Lisebelisoa tsa Titanium le Titanium Alloy Forgings

Li-alloys tsa "titanium" le "titanium" li na le melemo ea khatello e tlase, matla a khethehileng a phahameng le ho hanyetsa kutu, 'me li sebelisoa haholo libakeng tse fapaneng.

Titanium forging ke mokhoa oa ho theha o sebelisang matla a kantle ho likheo tsa tšepe tsa titanium (Ho sa kenyeletsoe lipoleiti) ho hlahisa deformation ea polasetiki, ho fetola boholo, sebopeho le ho ntlafatsa ts'ebetso. E sebelisetsoa ho etsa likarolo tsa mochini, lisebelisoa, lisebelisoa kapa likheo. Ntle le moo, ho latela mokhoa oa motsamao oa selaete le mekhoa e otlolohileng le e otlolohileng ea selaete (bakeng sa ho theha likarolo tse tšesaane, ho tlotsa le ho pholisa, le ho theha likarolo tsa tlhahiso ea lebelo le holimo), likarolo tse ling tsa motsamao li ka eketsoa ka ho sebedisa sesebedisoa sa puseletso.

Mekhoa e kaholimo e fapane, 'me matla a hlokahalang a ho qhekella, ts'ebetso, sekhahla sa tšebeliso ea thepa, tlhahiso, mamello ea boholo, le mekhoa ea ho tlotsa le ho pholisa le eona e fapane. Lintlha tsena hape ke lintlha tse amang boemo ba automation.

Forging ke mokhoa oa ho sebelisa polasetiki ea tšepe ho fumana mokhoa oa ho etsa polasetiki o nang le sebopeho se itseng le thepa ea sebopeho sa sekheo tlas'a tšusumetso kapa khatello ea sesebelisoa. Bophahamo ba tlhahiso ea forging ke hore e ke ke ea fumana sebopeho sa likarolo tsa mochini feela, empa hape e ntlafatsa sebopeho sa kahare sa thepa le ho ntlafatsa thepa ea mochini ea likarolo tsa mochini.

1. Forging Free

Free forging ka kakaretso e etsoa pakeng tsa tse peli tse bataletseng dies kapa hlobo ntle le cavity. Lisebelisoa tse sebelisoang ho forging mahala li bonolo ka sebopeho, lia tenyetseha, li khuts'oane nakong ea tlhahiso le theko e tlase. Leha ho le joalo, matla a basebetsi a phahame, ts'ebetso e thata, tlhahiso e tlase, boleng ba ho forging ha bo phahame, 'me chelete ea ho sebetsa ea machining e kholo. Ka hona, e loketse feela ho sebelisoa ha ho se na litlhoko tse khethehileng mabapi le ts'ebetso ea likarolo le palo ea likotoana e nyenyane.

2. Open Die Forging (Die Forging with Burrs)

Sekheo se holofetse pakeng tsa li-module tse peli tse nang le li-cavities tse betliloeng, forging e koaletsoe ka har'a sekoti, 'me tšepe e feteletseng e tsoa ka lekhalo le moqotetsane pakeng tsa tse peli tse shoang, li etsa li-burrs ho pota-pota. Tlas'a khanyetso ea hlobo le li-burrs tse pota-potileng, tšepe e qobelloa ho hatelloa ka sebōpeho sa mokoti oa hlobo.

3. Closed Die Forging (Die Forging without Burrs)

Nakong ea ts'ebetso e koetsoeng ea lefu, ha ho na li-burrs tse pota-potileng tse ka lehlakoreng la motsamao oa lefu tse thehoang. Sekoti se koetsoeng se na le mesebetsi e 'meli: e' ngoe ke ea ho etsa sekheo, 'me e 'ngoe ke ea ho tataisa.

4. Extrusion Die Forging

Ho sebelisoa mokhoa oa extrusion bakeng sa ho forging, ho na le mefuta e 'meli ea ho forging, extrusion pele le reverse extrusion. Extrusion die forging e ka etsa likarolo tse fapaneng tse se nang letho le tse tiileng, 'me e ka fumana forgings ka mokhoa o nepahetseng oa boemo bo phahameng ba geometri le sebopeho sa kahare se teteaneng.

5. Multi-Directional Die Forging

E etsoa ka mochini oa forging o nang le likarolo tse ngata. Ntle le ente e otlolohileng le ea plug, mochini oa forging oa multidirectional o boetse o na le li-plungers tse peli tse otlolohileng. Ejector ea eona e ka boela ea sebelisoa bakeng sa ho phunya. Khatello ea ejector e phahame ho feta ea mochine o tloaelehileng oa hydraulic. Ho ba moholo. Ka mekhoa e mengata ea li-die forging, slide e sebetsa ka mokhoa o fapaneng le ka kopanelo holim'a sesebedisoa ho tloha litseleng tse otlolohileng le tse rapameng, 'me ho sebelisoa litebele tse le 'ngoe kapa ho feta ho etsa hore tšepe e phalle ka ntle ho tloha bohareng ba sekoti ho finyella sepheo sa ho tlatsa. lesoba.

6. Arohane Forging

Bakeng sa ho theha li-forging tse kholo khatellong e teng ea hydraulic, mekhoa ea ho etsa likarolo tse kang karolo ea "die forging" le "shim plate die forging" e ka sebelisoa. Tšobotsi ea mokhoa oa ho etsa karolo ea lefu ke ho sebetsana le sekhechana sa forging ka sengoathoana, ho sebetsana le karolo e le 'ngoe ka nako, kahoo thepa e hlokahalang ea tonnage e ka ba nyenyane haholo. Ha re bua ka kakaretso, mokhoa ona o ka sebelisoa ho sebetsana le li-forging tse kholo ho feta mecheng ea boholo bo bohareng ea hydraulic.

7. Isothermal Die Forging

Pele ho forging, hlobo e futhumetse ho mocheso oa forging oa letho, 'me mocheso oa hlobo le sekoti o lula o tšoana nakong eohle ea ts'ebetso ea forging, e le hore ho ka fumanoa palo e kholo ea deformation tlas'a ketso ea matla a fokolang a deformation. . Isothermal die forging le isothermal superplastic die forging li tšoana haholo, phapang ke hore pele lefu la forging, sekheo se hloka ho ba superplasticized [i] ho etsa hore e be le lithollo tse lekanang [ii].

Titanium alloy forging process e sebelisoa haholo indastering ea lifofane le lifofane (Isothermal Die Forging Processe sebelisitsoe ho hlahisa likarolo tsa enjene le likarolo tsa sebopeho sa lifofane), 'me e ntse e tsebahala haholo makaleng a indasteri a kang likoloi, matla a motlakase le likepe.

Hona joale, litšenyehelo tsa tšebeliso ea thepa ea titanium li batla li phahame, 'me masimo a mangata a baahi ha a e-s'o hlokomele ka botlalo botle ba li-alloys tsa titanium. Ka tsoelo-pele e tsoelang pele ea saense, ho lokisoa ha theknoloji ea lihlahisoa tsa titanium le titanium alloy ho tla ba bonolo haholoanyane 'me litšenyehelo tsa ho sebetsa li tla fokotseha,' me botle ba lihlahisoa tsa titanium le titanium alloy bo tla totobatsoa likarolong tse ngata tse fapaneng.

Using extrusion mokhoa bakeng sa die forging, ho na le mefuta e 'meli ea forging, Forward Extrusion le Reverse Extrusion. Extrusion Die Forging e ka etsa likarolo tse fapaneng tse se nang letho le tse tiileng, 'me e ka fumana lifeme ka nepo e phahameng ea geometrical le sebopeho sa kahare se teteaneng.

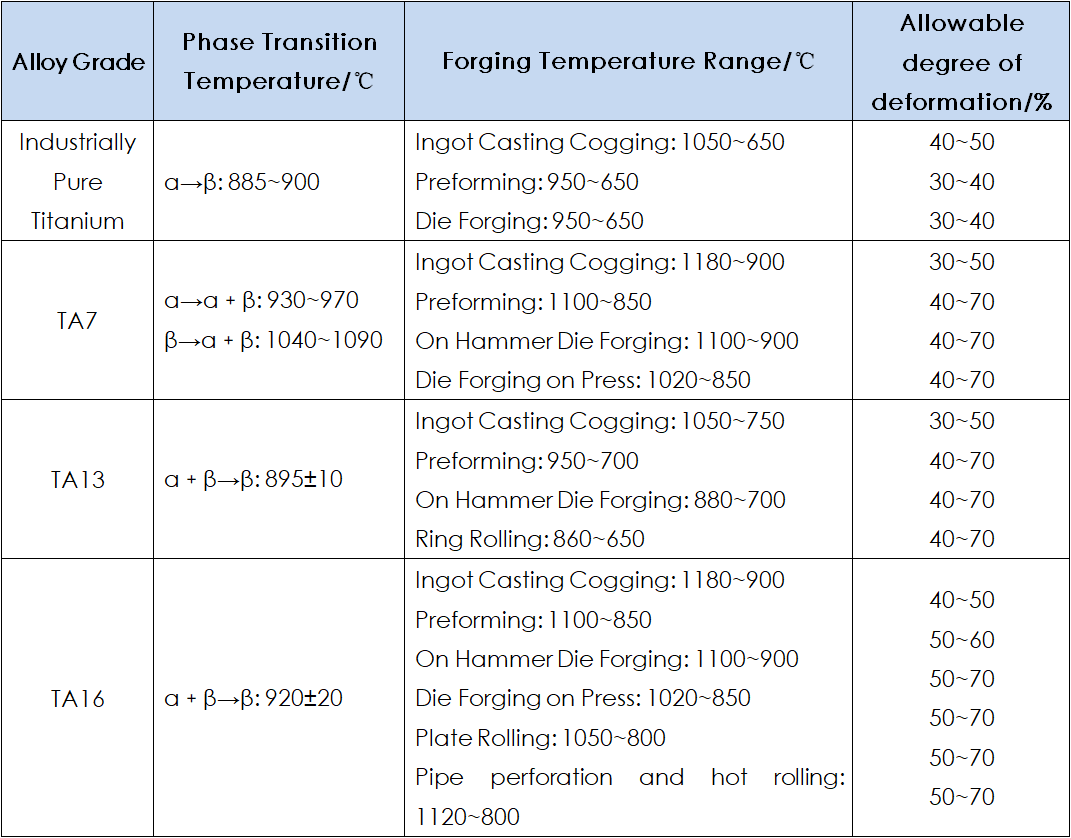

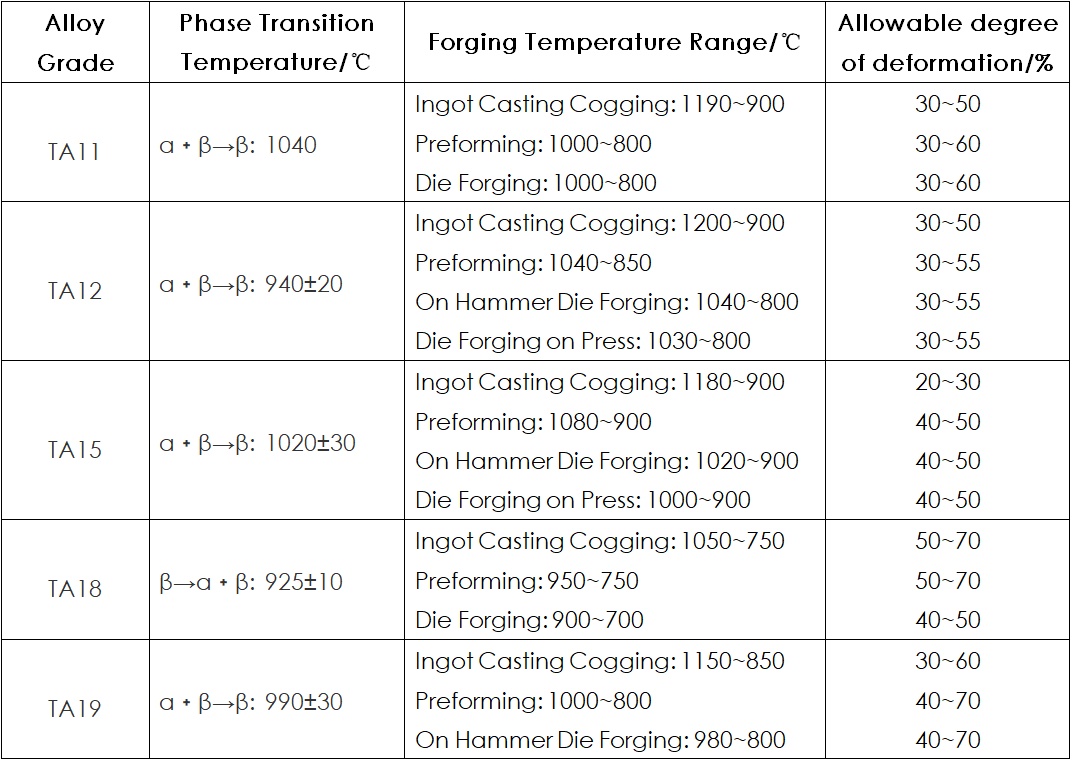

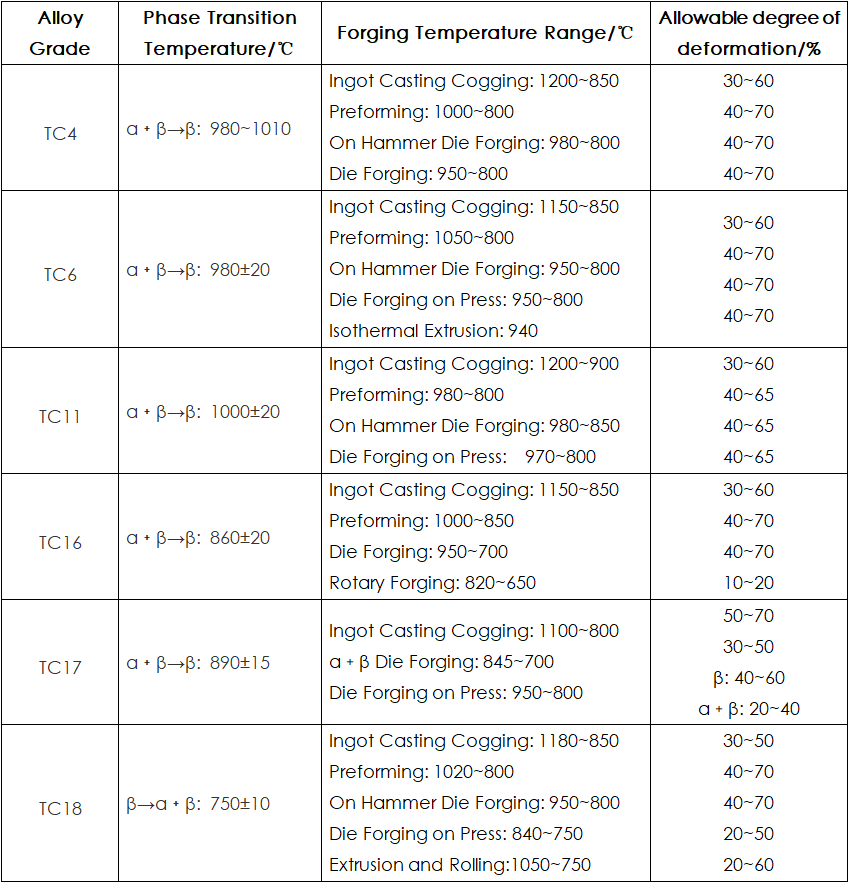

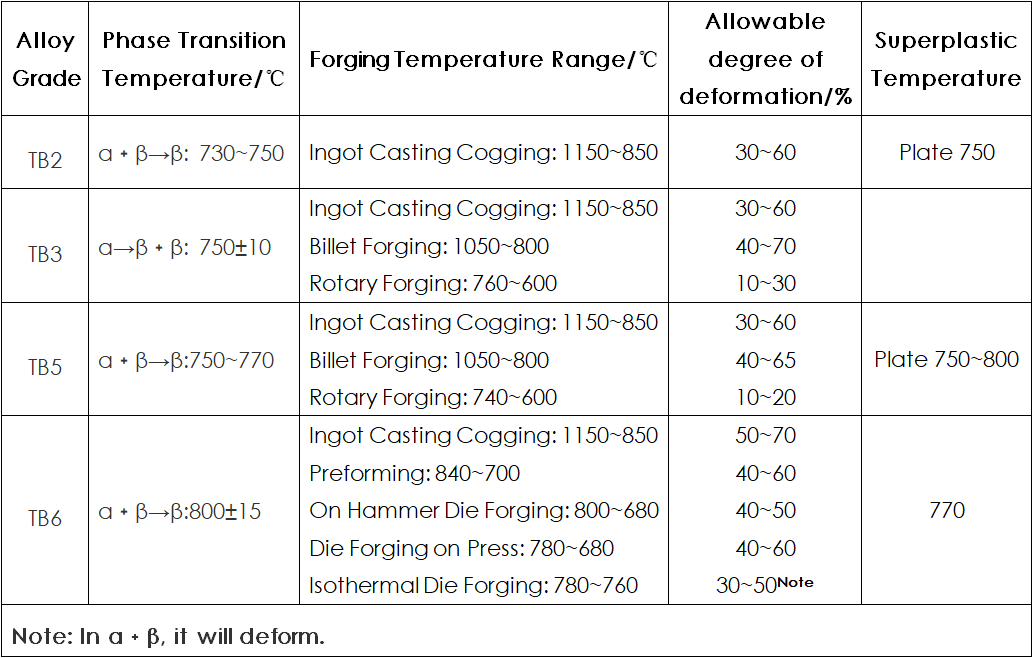

Ho ea ka lipatlisiso tsa khopolo-taba le phihlelo ea tlhahiso ea fektheri, lintlha tsa ts'ebetso ea ts'ebetso ea α-mofuta, mofuta o haufi-α, mofuta oa α﹢β-le mefuta e haufi-ufi ea mofuta oa titanium alloys e akaretsoa ho Lethathamo la 1 ho ea ho Lethathamo la 4, ka ho latellana.

Ho tloha ho data ho Lethathamo la 1 ho ea ho Lethathamo la 4, ho ka bonoa hore mocheso oa billeting oa li-ingots tse ngata tsa titanium alloy o pakeng tsa 1150 ° C ho isa ho 1200 ° C, 'me mocheso oa pele oa ho qapa oa li-ingots tse ling tsa titanium alloy o sebakeng se fapaneng. ea 1050°C ho isa ho 1100°C; Libaka tsena tse peli tsa mocheso ka bobeli li sebakeng sa β phase, 'me ea pele e phahame ho feta mocheso oa phetoho ea mohato ka mabaka a mangata.

Taba ea pele, alloy e na le sebopeho se phahameng le khanyetso e tlase ea deformation sebakeng sa β phase. E le ho ikitlaelletsa ho qeta nako e telele, Ho molemo ho ntlafatsa tlhahiso; ea bobeli, billet bakeng sa ingot blooming e haholo-holo e fanoa e le sekheo bakeng sa ho forging. Ka mor'a ho theha ka tekanyo e kholo ea deformation, mohaho o ka ntlafatsoa ntle le ho ama ts'ebetso ea ho qhekella. Ka hona, ho khethoa mokhoa o nang le tlhahiso e phahameng.

Ho tloha ho data ho Lethathamo la 1 ho ea ho Lethathamo la 4, ho ka bonoa hore mocheso oa pele oa ho forging oa "die forging" mochineng oa khatiso ha o fokotsehe haholo ho feta mocheso oa pele oa "ingot billet", empa hape o tlase ho feta mocheso oa phetoho ea α / β. ka 30 ℃ ~ 50 ℃. Boholo ba titanium Mocheso oa "die forging" oa alloy o maemong a 930 ℃ ~ 970 ℃, e leng ho netefatsa deformation sebakeng sa α﹢β ho fumana microstructure e hlokahalang le thepa ea forging. Kaha forging hamore die forging e hloka lithupa tse ngata 'me nako ea ts'ebetso e telele, mocheso oa mocheso oa "die forging heat of the forgings" o ka eketsoa ka mokhoa o nepahetseng ka 10 ℃ ~ 20 ℃ ho feta oa mochini oa khatiso. Leha ho le joalo, molemong oa ho etsa bonnete ba hore sebopeho le thepa ea mochini oa titanium alloy e felile, Ka hona, mocheso oa ho qetela oa mokhoa oa ho forging o lokela ho laoloa sebakeng sa α﹢β sa mekhahlelo e 'meli.

Ho ka bonoa hape ho tsoa ho data ho Lethathamo la 1 ho ea ho Lethathamo la 4 hore mocheso oa pele oa ho forging oa li-preform tse ngata tsa titanium alloy o phahame hanyane kapa o haufi le mocheso oa phetoho ea mohato. Mocheso oa pele oa α/β oa mokhoa oa phetoho o kang preforming o tlase ho feta mocheso oa lipalesa oa ingot, 'me o phahame ho feta mocheso oa pele oa forging oa die forging. Deformation sebakeng sena sa mocheso ha e hlokomele tlhahiso feela, empa hape e lokisetsa sebopeho se setle bakeng sa ho qapa.

Letlapa la 1 Ho theha data ea ts'ebetso ea mofuta oa α-titanium

Letlapa la 2 Ho theha data ea ts'ebetso ea ts'ebetso ea haufi le α-mofuta oa titanium alloy

Letlapa la 3 Ho theha data ea ts'ebetso ea α﹢β motsoako oa titanium

Letlapa la 4 Ho theha data ea ts'ebetso ea ts'ebetso ea haufi le mofuta oa β-titanium alloy

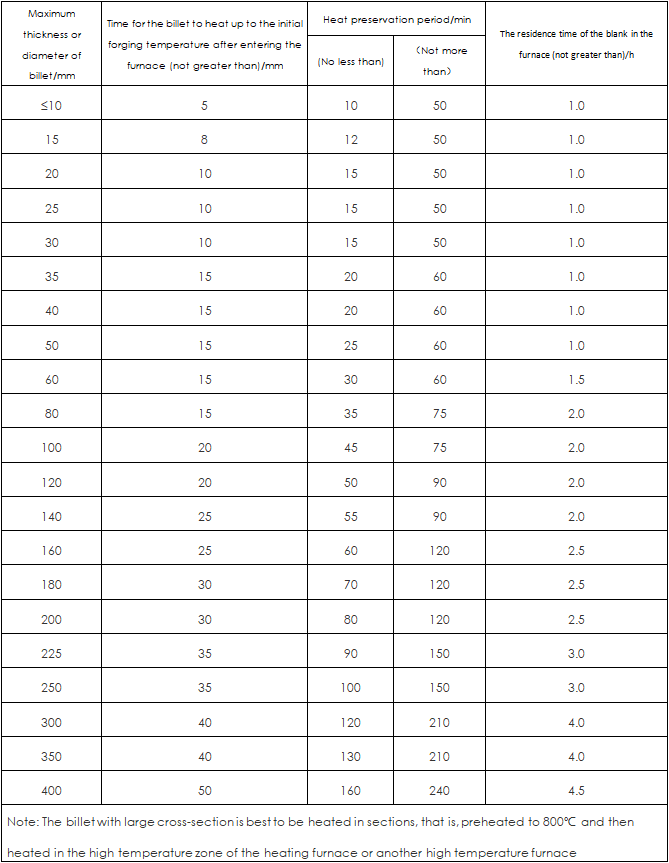

Letlapa la 5 Ho futhumatsa le ho tšoara nako ea likheo tsa motsoako oa titanium

BMT e ipapisitse le ho hlahisa premium titanium forging le titanium alloy forging e nang le bokhoni bo botle ba mochini, ho tiea, ho hanyetsa kutu, letsoalo le tlase le matla a holimo. Tlhahiso e tloaelehileng ea lihlahisoa tsa BMT tsa titanium le mokhoa oa ho lemoha o hlotse ho rarahana ha theknoloji le bothata ba machining ba tlhahiso ea ho etsa titanium.

Tlhahiso ea boleng bo holimo ea titanium e ipapisitse le moralo oa ts'ebetso le mokhoa o tsoelang pele butle butle. BMT titanium forging e ka sebelisoa ho tloha mohahong o monyane oa skeleton ho isa ho boholo bo boholo ba titanium forging bakeng sa lifofane.

BMT forgings titanium e sebelisoa haholo liindastering tse ngata, tse kang sefofane, boenjiniere ba lebōpong la leoatle, oli le khase, lipapali, lijo, koloi, joalo-joalo. Matla a rona a selemo a tlhahiso ea selemo a fihla ho lithane tse 10,000.

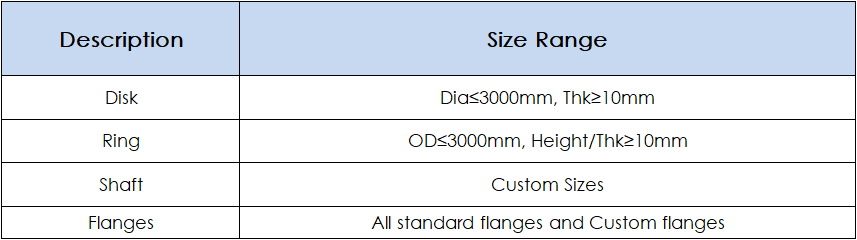

Boholo ba mefuta:

Lintho Tse Fumanehang Moetso oa Lik'hemik'hale

Lintho Tse Fumanehang Moetso oa Lik'hemik'hale

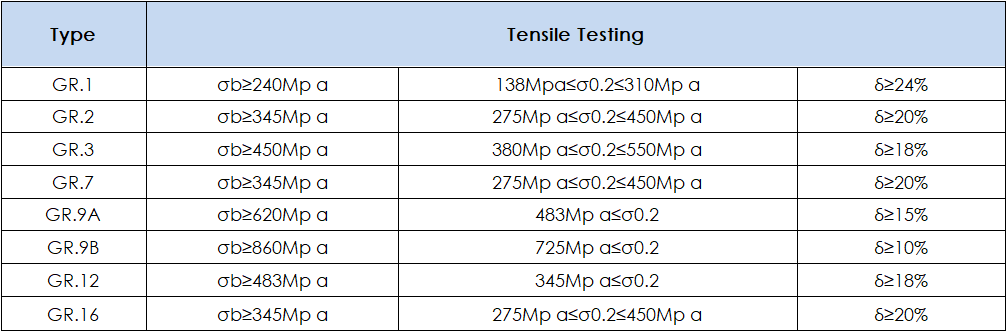

Tlhahlobo ea tlhahlobo:

- Tlhahlobo ea Sebopeho sa Lik'hemik'hale

- Teko ea Thepa ea Mechini

- Teko ea Teko

- Flaring Test

- Teko e bataletseng

- Teko ea ho Koba

- Teko ea Hydro-Static

- Teko ea Pneumatic (Teko ea khatello ea moea tlas'a metsi)

- Tlhahlobo ea NDT

- Teko ea Eddy-Hajoale

- Tlhahlobo ea Ultrasonic

- Tlhahlobo ea LDP

- Teko ea Ferroxyl

Tlhahiso (Boholo le Bonyane Bongata ba Order):E se nang moeli, ho latela taelo.

Lead time:Nako ea ho tsamaisa ka kakaretso ke matsatsi a 30. Leha ho le joalo, ho itšetlehile ka palo ea taelo ka mokhoa o nepahetseng.

Lipalangoang:Mokhoa o akaretsang oa lipalangoang ke ka Leoatle, ka Moea, ka Express, ka Terene, e tla khethoa ke bareki.

Ho paka:

- Pipe e qetella e sirelelitsoe ka li-caps tsa polasetiki kapa tsa cardboard.

- Lisebelisoa tsohle li lokela ho paka ho sireletsa lipheletsong le ho shebana.

- Thepa e 'ngoe kaofela e tla tlatsoa ka liphaephe tsa foam le mekotla ea polasetiki e amanang le eona.

- Patsi efe kapa efe e sebelisetsoang ho paka e tlameha ho ba e loketseng ho thibela tšilafalo ka ho kopana le lisebelisoa tsa ho tšoara.