Moetsi oa Titanium Precision Machining o Kenyelletsa Theknoloji ea Cutting-Edge ho Ntlafatsa Tlhahiso

Ka sepheo sa ho ipabola tlholisanong e phahamengho sebetsa ka nepoindasteri, moetsi e mong ea tummeng oa likarolo tsa titanium o sa tsoa kenyelletsa theknoloji ea morao-rao tšebetsong ea eona ea tlhahiso. Khamphani, e tsebahalang ka boitseanape ba eona bo ke keng ba lekanngoa ba ho etsa machining ea titanium, e ikemiselitse ho ntlafatsa bokhoni ba eona bo nepahetseng le ho fana ka lihlahisoa tsa boleng bo holimo ho bareki ba eona ho pota lefatše. Ka phihlelo ea lilemo tse tlas'a lebanta la eona, k'hamphani e 'nile ea leka ho lula e le ka pele ho tsoelo-pele ea theknoloji. Peeletso ena ea morao-rao e bonts'a boitlamo ba eona ba ho tsoela pele ho ntlafatsa ts'ebetso le ho fihlela litlhoko tse ntseng li tsoela pele tsa bareki ba eona.

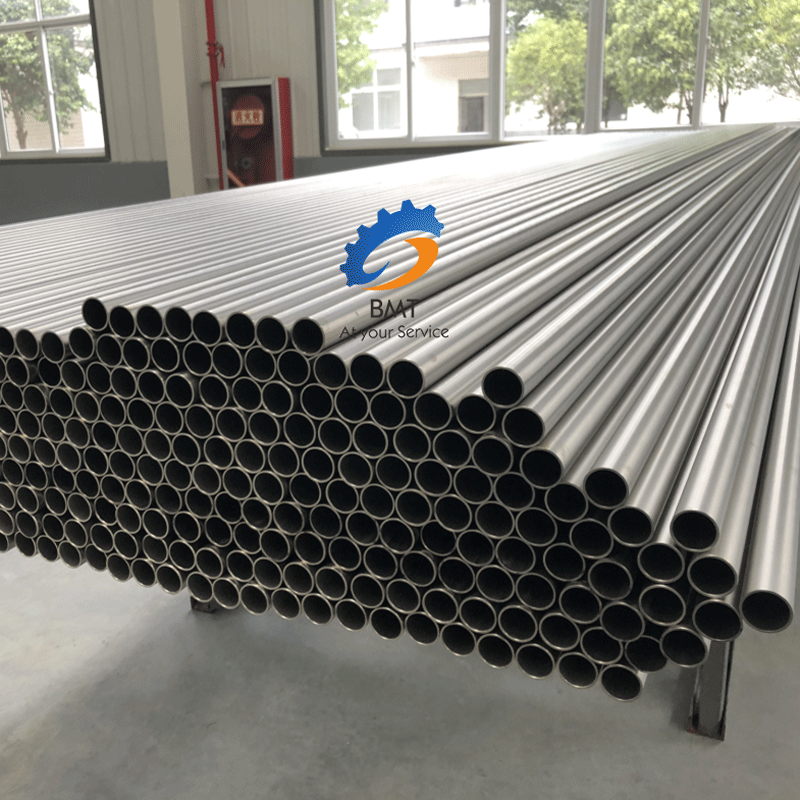

Ka ho kopanya mechini e tsoetseng pele le software, moetsi o butse menyetla e mecha ea boqapi le bokhoni. Kenyelletso ea mechini e tsoetseng pele e phahamisitse haholo ho nepahala le ho nepahala ha tšebetso ea tlhahiso. Hona joale k'hamphani e ithorisa ka mechine ea morao-rao ea ho laola lipalo tsa k'homphieutha (CNC), e sebelisang lisebelisoa tse nepahetseng tsa ho itšeha ho etsa likarolo tsa titanium ho latela litlhaloso tse tobileng. Theknoloji ena e netefatsa boleng bo tsitsitseng le ho khomarela mamello e tiileng, ea bohlokoa liindastering tse kang sefofane, bongaka le likoloi.

Ho feta moo, ts'ebetsong ea litsamaiso tse tsoetseng pele tsa software li fetotse meralo le lits'ebetso tsa tlhahiso. Moralo o matla oa khomphutha (CAD) le software e thusang khomphutha (CAM) e lumella ho etsa mohlala oa likarolo tse tsoetseng pele, ho hlahisa lisebelisoa tse sebetsang hantle, le maano a ntlafalitsoeng a mochini. Litharollo tsena tsa dijithale ha lia eketsa tlhahiso feela empa li boetse li fokolitse liphoso le ho khutsufatsa linako tsa ho etella pele, ho beha k'hamphani e le molekane ea tšepahalang le ea sebetsang hantle. Bokhoni bo ntlafetseng ba tlhahiso ha boa ka ba hlokomeloa, kaha bareki ba 'maloa ba boemo bo phahameng ba se ba bontšitse thahasello linyehelong tsa moetsi.

Lekala la lifofane, haholo-holo, le fana ka monyetla o moholo oa kholo bakeng sa k'hamphani, moo ho nepahala le ho tšepahala ho leng bohlokoa haholo. Ka bokhoni ba eona bo bocha ba ho hlahisa likarolo tse rarahaneng tsa titanium ka ho nepahala ho sa sekisetseng, moetsi o mothating oa ho iponahatsa e le sebapali sa bohlokoa indastering ena. Ho feta moo, k'hamphani e hlokomela bohlokoa ba ho tšoarella le mekhoa e ikarabellang ea tlhahiso. Kaha titanium e tsebahala ka thepa ea eona e bobebe le e matla haholo, ke khetho e nepahetseng bakeng sa ho fokotsa tlhahiso ea khabone liindasteri tse fapaneng. Ka ho eketsa bokhoni ba thepa ena e tšoarellang le eco-friendly, moetsi o kenya letsoho bokamosong bo botala.

Ntle le theknoloji ea morao-rao, k'hamphani e fana ka katleho ea eona ho basebetsi ba nang le boiphihlelo. Ka sehlopha sa baenjiniere ba nang le phihlelo le litsebi, e mong le e mong a na le kutloisiso e tebileng eamochini oa titanium, khampani e khona ho hlōla esita le mathata a rarahaneng ka ho fetisisa. Mananeo a koetliso ea basebetsi le matsapa a tsoelang pele a nts'etsopele ea litsebi a netefatsa hore basebetsi ba lula ba le morao-rao le mekhoa ea morao-rao ea indasteri.

Ha indasteri ea machining e ntse e tsoela pele, moetsi enoa oa titanium o lula a ikemiselitse ho ikamahanya le maemo le ho hola haufi le eona. Ka ho tsetela ho theknoloji e tsoetseng pele, k'hamphani e tšehetsa boitlamo ba eona ba ho fana ka lihlahisoa tse ntle haholo le ho boloka boemo ba eona e le moetapele 'marakeng. Ha bareki ba batla maemo a holimo a ho nepahala, moetsi enoa o hlomeletsoe hantle ho feta litebello tsa bona le ho ba fa litharollo tse tsoetseng pele.

Nako ea poso: Jul-03-2023