Likarolo tsa mochini oa CNC tse nang le Ts'ebeletso ea Anodizing

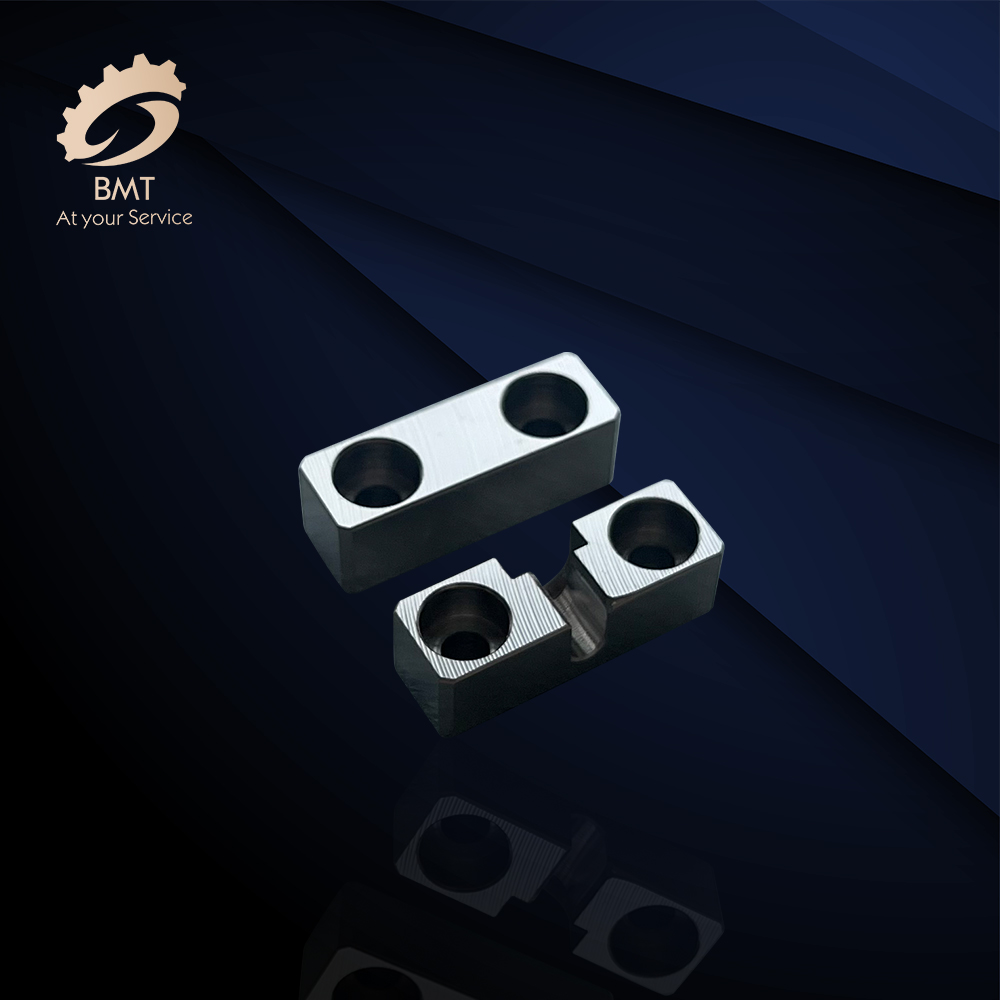

Ho hlahisa maemo a rona a morao-raoLikarolo tse entsoeng ka mochini oa CNCka Anodizing Service, e etselitsoeng ho fihlela litlhoko tsa hau tse nepahetseng tsa tlhahiso. Hore na o indastering ea likoloi, ea sefofane, kapa ea lisebelisoa tsa elektroniki, likarolo tsa rona tsa mochini tsa boleng bo holimo li tla feta tebello ea hau ho latela matla, ho nepahala le botle. Likarolo tsa rona tsa CNC Machined li entsoe ka theknoloji e tsoetseng pele ea taolo ea linomoro tsa khomphutha (CNC), ho netefatsa tlhahiso e nepahetseng le e nepahetseng nako le nako. Re sebelisa sehlopha sa litsebi tse nang le litsebo tseo e leng litsebi tsa ho sebelisa mechine ea rona ea CNC e tsoetseng pele, e tiisang hore karolo e 'ngoe le e' ngoe e hlahisoa ka mamello e thata le litlhaloso tse nepahetseng.

Ka mechini ea rona e matla, re ka sebetsana le merero ea sekala sefe kapa sefe, ho tloha ho likarolo tse nyane tse rarahaneng ho isa ho tse kholo, tse rarahaneng. Se behang ronaLikarolo tse entsoeng ka mochini oa CNCka thoko ke Tšebeletso e eketsehileng ea Anodizing eo re fanang ka eona. Anodizing ke ts'ebetso ea electrochemical e ntlafatsang bokaholimo ba tšepe ka ho etsa lesela le tšoarellang, le hananang le ho bola. Kalafo ena ha e ntlafatse ponahalo ea karolo feela empa e boetse e fana ka tšireletso e eketsehileng khahlanong le ho senya, ho lelefatsa nako ea bophelo le ho fokotsa litšenyehelo tsa tlhokomelo.

Ea ronamokhoa oa anodizingho kenyelletsa ho qoelisa karolo e entsoeng ka mochine ka tharollo ea electrolytic le ho fetisa motlakase ho eona. Sena se etsa lera la oxide holim'a tšepe, le ka dauoang hore le fumane mebala e fapaneng kapa le tlohe boemong ba lona ba tlhaho bakeng sa chebahalo e boreleli ea tšepe. Botenya ba lera la anodized le bona bo ka hlophisoa ho fihlela litlhoko tsa hau tse ikhethileng, ho netefatsa ts'ebetso le ts'ebetso e nepahetseng. Re fana ka mefuta e mengata ea likhetho tsa anodizing, ho kenyelletsa le mofuta oa 2 oa anodizing, o tsejoang hape e le anodizing e tloaelehileng, e hlahisang mokhabiso oa mokhabiso le ho ntlafatsa ho hanyetsa ho bola ha karolo. Bakeng sa lits'ebetso tse hlokang ho tšoarella le ho thatafala, re fana ka anodizing ea Mofuta oa III, eo hangata e bitsoang hard coat anodizing.

Ts'ebetso ena e etsa hore ho be le lesela le letenya le sa khoneng ho hoboha, le etsa hore e be e loketseng bakeng sa likarolo tse tlas'a maemo a thata kapa tšebeliso ea khafetsa. Ho BMT, re motlotlo ka ho fana ka lihlahisoa tse fihlelang maemo a holimo a indasteri. Likarolo tsa rona tsa CNC Machined tse nang le Ts'ebeletso ea Anodizing li nka mehato e matla ea taolo ea boleng ho netefatsa hore li kopana kapa li feta litebello tsa bareki. Re kentse tšebetsong ts'ebetso ea tlhahlobo e felletseng e kenyelletsang tlhahlobo e felletseng, tlhahlobo ea pono le tlhahlobo ea ts'ebetso.

Ho feta moo, rea utloisisa hore litlhoko tsa moreki e mong le e mong li ka fapana, ke ka lebaka leo re fanang ka likhetho tsa ho itlhophisa ho tsamaisa lihlahisoa tsa rona ho latela litlhoko tsa hau tse ikhethileng. Ho tloha khethong ea thepa ho fihlela qetellong le kalafo ea bokaholimo, sehlopha sa rona se nang le tsebo se tla sebetsa haufi-ufi le uena ho theha likarolo tsa CNC Machined tse loketseng kopo ea hau. Ka bokhutšoanyane, likarolo tsa rona tsa CNC Machined tse nang le Ts'ebeletso ea Anodizing li kopanya tlhahiso e nepahetseng le kalafo e holimo holimo ho u fa likarolo tsa boleng bo holimo tse ipabolang ts'ebetsong le botleng. Tšepa BMT ho fana ka liphetho tse ikhethang tse tla ntlafatsa lihlahisoa tsa hau le ho u fa monyetla oa tlholisano 'marakeng.

Re romelle molaetsa oa hau:

-

Axis High Precision CNC Machining likarolo

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes

-

Aluminium CNC Machining likarolo

-

Auto Parts Machining

-

Likarolo tsa CNC Auto Likarolo tse entsoeng

-

Lisebelisoa tsa mochini oa CNC

-

Aluminium Sheet Metal Fabrication

-

Indasteri ea Likoloi

-

Ho Sila ho se Setsi

-

CNC Machining Melemo

-

CNC Machining Aluminium likarolo