Lithapo tsa Titanium le Titanium Alloy

Titanium e hloekileng ke tšepe e tšoeu ea silevera, e nang le lintho tse ngata tse babatsehang. Titanium e na le boima ba 4.54g/cm3, 43% e bobebe ho feta tšepe 'me e boima ho feta magnesium ea tšepe e khanyang. Empa matla a mochine a batla a lekana le tšepe, a matla ho feta aluminium ka makhetlo a mabeli le ka makhetlo a mahlano ho feta magnesium. Titanium e hanyetsana le mocheso o phahameng 'me e na le ntlha ea ho qhibiliha ea 1942K, hoo e batlang e le 1000K holimo ho khauta le hoo e batlang e le 500K ho feta tšepe.

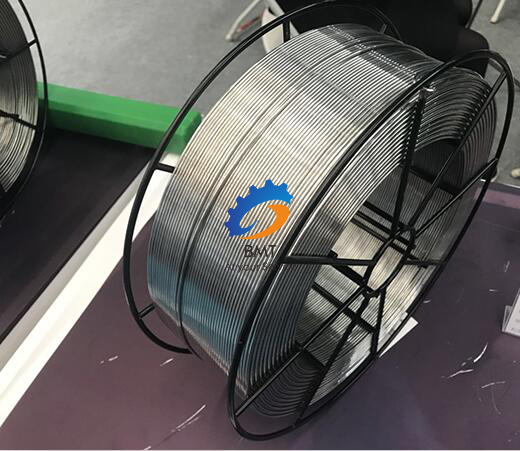

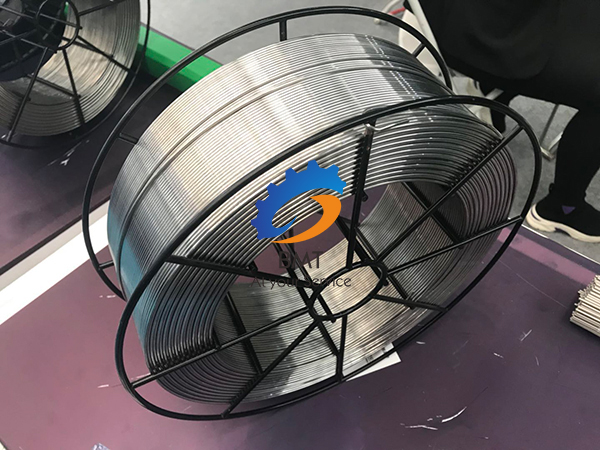

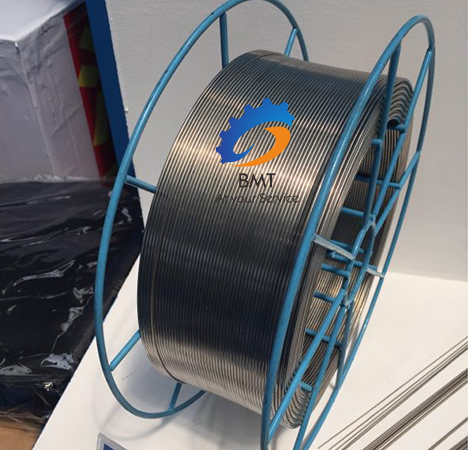

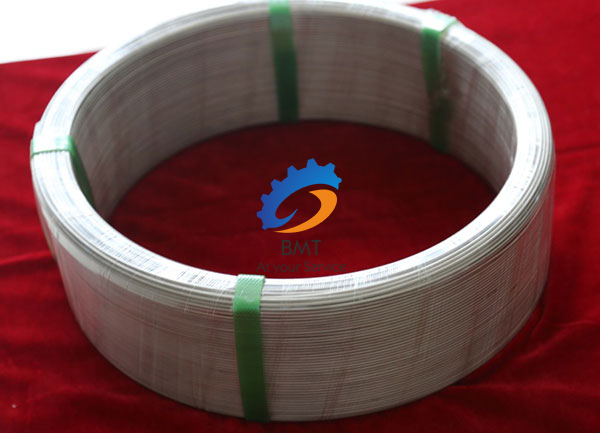

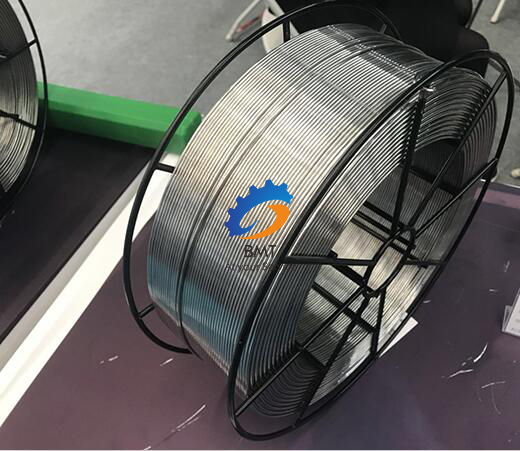

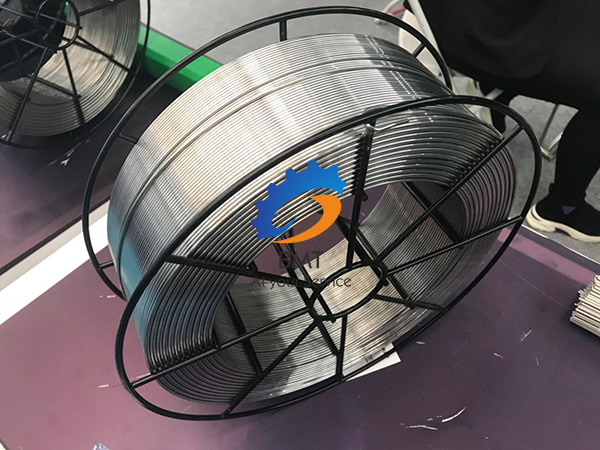

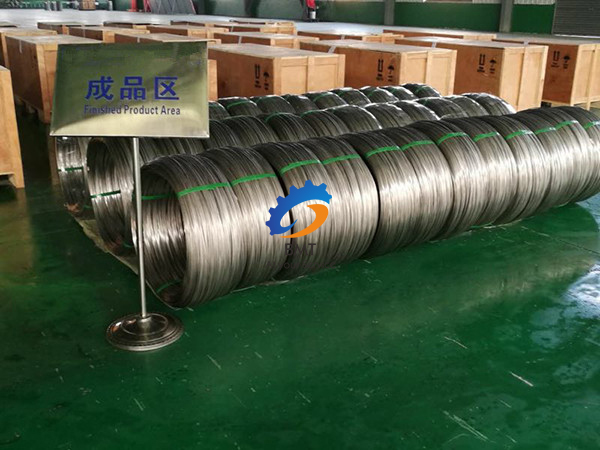

Titanium terata e arotsoe ka: terata ea titanium, titanium alloy wire, pure titanium eyeglass wire, titanium otlolohileng wire, pure titanium wire, titanium welding wire, titanium hanging wire, titanium disk wire, titanium light wire, medical titanium wire, titanium nickel alloy wire. .

Litlhaloso tsa mohala oa Titanium

A. Litlhaloso tsa terata ea Titanium: φ0.8-φ6.0mm

B. Litlhaloso tsa terata ea titanium ea likhalase: φ1.0-φ6.0mm terata e khethehileng ea titanium

C. Litlhaloso tsa terata ea Titanium: φ0.2-φ8.0mm ka ho fanyeha ho khethehileng

Tloaelo:GB/T,GJB,AWS,ASTM,AMS,JIS

Sehlopha sa Titanium Wire

GR1, GR2, GR3, GR5, GR7, GR9, GR11, GR12, GR16, joalo-joalo.

Libaka tsa Tšebeliso ea Titanium Wire

Indasteri ea sesole, bongaka, thepa ea lipapali, likhalase, masale, liaparo tsa hlooho, ho fanyeha electroplating, terata ea welding le liindasteri tse ling.

State of Titanium Wire

Boemo ba ho lla (M)

Boemo ba ho sebetsa bo chesang (R)

Sebaka sa ho sebetsa se batang (Y)

(Annealing, Ultra-Generation Testing)

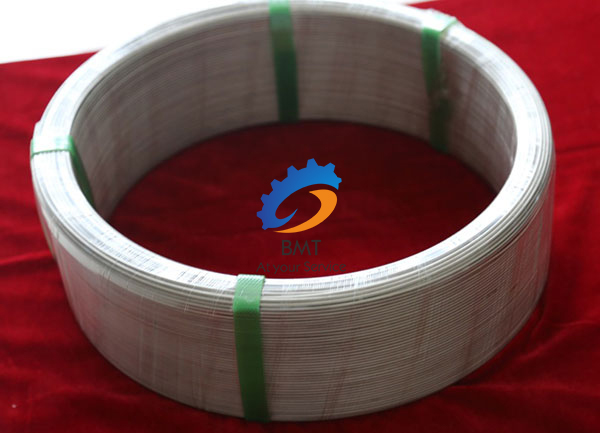

Bokaholimo ba Titanium Wire

Bokaholimo bo khantšang kapa bo phatsimang

Titanium terata e etsa carbide e tsitsitseng e nang le boima bo phahameng bo nang le carbon. Khōlo ea lera la carbonized pakeng tsa titanium le carbon e khethoa ke sekhahla sa ho hasana ha titanium sebakeng sa carbonized.

Thesolubility ea carbon ho titanium e nyane, e fihla ho 0.3% ho 850X: 'me e fokotseha hoo e ka bang 0.1% ho 600C B Ka lebaka la ho qhibiliha ha carbon ho titanium, ho thatafala ha bokaholimo ho finyelloa feela ka lera la titanium carbide le akimbo ea eona. lera ka tlase. Carburizing e tlameha ho etsoa tlas'a boemo ba ho tlosoa ha oksijene, hobane boima ba bokaholimo ba phofo bo atisang ho sebelisoa bakeng sa tšepe ea carburizing khahlanong le holim'a carbon monoxide kapa carbon monoxide e nang le oksijene ho fihla ho 2700MPa le 8500MPa, le letlooeng. Ho bonolo ho ebola.

Lintho Tse Fumanehang Moetso oa Lik'hemik'hale

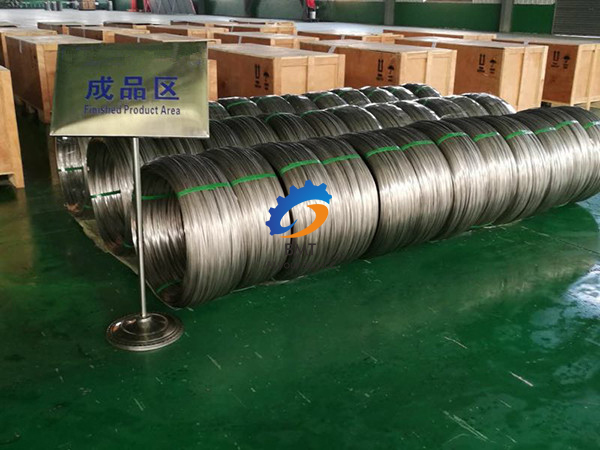

Tlhahiso (Boholo le Bonyane Bongata ba Order):E se nang moeli, ho latela taelo.

Lead time:Nako ea ho tsamaisa ka kakaretso ke matsatsi a 30. Leha ho le joalo, ho itšetlehile ka palo ea taelo ka mokhoa o nepahetseng.

Lipalangoang:Mokhoa o akaretsang oa lipalangoang ke ka Leoatle, ka Moea, ka Express, ka Terene, e tla khethoa ke bareki.

Ho paka:

- Pipe e qetella e sirelelitsoe ka li-caps tsa polasetiki kapa tsa cardboard.

- Lisebelisoa tsohle li lokela ho paka ho sireletsa lipheletsong le ho shebana.

- Thepa e 'ngoe kaofela e tla tlatsoa ka liphaephe tsa foam le mekotla ea polasetiki e amanang le eona.

- Patsi efe kapa efe e sebelisetsoang ho paka e tlameha ho ba e loketseng ho thibela tšilafalo ka ho kopana le lisebelisoa tsa ho tšoara.

.jpg)

Ka lehlakoreng le leng, tlas'a boemo ba deoxygenation kapa decarburization, lesela le tšesaane la titanium carbide le ka thehoa ha carburized ka mashala. Ho thatafala ha lera lena ke 32OUOMpa, e lumellanang le ho thatafala ha titanium carbide. Botebo ba carburizing layer hangata bo boholo ho feta ba nitriding layer ha nitriding e sebelisoa tlasa maemo a tšoanang. Tlas'a boemo ba ho matlafatsa oksijene, phello ea ho monya oksijene botebong bo thata e tlameha ho nahanoa. Ke feela tlas'a boemo ba botenya bo fokolang haholo moo matla a lekaneng a sekhomaretsi a ka thehoang ka carburizing carbon powder ka vacuum kapa argon-methane sepakapaka. Ka lehlakoreng le leng, ts'ebeliso ea "carburizing agent" ea khase e ka theha lesela le thata le le tiileng la titanium carbide. Ka nako e ts'oanang, ho ata ha thata ho thehoa mocheso pakeng tsa 950T: le 10201:. Ka keketseho ea botenya ba lera, lesela la TiC le fetoha le senyehileng le ho feta 'me le atisa ho putlama. E le ho qoba ho kenella ha carbon inclusions ka har'a lera la TiC ka lebaka la ho senyeha ha Reane, carburizing ea khase e lokela ho etsoa ka khase e sa sebetseng e nang le kenyelletso e behiloeng ea tekanyo e ka bang 2% ea Reane. Botebo bo tlase bo fumanoa ha methane e kenngoe ka li-additives tsa propane. Ha matla a tlamahano a fihla ho OKPA 'me ho sebelisoa propane ea khase ea khase, le hoja tekanyo e lekantsoeng e thata ea lera e le tšesaane haholo, e na le ho hanyetsa ka ho fetisisa ho apara. Hydrojene e monngoa ke sekoaelo sa khase, empa e tlameha ho ntšoa hape nakong ea vacuum annealing.