Liphaephe le Liphaephe tsa Titanium tse Seamless

Gr1, Gr 2, Gr 3 kaofela ke titanium e hloekileng ea indasteri. Li na le thepa e phahameng ea mochini, ts'ebetso e ntle ea litempe, 'me li ka chesetsoa ka mefuta e fapaneng. Matla a motsoako o nang le welded a ka fihla ho 90% ea matla a tšepe ea motheo, 'me ts'ebetso ea ho itšeha e ntle. Titanium tube e na le khanyetso e phahameng ea kutu ho chloride, sulfide le ammonia. Titanium e thibela ho bola metsing a leoatle e phahame ho feta ea lialloys tsa aluminium, tšepe e sa hloekang le li-alloys tse thehiloeng ho nickel. Titanium e boetse e hanana le tšusumetso ea metsi.

Titanium alloy e sebelisoa haholo bakeng sa tlhahiso ea likarolo tsa enjene ea sefofane, e lateloang ke likarolo tsa sebopeho sa lirokete, limisaele le lifofane tse lebelo le holimo. Bohareng ba lilemo tsa bo-1960, titanium le metsoako ea eona e 'nile ea sebelisoa indastering e akaretsang ho etsa li-electrode indastering ea electrolysis, li-condenser liteisheneng tsa motlakase, lihitara bakeng sa tlhoekiso ea peterole le ho ntša letsoai metsing a leoatle, le lisebelisoa tsa ho laola tšilafalo ea tikoloho. Titanium le li-alloys tsa eona li fetohile mofuta oa thepa ea sebopeho e sa jeng. Ho feta moo, e boetse e sebelisoa ho hlahisa lisebelisoa tsa polokelo ea haedrojene le li-alloys tsa memori tsa sebopeho.

Ha ho bapisoa le lisebelisoa tse ling tsa tšepe, motsoako oa titanium o na le melemo e latelang:

- Matla a phahameng a khethehileng (matla a matla / boima), matla a matla a ka fihla ho 100 ~ 140kgf / mm2, 'me boima ke 60% feela ea tšepe.

- Mocheso o mahareng o na le matla a matle, mocheso oa tšebeliso o phahame ka likhato tse makholo a 'maloa ho feta oa motsoako oa aluminium, o ntse o ka boloka matla a hlokahalang ka mocheso o mahareng,' me o ka sebetsa nako e telele mocheso oa 450 ~ 500 ℃.

- Khanyetso e ntle ea kutu. Filimi ea junifomo le e teteaneng ea oxide e thehoa hang-hang holim'a titanium sepakapakeng, e nang le bokhoni ba ho hanela kutu ka mecha e fapaneng ea litaba. Ka kakaretso, titanium e na le khanyetso e ntle ea kutu mecheng ea litaba ea oxidizing le e sa nke lehlakore, 'me e na le khanyetso e ntle ea kutu metsing a leoatle, chlorine e metsi le tharollo ea chloride. Empa ho fokotsa mecha ea litaba, joalo ka hydrochloric acid le litharollo tse ling, ho hanyetsa ho bola ha titanium ho fokola.

- Li-alloys tsa Titanium tse nang le ts'ebetso e ntle ea mocheso o tlase le likarolo tse tlase haholo tsa interstitial, joalo ka Gr7, li ka boloka boemo bo itseng ba polasetiki ho -253 ℃.

- Modulus ea elasticity e tlase, conductivity ea mocheso e nyane, 'me ha e na ferromagnetic.

BMT e khethehile ho romela liphaephe le liphaephe tsa titanium tse se nang moeli, 'me e na le tlhahiso ea selemo le selemo ea lithane tse 5,000. Liphaephe le li-tubes tse se nang moeli tsa BMT li na le matla a phahameng a ikhethileng, ho hanyetsa kutu, thepa e ntle ea cryogenic, modulus e tlase ea elasticity, conductivity e tlase ea mocheso ebile ha e na ferromagnetism.

Mofuta oa BMT oa liphaephe tsa titanium tse se nang moeli le li-tube li rekisoa lefatšeng ka bophara. Tlhokomelo e nepahetseng e etsoa ho latela boleng, ho kenyelletsa tlhahlobo ea likarolo tsa lik'hemik'hale, tlhahlobo ea khatello ea moea, tlhahlobo e sa senyeheng, tlhahlobo ea eddy hajoale le tlhahlobo ea ultrasonic. Re boetse re na le tlhahlobo ea mochini, e koahelang teko ea matla, tlhahlobo ea ho phatloha, tlhahlobo ea ho bata, tlhahlobo ea ferroxyl, RT, tlhahlobo ea X-Ray, joalo-joalo.

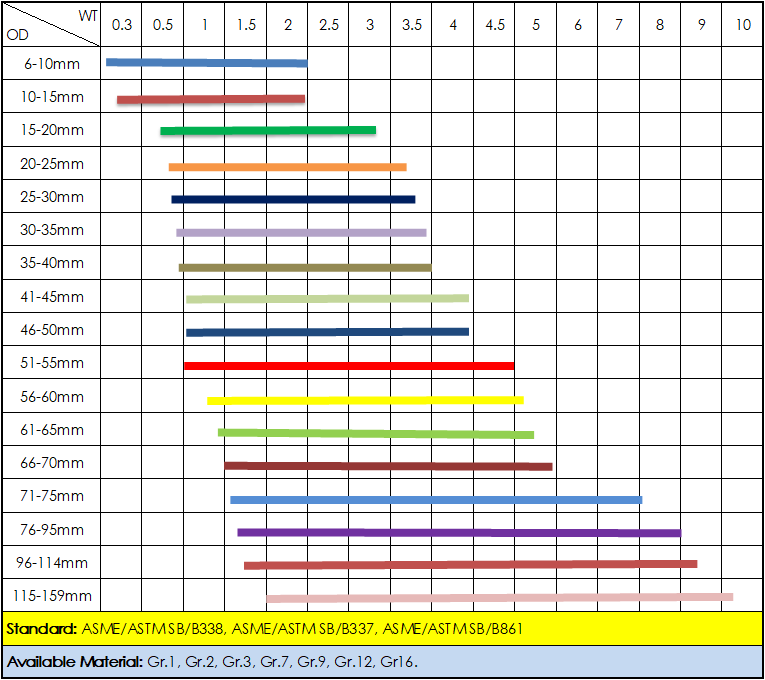

Liphaephe tse Seamless tsa Titanium le Range ea Boholo ba Liphaephe:

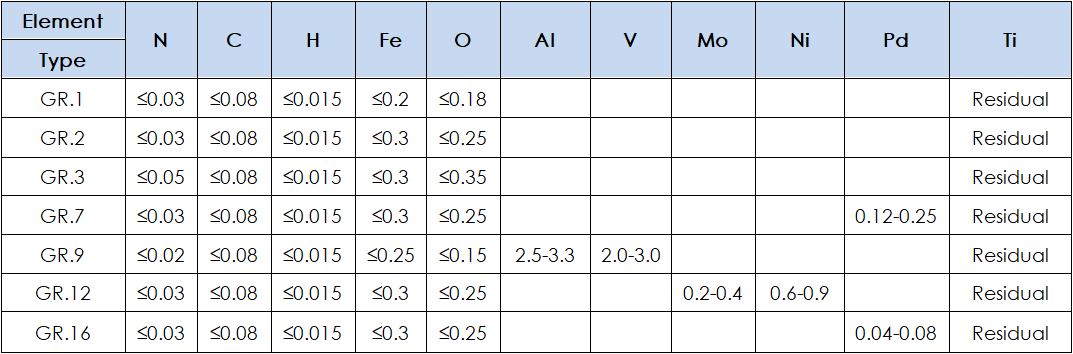

Sebopeho sa Lik'hemik'hale Tse Fumanehang:

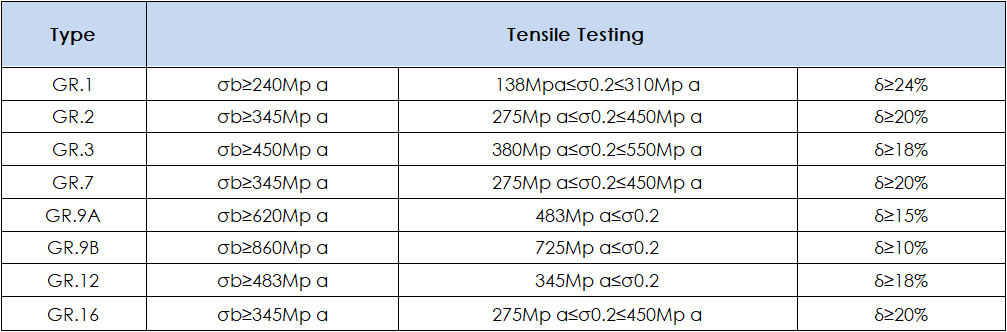

Thepa e Fumanehang ea Mechini:

Tlhahlobo ea tlhahlobo:

- Tlhahlobo ea Sebopeho sa Lik'hemik'hale

- Teko ea Thepa ea Mechini

- Teko ea Teko

- Flaring Test

- Teko e bataletseng

- Teko ea ho Koba

- Teko ea Hydro-Static

- Teko ea Pneumatic (Teko ea khatello ea moea tlas'a metsi)

- Tlhahlobo ea NDT

- Teko ea Eddy-Hajoale

- Tlhahlobo ea Ultrasonic

- Tlhahlobo ea LDP

- Teko ea Ferroxyl

Tlhahiso (Boholo le Bonyane Bongata ba Order):E se nang moeli, ho latela taelo.

Lead time:Nako ea ho tsamaisa ka kakaretso ke matsatsi a 30. Leha ho le joalo, ho itšetlehile ka palo ea taelo ka mokhoa o nepahetseng.

Lipalangoang:Mokhoa o akaretsang oa lipalangoang ke ka Leoatle, ka Moea, ka Express, ka Terene, e tla khethoa ke bareki.

Ho paka:

- Pipe e qetella e sirelelitsoe ka li-caps tsa polasetiki kapa tsa cardboard.

- Lisebelisoa tsohle li lokela ho paka ho sireletsa lipheletsong le ho shebana.

- Thepa e 'ngoe kaofela e tla tlatsoa ka liphaephe tsa foam le mekotla ea polasetiki e amanang le eona.

- Patsi efe kapa efe e sebelisetsoang ho paka e tlameha ho ba e loketseng ho thibela tšilafalo ka ho kopana le lisebelisoa tsa ho tšoara.