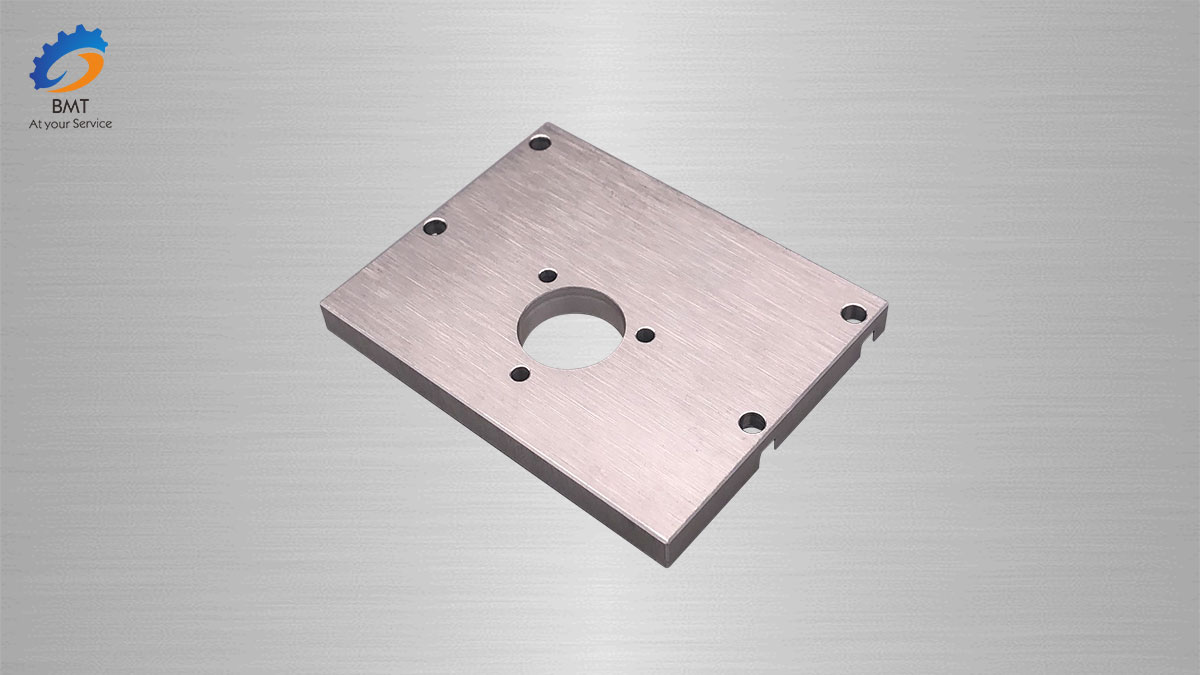

CNC Machining Processing Analysis

Tlhahlobo ea ts'ebetso

Litaba tsa tekheniki tsa machining a CNC a likarolo tse sebetsitsoeng li kenyelletsa likarolo tse fapaneng.Se latelang se kopanya monyetla le boiketlo ba mananeo ho hlahisa litaba tse ling tsa mantlha tse tlamehang ho hlahlojoa le ho hlahlojoa.

Litekanyo tsa ho mena li lokela ho lumellana le litšobotsi tsa mochini oa CNC

Lenaneong la CNC, boholo le boemo ba lintlha tsohle, mela, le bokaholimo li ipapisitse le tšimoloho ea lenaneo.Ka hona, ho molemo ho fana ka boholo ba khokahanyo ka kotloloho ho setšoantšo sa karolo, kapa leka ho qotsa boholo ka datum e tšoanang.

Maemo a ho phutha likarolo tsa geometri e lokela ho ba tse felletseng le tse nepahetseng

Lenaneong, moetsi oa lenaneo o tlameha ho utloisisa ka botlalo liparamente tsa likarolo tsa geometri tse etsang mokoloko oa karolo le kamano lipakeng tsa likarolo tsa jeometri.Hobane likarolo tsohle tsa geometri tsa karolo ea karolo li tlameha ho hlalosoa nakong ea lenaneo la othomathike, lihokahanyo tsa node ka 'ngoe li tlameha ho baloa nakong ea mananeo a matsoho.Ho sa tsotellehe hore na ke ntlha efe e sa hlakang kapa e sa tsitsang, lenaneo le ke ke la etsoa.Leha ho le joalo, ka lebaka la ho se nahanele ka ho lekaneng kapa ho hlokomolohuoa ke baqapi ba karolo ea moralo, hangata ho na le litekanyo tse sa fellang kapa tse sa hlakang, tse kang arc le line e otlolohileng, arc le arc hore na ke tangent kapa intersecting kapa tse arohaneng.Ka hona, ha u hlahloba le ho hlahloba litšoantšo, u tlameha ho ba hlokolosi 'me u ikopanye le moqapi ka nako haeba u fumana mathata.

Datum e tšepahalang ea ho mena

Ho machining a CNC, lits'ebetso tsa machining hangata li tsepame, 'me ho bohlokoa haholo ho li fumana ka mokhoa o ts'oanang.Ka hona, hangata hoa hlokahala ho beha li-datum tse ling tse thusang, kapa ho eketsa baokameli ba ts'ebetso ho sekheo.

Mena mofuta oa geometry o tšoanang kapa boholo

Ho molemo ho amohela mofuta o tšoanang oa geometri kapa boholo bakeng sa sebopeho le sekoti se ka hare sa karolo, e le hore palo ea liphetoho tsa sesebelisoa e fokotsehe, hape ho ka khoneha ho sebelisa lenaneo la taolo kapa lenaneo le khethehileng la ho khutsufatsa bolelele. ea lenaneo.Sebopeho sa likarolo se lekana ka hohle kamoo ho ka khonehang, se loketseng bakeng sa lenaneo le nang le seipone sa mochine oa mochine oa CNC ho boloka nako ea lenaneo.