Bohlokoa ba ho Koba ha Sheet Metal Works

Le hoja ho kobeha ha pampiri ea tšepe ho bonahala ho le bonolo haholo, ho pata letoto la melao le theknoloji e u lumellang ho lemoha libopeho tse bonolo kapa tse rarahaneng haholo. Ho kobeha ha pampiri ea tšepe ke e 'ngoe ea lits'ebetso tse atileng haholo indastering ea tlhahiso.

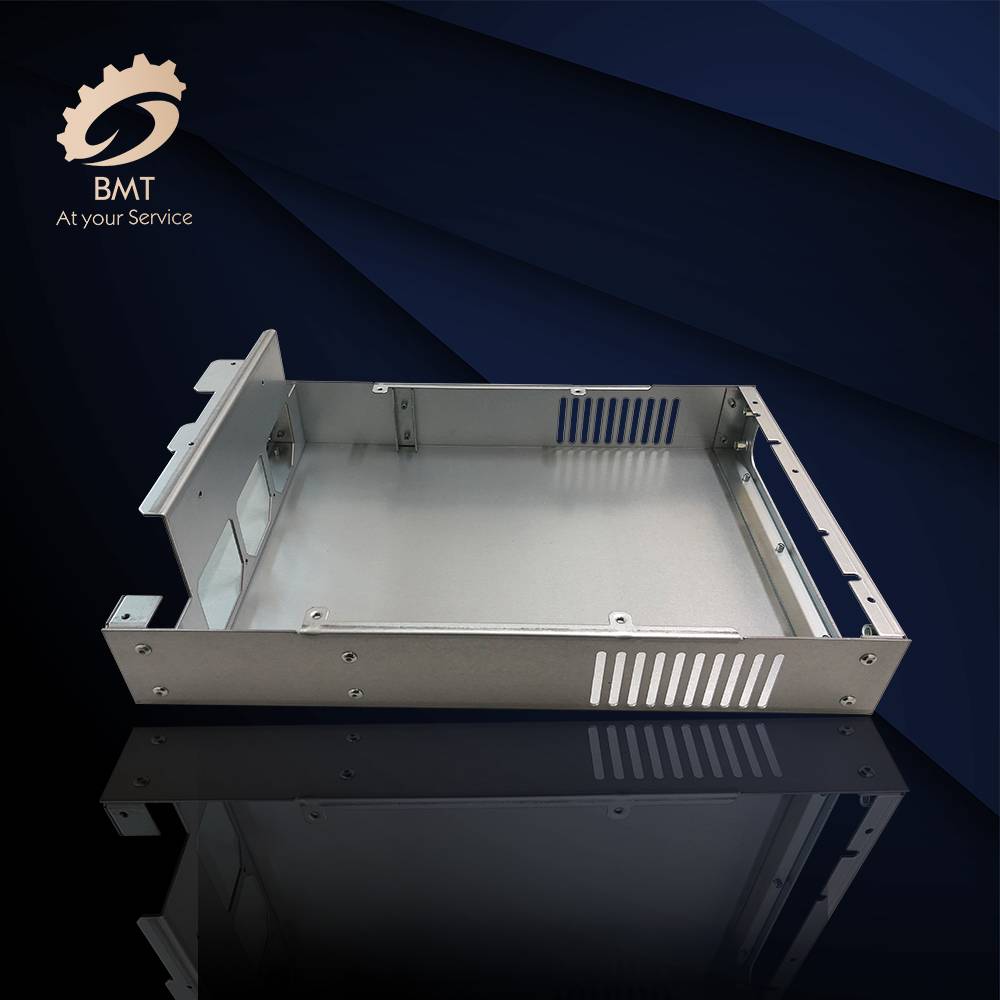

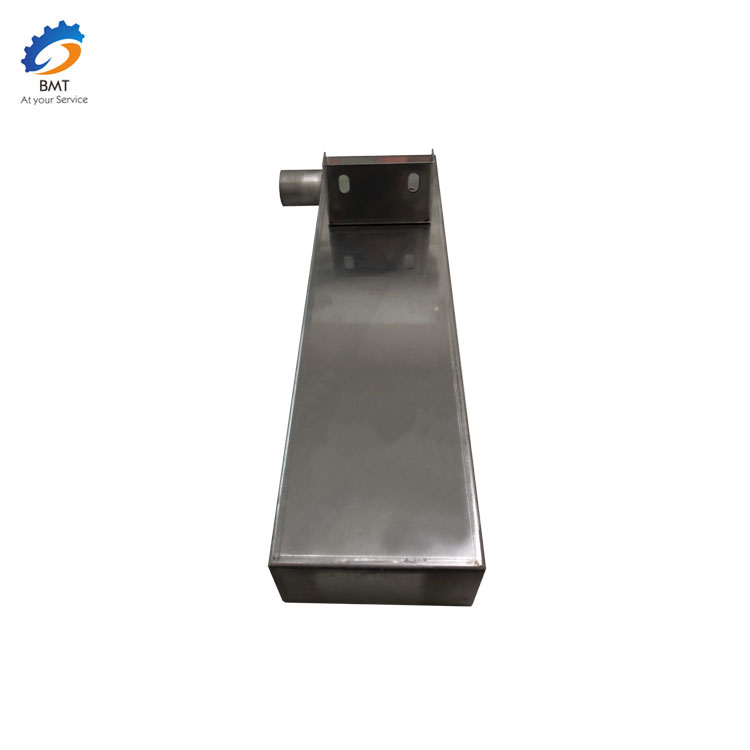

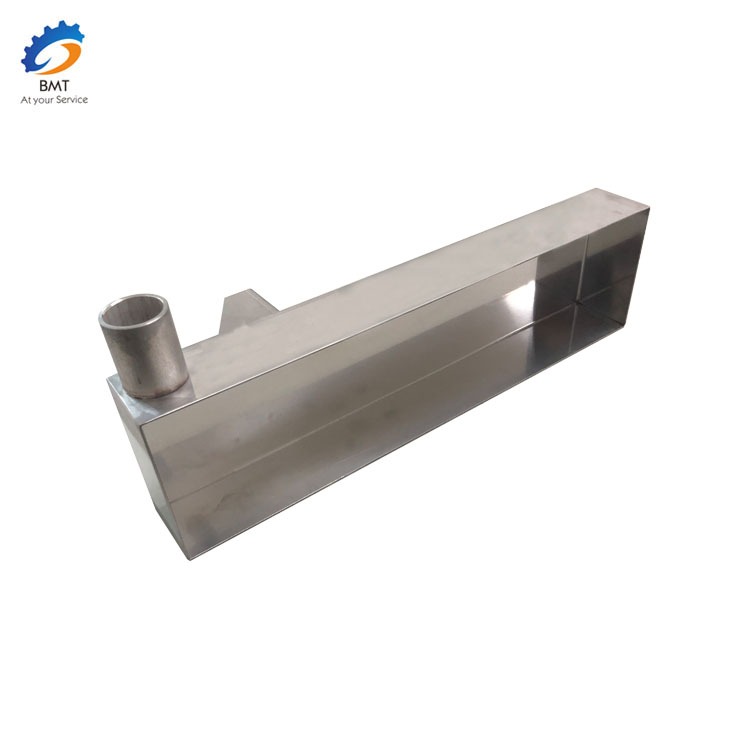

Ho ts'oana le ts'ebetso ea ho etsa, mesebetsi ea ho kobeha e etsa phetoho ea tataiso ka tšepe ea sheet. Ka mohlala, fetola lesela le sephara la tšepe hore e be letlapa la angular. Ha e le hantle, ka tšebeliso ea mochine oa khatiso oa CNC, hlobo, mochine o kobehang kapa mechine leha e le efe e meng, lesela la tšepe le ka fihla sebōpeho sa sekhutlo.

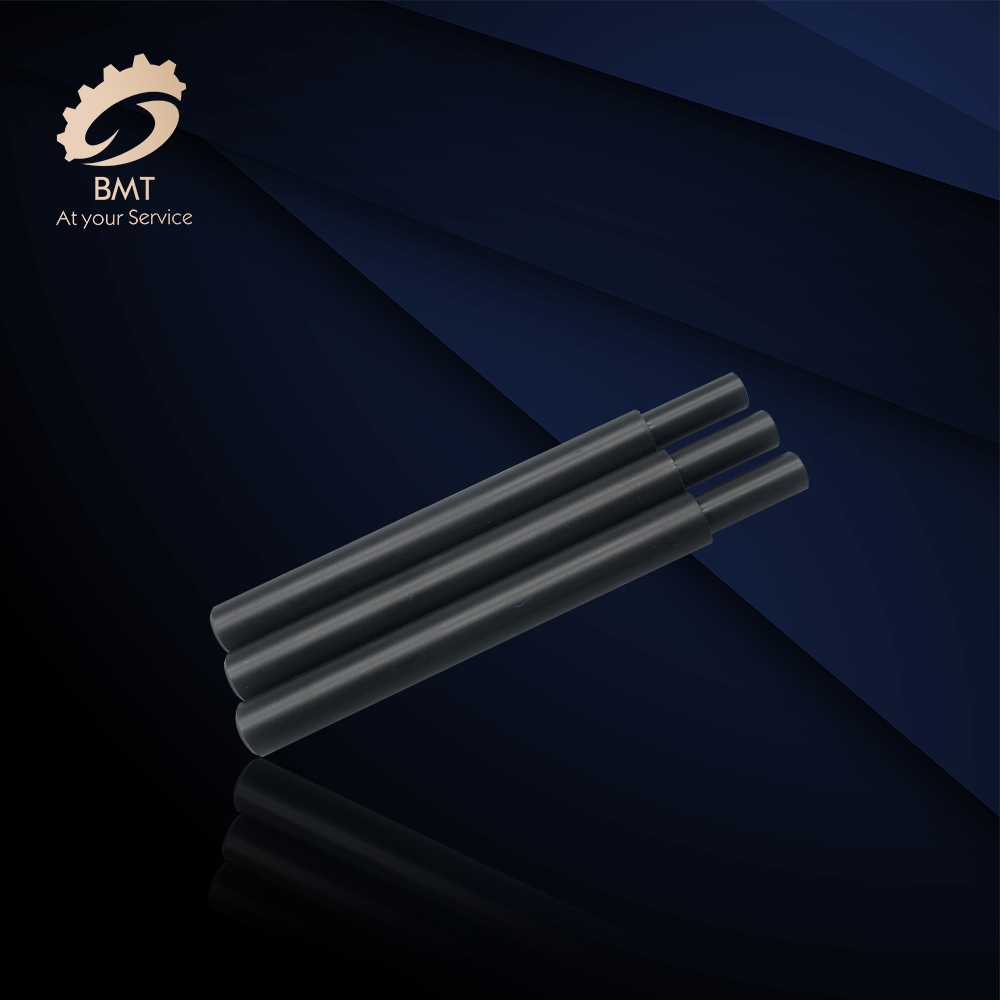

Lisebelisoa tsa tšepe tsa pampiri ke mokhoa o u lumellang hore u lemohe libopeho tse bonolo kapa tse rarahaneng haholo 'me li ka sebelisoa ka mefuta e mengata ea tšepe: ho tloha tšepe ho ea ho koporo, ho tloha ka koporo ho ea aluminium, ho tloha tšepe e sa hloekang ho ea ho li-alloys tse ling tse khethehileng.

Ha o hloka ho etsa qeto ea mofuta oa ho kobeha, o tlameha ho ela hloko: botenya ba tšepe, mofuta oa lekhalo, lehlakoreng la koba, litekanyo tsa workpiece le lintlha tse ling tse amanang le tsona.

Molao o akaretsang mabapi le sena e ka ba: e kholoanyane ke ho kobeha, tekanyo e tlase e matla lipakeng tsa hlobo e kaholimo le e tlase. Mabapi le litaba tseo re sa tsoa li bua, u ka khetha mefuta e fapaneng ea ho kobeha.

Ho na le lintlha tse ngata tse ka amang phello eaho kobeha ka lesela. Ka mohlala, tse bohlokoa ka ho fetisisa ke:

1. Thepa ea tšepe

2. Khatello e bakoang ke ts'ebetso e fetileng

3. Mofuta oa mahlakore ao u batlang ho a hlokomela

4. Bolelele le botenya ba karolo ea mosebetsi

5. Mocheso oa ho sebetsa

Ho na le melemo e mengata ea Sheet Metal Fabrication, ho kenyelletsa khetho ea thepa (Aluminium, Copper, Stainless Steel le tse ling), khetho ea ho qetela (Bead Blasting, Anodizing, Plating, Powder Coating, joalo-joalo), khetho ea botenya (Ho itšetlehile ka likhakanyo), durability, scalability, phetoho e potlakileng, joalo-joalo. Bakeng sa lintlha tse ling, ka kopo sheba chate e ka tlase.

| NO | LINTLHA | LITŠOANTŠISO |

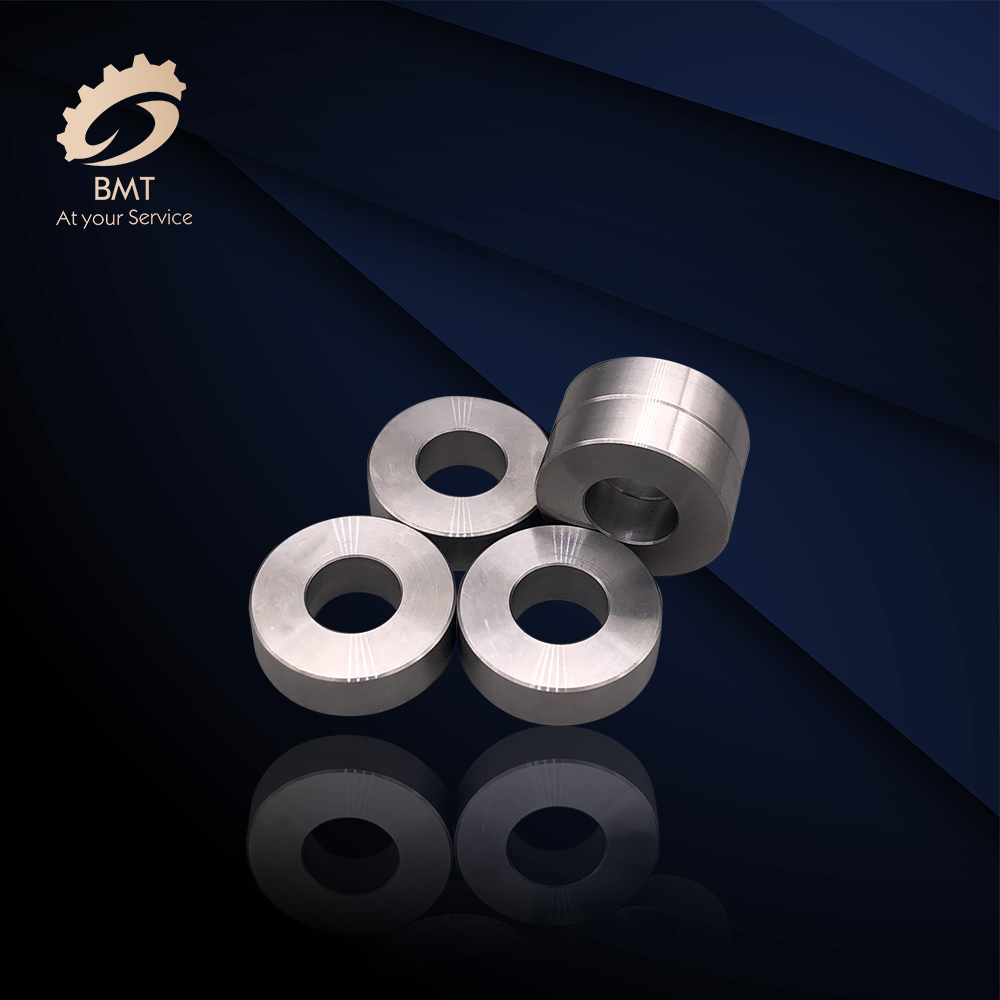

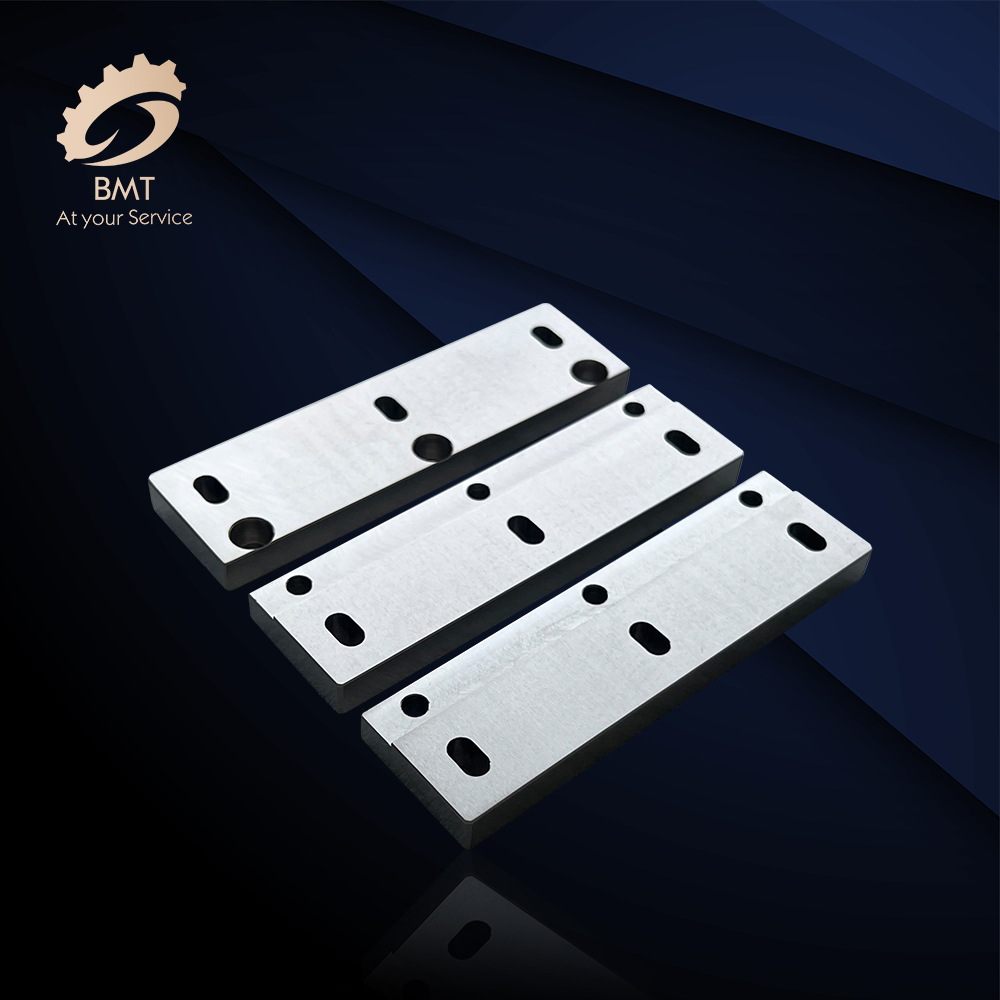

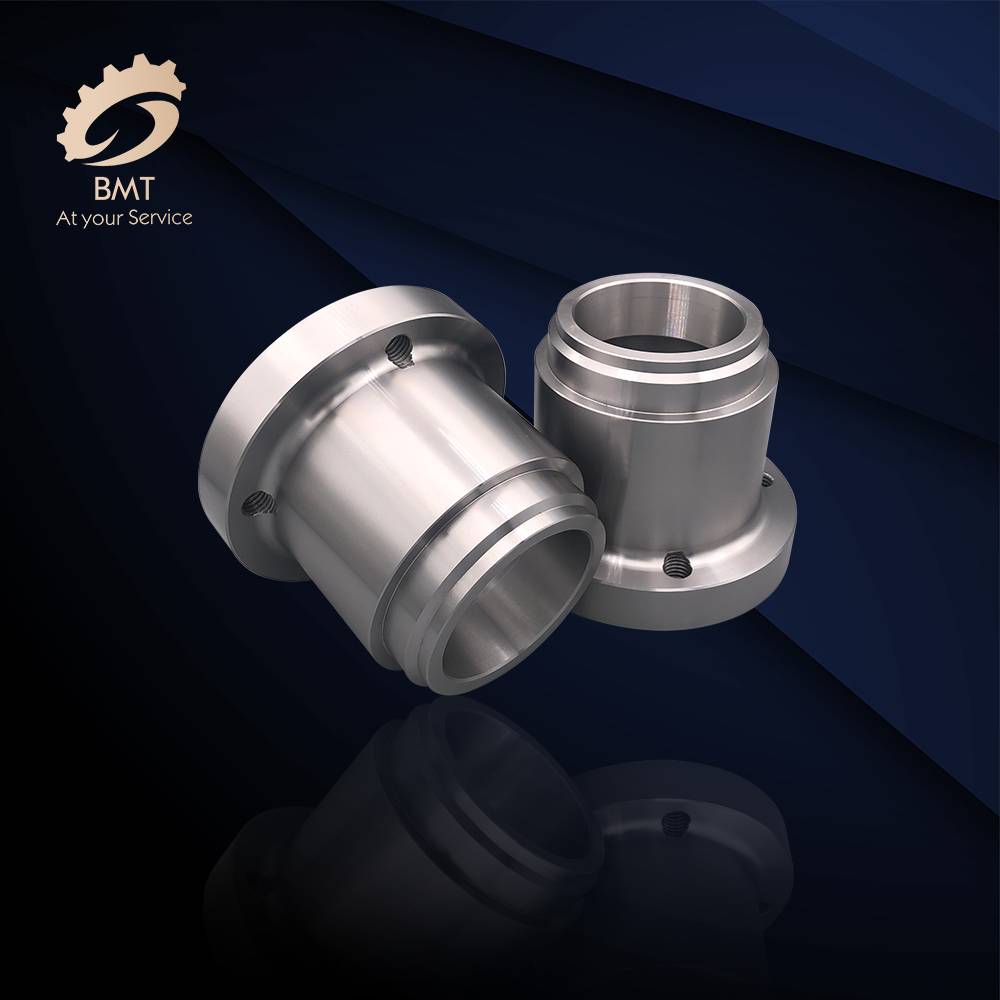

| 1 | Lintho tse bonahalang | Aluminium, tšepe, koporo, koporo, tšepe e sa hloekang, polasetiki, POM, Derlin, Titanium Alloy, joalo-joalo. |

| 2 | Kalafo ea Bokaholimo | Zinc plating, Anodization, Chemical film, Powder coating, Passivation, Lehlabathe le qhomisang, Brushing & polishing, joalo-joalo. |

| 3 | Lisebelisoa tsa ho sebetsa | Cnc Machining Center, CNC Lathe, Grinding Machine, Automatic Lathe Machine, Lathe Machine, Milling Machine, EDM, joalo-joalo. |

| 4 | Thepa ea ho Hlahloba | 3D CMM; Sesebelisoa sa ho metha sa litšoantšo tsa 2.5D, Rughness meter, slide caliper, micrometers, gauge block, dial indicator, thread gauge, universal angle rule, joalo-joalo. |

| 5 | Litšebeletso tsa Rōna | CNC Machining, Milling, Turning, Grinding, Stamping, Punching, le kopano, joalo-joalo. |

| 6 | Sistimi ea QC | Tlhahlobo ea 100% pele e romelloa, tlhahlobo ea Mokha oa Boraro e fumaneha ka kopo. |

| 7 | Ho paka | Foam, Carton, Mabokose a lehong, joalo ka litlhoko tse hlophisitsoeng. |

| 8 | Melao ea Tefo | 30% T / T esale pele, 70% e leka-lekaneng pele e romelloa. |

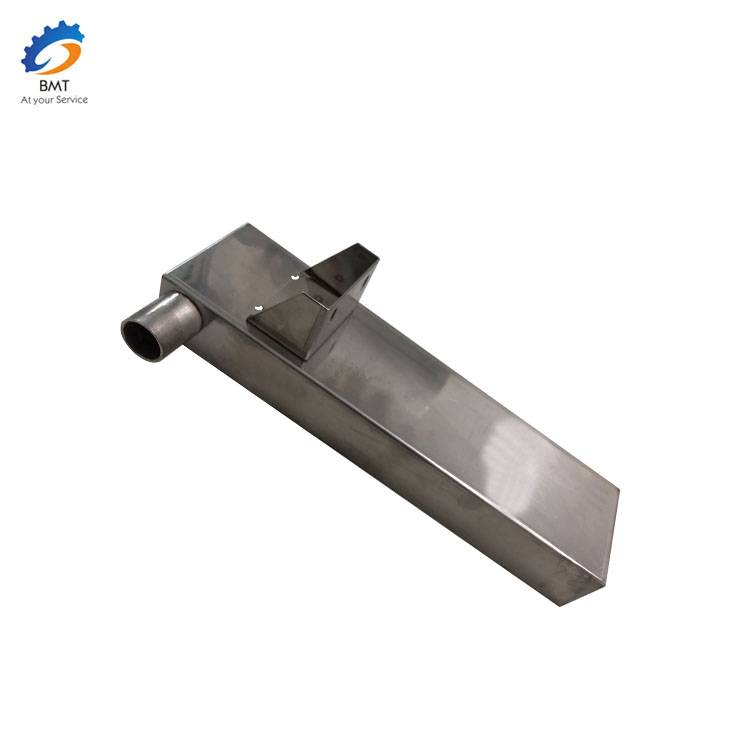

| 9 | Sebaka sa Sehlahisoa | Likarolo tsa CNC tsa machining / tse fetolang, Jig & Fixture Design le ho Etsa, Likarolo tsa Metal tsa Sheet le Likarolo tsa Setempe. |

| 10 | Kopo | Mochini oa othomathike, mochini oa indasteri, lisebelisoa tsa motlakase, Likarolo tsa Auto, Likarolo tsa Thepa, Likarolo tsa Mochini, Lisebelisoa tsa mabone, jj. |

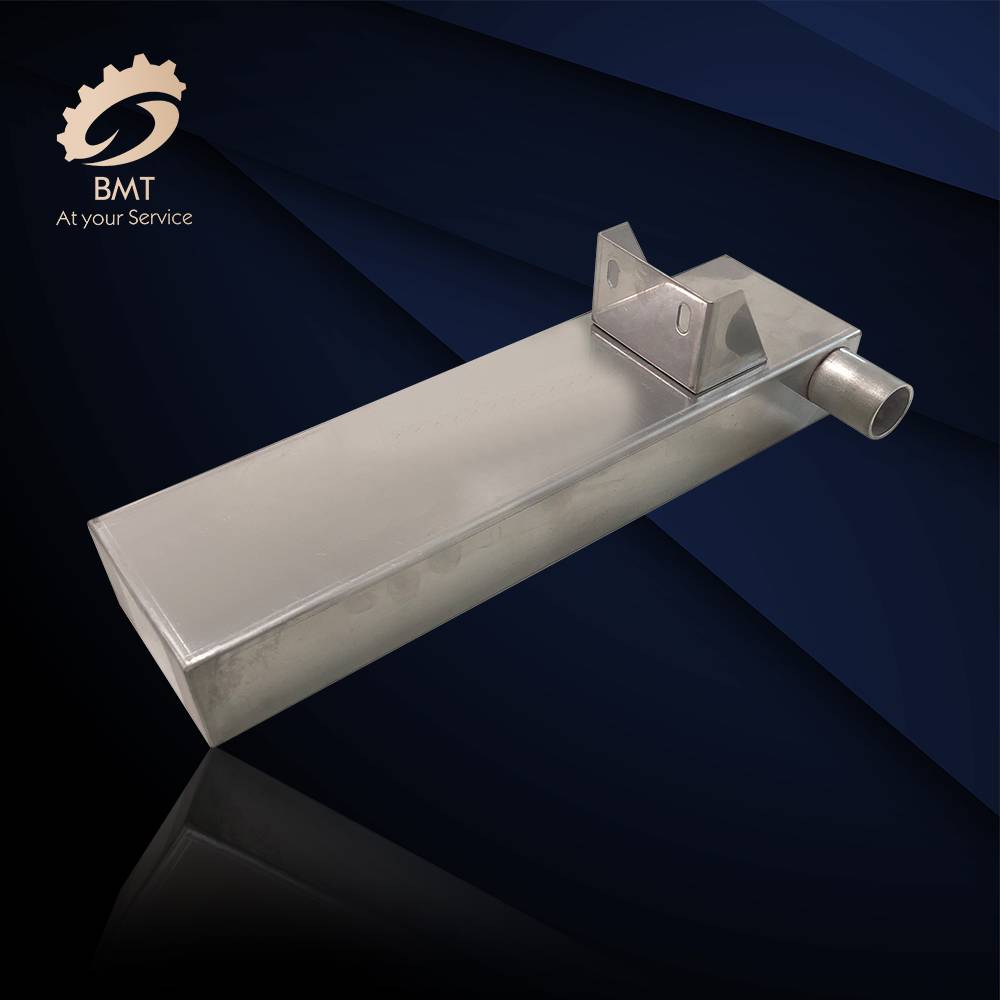

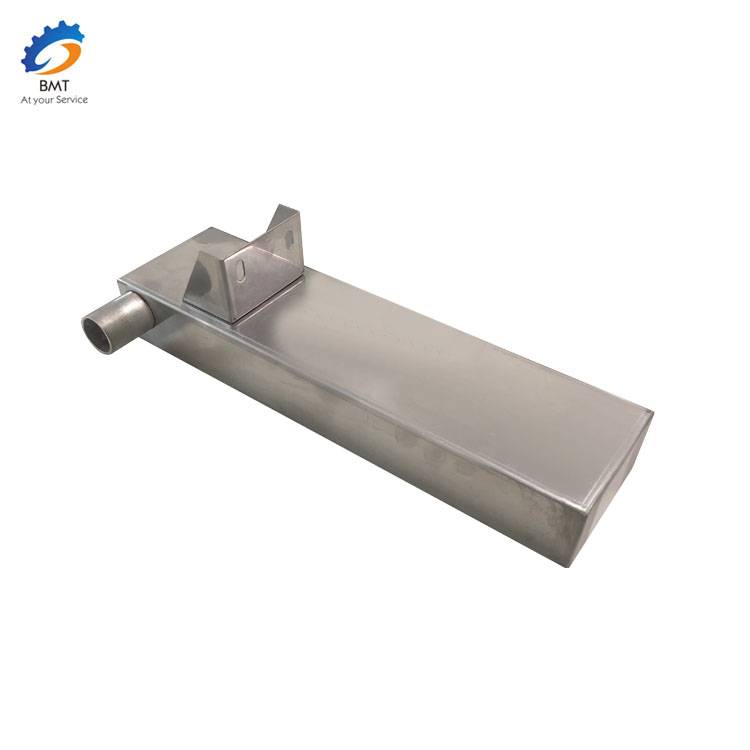

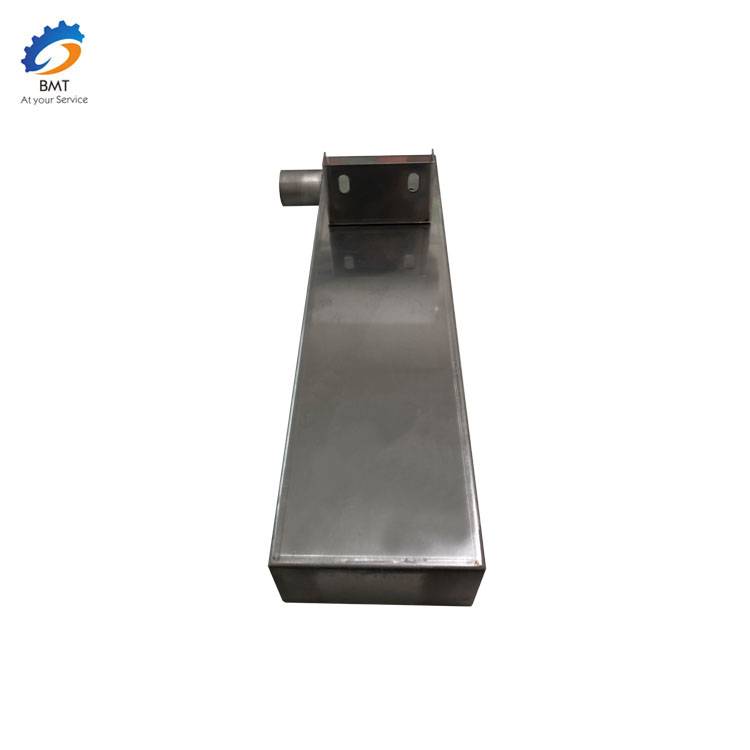

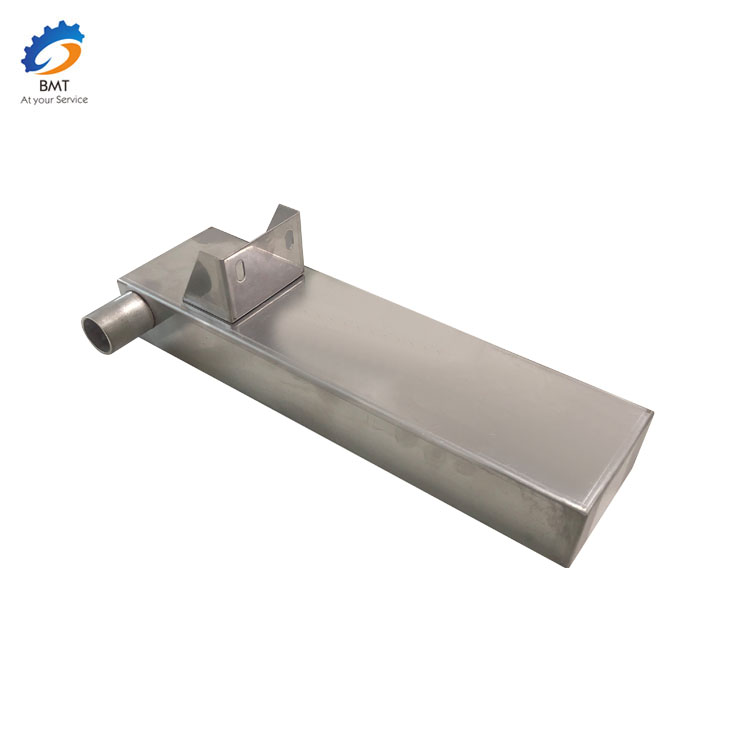

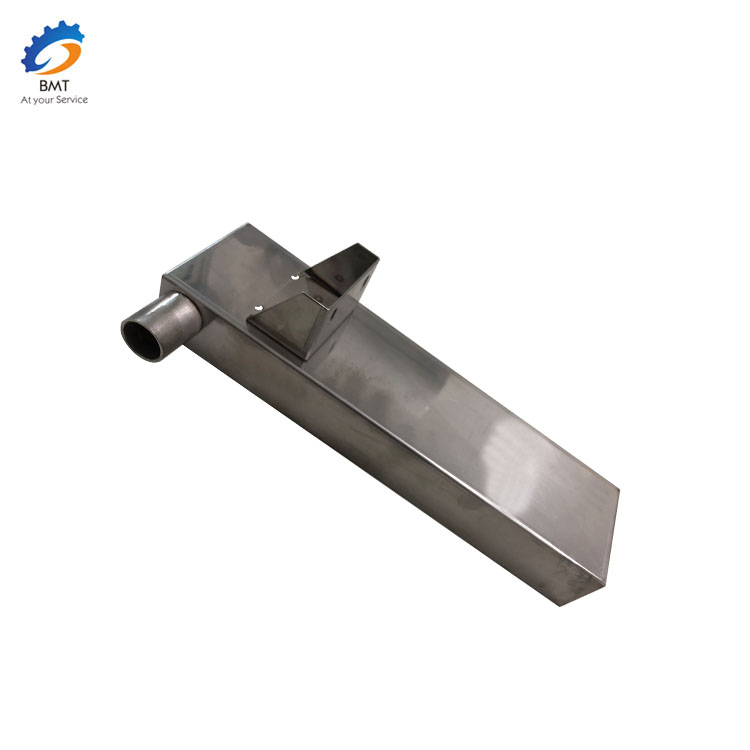

Tlhaloso ea Sehlahisoa

Lihlahisoa tse ling tseo re li Etsang