Titanium Alloy Welding

Ke motsoako oa mohato o le mong o entsoeng ka tharollo e tiileng ea β-phase. Ntle le kalafo ea mocheso, e na le matla a phahameng. Ka mor'a ho tima le ho tsofala, motsoako o tsoetse pele.Mohato o le mong oa ho matlafatsa, matla a mocheso oa kamoreng a ka fihla ho 1372 ~ 1666 MPa; Empa botsitso ba mocheso bo futsanehile, ha boa lokela ho sebelisoa mocheso o phahameng.

Ke motsoako oa biphasic, o na le thepa e ntle e akaretsang, botsitso bo botle ba sebopeho, ho tiea ho hotle, polasetiki le thepa ea deformation e phahameng ea mocheso, e ka ba molemo bakeng sa ts'ebetso ea khatello e chesang, e ka tima, botsofali ho matlafatsa motsoako. Matla ka mor'a phekolo ea mocheso ke hoo e ka bang 50% ~ 100% e phahameng ho feta ka mor'a hore annealing; Matla a mocheso o phahameng, a ka sebetsa ka mocheso oa 400 ℃ ~ 500 ℃ nako e telele, botsitso ba eona ba mocheso bo tlase ho α titanium alloy.

Har'a li-alloys tse tharo tsa titanium, tse sebelisoang ka ho fetisisa ke α titanium alloy le α + β titanium alloy; Ts'ebetso ea ho itšeha ea α titanium alloy ke eona e ntle ka ho fetisisa, e lateloa ke α+β titanium alloy, le β titanium alloy ke eona e mpe ka ho fetisisa. α titanium alloy code for TA, β titanium alloy code for TB, α+β titanium alloy code for TC.

Alloy ea titanium e ka aroloa ka motsoako oa mocheso o hanyetsanang le mocheso, motsoako o matla o matla, motsoako o thibelang ho bola (titanium - molybdenum, titanium - palladium alloy, joalo-joalo), motsoako o tlaase oa mocheso le motsoako o khethehileng oa ts'ebetso (titanium - tšepe ea polokelo ea hydrogen le titanium - memori ea nickel. motsoako). Sebopeho le thepa ea li-alloys tse tloaelehileng li bontšoa tafoleng.

Mefuta e fapaneng ea likarolo le li-microstructure tsa li-alloys tsa titanium tse nang le mocheso li ka fumanoa ka ho fetola mokhoa oa ho phekola mocheso. Ka kakaretso ho lumeloa hore mehaho e metle ea equiaxed e na le polasetiki e ntle, botsitso ba mocheso le matla a mokhathala. Sebopeho sa spiculate se na le nako e telele e tšoarellang, matla a ho hahaba le ho thatafala ha fracture. Li-tissue tse tsoakiloeng tsa equiaxial le tse kang nale li na le thepa e phethahetseng. Titanium ke mofuta o mocha oa tšepe, ts'ebetso ea titanium e amana le likahare tsa carbon, naetrojene, hydrogen, oksijene le litšila tse ling, litšila tse hloekileng tsa titanium iodide ha li fete 0.1%, empa matla a eona a tlase, polasetiki e phahameng. .

Thepa ea 99.5% ea titanium e hloekileng ea indasteri ke e latelang: density ρ=4.5g/ cubic cm, melting point 1725℃, thermal conductivity λ=15.24W/(mK), tensile strength σb=539MPa, elongation δ=25%, karolo ho honyela ψ=25%, elastic modulus E=1.078×105MPa, ho thatafala HB195. Boima ba alloy ea titanium hangata bo ka bang 4.51g / cubic centimeter, ke 60% feela ea tšepe, matla a titanium e hloekileng a haufi le matla a tšepe e tloaelehileng, alloy e matla ea titanium e feta matla a tšepe e mengata ea alloy. Ka hona, matla a khethehileng (matla / boima) ba alloy ea titanium e kholo haholo ho feta ea lisebelisoa tse ling tsa mohaho oa tšepe, joalokaha ho bontšitsoe Lethathamong la 7-1. E ka hlahisa likarolo le likarolo tse nang le matla a phahameng a li-unit, ho tiea hantle le boima bo bobebe. Hona joale, li-alloys tsa titanium li sebelisoa likarolong tsa enjene, skeleton, letlalo, li-fasteners le lisebelisoa tsa ho lulisa.

Re romelle molaetsa oa hau:

-

Aluminium CNC Machining likarolo

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining likarolo

-

Likarolo tse entsoeng ke CNC bakeng sa Italy

-

CNC Machining Aluminium likarolo

-

Auto Parts Machining

-

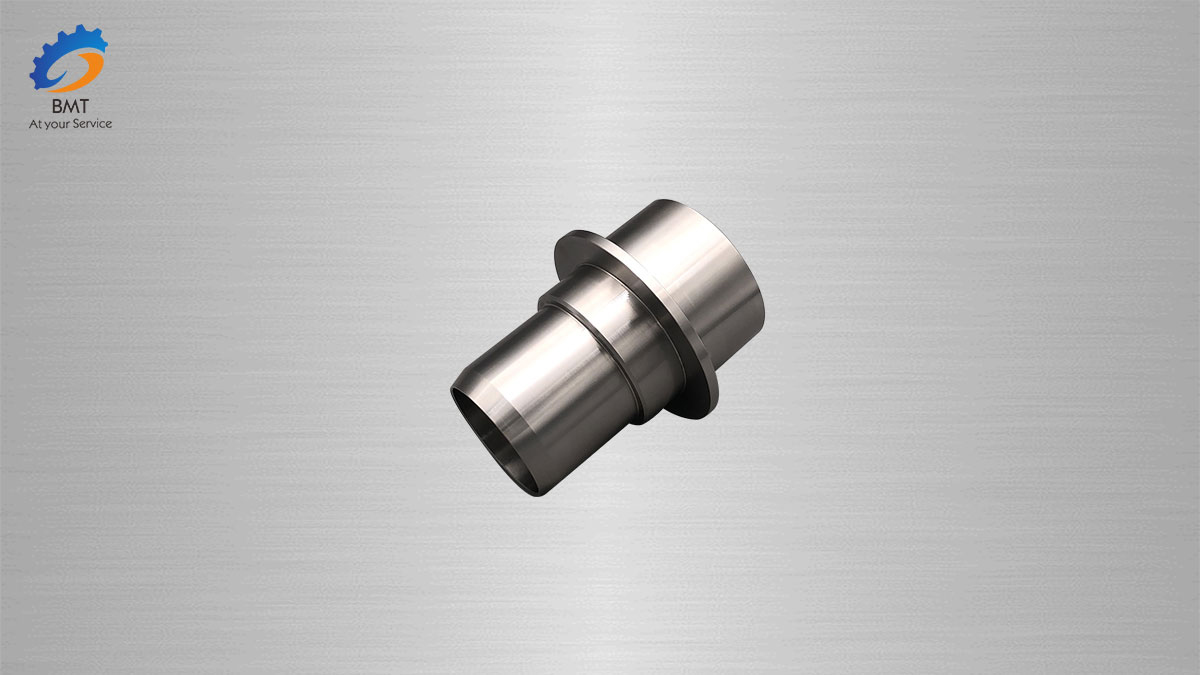

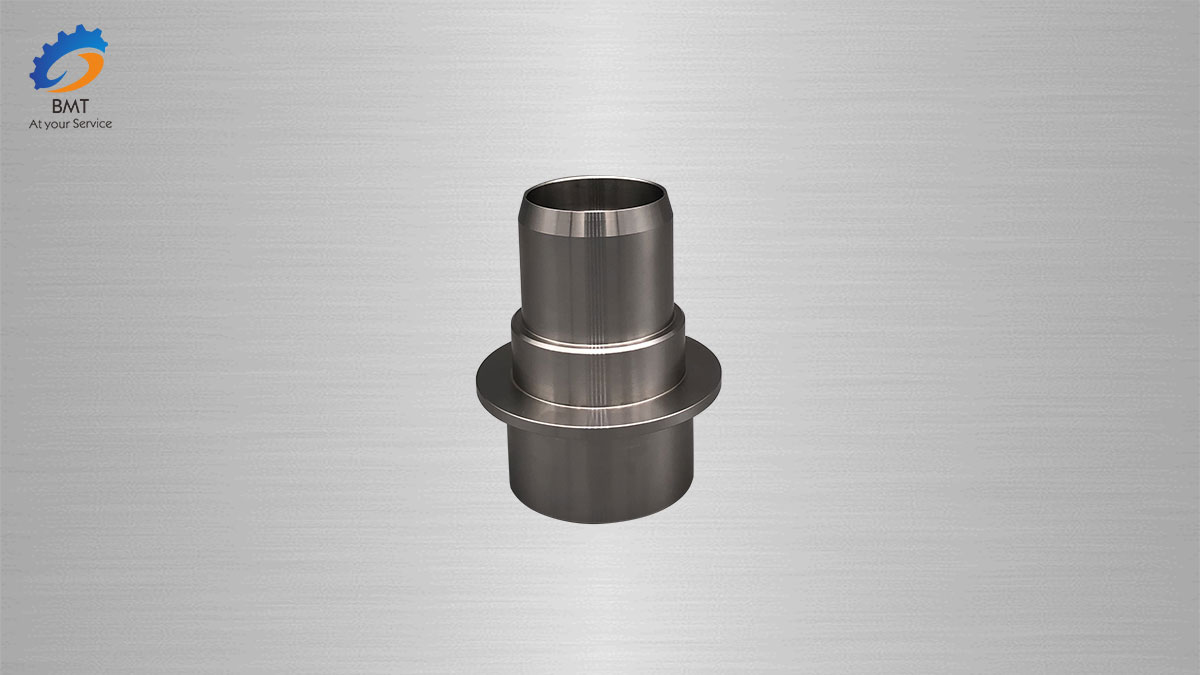

Lisebelisoa tsa Titanium Alloy Forgings

-

Lisebelisoa tsa Titanium le Titanium Alloy

-

Lisebelisoa tsa Titanium le Titanium Alloy Forgings

-

Lithapo tsa Titanium le Titanium Alloy

-

Libaka tsa Titanium

-

Liphaephe / Li-tubes tse se nang Mokono oa Titanium

-

Titanium Welded Pipes/Tubes