Letlapa la Titanium, Sheet le Coil

Ts'ebetso ea Tlhahiso ea Letlapa la Titanium

Hot Forging Mokhoa oa ho qhekella oo tšepe e nchafatsoang ka holim'a mocheso.Hot rolling/ Boemo ba ho thetheha ka dithempereichara ka hodimo ho recrystallization.Cold rolling process eo ho eona mocheso oa polasetiki oa deformation o tlase ho feta mocheso oa ho hlaphoheloa.

Annealing: Mokhoa oo ho oona litšepe li futhumatsoang butle ho mocheso o itseng, ka nako e lekaneng, ebe li pholile (hangata butle, ka linako tse ling li laoloa) ka tekanyo e loketseng.

Pickling: Kenya sehlahisoa ka tharollo e nang le metsi, e kang sulfuric acid, ho tlosa li-oxide le lifilimi tse ling tse tšesaane holim'a tšepe ea tšepe.

Litšobotsi tsa poleiti ea titanium

1. Letlapa la peo ea Titanium ke filimi e nang le oxidized holim'a metsi, e lekanang le moemeli o motle oa ho arohana ha moriri. Tšebeliso ea poleiti ea peō ea titanium e boloka moemeli oa karohano, e etsa hore poleiti e be bonolo ho ebola, e felisa ts'ebetso ea pele ea ho lokisa letlapa la peo, 'me poleiti ea peō ea titanium e bobebe ho feta poleiti ea peo ea koporo.

2. Bophelo ba ts'ebeletso ea poleiti ea peo ea titanium bo feta makhetlo a 3 ho feta ea poleiti ea peo ea koporo, e ka fihlang lilemo tse 10 ho isa ho tse 20 ho latela maemo a ts'ebetso.

3. Electrolytic koporo e entsoeng ka poleiti ea peo ea titanium e na le sebopeho sa kristale e kopaneng, bokaholimo bo boreleli le boleng bo holimo.

4. Hobane poleiti ea titanium ha e hloke ho koaheloa ka moemeli oa karohano, e ka qoba tšilafalo ea electrolyte ea koporo.

5. Ntlafatsa bokhoni ba tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso ea koporo ea electrolytic, e le ho finyella melemo e metle ea moruo.

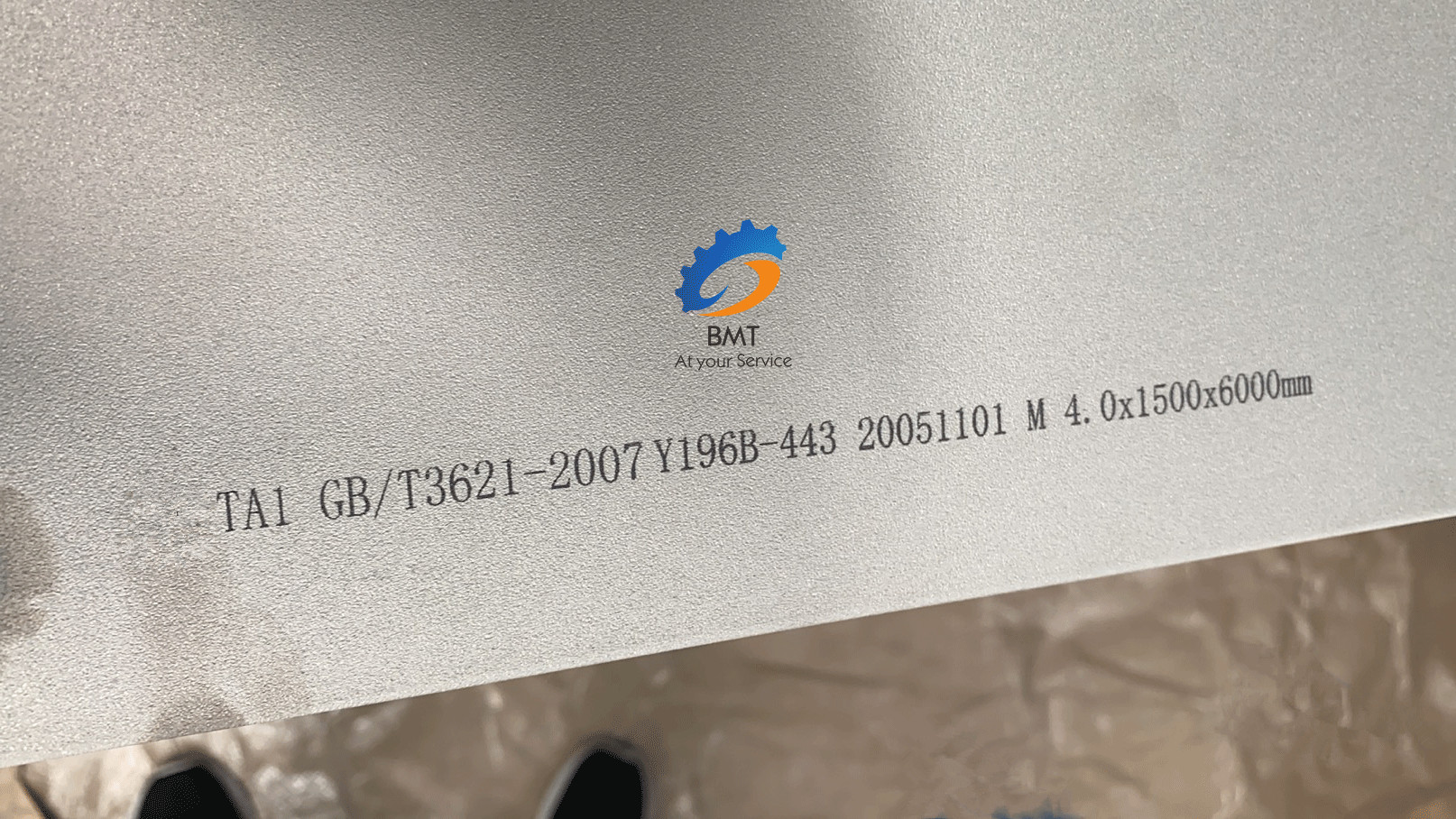

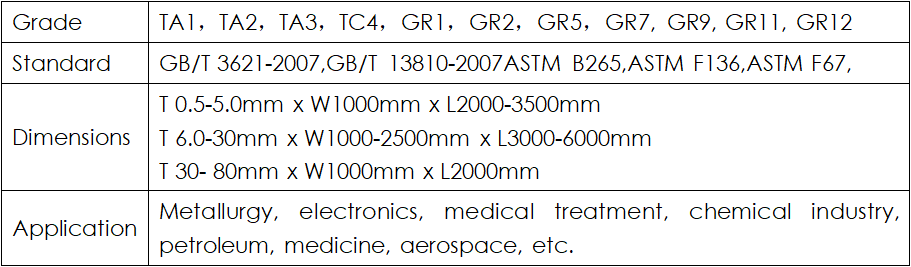

Lethathamo la BMT la letlapa la titanium le poleiti hangata li hlahisoa ho latela maemo a kang ASTM/ASME B/SB265, ASTM F136, ASTM F67, AMS 4911, le AMS4900.

Tlhahiso ea selemo le selemo ea BMT ea maqephe a titanium le paltes ke lithane tse 10000, ho kenyeletsoa lithane tse 2000 bakeng sa PHE (Plate for heat exchanger), le lithane tse 8000 bakeng sa lisebelisoa tse ling. Lipampiri le lipoleiti tsa boleng bo phahameng tsa BMT tsa titanium, ho kenyeletsoa maqephe a batang a titanium a kolobisitsoeng le lipoleiti tsa titanium tse kolobisitsoeng tse chesang, li ntse li lateloa ka thata-thata le ho hlahlojoa ka thepa e tala—seponche sa titanium. BMT e laola ts'ebetso eohle, joalo ka ho qhibiliha, ho ferekana, ho bilika ho chesang, ho bilika ho batang, ho phekola mocheso, joalo-joalo. Re romela lihlahisoa ho pota lefatše 'me re u amohela ka mofuthu hore u sebelisane le rona.

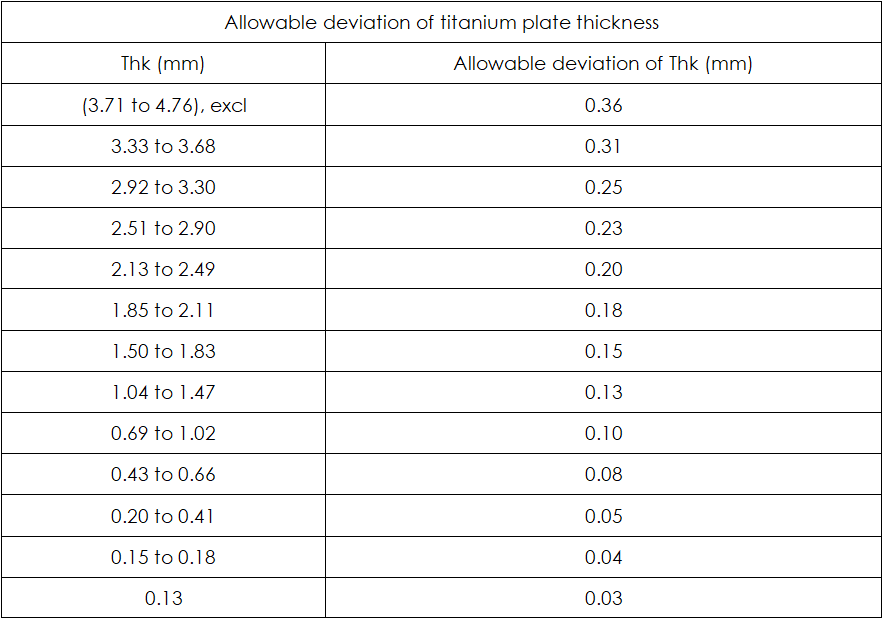

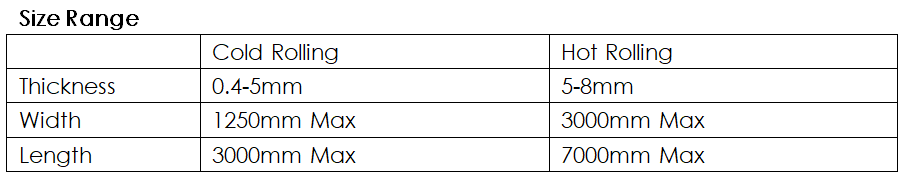

Botenya ba Titanium Plate Botenya bo Amohelehang:

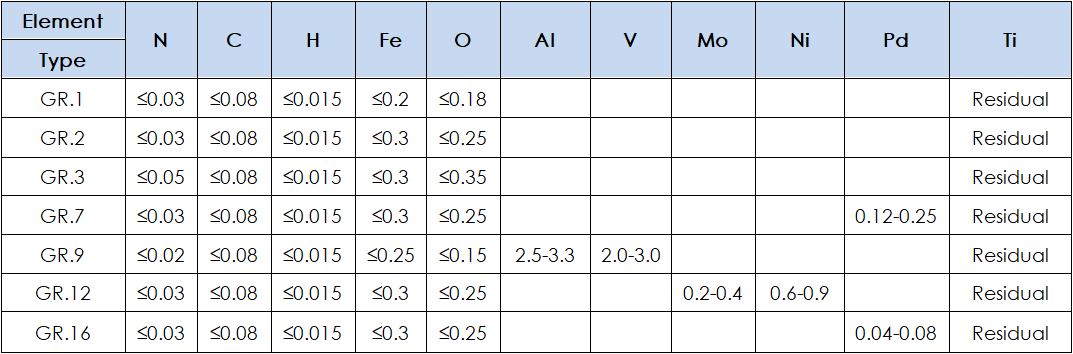

Sebopeho sa Lik'hemik'hale Tse Fumanehang:

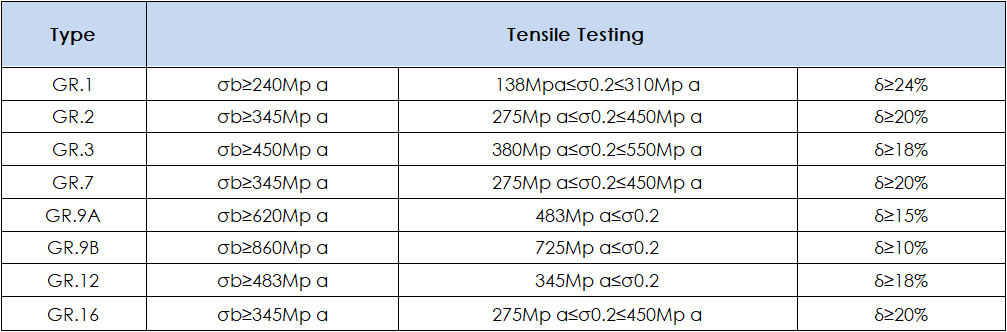

Thepa e Fumanehang ea Mechini:

Tlhahlobo ea tlhahlobo:

- Tlhahlobo ea Sebopeho sa Lik'hemik'hale

- Teko ea Thepa ea Mechini

- Teko ea Teko

- Flaring Test

- Teko e bataletseng

- Teko ea ho Koba

- Teko ea Hydro-Static

- Teko ea Pneumatic (Teko ea khatello ea moea tlas'a metsi)

- Tlhahlobo ea NDT

- Teko ea Eddy-Hajoale

- Tlhahlobo ea Ultrasonic

- Tlhahlobo ea LDP

- Teko ea Ferroxyl

Tlhahiso (Boholo le Bonyane Bongata ba Order):E se nang moeli, ho latela taelo.

Lead time:Nako ea ho tsamaisa ka kakaretso ke matsatsi a 30. Leha ho le joalo, ho itšetlehile ka palo ea taelo ka mokhoa o nepahetseng.

Lipalangoang:Mokhoa o akaretsang oa lipalangoang ke ka Leoatle, ka Moea, ka Express, ka Terene, e tla khethoa ke bareki.

Ho paka:

- Pipe e qetella e sirelelitsoe ka li-caps tsa polasetiki kapa tsa cardboard.

- Lisebelisoa tsohle li lokela ho paka ho sireletsa lipheletsong le ho shebana.

- Thepa e 'ngoe kaofela e tla tlatsoa ka liphaephe tsa foam le mekotla ea polasetiki e amanang le eona.

- Patsi efe kapa efe e sebelisetsoang ho paka e tlameha ho ba e loketseng ho thibela tšilafalo ka ho kopana le lisebelisoa tsa ho tšoara.