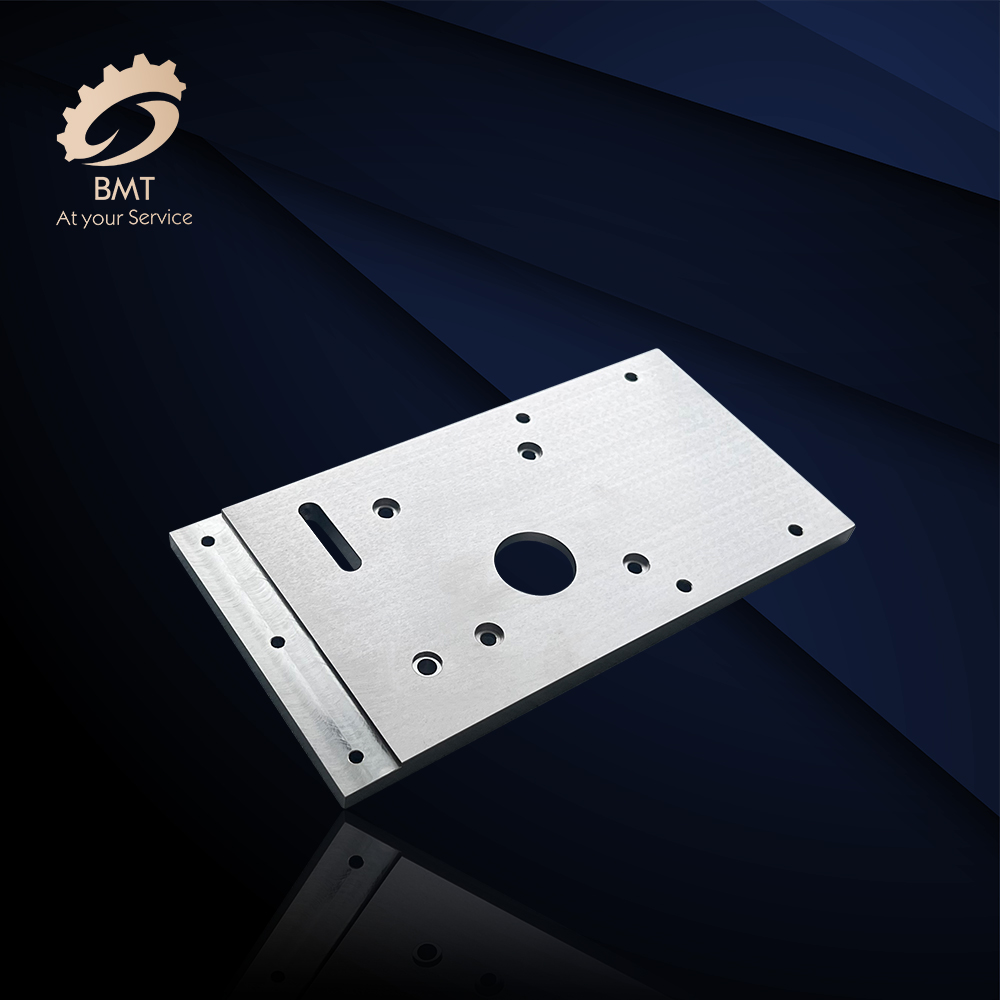

Aluminium Precision CNC Machining Service

Khamphaning ea rona, re motlotlo ho u fa CNC e tsoetseng pele haholo (Taolo ea Linomoro tsa Khomphutha) lits'ebeletso tse etselitsoeng ho sebetsa ka mokhoa o nepahetseng oa aluminium. Mehaho ea rona ea morao-rao le theknoloji ea morao-rao e netefatsa ho nepahala ho ke keng ha bapisoa le boleng bo ikhethang bakeng sa litlhoko tsohle tsa hau tsa machining tsa aluminium. Ka tlhokahalo e ntseng e eketseha ea lisebelisoa tse bobebe le tse tšoarellang nako e telele, aluminium e fetohile khetho ea mantlha bakeng sa liindasteri tse kang sefofane, likoloi le lisebelisoa tsa elektroniki. Ho fihlela litlhoko tsena, re ntlafalitse litsebo tsa rona tsa mochini oa CNC ka ho khetheha bakeng sa aluminium, e leng se re lumellang ho u fa likarolo tsa boleng bo holimo tse fihlelang litlhaloso tsa hau hantle.

Sehlopha sa rona se nang le litsebo tsa baenjiniere le litsebi ke litsebi lefapheng la machining la CNC. Ba na le phihlelo e pharaletseng ea ho sebetsa ka lisebelisoa tsa aluminium, tse re nolofalletsang ho sebetsana le merero e rarahaneng ka ho fetisisa. Hore na o hloka ho sila ka nepo, ho phethoha, ho cheka, kapa eng kapa engMokhoa oa ho etsa mochini oa CNC, re netefatsa ho nepahala ho holimo le ho pheta-pheta, ho netefatsa hore karolo ka 'ngoe e kopana le mamello ea hau. E 'ngoe ea melemo ea bohlokoa ea lits'ebeletso tsa rona tsa mochini oa CNC ke bokhoni ba ho hlahisa meralo e rarahaneng le e rarahaneng eo ho neng ho ka se khonehe ho e fihlela ka mekhoa ea khale ea machining. Theknoloji ea rona e tsoetseng pele ea CNC e sebelisa moralo o thusoang ke komporo (CAD) le software e thusang komporo (CAM) ho laola ka nepo ts'ebetso ea mochini, e hlahisang likarolo tse nepahetseng le tse sa fetoheng.

Ho feta moo, ea ronaCNCMechini e na le lilepe tse ngata le lisebelisoa tsa ho itšeha, tse re lumellang ho etsa ts'ebetso e mengata ka mokhoa o le mong. Sena se fokotsa haholo nako ea tlhahiso le litšenyehelo ha se ntse se boloka boleng bo ikhethang le ho nepahala. Ka lits'ebetso tsa rona tse sebetsang hantle le tse hlophisitsoeng, re ka fihlela linako tsa hau tse thata ntle le ho sekisetsa ho nepahala. Ntle le ho nepahala le katleho e ke keng ea lekanngoa ea lits'ebeletso tsa rona tsa mochini oa CNC, re boetse re etelletsa pele boleng le bots'epehi ba likarolo tsa hau. Re khomarela litekanyetso tse thata tsa taolo ea boleng ho pholletsa le ts'ebetso ea mochini ho netefatsa hore karolo e 'ngoe le e' ngoe e kopana le litlhaloso tsa hau mme e feta litebello tsa hau. Boitlamo ba rona ba khotsofalo ea bareki bo atolohela ho theko ea rona ea tlholisano le litšebeletso tsa bareki tse potlakileng.

Re utloisisa bohlokoa ba ho boloka litšenyehelo le ho tlisa thepa ka nako 'marakeng oa kajeno oa tlholisano, 'me re ikemiselitse ho u fa boleng bo holimo bakeng sa matsete a hau. Sehlopha sa rona se arabelang se lula se ikemiselitse ho u thusa ka lipotso leha e le life, lintho tse u tšoenyang, kapa tšehetso ea tekheniki eo u ka e hlokang. Ho tloha ho likarolo tsa sefofane ho ea ho likarolo tsa likoloi, tsa ronaaluminium ho nepahala CNC machininglits'ebeletso ke tharollo e nepahetseng bakeng sa litlhoko tsa hau tsa tlhahiso. Ka boitseanape ba rona, theknoloji e tsoetseng pele, le boitlamo ba boleng, re netefatsa liphetho tse ikhethang tse tla ntšetsa pele khoebo ea hau.

Ikopanye le rona kajeno ho ithuta haholoanyane ka lits'ebeletso tsa rona tsa Aluminium Precision CNC Machining le hore na re ka u thusa joang ho fihlela lipheo tsa hau tsa mochini. Eba le ho nepahala le bokhabane bo re khethollang indastering 'me u re lumelle ho ba molekane oa hau eo u mo tšepang mosebetsing oa ho etsa aluminium.

Re romelle molaetsa oa hau:

-

Axis High Precision CNC Machining likarolo

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes

-

Aluminium CNC Machining likarolo

-

Auto Parts Machining

-

Likarolo tsa CNC Auto Likarolo tse entsoeng

-

Lisebelisoa tsa mochini oa CNC

-

Aluminium Sheet Metal Fabrication

-

Indasteri ea Likoloi

-

Ho Sila ho se Setsi

-

CNC Machining Melemo

-

CNC Machining Aluminium likarolo