Titanium Alloy Mechanical Properties

Tšebeliso ea mocheso ke likhato tse makholo a seng makae tse phahameng ho feta motsoako oa aluminium, ka mocheso o mahareng o ntse o ka boloka matla a hlokahalang, e ka ba mocheso oa 450 ~ 500 ℃ ka nako e telele o sebetsa li-alloy tsena tse peli tsa titanium ka mefuta e fapaneng ea 150 ℃ ~ 500 ℃ e ntse e na le matla a khethehileng a phahameng haholo, 'me motsoako oa aluminium ho 150 ℃ matla a khethehileng a fokotsehile haholo. Mocheso o sebetsang oa motsoako oa titanium o ka fihla ho 500 ℃, 'me motsoako oa aluminium o ka tlase ho 200 ℃. Ho phutha ha kutu e ntle.

Ho hanyetsa kutu ea alloy ea titanium ho molemo haholo ho feta ea tšepe e sa hloekang ha e sebetsa sebakeng se mongobo le metsi a leoatle. Haholo-holo ho hanyetsa ka matla ho pitting corrosion, corrosion ea acid le khatello ea kelello; E na le khanyetso e ntle haholo ea ho bola ho alkali, chloride, chlorinated organic goods, nitric acid, sulfuric acid, joalo-joalo.

Titanium alloy e ka boloka thepa ea eona ea mochini maemong a mocheso a tlase le a tlase haholo. Li-alloys tsa Titanium tse nang le ts'ebetso e ntle ea mocheso o tlase le likarolo tse tlase haholo tsa interstitial, joalo ka TA7, li ka boloka polasetiki e itseng ho -253 ℃. Ka hona, alloy ea titanium le eona ke sesebelisoa sa bohlokoa sa sebopeho sa mocheso o tlase. Mosebetsi oa lik'hemik'hale oa titanium o phahame, 'me sepakapaka se O, N, H, CO, CO₂, mouoane oa metsi, ammonia le lik'hemik'hale tse ling tse matla tsa lik'hemik'hale. Ha carbon content e feta 0.2%, e tla theha TiC e thata ka alloy ea titanium;

Ka mocheso o phahameng, tšebelisano le N e tla boela e thehe sebaka se thata sa TiN; Ka holimo ho 600 ℃, titanium e monya oksijene ho etsa lera le thatafalang le thata haholo; Lera la embrittlement le tla boela le thehoe ha hydrogen content e phahama. Botebo ba sebaka se thata sa brittle se hlahisoang ke khase e monyang bo ka fihla ho 0.1 ~ 0.15mm, 'me tekanyo e thata ke 20% ~ 30%. Tšebelisano ea lik'hemik'hale ea titanium le eona e kholo, e bonolo ho hlahisa ho khomarela ka holim'a likhohlano.

Thermal conductivity ea titanium λ=15.24W/ (mK) e batla e le 1/4 ea nickel, 1/5 ea tšepe, 1/14 ea aluminium, 'me conductivity ea mocheso ea mefuta eohle ea alloy ea titanium e ka tlase ho 50% ho feta moo. ea titanium. The elastic modulus ea titanium alloy ke hoo e ka bang 1/2 ea tšepe, kahoo ho tiea ha eona ha ho bonolo, ho bonolo ho bōptjoa, ha ea lokela ho etsoa ka molamu o mosesaane le likarolo tse tšesaane tse nang le marako, ho itšeha, molumo oa ho rema holimo o moholo, hoo e ka bang makhetlo a 2 ~ 3. ea tšepe e sa hloekang, e bakang khohlano e matla, ho khomarela, ho apara ka mor'a sesebelisoa.

Re romelle molaetsa oa hau:

-

Aluminium CNC Machining likarolo

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining likarolo

-

Likarolo tse entsoeng ke CNC bakeng sa Italy

-

CNC Machining Aluminium likarolo

-

Auto Parts Machining

-

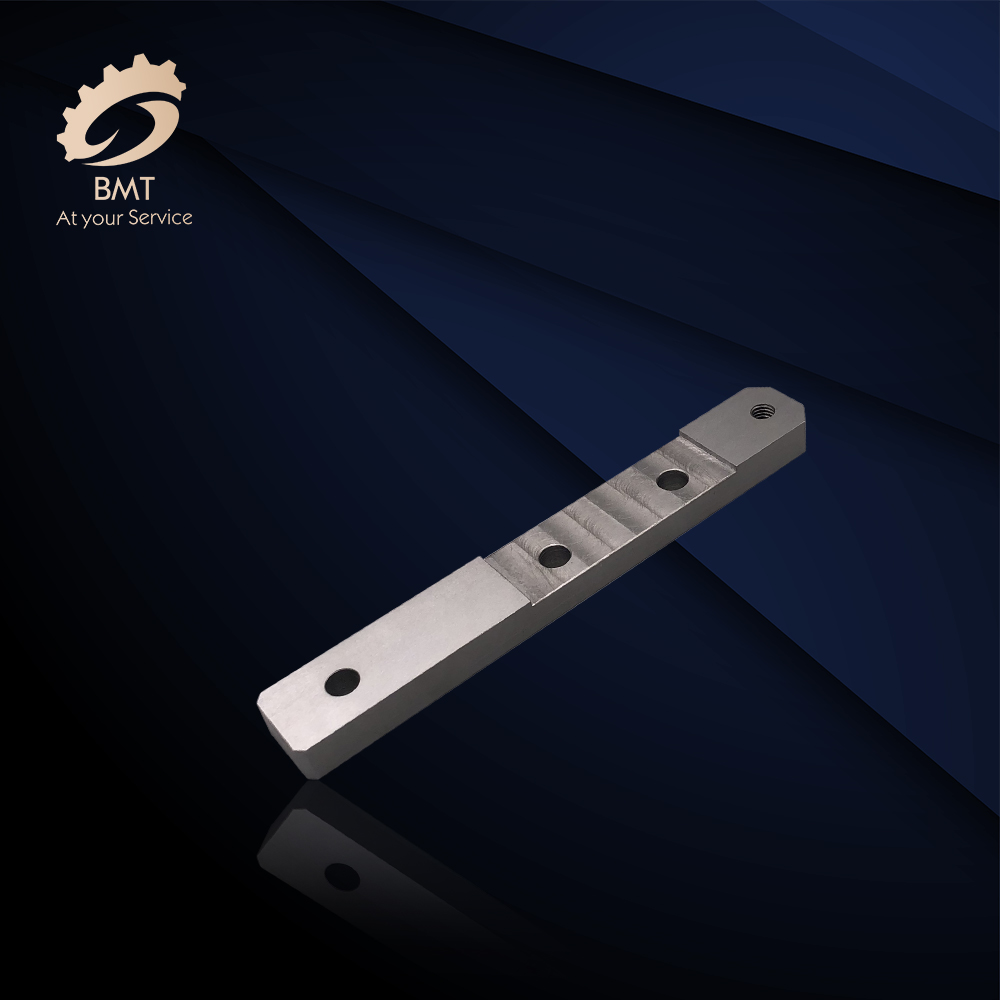

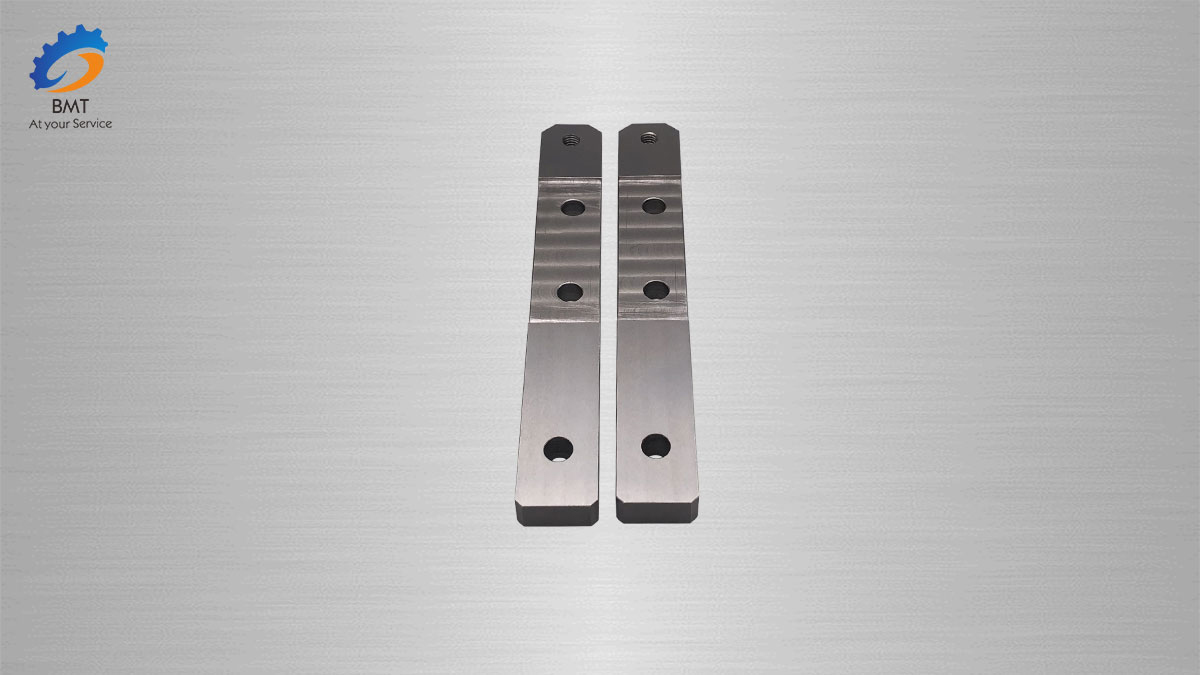

Lisebelisoa tsa Titanium Alloy Forgings

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes