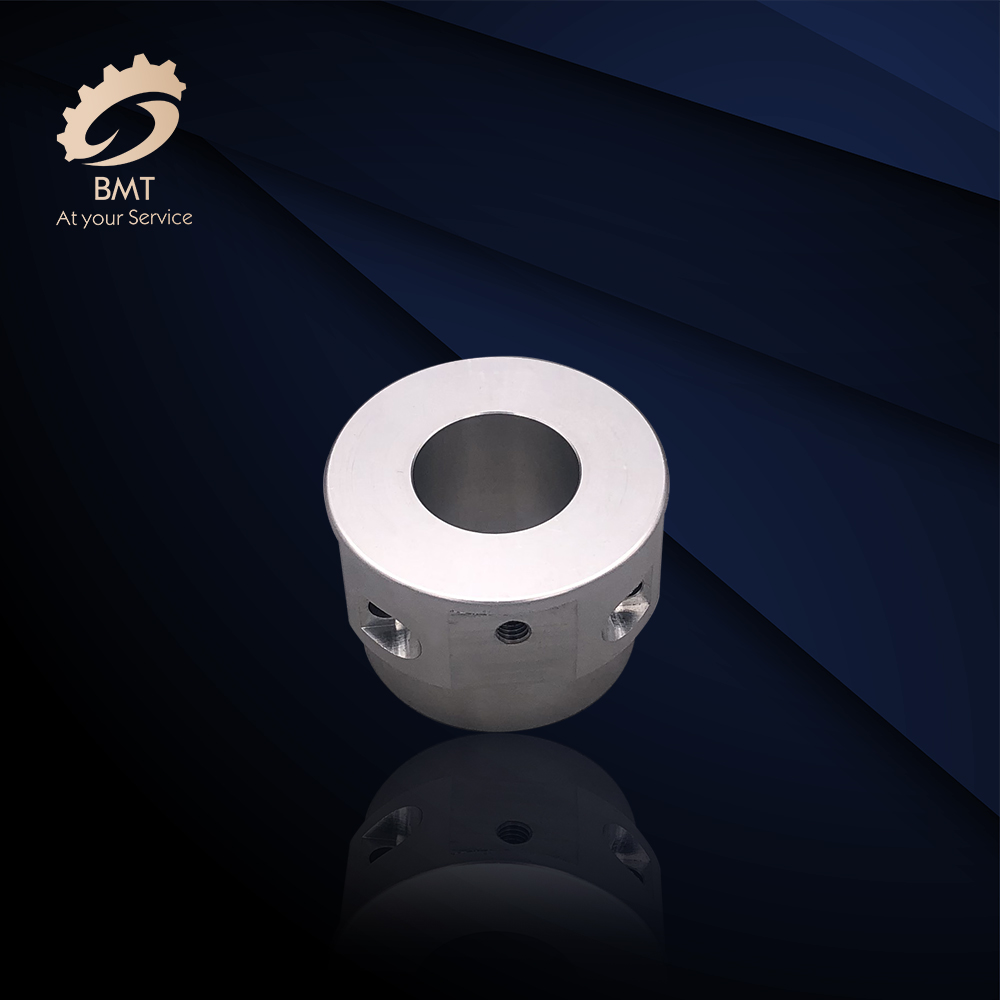

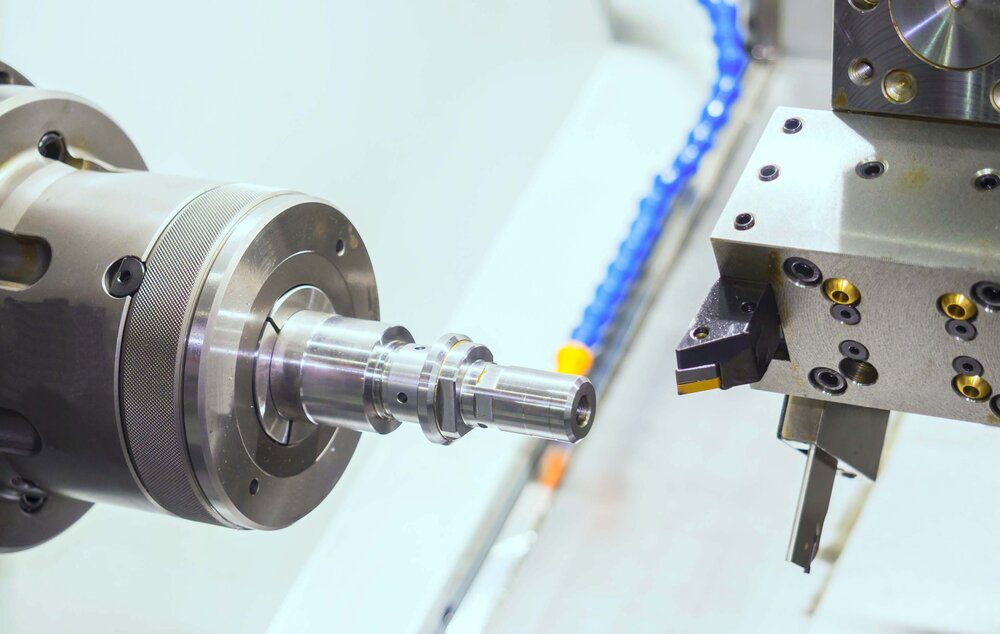

Mokhoa ona oa ho etsa thepa ke mochini o itirisang ka botlalo o sebelisang software ea tlhahiso e thusoang ke komporo le moralo o thusoang ke komporo.Bakeng sa likarolo tse nang le meralo e bonolo, opareitara e ka kenya mananeo a litaelo ka kotloloho mochining.Empa bakeng sa meralo e rarahaneng haholoanyane, setšoantšo sa CAM kapa CAD se tlameha ho hlahisoa pele le ho kopanngoa le sistimi.Mokhoa o mong ke ho sebelisa Coordinate Measuring Machines (CMMs) ho etsa 'mapa oa litaelo tsa moralo ka har'a sistimi.Software e tla theha le ho fana ka mehato e hlokahalang bakeng sa mochini ka bo eona ho theha likarolo tseo re li hlokang.

Ho na le sebaka se fokolang sa phoso hobane mochini o tla latela litaelo ho theosa le lengolo ho theha sehlahisoa.Ho hotle le ho feta ke hore ts'ebetso ena e phetoa haholo, e lumellang tlhahiso e potlakileng ea likarolo tse ts'oanang.

Lisebelisoa tsa pejana tsa mechini ea CNC li lieha ebile li sebelisoa feela bakeng sa tlhahiso ea molumo o phahameng.Hona joale, ho BMT, theknoloji e ntlafetse haholo.Ho sebelisa lisebelisoa tse rarahaneng le lisebelisoa, e lumella ho kopanngoa ka ho toba ha mefuta e entsoeng ka k'homphieutha lenaneong la hore ts'ebetso e be kapele le ho feta.Sena se boetse se lumella ho sebelisa lits'ebeletso tsa mochini oa CNC bakeng sa litlhoko tse tlase tsa molumo hore e be theko e tlase le e sebetsang.

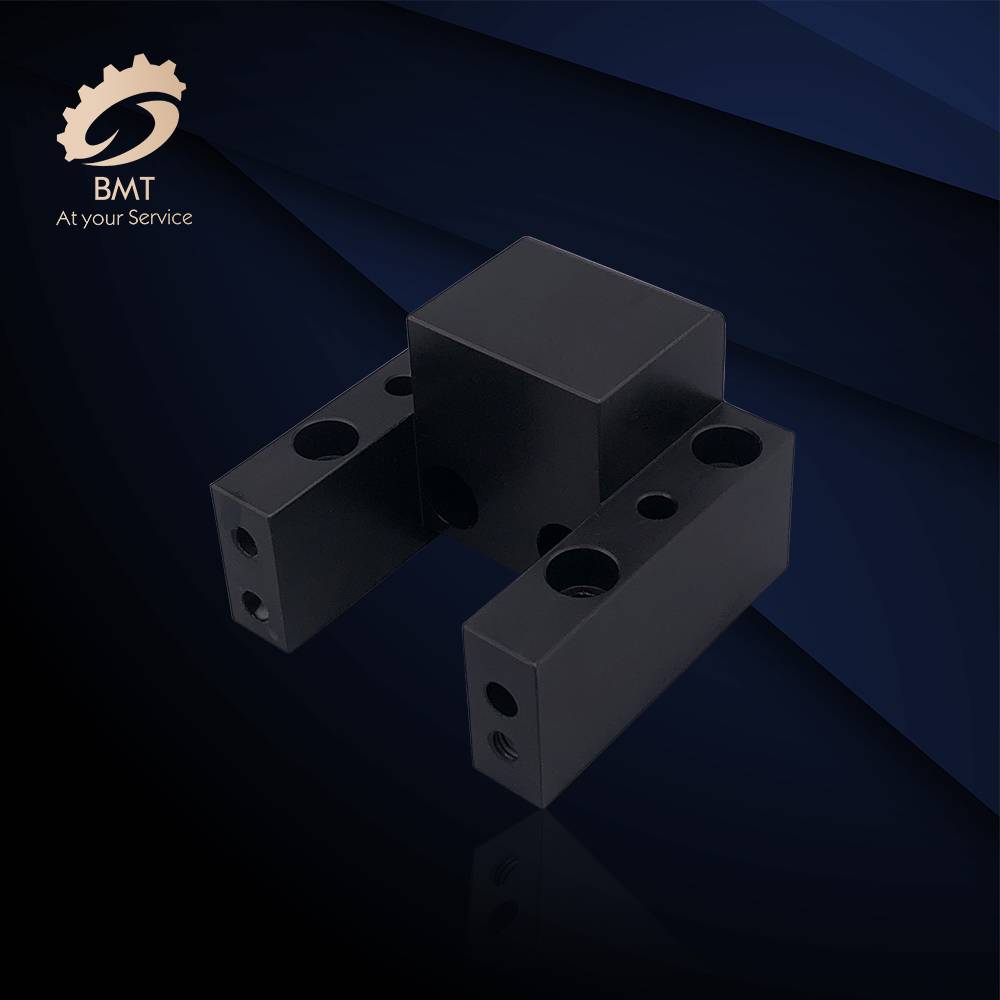

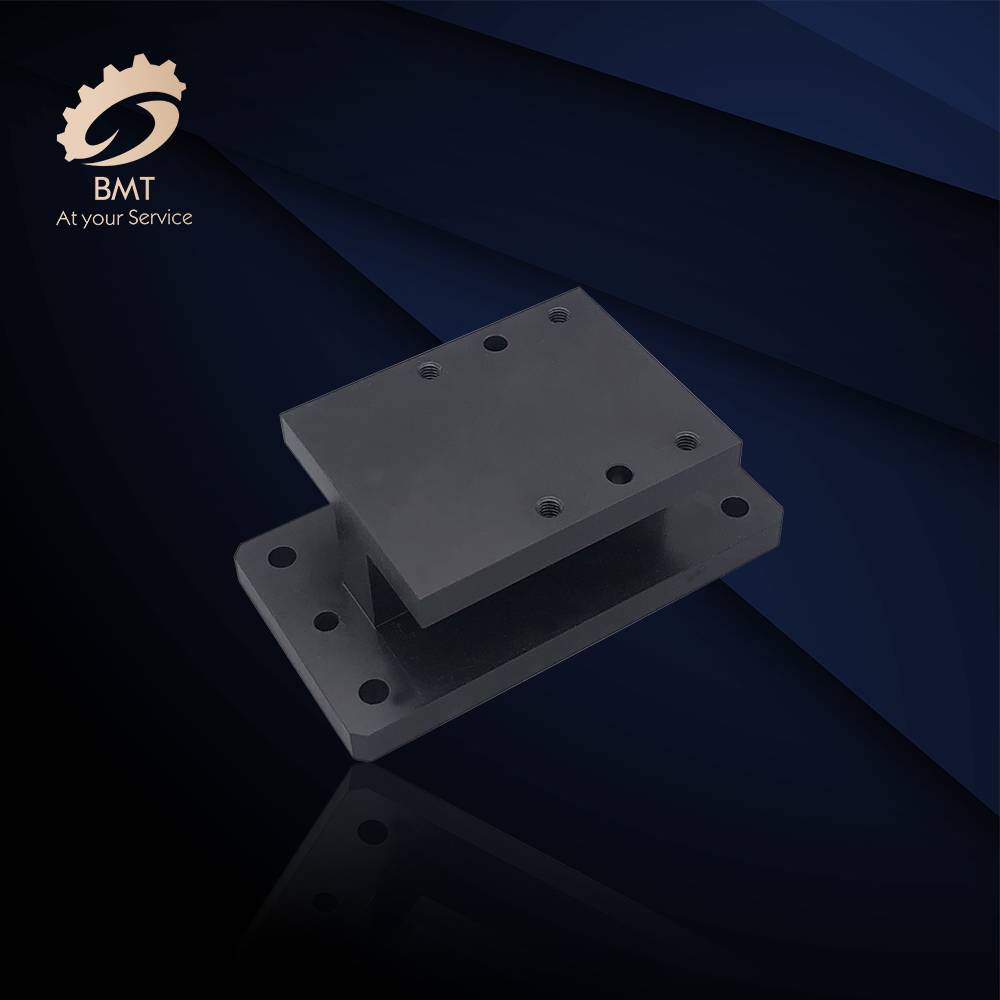

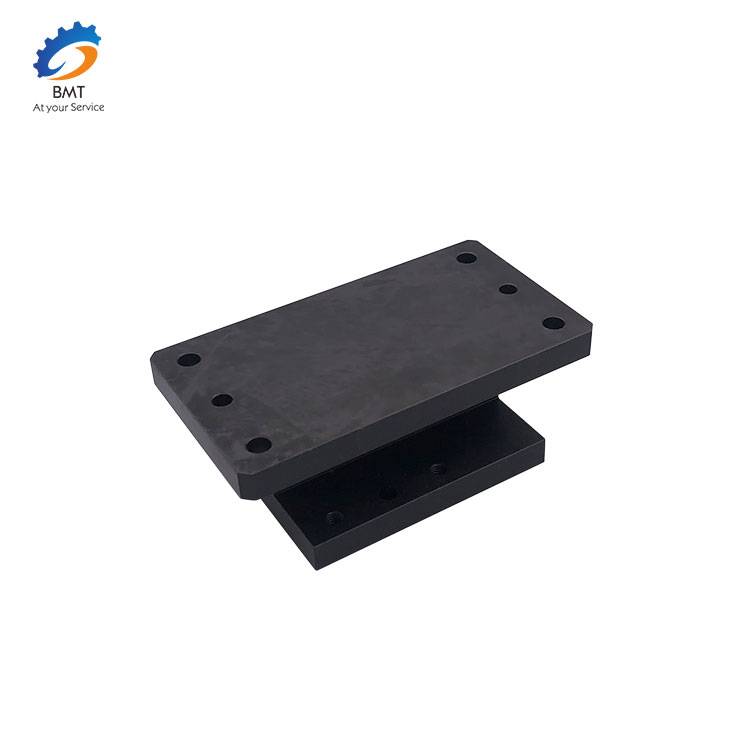

Ho sa tsotelehe hore na u indastering efe kapa tlhoko ea hau ke efe, ka ts'ebeliso ea lits'ebeletso tsa rona tse holimo tsa mochini oa CNC, re ka etsa li-prototypes, li-odara tse nyane, le tlhahiso ea molumo o tlase.Khamphani ea rona e kopanya ts'ebeliso ea mahlale a morao-rao, mechini e tsoetseng pele le baenjiniere ba nang le talenta mme re ka fana ka lihlahisoa ho feta tebello ea hau.Mechini ea CNC eo re nang le eona e ka mamella maemo a feteletseng le tikoloho bakeng sa lits'ebetso tse 'maloa hoo e batlang e le indastering e ngoe le e ngoe.

Litšepe le Lisebelisoa tsa Plastiki

Litšepe le lisebelisoa tsa polasetiki tseo re li sebelisang hangata li thathamisitsoe ka tlase mme u ka khetha seo u se batlang:

| LITŠEPE | MAMELLO MAMANE | MELEMO LE MAIKUTLO | QETELA LE PONAHALO |

| Ts'epe e sa beng le mabali | +/- 0.005″ | Matla a Phahameng High Corrosion Resistance Ho Weldability e Phahameng | Standard Machined Finish le moreki wa ponahalo likopo, joalo ka plating, anodizing, ho phatloha, joalo-joalo. |

| Tšepe ea Carbon | +/- 0.005″ | Phahameng Machinability Ho Weldability e Phahameng E ka Thatafala Ha e Thing ho Corrosion | |

| Aluminium | +/- 0.005″ | Matla a PhahamengMatla a Phahameng Boima bo tlase Phahameng Machinability Theko e tlase | |

| Koporo | +/- 0.005″ | Matla a Phahameng Boima bo tlase Phahameng Machinability Theko e tlase |

| LIPlasetiki | MAMELLO MAMANE | MELEMO LE MAIKUTLO | QETELA LE PONAHALO |

| HDPE | +/- 0.008″ | Matla a Tšusumetso e Mahareng E tenyetsehang | Standard Machined Finish |

| PC | +/- 0.008″ | Tensile e Bohareng Matla a Tšusumetso e Phahameng E boloka Thepa Ho Feta Thempereichara Ho Hlakola ho Phahameng ka ho Fetisisa | |

| ABS | +/- 0.008″ | Tensile e Bohareng Matla a Tšusumetso e Phahameng Motlakase oa Motlakase Phahameng Machinability Theko e tlase | |

| Acrylic | +/- 0.008″ | Matla a Matla a Phahameng E ka Folefatsoa | |

| Nylon | +/- 0.008″ | Matla a Phahameng Matla a Tšusumetso e Mahareng E boloka Thepa Ho Feta Thempereichara | |

| Delrin | +/- 0.008″ | Tensile e Bohareng Matla a Tšusumetso e Mahareng E tšoara Mamello ea Machining Hantle Ho Hanyetsa Mokhathala o Molemo le Mokhathala | |

| TLHOKOMELISO | +/- 0.008″ | Matla a Matla a Phahameng Mocheso o Phahameng oa ho sebetsa Motlakase oa Motlakase Ho Hlakola ho Phahameng ka ho Fetisisa |

Na u batla ho khutsufatsa potoloho ea tlhahiso le ho fokotsa litšenyehelo tsa hau tsa tlhahiso ka kakaretso?

BMT e na le tharollo e nepahetseng.Nolofatsa ts'ebetso ea tlhahiso ka lits'ebeletso tsa machining tsa CNC, tse ka u thusang ho potlakisa tlhahiso ea likarolo tse ngata tse entsoeng ka mochini ka boemo bo phahameng ka ho fetesisa le ho nepahala.

Tlhahisong ea kajeno, ho fana ka litšebeletso kantle ho naha ke senotlolo.BMT e ka u fa mochini oa CNC o potlakileng ho latela litlhoko tsa hau tse ikhethileng.Seo u hlokang ho se etsa feela ke ho romella lifaele tsa CAD kapa ho tlohela potso ho lengolo-tsoibila la rona.Re u fa qotsulo e potlakileng le ea mahala bakeng sa lits'ebeletso tsa mochini oa CNC le ho u fa likarolo tse entsoeng ka mochini ka nako e khuts'oane ka ho fetesisa.