Lefatšeng la tlhahiso, ho nepahala ke ntho ea bohlokoa. 'Me ha ho tluoa tabeng ea likarolo tsa mochine, tlhokahalo ea ho nepahala ho phahameng e bohlokoa le ho feta. Mona ke moo tloaelolikarolo tse phahameng tsa ho sebetsa ka koporokena papaling. Likarolo tsena ke likarolo tsa bohlokoa liindastering tse fapaneng, ho tloha sebakeng sa sefofane le likoloi ho ea ho lisebelisoa tsa elektroniki le tsa bongaka. Koporo ke thepa e feto-fetohang le e tšoarellang haholo e sebelisoang haholo indastering ea tlhahiso. Ts'ebetso ea eona e ntle ea motlakase le ea mocheso, ho hanyetsa kutu, le ho senyeha ha eona ho e etsa khetho e nepahetseng bakeng sa likarolo tsa mochini tse hlokang ho nepahala ho holimo. Likarolo tsa machining tsa koporo tse tloahelehileng haholo li sebelisoa lits'ebetsong tse fapaneng, ho kenyeletsoa lihokelo tsa motlakase, li-exchange tsa mocheso le lisebelisoa tse nepahetseng.

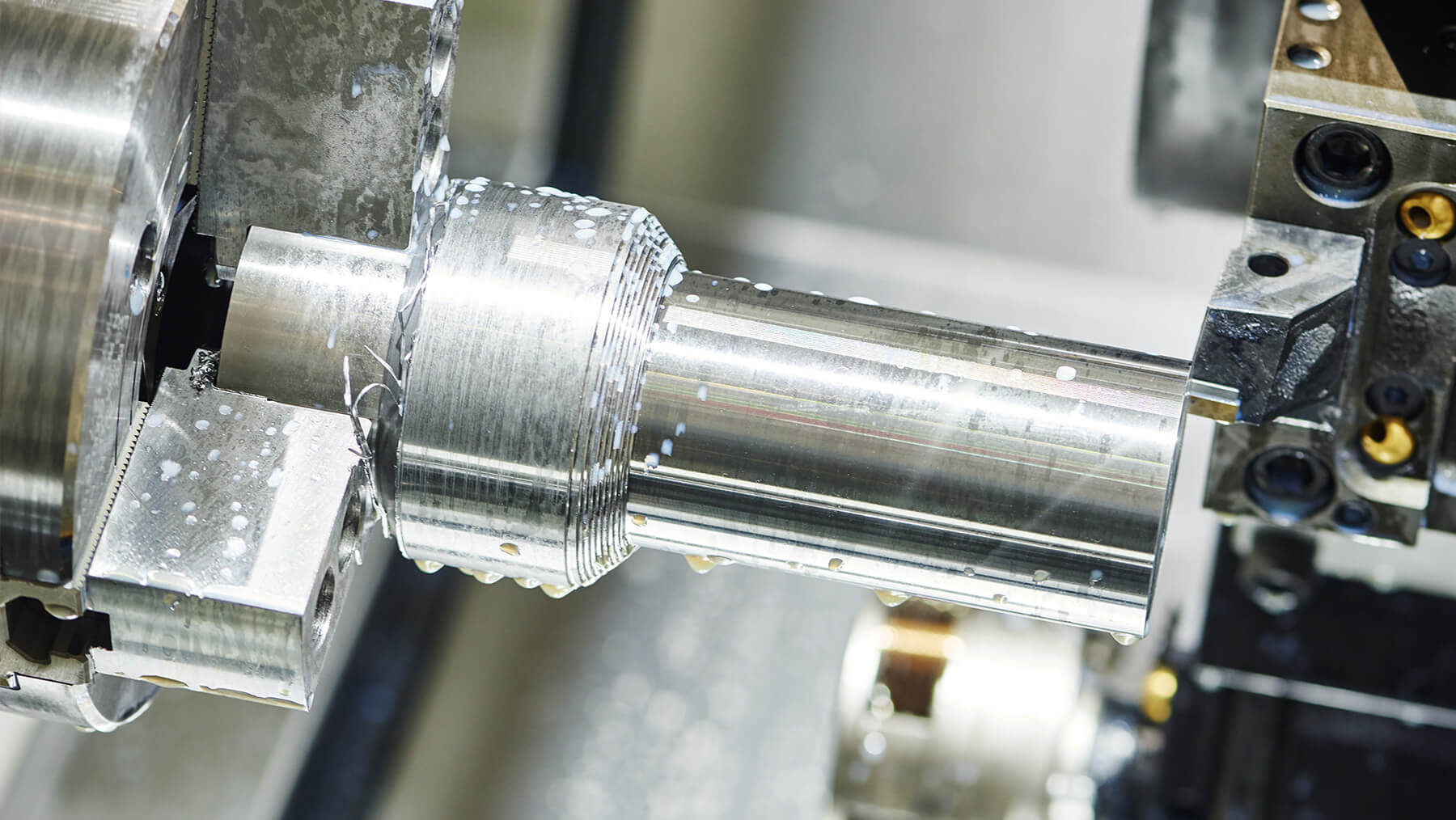

Mokhoa oa ho lokisa likarolo tsa koporo o hloka theknoloji e tsoetseng pele le tsebo ea ho netefatsa boemo bo phahameng ka ho fetisisa ba ho nepahala.CNC(Computer Numerical Control) machining e atisa ho sebelisoa ho hlahisa likarolo tsa koporo tse nepahetseng haholo. Theknoloji ena e lumella ho theha meralo e rarahaneng le e rarahaneng e nang le mamello e thata, ho etsa bonnete ba hore likarolo tse phethiloeng li kopana le litlhaloso tse nepahetseng tse hlokoang ke moreki. E 'ngoe ea melemo ea mantlha ea likarolo tsa machining tsa koporo ke bokhoni ba tsona ba ho mamella maemo a feteletseng. Koporo e na le conductivity e ntle ea mocheso, e e etsa khetho e nepahetseng bakeng sa likarolo tse pepesehileng mocheso o phahameng. Sena se etsa hore e be khetho e tsebahalang bakeng sa li-exchangers tsa mocheso le likarolo tse ling tse sebelisoang libakeng tse hlokang.

Ntle le thepa ea eona ea mocheso, koporo e boetse e fana ka conductivity e ntle ea motlakase, e etsang hore e be thepa ea bohlokoa bakeng sa lihokelo tsa motlakase le likaroloana. Mokhoa o phahameng oa ho sebetsa ka mokhoa o nepahetseng o tiisa hore likarolo tsena li finyella litlhoko tse thata bakeng sa ts'ebetso ea motlakase, e leng se etsang hore li tšoanelehe bakeng sa mefuta e mengata ea lisebelisoa tsa elektronike. Indasteri ea bongaka e boetse e rua molemo ho likarolo tsa machining tsa koporo tse tloahelehileng haholo. Lintho tse thibelang likokoana-hloko tsa koporo li etsa hore e be thepa e loketseng bakeng sa lisebelisoa tsa bongaka le lisebelisoa. Themokhoa o nepahetseng oa ho sebetsae tiisa hore likarolo tsena li finyella litekanyetso tse thata tse hlokahalang bakeng sa likopo tsa bongaka, ho fana ka tharollo e tšepahalang le e sireletsehileng bakeng sa litsebi tsa tlhokomelo ea bophelo le bakuli ka ho tšoanang.

Liindasteri tsa lifofane le tsa likoloi le tsona li itšetlehile ka likarolo tsa machining tsa koporo tse nepahetseng bakeng sa likarolo tsa bohlokoa. Ho tloha litsing tsa mafura le li-hydraulic fittings ho ea ho lisebelisoa tse nepahetseng le li-sensor, likarolo tsa koporo li phetha karolo ea bohlokoa ho netefatsa polokeho le ts'ebetso ea lifofane le likoloi. Ha tlhokeho ea likarolo tsa mochini oa koporo e nepahetseng e ntse e hola, bahlahisi ba tsetela ho theknoloji e tsoetseng pele le boiphihlelo ho fihlela litlhoko tsa bareki ba bona. Sena se kenyelletsa tšebeliso ea lisebelisoa tsa morao-rao tsa mochini oa CNC, hammoho le baenjiniere ba nang le litsebo tse phahameng le bo-machini ba khonang ho hlahisa likarolo tse rarahaneng le tse rarahaneng tsa koporo ka boemo bo phahameng ka ho fetisisa ba ho nepahala.

Qetellong, likarolo tsa machining tsa koporo tse nepahetseng ke likarolo tsa bohlokoa liindastering tse fapaneng, tse fanang ka conductivity e ikhethang ea mocheso le motlakase, ho hanyetsa kutu, le thepa ea antimicrobial. Theknoloji e tsoetseng pele le tsebo e hlokahalang ho hlahisa likarolo tsena li netefatsa hore li finyella litlhoko tse tiileng tsa ho nepahala le ts'ebetso, e leng se etsang hore e be tharollo ea bohlokoa bakeng sa mefuta e fapaneng ea likopo.

Nako ea poso: May-17-2024