Sheet Metal Fabrication ke eng?

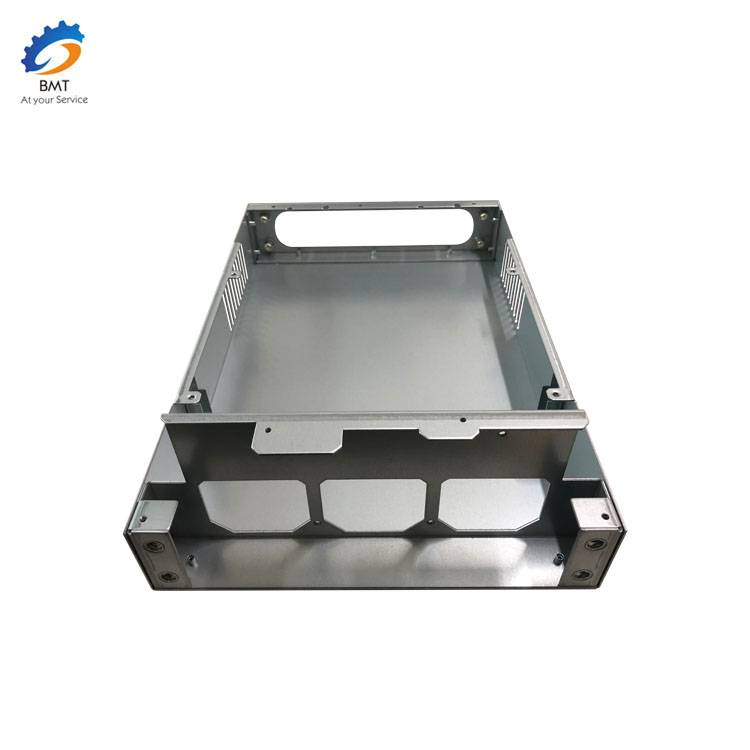

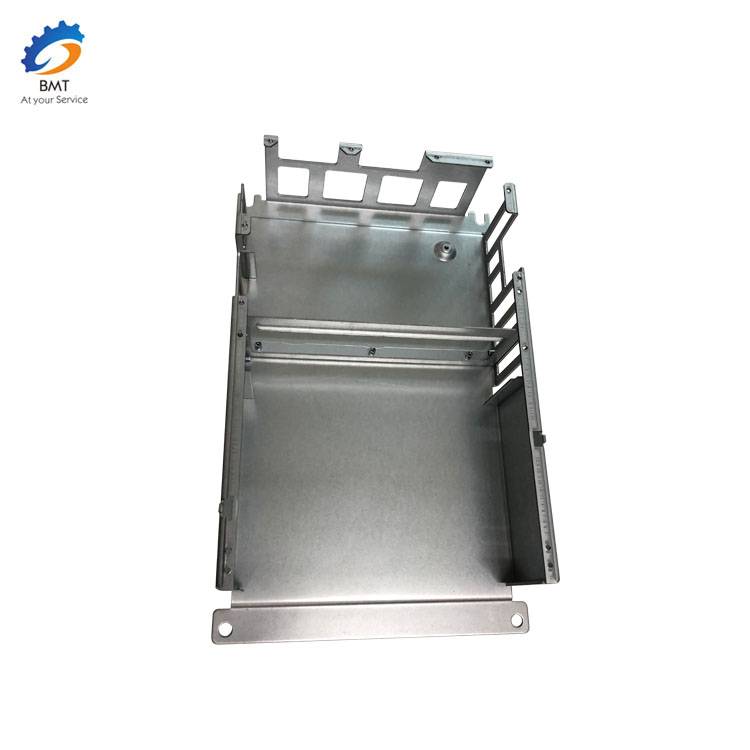

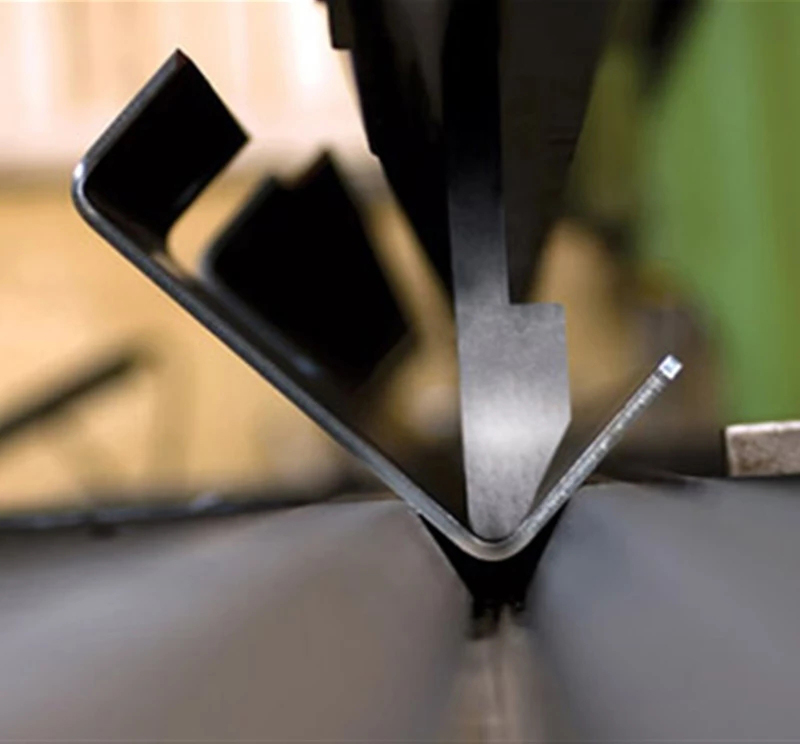

Sheet Metal Fabrication ke sete sa mekhoa ea tlhahiso e sebelisetsoang ho fetola stock metal stock hore e be likarolo tse sebetsang. Ho na le lits'ebetso tse 'maloa tse oelang ho 'Sheet Metal Fabrication', ho kenyelletsa ho seha, ho kobeha le ho otla, tse ka sebelisoang hammoho kapa ka bonngoe.

Sheet Metal Fabrication e ka sebelisoa ho theha li-prototype tse sebetsang hantle le likarolo tsa ts'ebeliso ea ho qetela, empa likarolo tsa tšepe tse sebelisoang ho qetela hangata li hloka mokhoa oa ho qetela pele li se li loketse ho rekisoa.

▷ Mamello ea Metal Sheet ke Efe?

Ho ea ka mekhoa ea tlhahiso le likarolo tsa likarolo, litlhoko tsa mamello li fapane. Ho mamellana ho itšetlehile ka palo e fokolang ea mehato ea ho etsa masela, ho nepahala ho tlase kapa ho feta. Ho phaella moo, karolo ea likoti e na le mamello e thata ho feta ho koba tšobotsi.

▷ The Common Fabrication Material ke Efe?

Ka tloaelo, ho na le mefuta e meraro ea lisebelisoa tse sebelisoang ho etsoa ka lesela la tšepe. Sheba lintlha tse ka tlase:

Mofuta oa pele ke TŠEPE, ho kenyeletsoa tšepe e sa hloekang 301 le 304, letlapa la Galvanized, lakane e kentsoeng ka serame, le tse ling. Ka lebaka la theko e tlaase le thepa e ntle ea machining, e fetoha thepa e loketseng ka ho fetisisa bakeng sa ho etsa lesela la tšepe.

Mofuta oa bobeli ke Koporo, ho kenyelletsa le koporo 101, koporo ea C110, le koporo 260. Ho loketse ho etsa prototype ea selemo le likarolo.

Aluminium, qetellong, ke ntho e 'ngoe e tloaelehileng bakeng sa masela a tloaelehileng a tšepe. Mofuta ona oa thepa o kenyelletsa Aluminium 1060, Aluminium 5052, Aluminium 6061 e nang le khanyetso e ntle ea kutu le tekanyo e phahameng ea boima ba 'mele.

▷ Liphello Tse Tloaelehileng ke Life?

Lithako tse tloaelehileng tsa shiti ea tšepe le likarolo tsa setempe hangata li kenyelletsa ho roala phofo, ho phatloha ha lifaha, anodizing, galvanizing, penta, joalo-joalo.

▷Ke Likopo Life Bakeng sa Likarolo Tse Tloaelehileng tsa Metal Fabrication?

Likarolo tse entsoeng ka tšepe tse tloahelehileng li sebelisoa haholo bakeng sa tikoloho ea kahare le kantle. Likarolo tsa tšepe li entsoe ka Mehaho e Tloaelehileng, Likhabinete, Chassis, Brackets, Custom Hardware, Computer, Temo, Railway, Aerospace, Automobile, Pharmaceutical, Oli le Gas, Sesole, Storage, Plumbing, Kaho, Bongaka, Electronics, Mehala, Lijo. Tšebeletso, Ho futhumatsa le ho Pholisa le tse ling, tse koahelang indasteri eohle ea tlhahiso.

▷ Mokhoa oa ho Khetha Khoebo e Ntle ea ho Etsa Litšepe?

Hoo e batlang e le indasteri e 'ngoe le e' ngoe e sebelisa litšepe ho isa bohōleng bo itseng. Ho etsoa ha tšepe ea pampiri ho sebelisoa maemong a mangata, ho sa tsotellehe hore na ua e hloka kapa che. Ka lebaka leo, ha u e hloka, u tlameha ho khetha khoebo e ka lumellanang le litlhoko tsa hau hantle.

Ho na le lik'hamphani tse ngata tsa ho etsa tšepe ka ntle, empa hase kaofela ha tsona tse ka u fang seo u se hlokang. Ho na le lintho tse 'maloa tseo u lokelang ho li hopola ha u khetha k'hamphani e sebetsang ka tšepe.

Ntho ea bohlokoa ka ho fetisisa le e totobetseng eo u lokelang ho e fumana ke phihlelo. Likhamphani tseo u khethang ho sebetsa le tsona li hloka ho ba le boiphihlelo ba 'nete ka mofuta oa tšepe oo u o hlokang. Ka mohlala, haeba ho etsoa ka tšepe ke seo u se hlokang, joale k'hamphani e sebetsanang le tšepe kapa alloy e ke ke ea lula e na le bokhoni ba ho u thusa ho finyella liphello tseo u li batlang. Moralo o nepahetseng o bohlokoa mme o lokela ho fihla k'hamphaning e nang le bokhoni ba ho etsa moralo.

Likhamphani tseo u khethang ho sebetsa le tsona li tlameha ho ba le lisebelisoa tse tsoetseng pele le tse sebetsang hantle pele ho thekiso le sehlopha sa litšebeletso tsa kamora ho rekisa. Ho phethahatsa litlhoko tsa hau tsa moralo oa lakane, o hloka ho hlahloba hore na k'hamphani ena e na le bokhoni bona. Mohlala, mohlomong u fumana k'hamphani e kholo e nang le lisebelisoa tsa theknoloji e phahameng 'me u nahana hore u ka fumana lihlahisoa tse ntle, leha ho le joalo, mohlomong u ke ke ua fumana litšebeletso tse ntle tsa pele ho thekiso le ka mor'a thekiso, hobane mohlomong u moreki e monyane ho tsona.

Khampani e ntle ea tšepe ea tšepe e ela hloko haholo bareki bohle le boleng ba lihlahisoa tseo ba li etsang, hobane boleng ke bophelo ba bona. Mohlomong u nahana hore theko eo u e fumanang e phahame ho feta ba bang, empa na u kile ua nahana ka Boleng boo u bo batlang? Mesebetsi e metle ke ea bohlokoa. Haeba ho khonahala, o ka sheba k'hamphani ea rona sebakeng sa marang-rang mme o bue le rona lifahleho li talimane.

U lokela ho etsa bonnete ba hore k'hamphani eo u sebetsang le eona e ka u fa mekhoa eohle ea kopano le litšebeletso tsohle tsa masela a tšepe, ho tloha ho ho itšeha ka laser ho isa ho ho kobeha ha tšepe le ho phunya, kapa esita le ho hatakela.

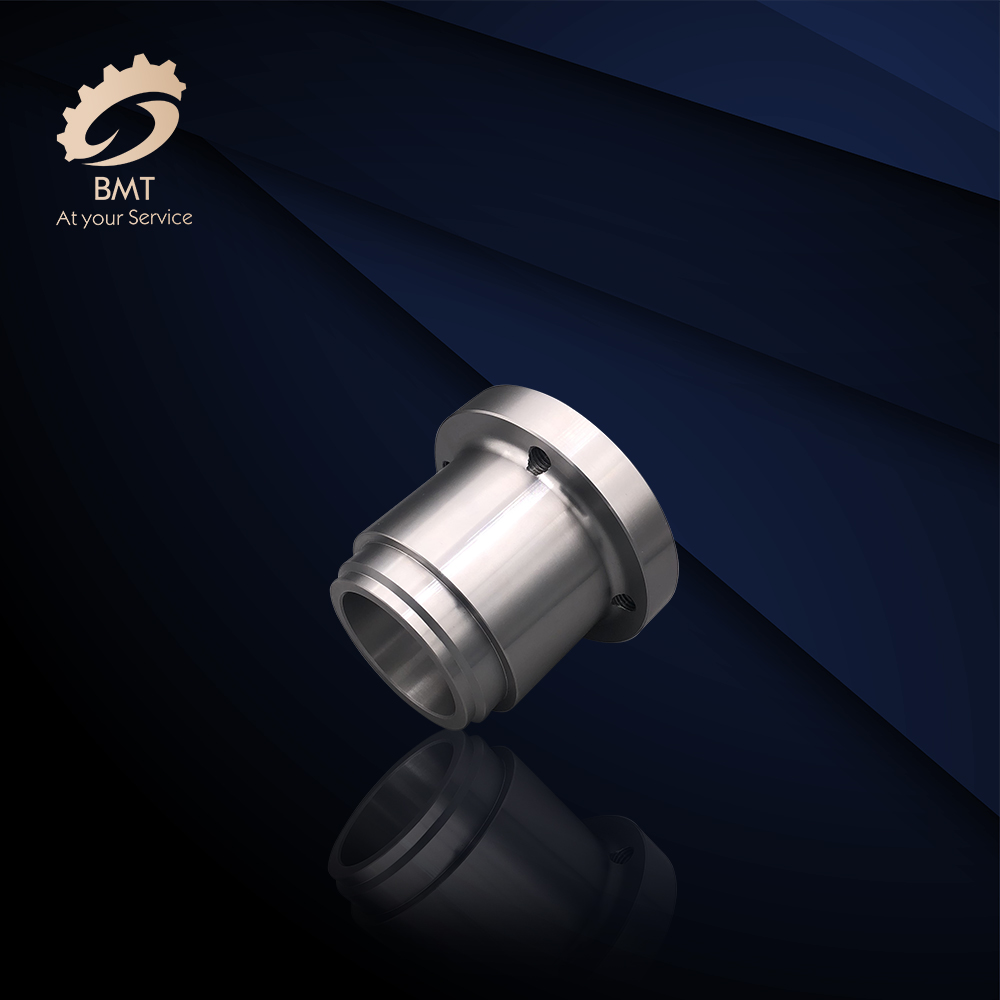

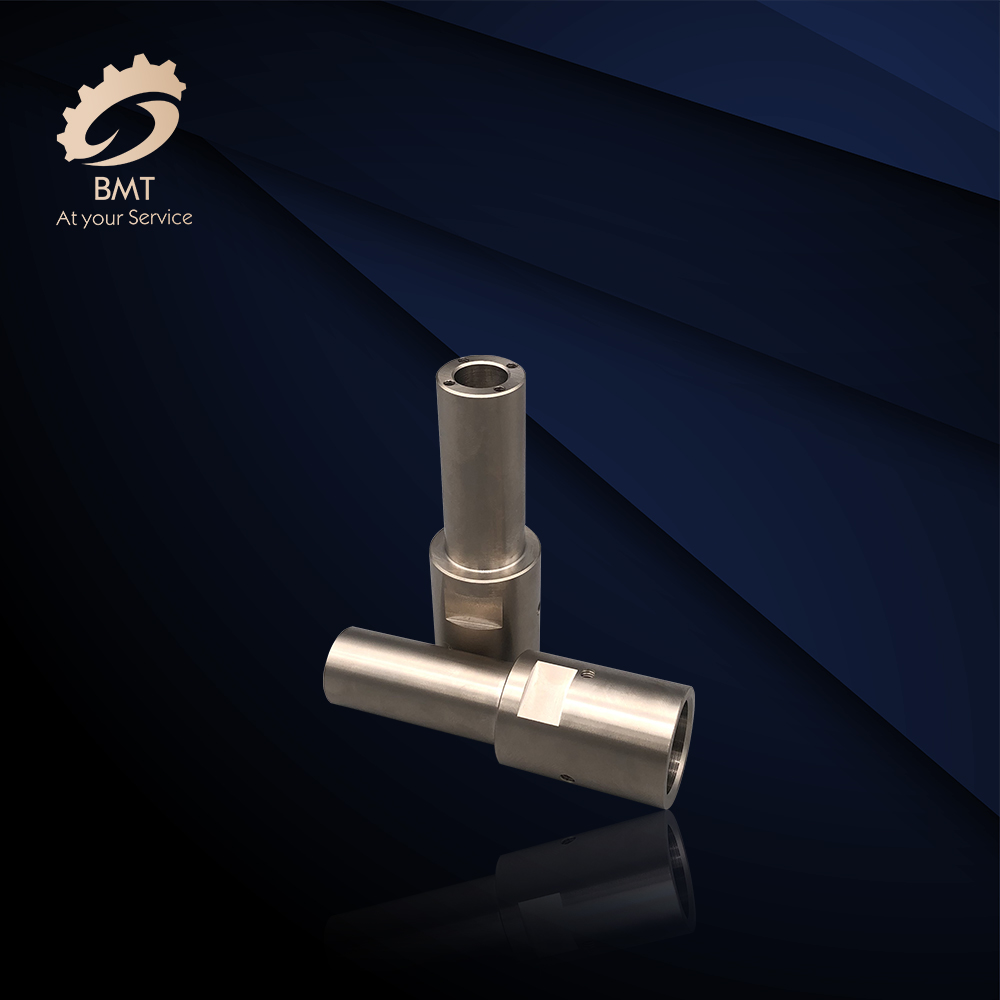

Ho etsa tšepe ke mosebetsi o rarahaneng. BMT e fana ka lits'ebeletso tsa CNC Machining le Sheet Metal hammoho ho fihlela litlhoko tsohle tsa hau tsa tlhahiso ka nako e le 'ngoe. Khamphani ea rona e na le bokhoni ba ho utloisisa litlhoko tsa hau e na le bokhoni ba ho etsa le ho hlokomela lintlha tse nyane haholo, e le hore o ka thabela lihlahisoa tse felileng.

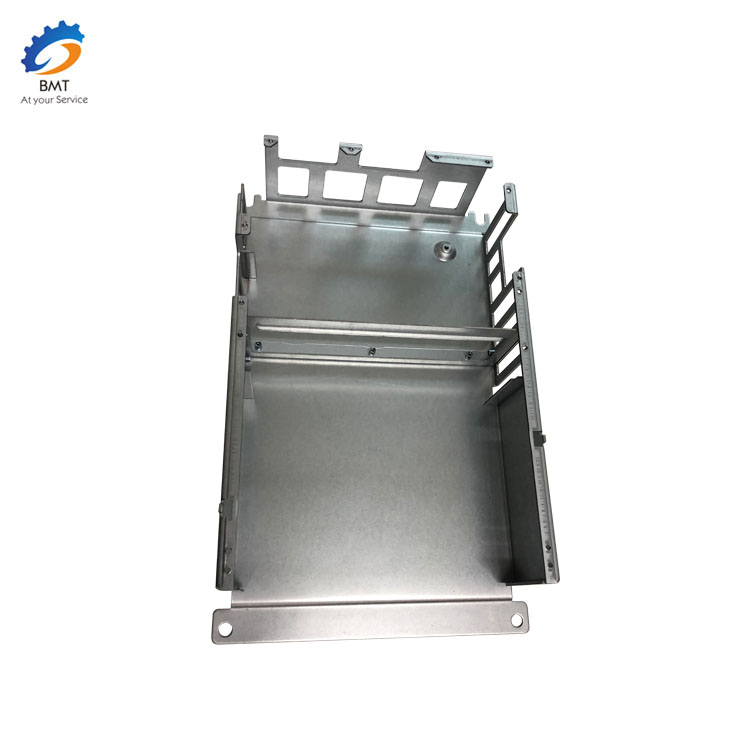

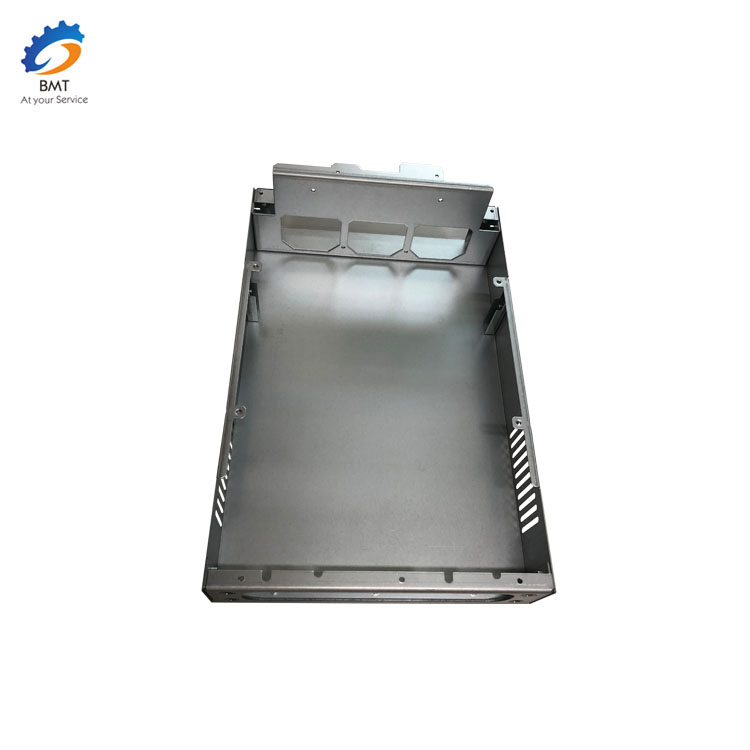

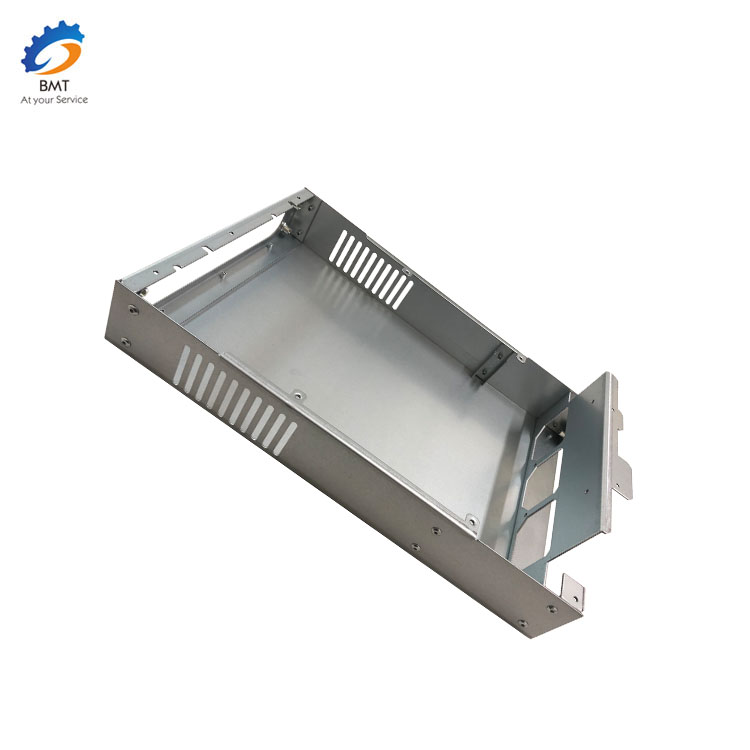

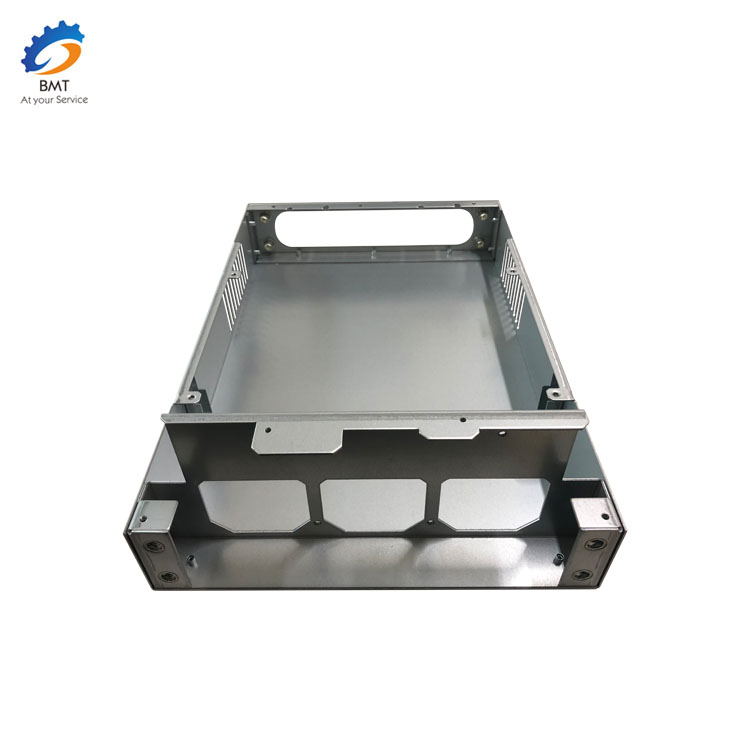

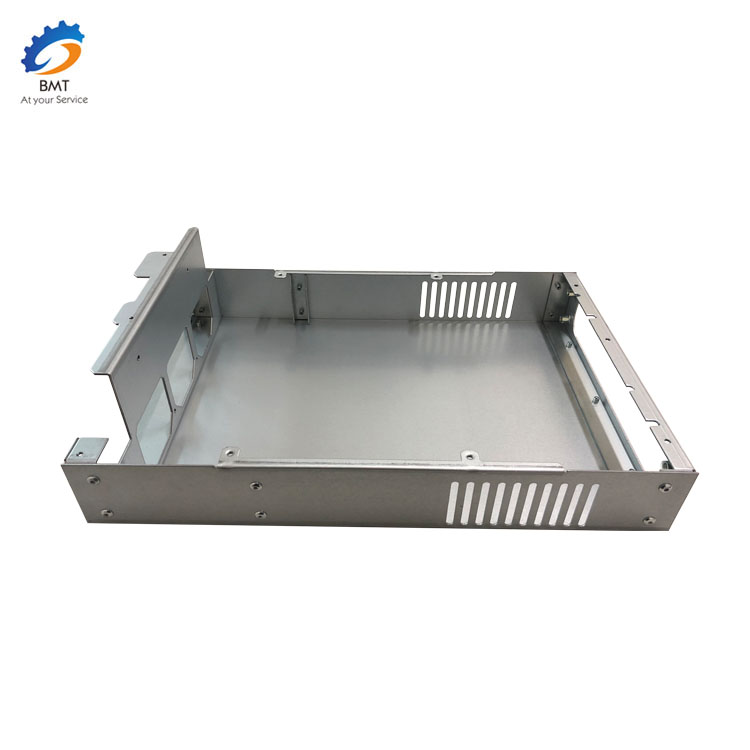

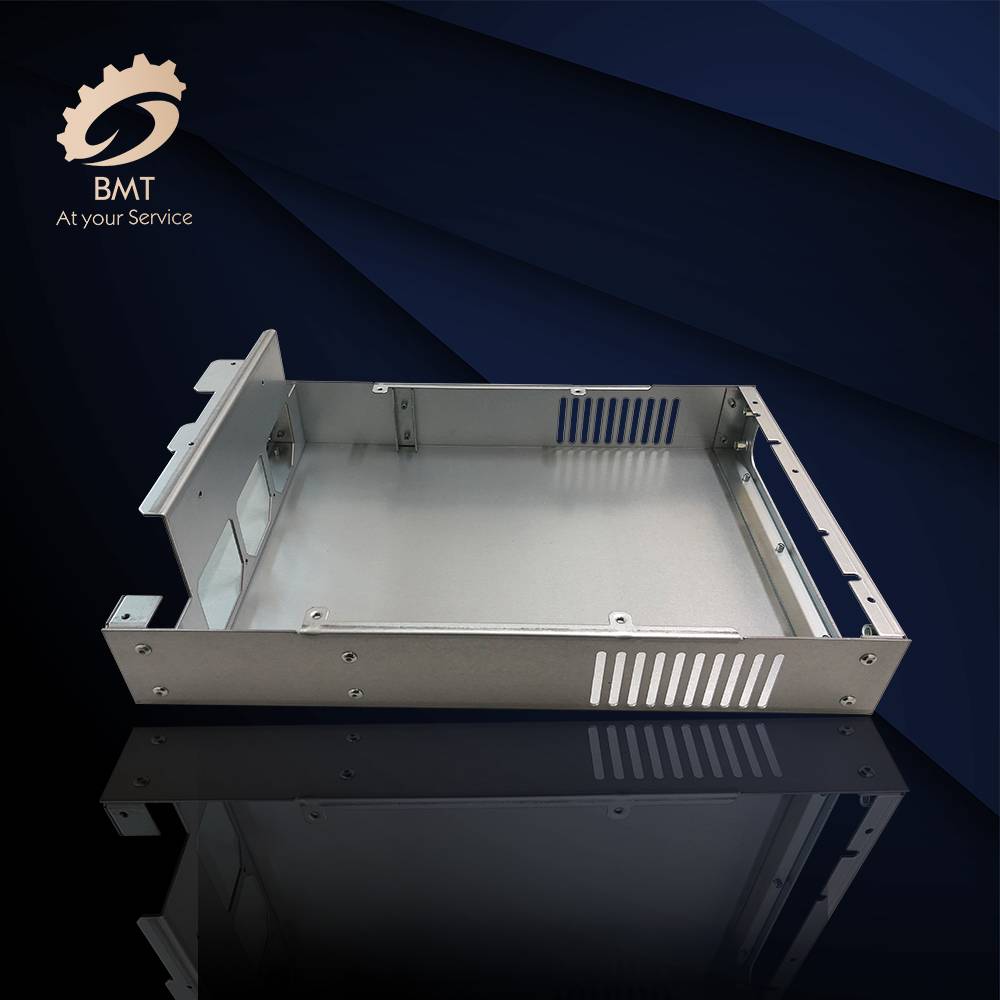

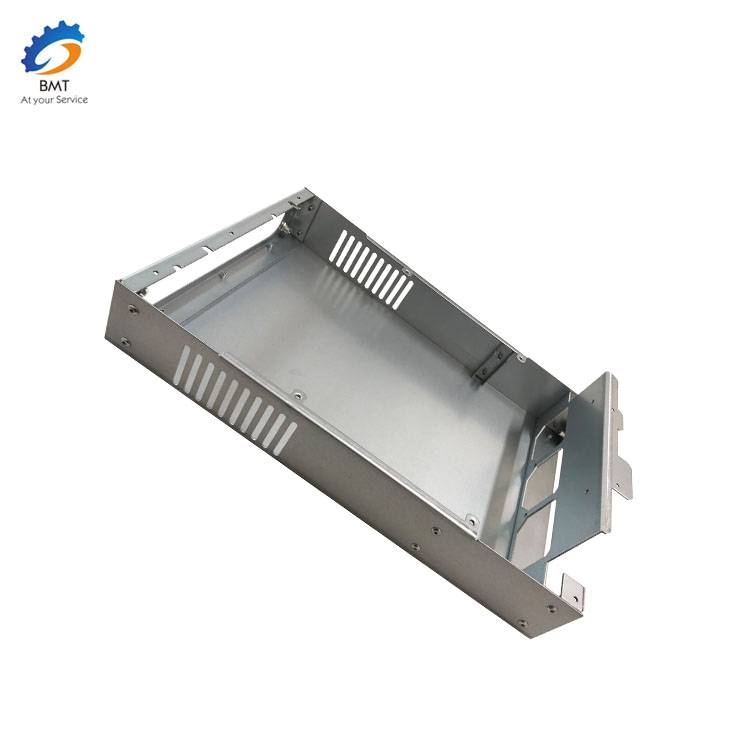

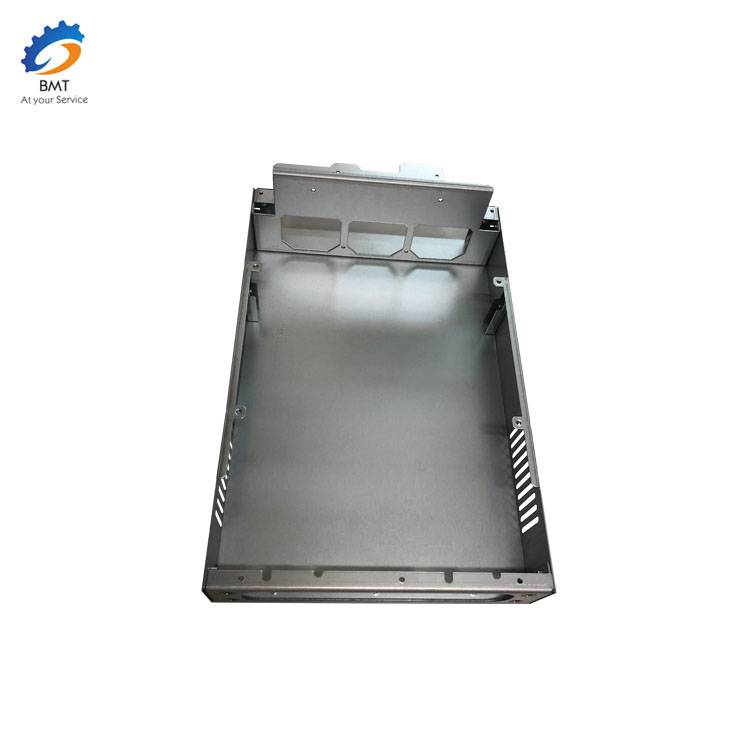

Tlhaloso ea Sehlahisoa