Mefuta ea Mechini ea Mechini

Sehlopha se seholo

Ho na le mefuta e 'meli ea mantlha ea machining: mochini oa matsoho le oa CNC. Ho sebetsa ka letsoho ho bolela mokhoa oa ho sebetsana le lisebelisoa tse fapaneng ka ts'ebetso ea matsoho ea lisebelisoa tsa mochini tse joalo ka mechini ea ho sila, lathes, metjhini ea ho phunya le metjhini e sakhang ke basebetsi ba mechini. Ho sebetsa ka letsoho ho loketse bakeng sa tlhahiso ea karolo e tlaase, e bonolo. CNC machining (CNC) e bua ka tšebeliso ea lisebelisoa tsa CNC ke basebetsi ba mechini bakeng sa ts'ebetso. Lisebelisoa tsena tsa CNC li kenyelletsa litsi tsa machining, litsi tsa ho fetola le ho sila, lisebelisoa tsa terata tsa EDM, mechine ea ho roala likhoele, joalo-joalo Boholo ba mabenkele a mochine a sebelisa theknoloji ea CNC ea machining. Ka lenaneo, lihokahanyo tsa maemo (X, Y, Z) tsa mosebetsi oa tsamaiso ea Cartesian coordinate li fetoloa puo ea lenaneo.

Molaoli oa CNC oa sesebelisoa sa mochini oa CNC o laola axis ea sesebelisoa sa mochini oa CNC ka ho tsebahatsa le ho toloka puo ea lenaneo, ebe o tlosa lisebelisoa ka bohona kamoo ho hlokahalang. , e le hore u fumane mosebetsi o felileng. CNC machining e sebetsana le li-workpieces ka mokhoa o tsoelang pele 'me e loketse likarolo tse ngata tse nang le libopeho tse rarahaneng.

Theknoloji ea ho sebetsa

Setsi sa machining se ka sebelisa sistimi ea CAD/CAM (Computer Aided Design Computer Aided Manufacturing) ho itlhophisa ka bo eona lisebelisoa tsa mochini oa CNC. Geometry ea karolo e fetisetsoa ka bo eona ho tloha tsamaisong ea CAD ho ea tsamaisong ea CAM, 'me setsebi sa machini se khetha mekhoa e fapaneng ea machining pontšong ea sebele. Ha setsebi sa machini se khetha mokhoa o itseng oa mochine, tsamaiso ea CAD/CAM e ka hlahisa khoutu ea CNC ka bo eona, eo hangata e bitsoang khoutu ea G, ebe e kenya khoutu ho molaoli oa mochine oa CNC bakeng sa ts'ebetso ea sebele ea mochine.

Thepa Tse Ling

Lisebelisoa tse ka morao ho fektheri, tse kang lisebelisoa tsa mochine oa tšepe (ho akarelletsa le ho reteleha, ho sila, ho rera, ho kenya le lisebelisoa tse ling), haeba likarolo tsa thepa e hlokahalang bakeng sa tlhahiso li robehile 'me li hloka ho lokisoa, li lokela ho romelloa mochine oa mochine. workshop bakeng sa ho lokisa kapa ho sebetsa. E le ho netefatsa tsoelo-pele e ntle ea tlhahiso, likhoebo tse akaretsang li na le lithupelo tsa machining, tseo haholo-holo li ikarabellang bakeng sa tlhokomelo ea thepa ea tlhahiso.

Mekhoa ea Ts'ebetso

I. Kakaretso

Mokhoa ona oa ts'ebetso o etsa litaelo tse tobileng le tse qaqileng bakeng sa basebetsi bohle ba sebetsanang le mechine ho netefatsa boleng ba karolo e 'ngoe le e' ngoe e entsoeng ka mochine.

2. Sebaka sa kopo

Taolo ena e totobatsa ts'ebetso e ikhethileng ea basebetsi ba machining (ho kenyeletsoa ho reteleha, ho sila, ho cheka, ho pola, ho sila, ho kuta, joalo-joalo) nakong ea mosebetsi.

3. Melao e akaretsang

Ts'ebetso ea mechine e tlameha ho etsoa ho latela molao ona nakong ea ts'ebetso ea likarolo tse fapaneng tsa mochini.

Re romelle molaetsa oa hau:

-

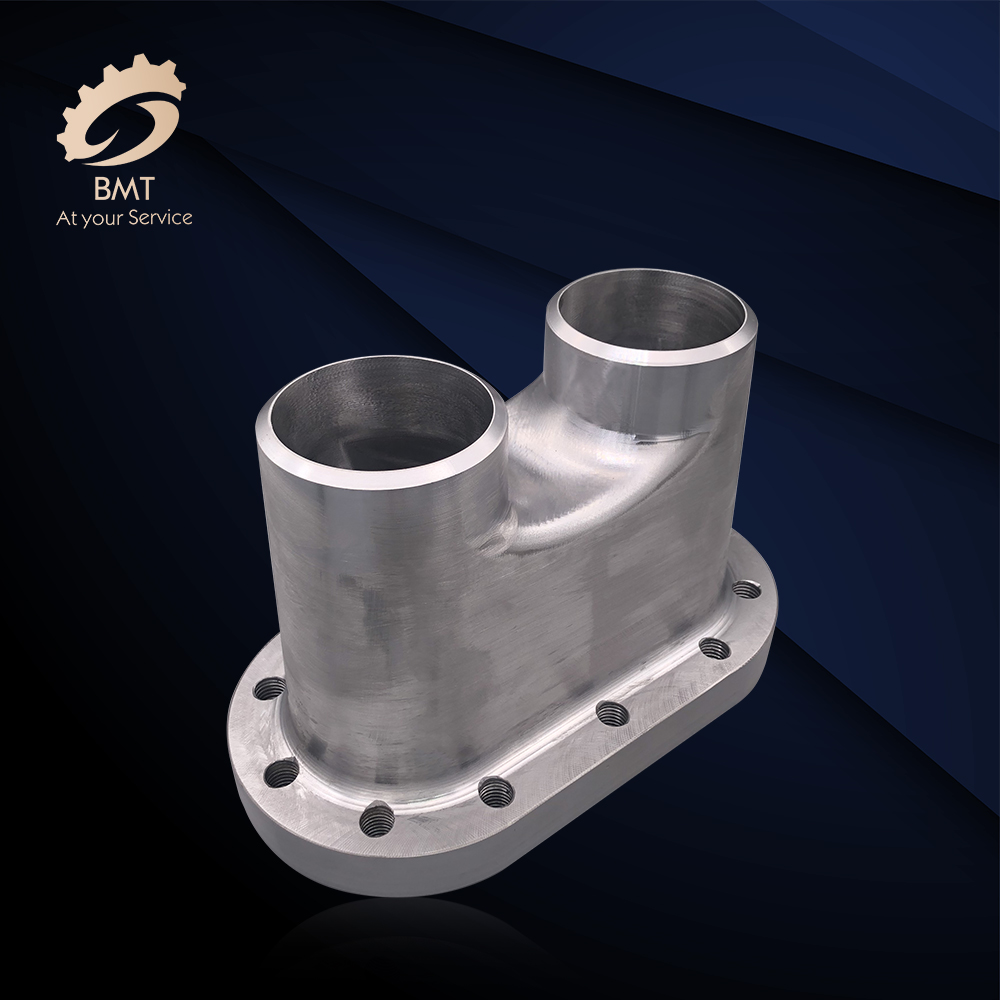

Aluminium CNC Machining likarolo

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining likarolo

-

Likarolo tse entsoeng ke CNC bakeng sa Italy

-

CNC Machining Aluminium likarolo

-

Auto Parts Machining

-

Lisebelisoa tsa Titanium Alloy Forgings

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes