Moetsi oa likarolo tsa mochini oa CNC - Seo re ka se Etsang?

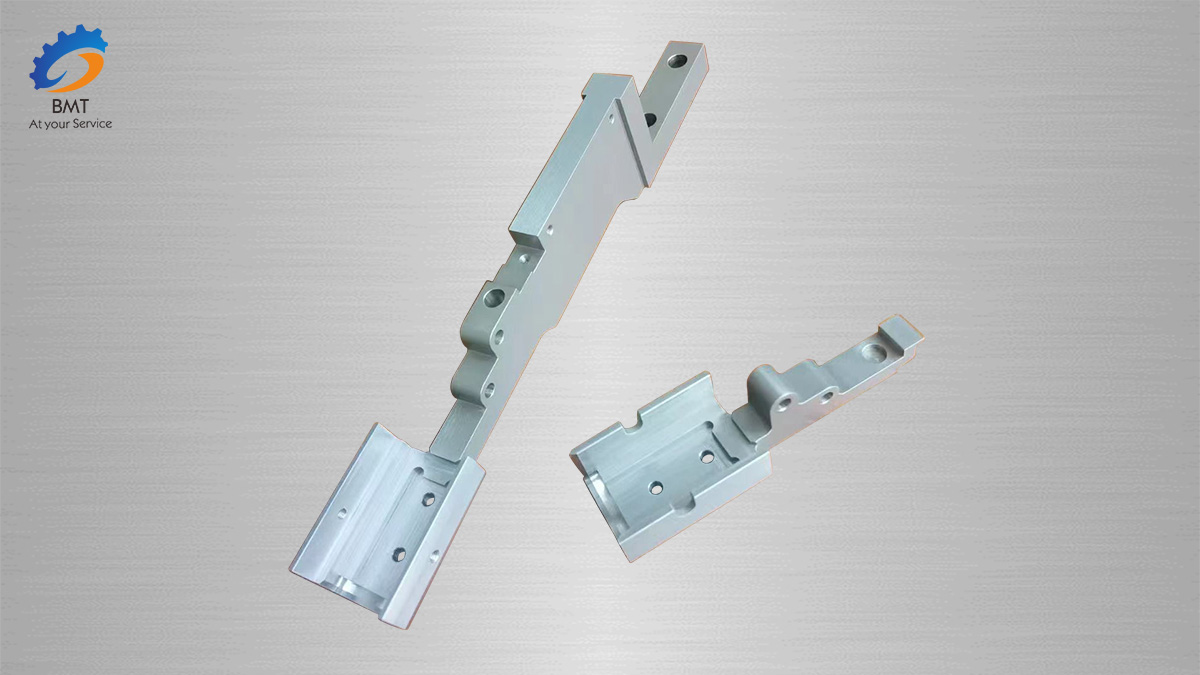

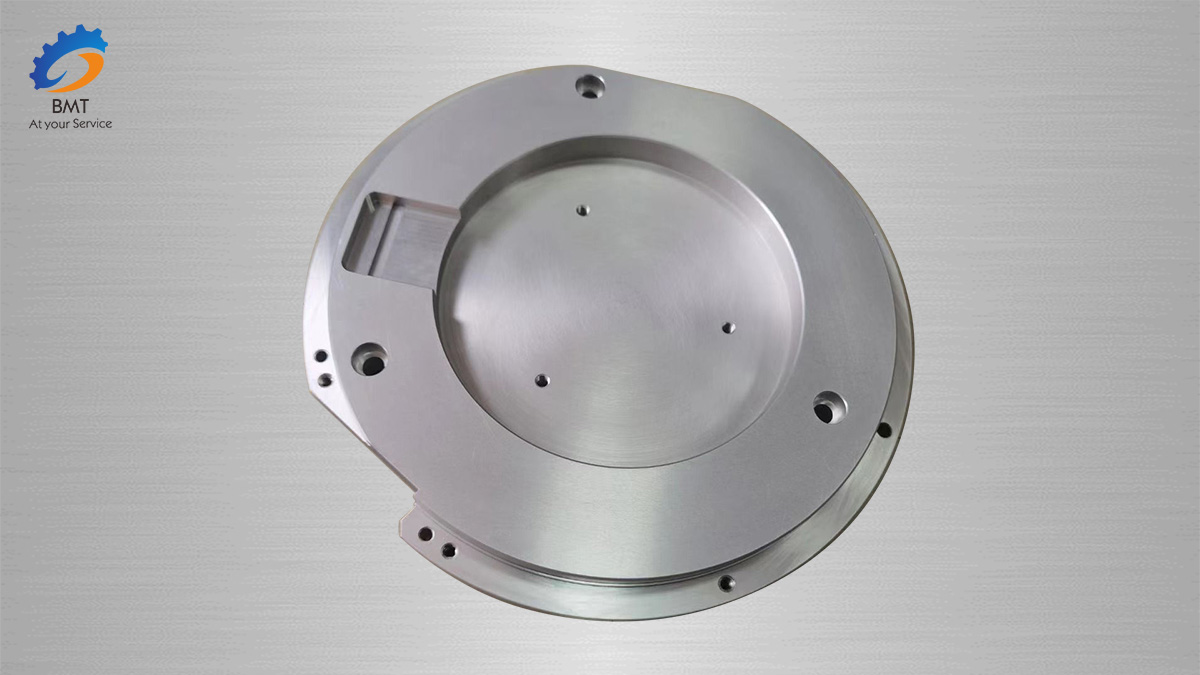

Joalo kaMoetsi oa likarolo tsa mochini oa CNC, re sebetsa ka ho khetheha ho hlahiseng likarolo tsa mochini tsa boleng bo holimo bakeng sa liindasteri tse fapaneng tse kang sefofane, bongaka, likoloi le lisebelisoa tsa elektroniki. Re ka etsa likarolo ka lisebelisoa tse fapaneng tse kang aluminium, tšepe e sa hloekang, koporo, polasetiki le tse ling. Ka boiphihlelo ba lilemo indastering, re iketselitse botumo ba bokhabane ba ho fana ka litharollo tsa moetlo ho fihlela litlhoko tsa bareki ba rona ka bomong. Sehlopha sa rona sa litsebi se sebelisa theknoloji ea morao-rao le lisebelisoa ho etsa likarolo tse nepahetseng haholo tse nang le mamello e thata.

Re ka etsa’ng? Re ka hlahisa likarolo tse nang le li-geometri tse rarahaneng, ho nepahala ho phahameng, le pheletso e ntle ea bokaholimo. Ho tloha ho prototyping ho isa tlhahisong, re ka fana ka litharollo tse sebetsang hantle le tse theko e boima ntle le ho senya boleng ba likarolo.

Prototyping

Litšebeletso tsa rona tsa prototyping li thusa bareki ho lekola meralo ea bona pele ho tlhahiso ea bongata. Hore na o hloka likarolo tse 'maloa kapa tse makholo, sehlopha sa rona se ka etsa prototype e lumellanang le litlhaloso tsa hau. Re sebelisa khatiso e tsoetseng pele ea 3D leMechine ea CNCtheknoloji ea ho etsa likarolo tse nepahetseng ka nako e khuts'oane.

Tlhahiso

Re ka etsa lihlahisoa tse ngata tsalikarolo tse entsoeng ka mochinika boleng bo tsitsitseng le mamello e thata. Mechini ea rona ea CNC e ka sebetsa khafetsa, e netefatsa nako ea phetoho e potlakileng. Re etsa mehato e matla ea taolo ea boleng ho netefatsa hore karolo ka 'ngoe e kopana le litlhoko tsa bareki ba rona.

Kopano

Re boetse re fana ka litšebeletso tsa kopano bakeng sa bareki ba rona ba hlokang lihlahisoa tse felileng. Sehlopha sa rona se ka kopanya likarolo ho li-subassemblies kapa lihlahisoa tsa ho qetela, ho latela litlhoko tsa hau. Re sebelisa lisebelisoa tse tsoetseng pele ho netefatsa hore karolo e 'ngoe le e' ngoe e lekana hantle, 'me sehlahisoa sa ho qetela se sebetsa kamoo se reriloeng kateng.

Boikemisetso

Rea utloisisa hore morero o mong le o mong o na le litlhoko tse ikhethang. Ke ka hona re fanang ka lits'ebeletso tsa ho itlhophisa ho fihlela litlhoko tsa bareki ba rona. Sehlopha sa rona se ka fana ka litharollo tsa motho ka mong ho netefatsa hore karolo ka 'ngoe e kopana le litlhaloso tsa hau.

Taolo ea Boleng

Khamphani ea rona ea ho etsa likarolo tsa mochini oa CNC, boleng ke ntho e tlang pele bophelong ba rona. Re etsa mehato e matla ea taolo ea boleng ho netefatsa hore karolo ka 'ngoe e kopana le litlhoko tsa bareki ba rona. Sehlopha sa rona se sebelisa lisebelisoa tse tsoetseng pele le theknoloji ho netefatsa hore karolo ka 'ngoe ke ea boleng bo holimo.

Qetello

Joalo kaLikarolo tsa mochini oa CNCmoetsi, re fana ka mefuta e fapaneng ea lits'ebeletso ho fihlela litlhoko tsa bareki ba rona. Ho tloha ho prototyping ho isa tlhahisong, re ka fana ka litharollo tse sebetsang hantle le tse theko e boima ntle le ho senya boleng ba likarolo. Re ikemiselitse ho fana ka litšebeletso tse ntle tsa bareki, 'me sehlopha sa rona se lula se le teng ho araba lipotso leha e le life tseo u ka bang le tsona. Ikopanye le rona kajeno ho ithuta haholoanyane ka hore na re ka u thusa joang ka projeke ea hau.

Re romelle molaetsa oa hau:

-

Axis High Precision CNC Machining likarolo

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes

-

Aluminium CNC Machining likarolo

-

Auto Parts Machining

-

Likarolo tsa CNC Auto Likarolo tse entsoeng

-

Lisebelisoa tsa mochini oa CNC

-

Aluminium Sheet Metal Fabrication

-

Indasteri ea Likoloi

-

Ho Sila ho se Setsi

-

CNC Machining Melemo

-

CNC Machining Aluminium likarolo