Litsela tse 5 tsa ho Ntlafatsa Likarolo tsa Metal tsa Sheet

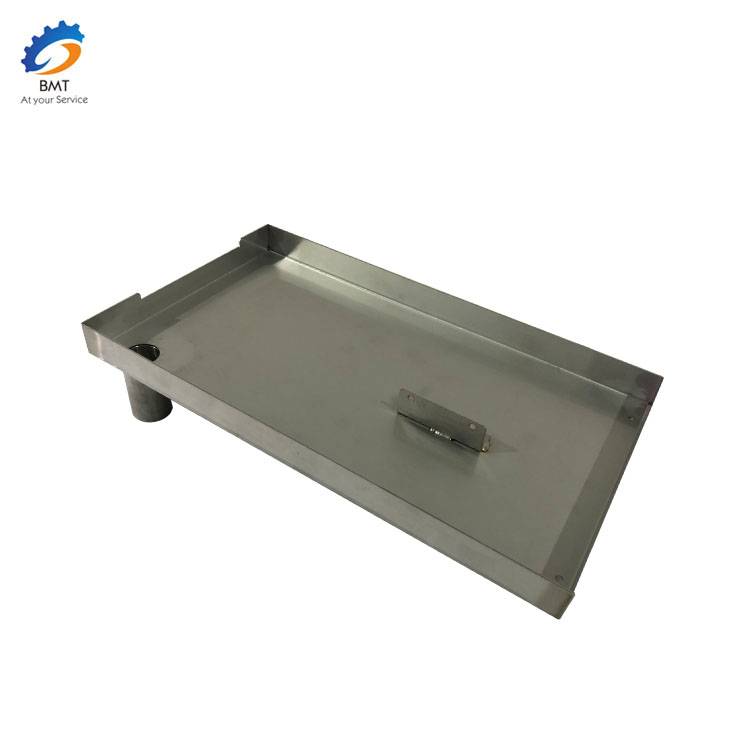

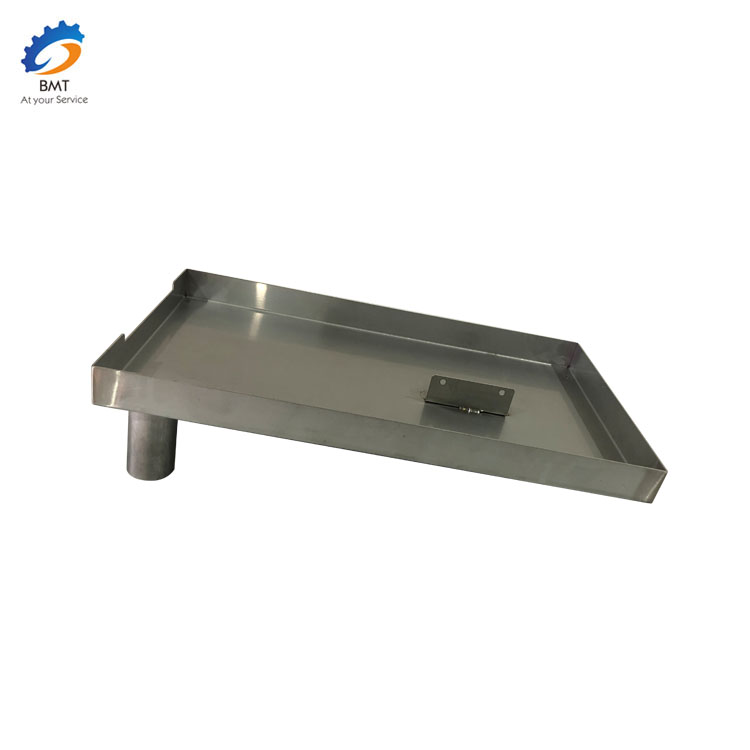

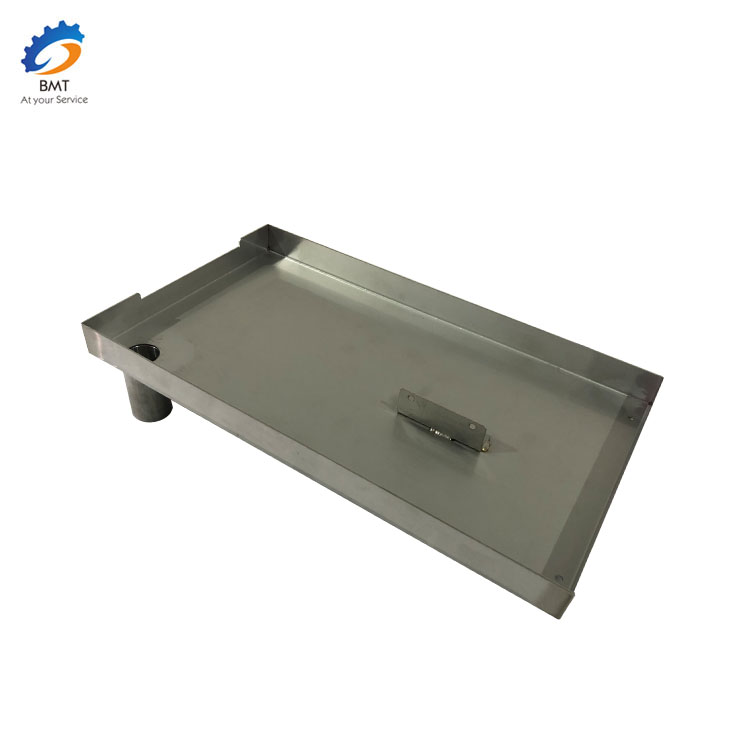

Sheet metal fabrication ke mokhoa o bonolo oa mekhoa ea tlhahiso e sebelisetsoang ho etsa likarolo ho tloha likotoana tse bataletseng tsa tšepe.Sheet metal e tla ka mefuta e fapaneng ea lisebelisoa le botenya, 'me e ka sebelisoa ho theha likarolo tse kang lisebelisoa, li-encreen, li-brackets, liphanele le chassis, joalo-joalo.

Ha ho bapisoa le machining a CNC, masela a tšepe a entsoe ka litlhaloso tse thata haholo tsa moralo.Bakeng sa basebetsi ba bang ba bacha bakeng sa ho etsa lesela la tšepe, mohlomong ho thata.Letlapa la tšepe le tlameha ho kobeha le ho khaoloa ka litsela tse itseng, 'me le loketse likarolo le lihlahisoa tse itseng feela.

Ha e le hantle, ke habohlokoa ho ithuta melao-motheo ea ho etsa lesela la tšepe pele u sebetsa.Ka ho sebelisa lesela la tšepe, litsebi li ka etsa likarolo tse tšoarellang, tse theko e tlaase tse tsoang thepa e fapaneng.Likarolo tsena li ka sebelisoa ho pholletsa le liindasteri tse fapaneng, ho tloha sebakeng sa sefofane ho ea ho lisebelisoa tsa lapeng.

Botenya ba tšepe bo sebelisoang ha ho etsoa tlhahiso hangata bo pakeng tsa 0.006 le 0.25 ", 'me boholo bo itšetlehile ka thepa e fanoeng le ho qetela ho sebelisoa ha karolo.

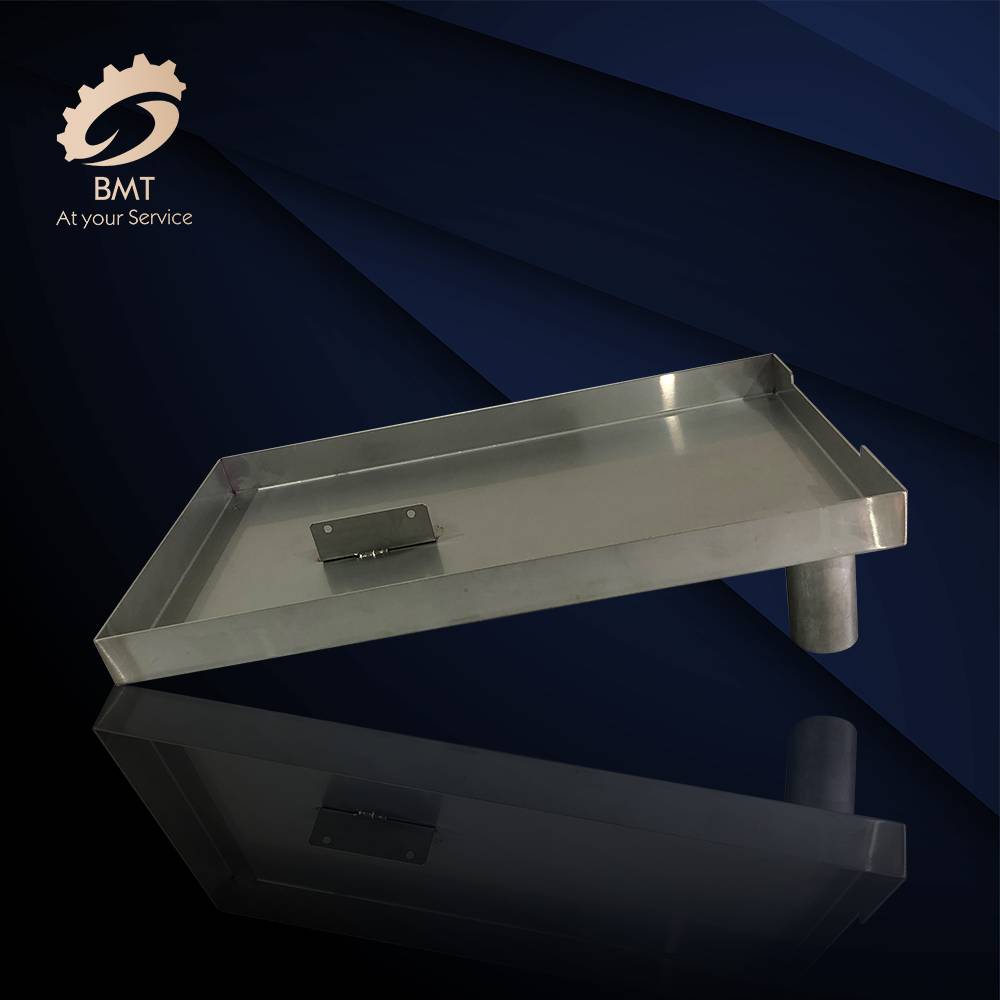

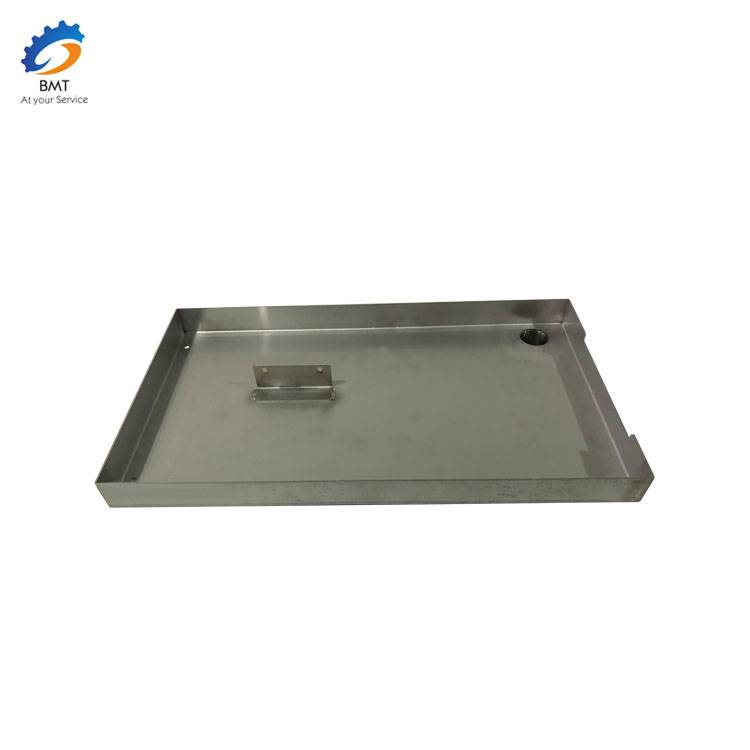

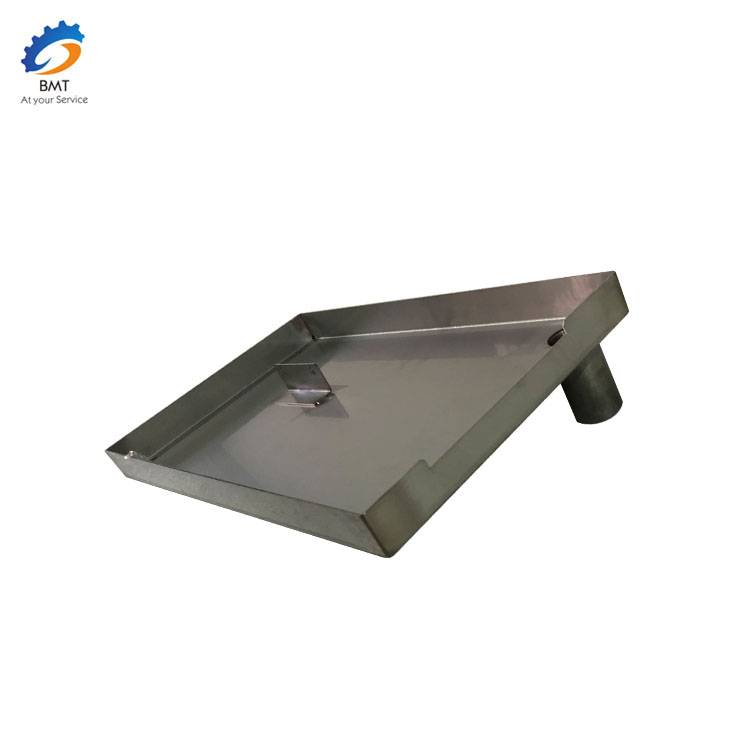

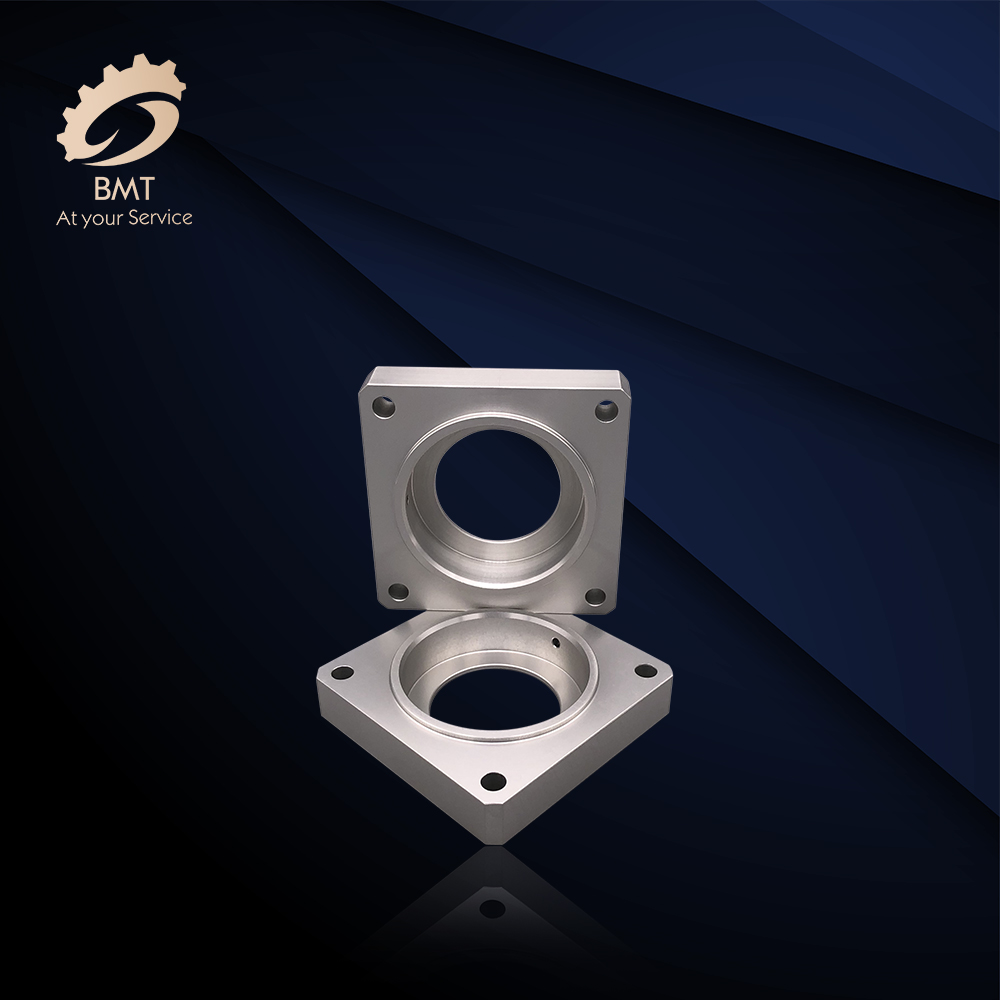

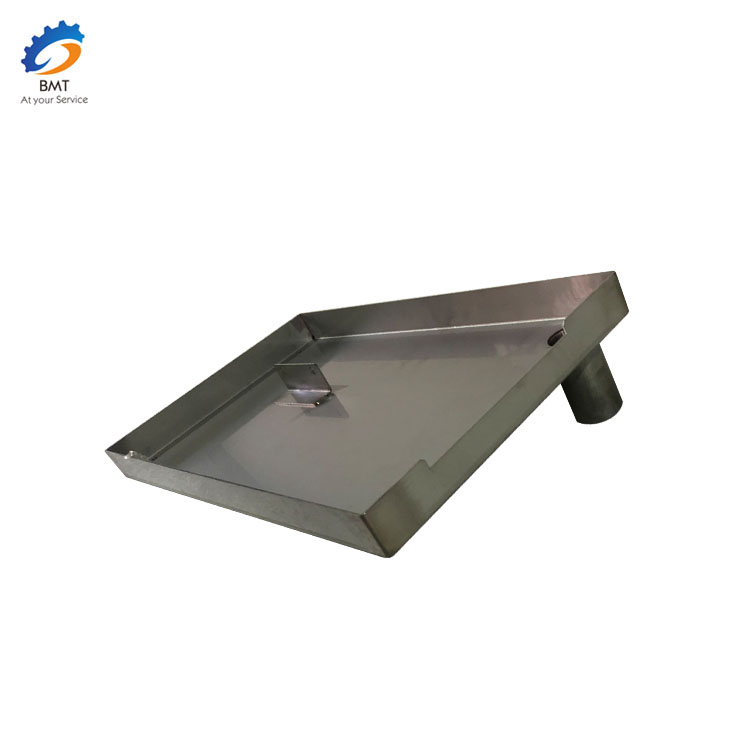

Tlhaloso ea Sehlahisoa

Ho etsoa ha tšepe ea pampiri ho ikhetha har'a mekhoa e sa tšoaneng ea tlhahiso.Ka lebaka lena, tekheniki e kanna ea rala likarolo tsa mochini oa CNC kapa likarolo tsa hlobo, empa ho thata ho rala likarolo tsa tšepe.

Ka ho ela hloko lintlha tse tšeletseng tse latelang, baqapi ba ka etsa likarolo tsa tšepe tse matla, tse bonolo ho li etsa le tse sa khoneng ho senya.

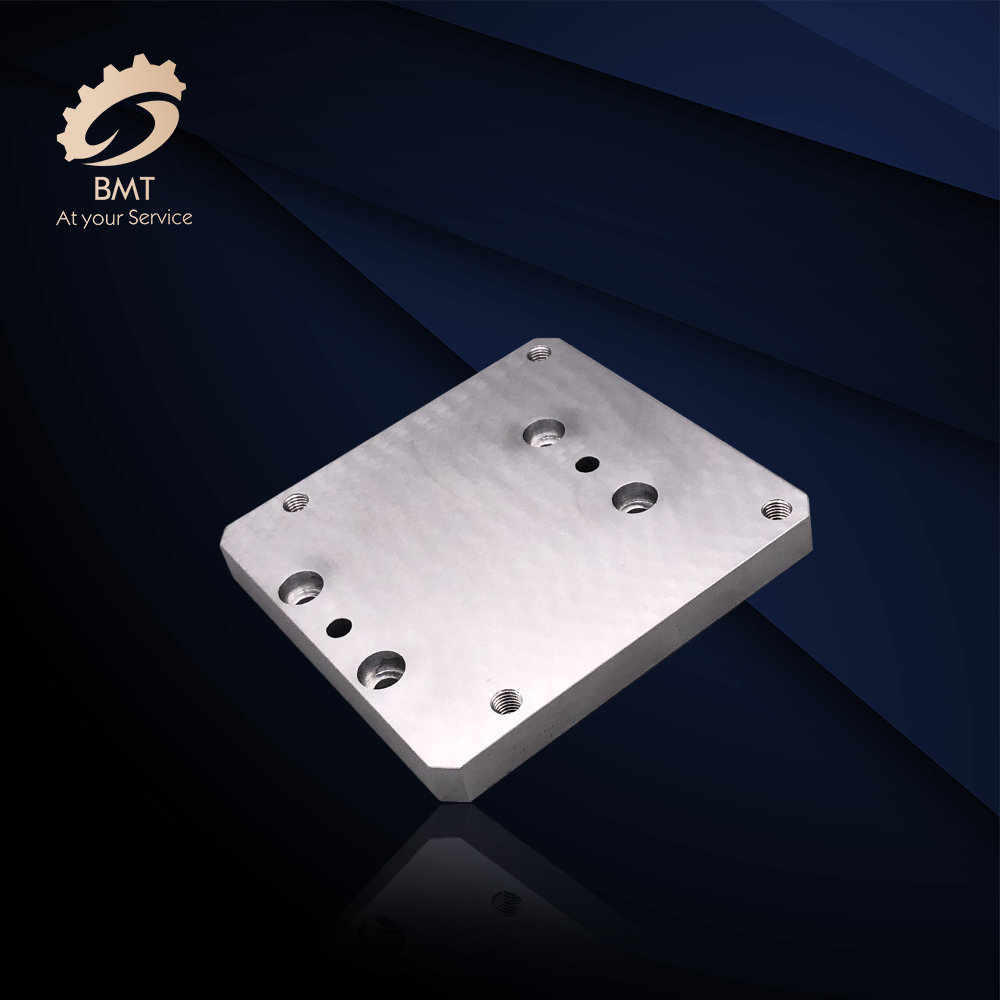

1. Likoti le Slots

Kaha masela a tšepe a sebelisoa hangata ho etsa likheo, li-brackets le lintho tse tšoanang, likoti le li-slots li atisa ho hlokoa bakeng sa li-screws, li-bolts kapa likarolo tse hokahaneng.Hangata likoti li bōptjoa ka punch 'me li shoe li kenngoa mochine oa khatiso, e leng se lumellang hore sebopeho se nepahetseng sa selikalikoe se khaotsoe ka lesela la tšepe.Empa haeba masoba a sa etsoa ka nepo, lesoba le ka ’na la holofala kapa la etsa hore karolo eo ka boeona e robehe.

Ha u phunya masoba ka lakane ea tšepe, melao e seng mekae ea bohlokoa e lokela ho lateloa.Likoti li lokela ho ba 1/8" ho tloha leboteng leha e le lefe kapa moeli 'me li lokela ho aroloa ka makhetlo a 6 ho feta botenya ba lakane.Ho feta moo, li-diameter tsa likoti tsohle le li-slots li lokela ho lumellana kapa ho feta botenya ba lakane ea tšepe.

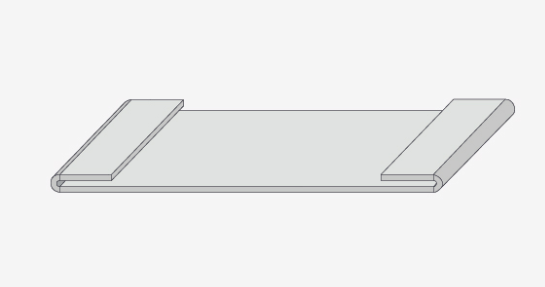

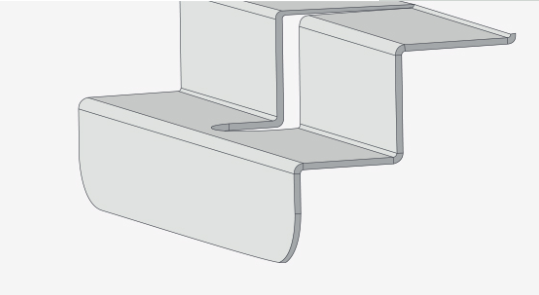

2. Li-Hems

Hemming ke mokhoa o motle oa ho etsa hore karolo ea tšepe e bolokehe ebile e sebetse.Re theha liheme tse bulehileng le tse koetsoeng.Mamello ea hem e itšetlehile ka radius ea hem, botenya ba thepa, le likarolo tse haufi le mohono.Re khothaletsa hore bonyane bophara bo ka hare bo lekana le botenya ba thepa, le bolelele ba ho khutla ba 6x.

Ha o eketsa hem karolong ea tšepe ea lakane, ho lokela ho lateloa litataiso tse 'maloa ho netefatsa ts'ebetso e nepahetseng.Ho qala, hoo e ka bang kamehla ho molemo ho qoba li-hems tse koetsoeng.Li-hems tse koetsoeng li kotsing ea ho senya thepa ka lebaka la lehlakoreng le feteletseng la ho kobeha, kahoo li-hems tse bulehileng, tse sieang lekhalo pakeng tsa mahlakore a mabeli a hem, li molemo ka ho fetisisa.

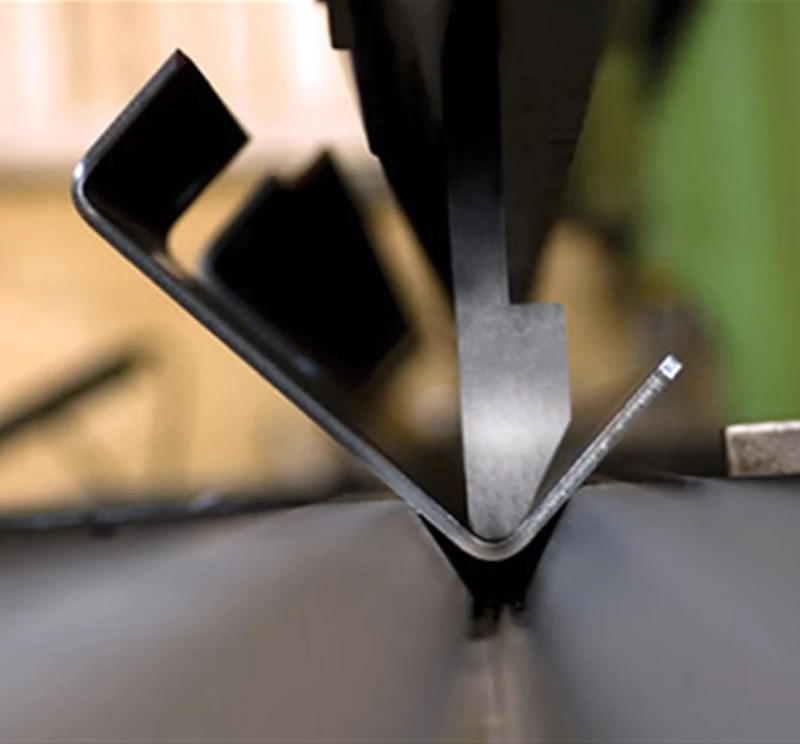

3. Koba

Ho khumama ke e 'ngoe ea mekhoa ea bohlokoahali ea ho theha masela a tšepe.Ho sebelisa lisebelisoa tse kang mariki le mechine ea khatiso, feme e khona ho fetola litšepe ka libopeho tse ncha.Bakeng sa ho khumama, e le ho etsa bonnete ba hore ho nepahetse esita le ho khumama, re lokela ho latela melao e itseng, 'me ho fokotsa monyetla oa ho senya thepa.

Molao o le mong o lokelang ho lateloa ke hore, ha ho etsoa karolo ea tšepe ea lakane e nang le li-bend, radius e ka hare ea bend e lokela ho bapisa kapa ho feta botenya ba lakane ea tšepe ho qoba deformation.Ho kgothaletswa ho sebelisa radius e tšoanang ho pota-pota hohle.Ho boloka botsitso tseleng e kobehang le radius ho ka thusa ho fokotsa litšenyehelo, kaha karolo e ke ke ea tlameha ho hlophisoa bocha mme lisebelisoa tse kobehang li ka pheta mokhoa o ts'oanang.

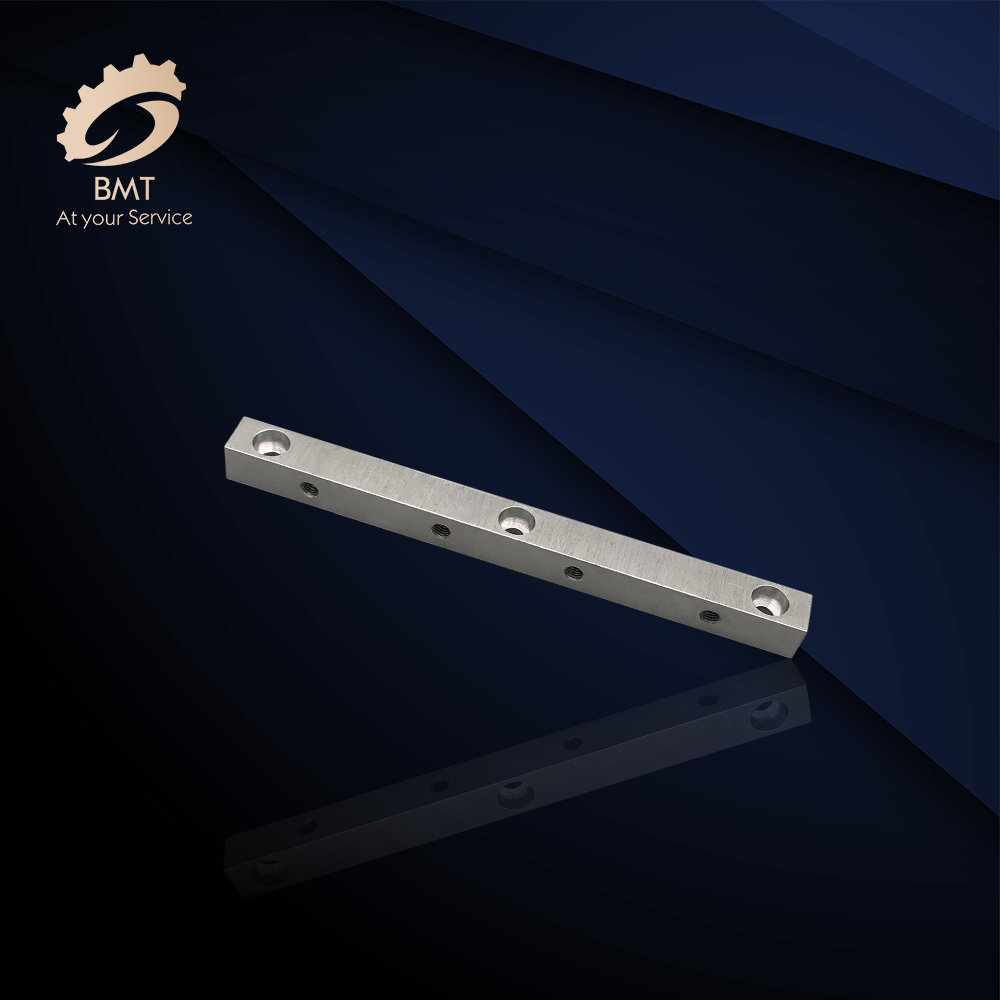

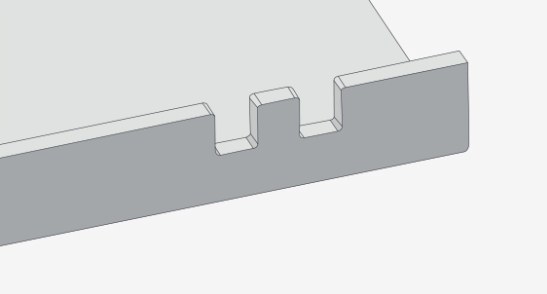

4. Linoto le Li-tab

Li-notch le li-tab ke likarolo tsa mantlha tsa likarolo tsa tšepe tse bohlokoa bakeng sa ho kenyelletsa li-screws kapa li-fasteners kapa ho kopanya likarolo tse ngata hammoho.Li-notch ke li-indent tse nyane moeling oa karolo, ha li-tab e le likarolo tse hlahelletseng.Letlapa le karolong e le 'ngoe ea tšepe hangata le kenyelletsoa hore le kene ka har'a notch ea karolo e' ngoe.

Joalo ka likarolo tse ling tsa tšepe, ho theha li-notch le li-tab tse loketseng ho boetse ho hloka ho latela melao e itseng: li-notch e tlameha ho ba bonyane botenya ba thepa kapa 1mm, ho sa tsotellehe hore na ke efe e kholo, 'me e ke ke ea feta makhetlo a 5 bophara ba eona.Li-tab li tlameha ho ba bonyane makhetlo a 2 ho botenya ba thepa kapa 3.2mm, ho sa tsotellehe hore na ke efe e kholoanyane, 'me e ke ke ea hlola e feta makhetlo a 5 bophara ba eona.

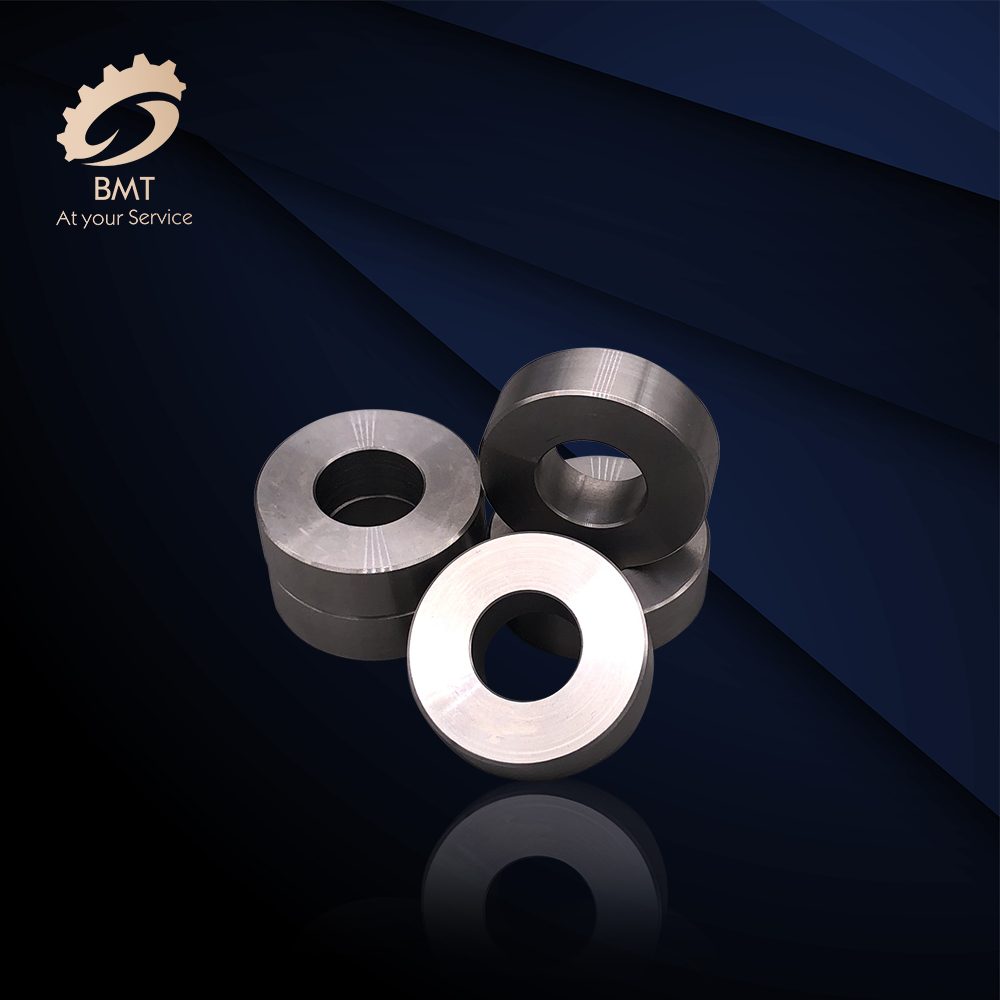

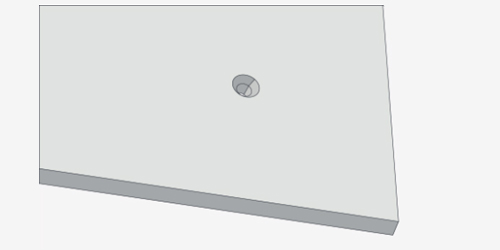

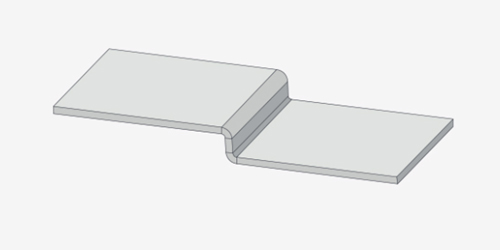

5. Offsets le Countersinks

Li-countersinks li ka etsoa ke CNC Machining kapa li entsoe ka lisebelisoa tse khethehileng.Mamello bakeng sa bophara bo boholo ba countersink e thata haholo, hobane mohlomong e hloka ho sebelisoa ka li-screws kapa li-fasteners.Li-offsets li sebelisoa ho theha li-profiles tse nang le sebopeho sa Z ka likarolo tsa tšepe.

6. Ho qeta

Ho ipapisitsoe le ts'ebeliso le lisebelisoa tse sebelisitsoeng, likarolo tsa tšepe li ka phethoa ka ho phatloha ha lifaha, anodizing, plating, ho roala phofo le lits'ebetso tse ling tse fapaneng, ebang ke molemong oa ts'ebetso kapa ho ntlafatsa ponahalo ea karolo feela.