CNC Machining Technology - Titanium

Khamphani ea rona e motlotlo ho hlahisa boqapi ba rona ba morao-rao ho CNC Machining Technology -CNC Machining ka Titanium. Ka sehlahisoa sena sa phetoho, re sutumelletsa meeli ea boenjiniere bo nepahetseng le ho fana ka boleng bo ke keng ba lekanngoa indastering ea tlhahiso.

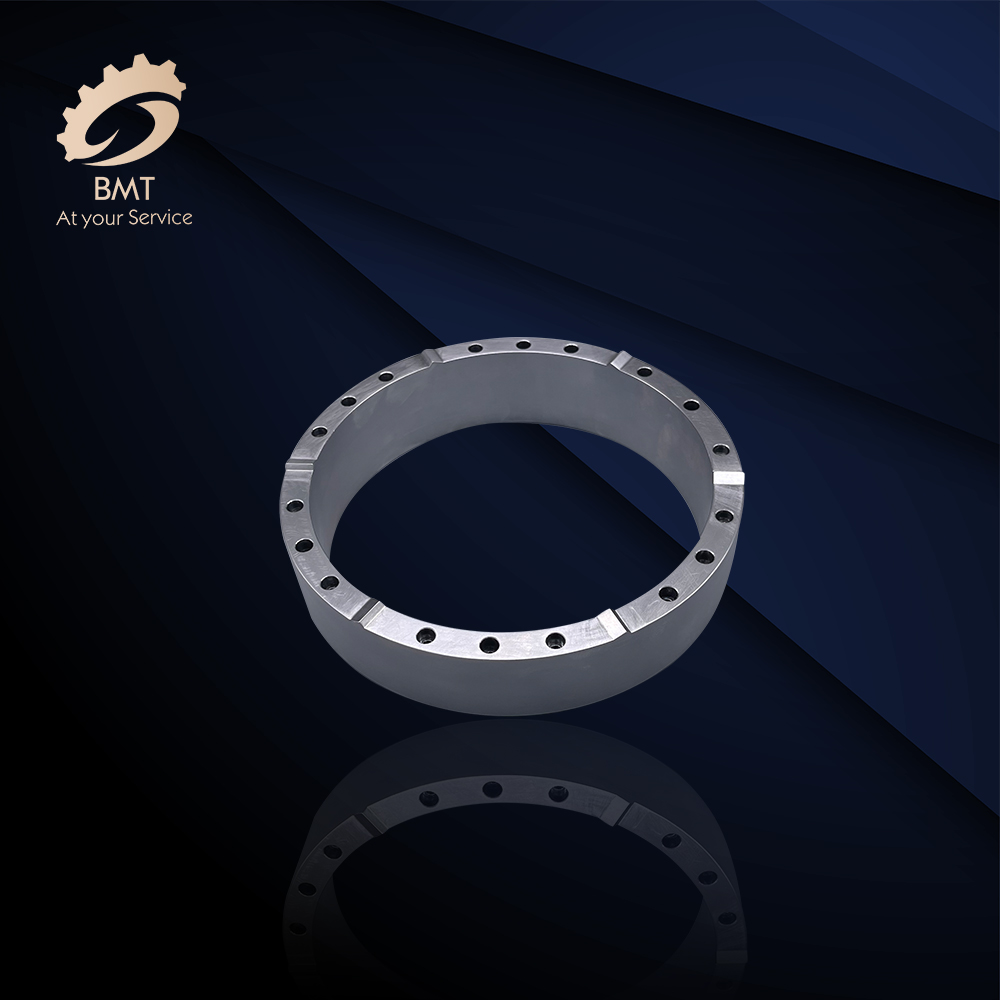

Tlhaloso ea Sehlahisoa:

CNC Machining ka Titanium ke thekenoloji ea mobu e lumellang tlhahiso ea likarolo tse rarahaneng, tsa boleng bo phahameng ka ho sebelisa e 'ngoe ea litšepe tse matla le tse tšoarellang ka ho fetisisa tse fumanehang - titanium. Ka ho kopanya mekhoa ea morao-rao ea machining ea CNC le thepa e ikhethang ea thepa ena e tsotehang, re thehile sehlahisoa se behang litekanyetso tse ncha indastering.

Titanium e tsebahala ka tekanyo ea eona e ikhethang ea matla ho boima ba 'mele, ho hanyetsa kutu, le ho hanyetsa mocheso. Thepa ena e etsa hore e be thepa e ratoang liindastering tse fapaneng, ho kenyeletsoa sefofane, likoloi, bongaka le ts'ireletso. Leha ho le joalo, ho sebetsa ka titanium ka tloaelo e bile phephetso ka lebaka la bothata ba eona ba ho sebetsa ka mochini.

Ka CNC Machining ka Titanium, re hlotse liqholotso tsena, ho lumella tlhahiso e nepahetseng le e sebetsang ea likarolo tsa titanium. Mechini ea rona e na le lisebelisoa tse tsoetseng pele, software ea sejoale-joale, le li-spindle tse lebelo le holimo, tse nolofalletsang ho etsa machining a boreleli le a nepahetseng a meralo e rarahaneng.

E 'ngoe ea likarolo tsa bohlokoa tsa CNC Machining ea rona e nang le Titanium ke bokhoni ba eona ba ho fana ka mamello e tiileng le liphetho tse ikhethang tsa bokaholimo. Boemo bona ba ho nepahala bo bohlokoa liindastering moo esita le ho kheloha ho honyenyane ho ka senyang ts'ebetso le ts'ebetso ea karolo. Sehlahisoa sa rona se netefatsa hore karolo e 'ngoe le e' ngoe e kopana le litlhaloso tse boletsoeng ke bareki ba rona, ho netefatsa khotsofalo ea bona le ho fokotsa kotsi ea liphoso kapa ho sebetsa bocha.

Ho feta moo, CNC Machining ea rona e nang le Titanium e fana ka melemo e mengata ho feta mekhoa ea setso ea tlhahiso. Tšebeliso ea mechine e laoloang ke k'homphieutha e felisa liphoso tsa batho 'me e nolofalletsa liphello tse tsitsitseng le tse ka phetoa. Sena se fella ka nako e khuts'oane ea ho etella pele, tlhahiso e ntlafetseng, le ho sebetsa hantle ha litšenyehelo. Ho phaella moo, ho feto-fetoha ha mechine ea rona ho lumella ho hlahisa likarolo tse peli tse kholo le tse nyenyane, ho sebetsana le mefuta e mengata ea likopo.

Khamphani ea rona, re utloisisa hore ho fihlela litlhoko tsa bareki ho bohlokoa 'marakeng oa kajeno oa tlholisano. Ke ka lebaka leo re fanang ka mokhoa oa motho ka mong morerong o mong le o mong, ho netefatsa hore CNC Machining ea rona ka Titanium e fihlela litlhoko tse ikhethileng tsa bareki ba rona. Baenjiniere le litsebi tsa rona tse nang le litsebo ba inehetse ho fana ka boemo bo phahameng ka ho fetisisa ba litsebi le tšehetso nakong eohle ea tlhahiso.

Qetellong, ea ronaCNC Machining ka Titaniumke sehlahisoa sa bohlokoa se kopanyang matla le ho tšoarella ha titanium ka ho nepahala le ho sebetsa hantle ha machining a CNC. Ho sa tsotellehe hore na u lefapheng la lifofane, tsa likoloi, tsa bongaka, kapa tsa ts'ireletso, sehlahisoa sa rona se fana ka liphetho tse ke keng tsa bapisoa 'me se beha litekanyetso tse ncha tsa boleng le tshebetso. Re thabetse ho tsebisa theknoloji ena 'marakeng mme re labalabela ho sebetsa le uena ho tlisa mehopolo ea hau bophelong.

Re romelle molaetsa oa hau:

-

Axis High Precision CNC Machining likarolo

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes

-

Aluminium CNC Machining likarolo

-

Auto Parts Machining

-

Likarolo tsa CNC Auto Likarolo tse entsoeng

-

Lisebelisoa tsa mochini oa CNC

-

Aluminium Sheet Metal Fabrication

-

Indasteri ea Likoloi

-

Ho Sila ho se Setsi

-

CNC Machining Melemo

-

CNC Machining Aluminium likarolo