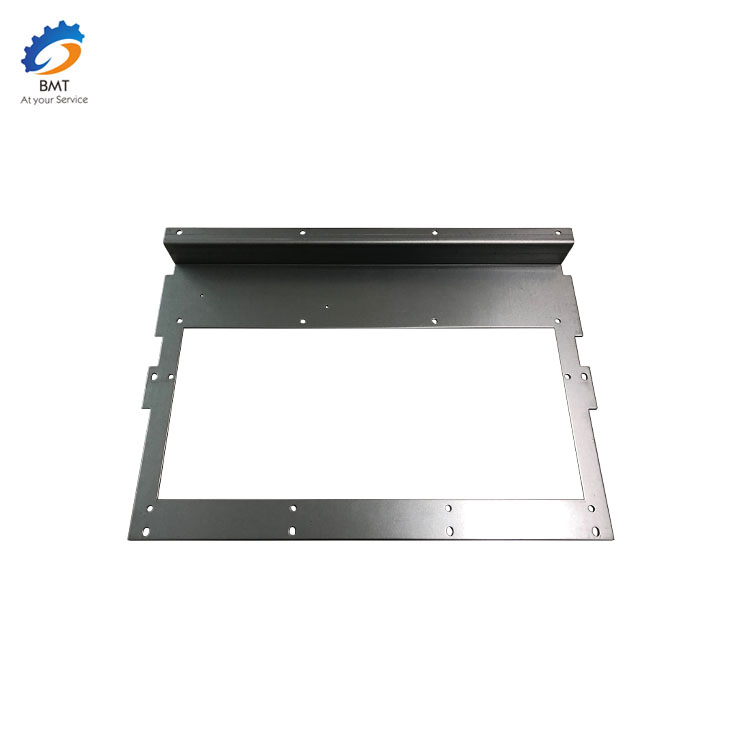

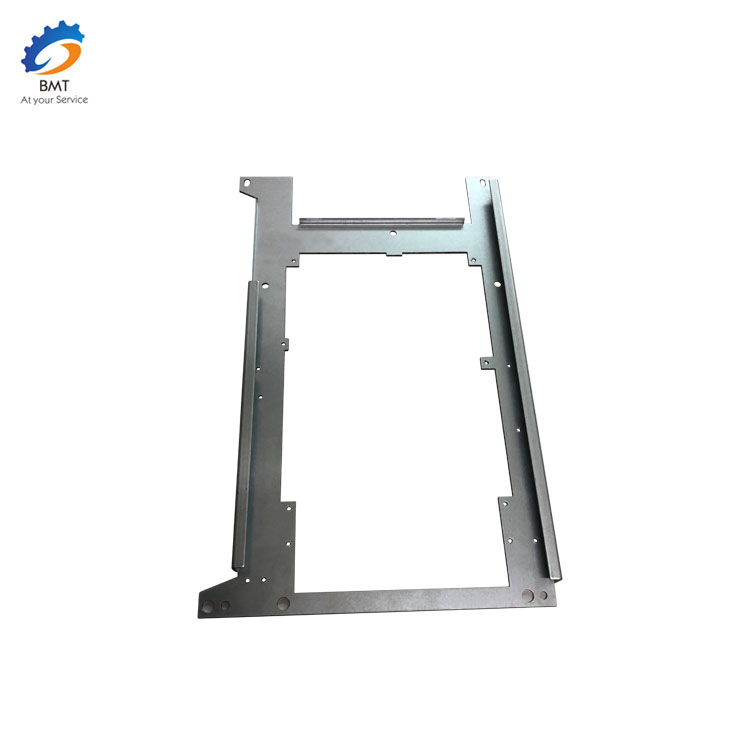

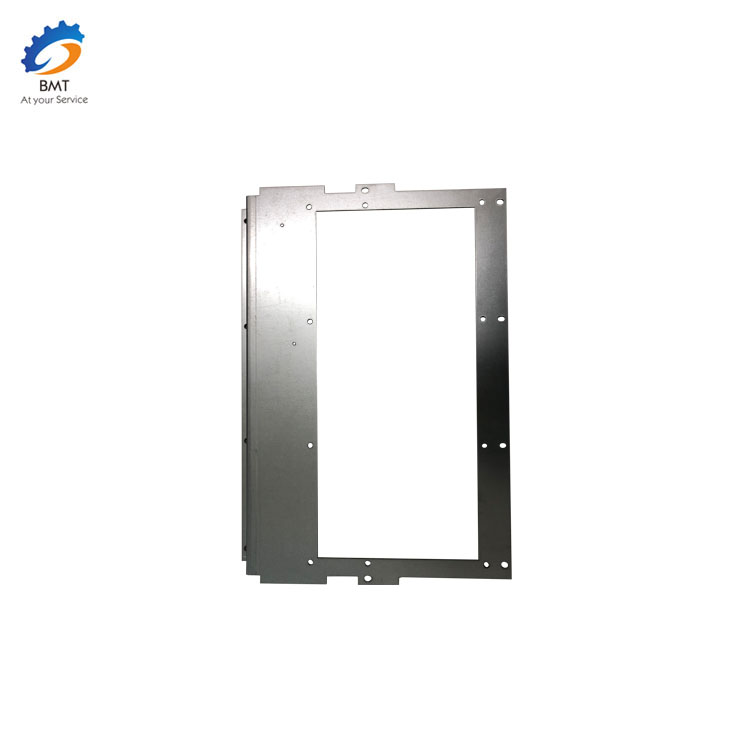

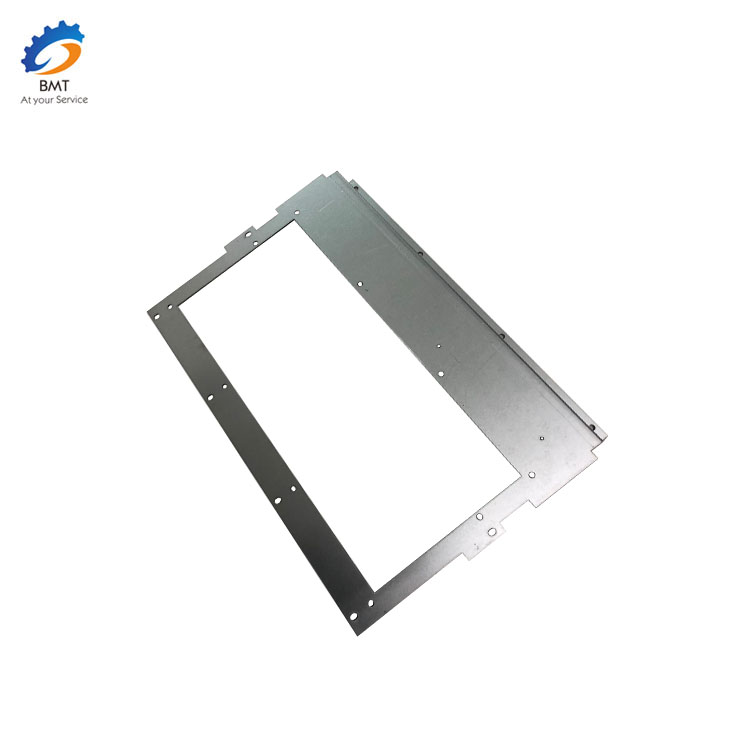

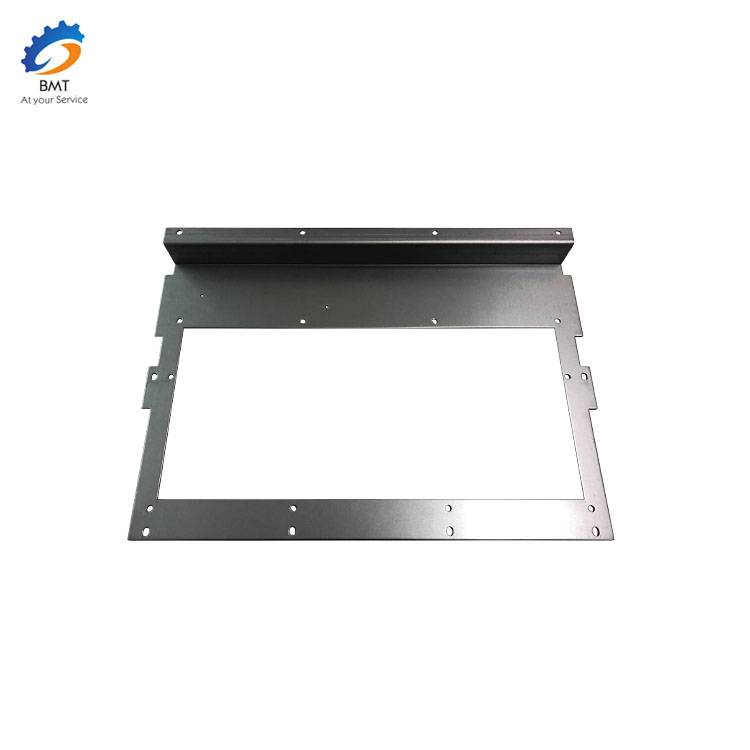

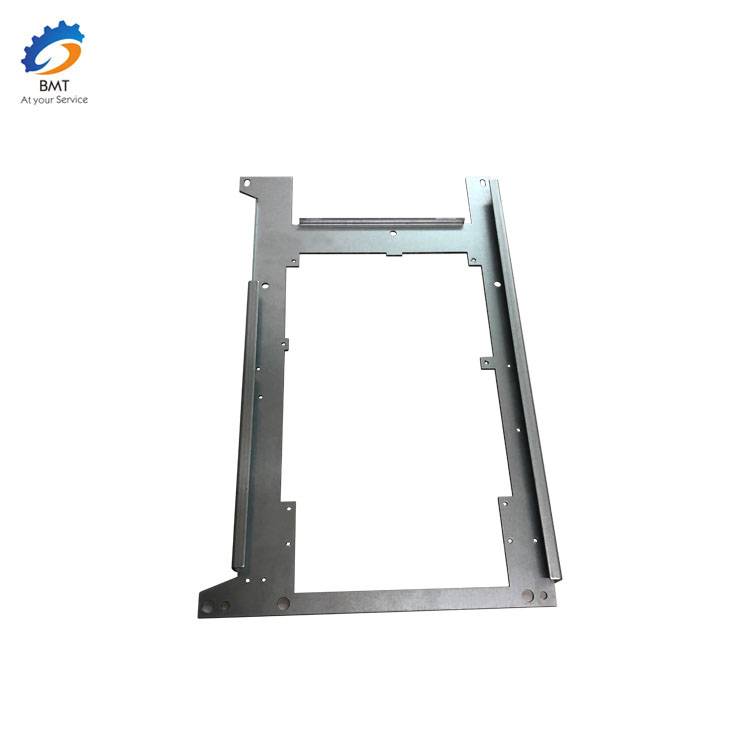

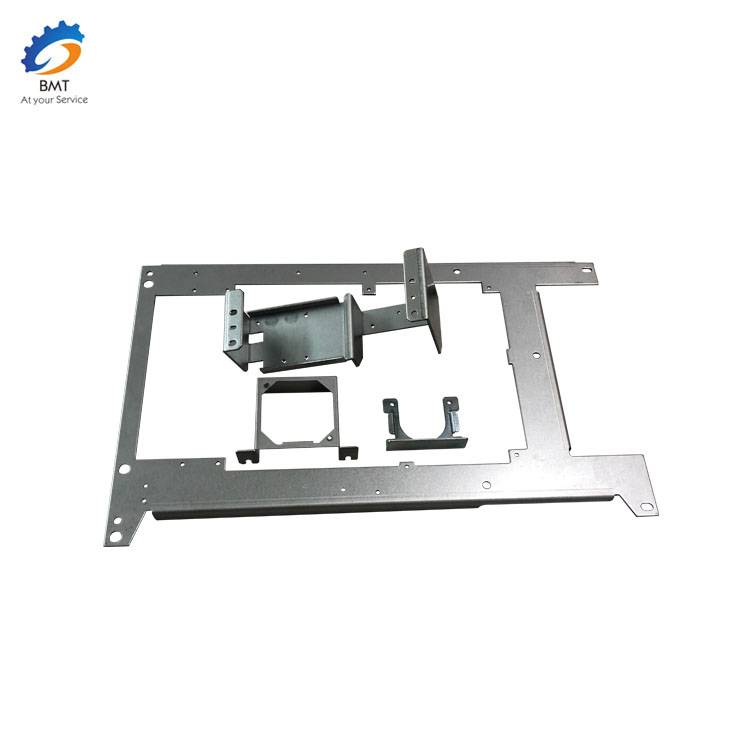

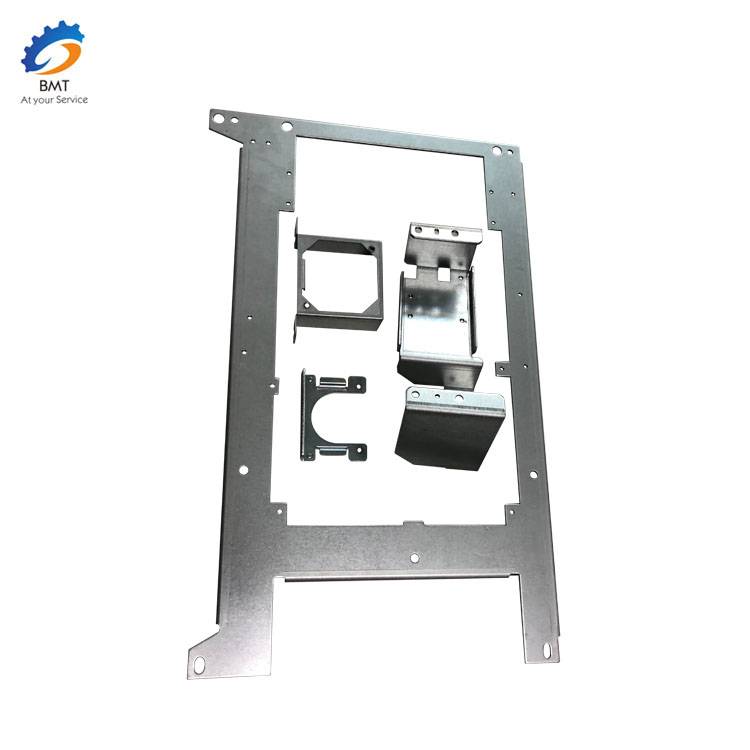

Mamello le ho Fabrication Tooling

Litlhoko tse thata tsa ho mamella

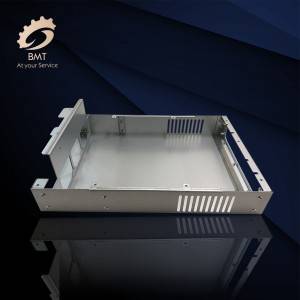

BMT e teng ho u thusa ho etsa khetho e nepahetseng bakeng sa masela a tšepe le ho nolofatsa moralo oa hau oa ho etsa. Re khoebong ho ba balekane ba hau ka mohato o mong le o mong oa nts'etsopele ea lihlahisoa le tlhahiso ea tloaelo. Ke uena feela ea lokelang ho re tšepa!

Maemong a mangata, litšenyehelo tsa thepa li nka karolo e kholo ea karolo ea letlapa la tšepe. Kahoo, ke habohlokoa ho khetha thepa e theko e tlaase tlas'a moralo oa hau o lumellang. Ka mohlala, aluminium e molemo ho feta thepa ea koporo. Ntle le moo, o hloka ho tseba hore boholo ba setoko bo theko e tlase haholo ho feta mefuta e meng ea lishiti tsa tšepe. Etsa bonnete ba hore u e etsa khetho ea pele nakong ea khetho ea thepa.

Pele ho tsohle, o hloka ho tseba hore likarolo tsohle tsa lakane li qala ho bata, ka hona, moralo oa karolo o hloka ho latela ka tekanyo e tloaelehileng bakeng sa likarolo tsohle. Leha ho le joalo, u khona ho ba le botenya bo fapaneng, empa u tlameha ho li kopanya, e leng se lebisang ho theko e phahameng.

Sebakeng sa bobeli, re hloka ho hlokomela hantle radius ea bend. Sebaka sa mosebetsi se tla ba le keketseho e kholo bakeng sa khatello ha radius ea bend e ntse e fokotseha, kahoo ho bohlokoa ho theha li-angles tse bonolo tse nang le radius e kholoanyane.

Qetellong, e nyenyane bakeng sa likoti, litšenyehelo li phahame nakong ea tsoelo-pele ea ho itšeha ka tšepe. Ntle le moo, e ka baka mathata a khopameng habonolo nakong ea ho itšeha. Kahoo, ho loketse ho boloka boholo ba ho ts'oara bo le boholo ho feta botenya ba lisebelisoa tsa tšepe.

Ka BMT Sheet tšepe e entsoeng ka tšepe, re na le tsamaiso e tiileng mabapi le lisebelisoa tsa masela le mamello, kaha re tseba ho mamellana ke karolo ea bohlokoa ka ho fetisisa bakeng sa ho sebetsa ka tšepe. Ka hona, ho bohlokoa haholo ho ela hloko lisebelisoa tsa ho lema. Ka kakaretso, karolo e rarahaneng e tla kopa lisebelisoa tse bolelang nako le litšenyehelo tse eketsehileng. Ka hona, ho eletsoa ho etsa moralo o bonolo o lumellang lisebelisoa tse tloaelehileng tsa brake tsa khatiso le lisebelisoa tse ling tse theko e tlase tse tloaelehileng.

Re mamela taolo ka botebo bakeng sa litlhoko tsa mamello ea bareki 'me re boloka mokhoa o tšoanang oa ho koba. Ho bua ka tloaelo, karolo ea tšepe e ka amohela mamello e hlephileng bakeng sa likarolo tse ngata, ke litekanyo tse 'maloa feela tse bohlokoa bakeng sa ts'ebetso. Ka ho amohela mamello e tlase, re ka ba le sekhahla se tlase sa sekoli le sekhahla se phahameng sa tlhahiso. Ka lebaka lena, re lokela ho bitsa feela mamello e tiileng bakeng sa likarolo tsa bohlokoa ho fokotsa litšenyehelo.

Ho phaella moo, re hloka ho tseba hore re tla hloka ho etsa phetoho haeba li-bends li sa etsoa ka tsela e le 'ngoe, e leng se bakang nako e eketsehileng ea tlhahiso le ho tlisa litšenyehelo ho latela. Ka lebaka lena, moqapi o lokela ho leka ho boloka li-bends tse tšoanang nakong ea moralo oa tsoelo-pele ea masela.

Tlhaloso ea Sehlahisoa