CNC Machining Melemo

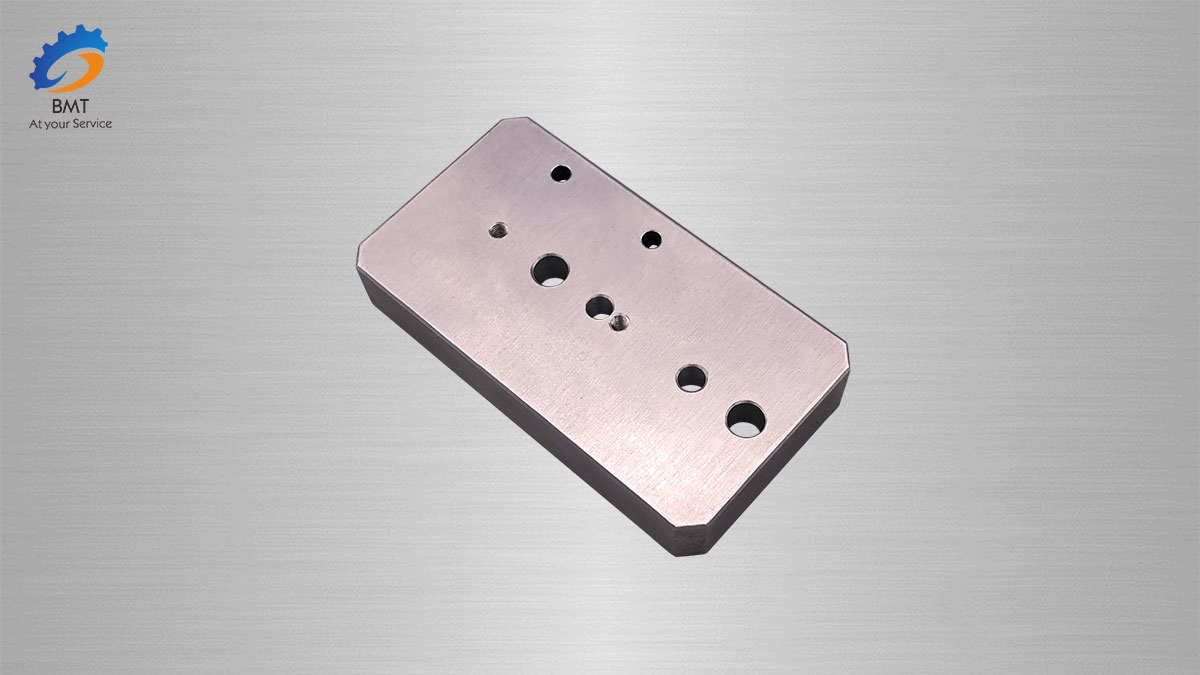

① Palo ea lisebelisoa e fokotsehile haholo, 'me lisebelisoa tse rarahaneng ha li hlokehe bakeng sa ho sebetsa likarolo tse nang le libopeho tse rarahaneng. Haeba o batla ho fetola sebopeho le boholo ba karolo, o hloka feela ho fetola lenaneo la ts'ebetso ea karolo, e loketseng bakeng sa nts'etsopele le phetoho ea sehlahisoa se secha.

② Boleng ba ts'ebetso bo tsitsitse, ho nepahala ha ts'ebetso ho phahame, 'me ho pheta-pheta ho nepahetseng ho phahame, e leng se loketseng litlhoko tsa ho sebetsana le sefofane.

③ Ts'ebetso ea tlhahiso e phahame tabeng ea tlhahiso ea mefuta e mengata le e nyenyane, e ka fokotsang nako ea ho lokisetsa tlhahiso, ho lokisa lisebelisoa tsa mochine le tlhahlobo ea ts'ebetso, le ho fokotsa nako ea ho itšeha ka lebaka la tšebeliso ea palo e ntle ka ho fetisisa ea ho itšeha.

④E ka sebetsana le li-profile tse rarahaneng tseo ho leng thata ho li sebetsa ka mekhoa e tloaelehileng, esita le ho sebetsana le likarolo tse ling tse sa bonahaleng tsa ts'ebetso.

Bobebe ba mochini oa CNC ke hore litšenyehelo tsa lisebelisoa tsa mochini li theko e boima ebile li hloka boemo bo holimo ba basebetsi ba tlhokomelo.

Bakeng sa ho ntlafatsa tekanyo ea tlhahiso ea boiketsetso, ho khutsufatsa nako ea lenaneo le ho fokotsa litšenyehelo tsa machining a CNC, letoto la mahlale a machining a CNC a tsoetseng pele a ntlafalitsoe mme a sebelisoa indastering ea sefofane. Ka mohlala, taolo ea linomoro tsa k'homphieutha, ke hore, sebelisa k'homphieutha e nyenyane kapa e nyenyane ho nkela molaoli sebakeng sa tsamaiso ea linomoro, 'me u sebelise software e bolokiloeng khomphuteng ho etsa lipalo le ho laola mesebetsi. Sistimi ena ea taolo ea linomoro tsa komporo e hokahantsoeng ka bonolo butle-butle e nkela sebaka sa pele sa tsamaiso ea lipalo. Taolo e tobileng ea linomoro e sebelisa k'homphieutha e le 'ngoe ho laola ka ho toba lisebelisoa tse ngata tsa mochine oa ho laola lipalo, tse loketseng haholo bakeng sa tlhahiso ea lifofane tse nyenyane le potoloho e khutšoanyane ea lifofane.

Sistimi e nepahetseng ea taolo ke sistimi e ikamahanyang le maemo e ka tsoelang pele ho fetola mekhahlelo ea ts'ebetso. Le hoja tsamaiso ka boeona e rarahane ebile e theko e boima, e ka ntlafatsa ts'ebetso ea ts'ebetso le boleng. Ntle le ntlafatso ea litsamaiso tsa CNC le lisebelisoa tsa mochini mabapi le hardware, nts'etsopele ea CNC e na le ntlha e 'ngoe ea bohlokoa e leng nts'etsopele ea software. Mananeo a thusoang ke k'homphieutha (hape a bitsoa "automatic programming)" a bolela hore ka mor'a hore moetsi oa lenaneo a ngole lenaneo ka puo ea taolo ea lipalo, le kenngoa k'homphieutheng bakeng sa ho fetolela, 'me qetellong k'homphieutha e itlhahisa ka bo eona teipi e phunyeletsoeng kapa theipi. Puo ea CNC e sebelisoang haholo ke puo ea APT. E batla e arotsoe ka lenaneo le ka sehloohong la ts'ebetso le lenaneo la post-processing. Ea pele e fetolela lenaneo le ngotsoeng ke moqapi ho bala tsela ea lisebelisoa; ea morao-rao e bokella tsela ea lisebelisoa ho kena lenaneong la ts'ebetso ea karolo ea mochine oa CNC.