Theliindasteri tsa sefofane le tsa bongakali lula li fetoha, 'me tlhokahalo ea thepa ea boleng bo holimo e khonang ho mamella maemo a feteletseng e lula e le teng. Ho theha Titanium, ho latela litekanyetso tsa ASTM B381, ho hlahile e le karolo ea bohlokoa ho fihlela litlhoko tsena. Ka matla a eona a ikhethang, tlhaho e bobebe, le ho hanyetsa ho bola, titanium e fetohile thepa ea khetho bakeng sa mefuta e mengata ea lisebelisoa, ho tloha ho likarolo tsa sefofane ho ea ho li-implants tsa bongaka. ASTM B381 ke tekanyetso e tloaelehileng bakeng sa forgings ea titanium le titanium alloy, e hlalosang litlhoko tsa sebopeho sa lik'hemik'hale, thepa ea mochini, le phapang e lumelletsoeng ea boholo.

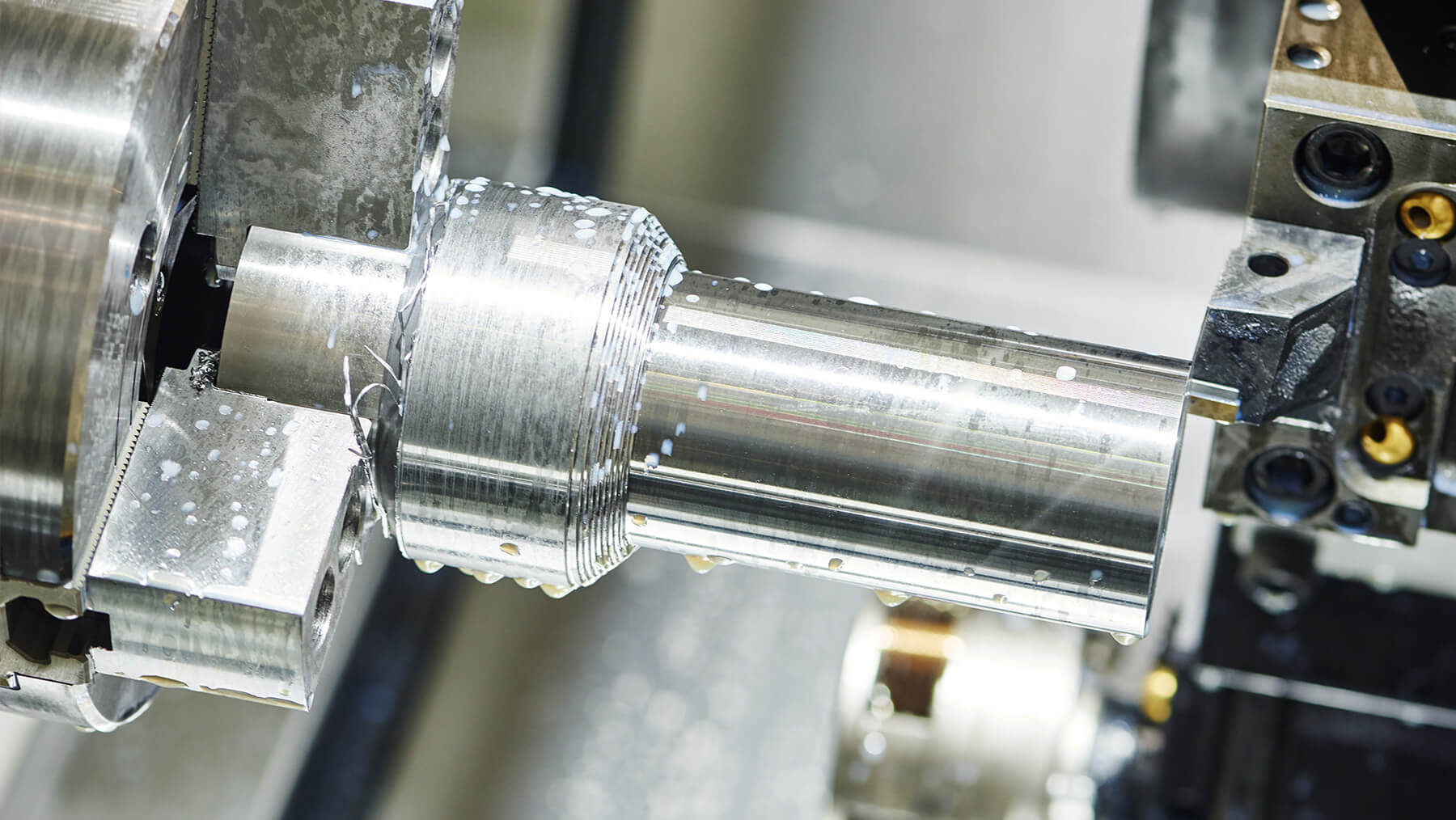

Tekanyetso ena e netefatsa hore li-titanium forgings li kopana le litekanyetso tse thata tsa boleng le ts'ebetso e hlokahalang bakeng sa ho sebelisoa lits'ebetsong tsa bohlokoa. Indastering ea sepakapaka, lintho tse entsoeng ka titanium li phetha karolo ea bohlokoa tlhahisong ea likarolo tsa lifofane. Ho tloha ho likarolo tsa sebopeho ho ea ho likarolo tsa enjene, tmatla a phahameng a itanium-karolelano ea boima ba 'mele e e etsa sesebelisoa se loketseng ho ntlafatsa ts'ebetso ea sefofane le ho sebetsa hantle ha mafura. Ho feta moo, ho hanyetsa ha eona ho kutu le maemo a mocheso o phahameng ho etsa hore e tšoanelehe bakeng sa lisebelisoa tsa sefofane. Ho feta moo, indasteri ea bongaka e boetse e amohetse tšebeliso ea lisebelisoa tsa titanium ka lebaka la ho lumellana ha tsona le ho hanyetsa maro a 'mele. Li-implants tsa Titanium, tse kang ho nkela sebaka sa noka le lengole, ho kenya meno le lisebelisoa tsa ho lokisa mokokotlo, li se li atile haholo, li fa bakuli tharollo e tšoarellang le ea nako e telele bakeng sa maemo a fapaneng a bongaka. Tšebeliso ea "titanium forgings" liindastering ka bobeli e lebisitse tsoelopeleng ea mahlale le mahlale a morao-rao.

Mohlala, nts'etsopele ea likarolo tse rarahaneng, tse bobebe li entsoe hore li khonehe kaho etsoa ka mokhoa o nepahetseng oa titanium, ho lumella ho ntlafatsa aerodynamics sebakeng sa sefofane le ho ntlafatsa ts'ebetso ea lisebelisoa tsa bongaka. Ho feta moo, ho amoheloa ha litekanyetso tsa ASTM B381 ho netefatsa hore lihlahisoa tsa titanium li fihlella litlhoko tsa boleng bo holimo le polokeho. Boemo bona ha bo ruise bahlahisi feela ka ho fana ka litataiso tse hlakileng tsa tlhahiso, empa hape bo kenya ts'epo ho basebelisi ba ho qetela mabapi le ts'epahalo le ts'ebetso ea "titanium forgings". Ha tlhoko ea forgings ea titanium e ntse e hola, boiteko ba lipatlisiso le nts'etsopele bo tsepamisitse maikutlo ho ntlafatseng thepa ea thepa le ho holisa lits'ebetso tsa eona. Tsoelo-pele e ntseng e tsoela pele ea mekhoa ea ho qapa le liqapi tsa alloy li reretsoe ho sututsa meeli ea seo titanium e ka se fihlelang, ho bula menyetla e mecha ea ts'ebeliso ea eona liindastering tse fapaneng.

Ntle le thepa ea eona ea mochini, ho tšoarella ha titanium forging le eona ke ntlha ea bohlokoa molemong oa ho amoheloa ha eona hohle. Titanium e ka sebelisoa hape ka botlalo, 'me mokhoa oa ho qhekella ka boeona o baballa matla, e leng se etsang hore e be khetho e ntle bakeng sa bahlahisi le basebelisi ba ho qetela. Ha re sheba pele, bokamoso ba ho theha titanium ho latela litekanyetso tsa ASTM B381 bo bonahala bo ts'episa. Ha tsoelo-pele ea theknoloji e ntse e tsoela pele ho fetoha ha theknoloji ea sepakapaka le ea bongaka, ho qhekella ha titanium ho tla tsoela pele ho ba ka pele ho boqapi, ho nolofalletsang nts'etsopele ea lihlahisoa tse sireletsehileng, tse sebetsang hantle le tse tšoarellang haholoanyane.

Qetellong, titanium forging ka ho latelaLitekanyetso tsa ASTM B381e fetohile thepa ea bohlokoa bakeng sa indasteri ea lifofane le tsa bongaka. Thepa ea eona e ikhethang, hammoho le netefatso e tiileng ea boleng e fanoeng ke maemo a ASTM, e behile forging ea titanium e le motheo oa tsoelopele ea theknoloji. Ka lipatlisiso le nts'etsopele e ntseng e tsoela pele, monyetla oa ho ntlafatsa le katoloso ea likopo tsa forgings ea titanium e kholo, e ts'episang bokamoso moo boitsebiso bona bo tsotehang bo tsoelang pele ho bopa bokapele ba theknoloji ea sefofane le ea bongaka.

Nako ea poso: Apr-07-2024