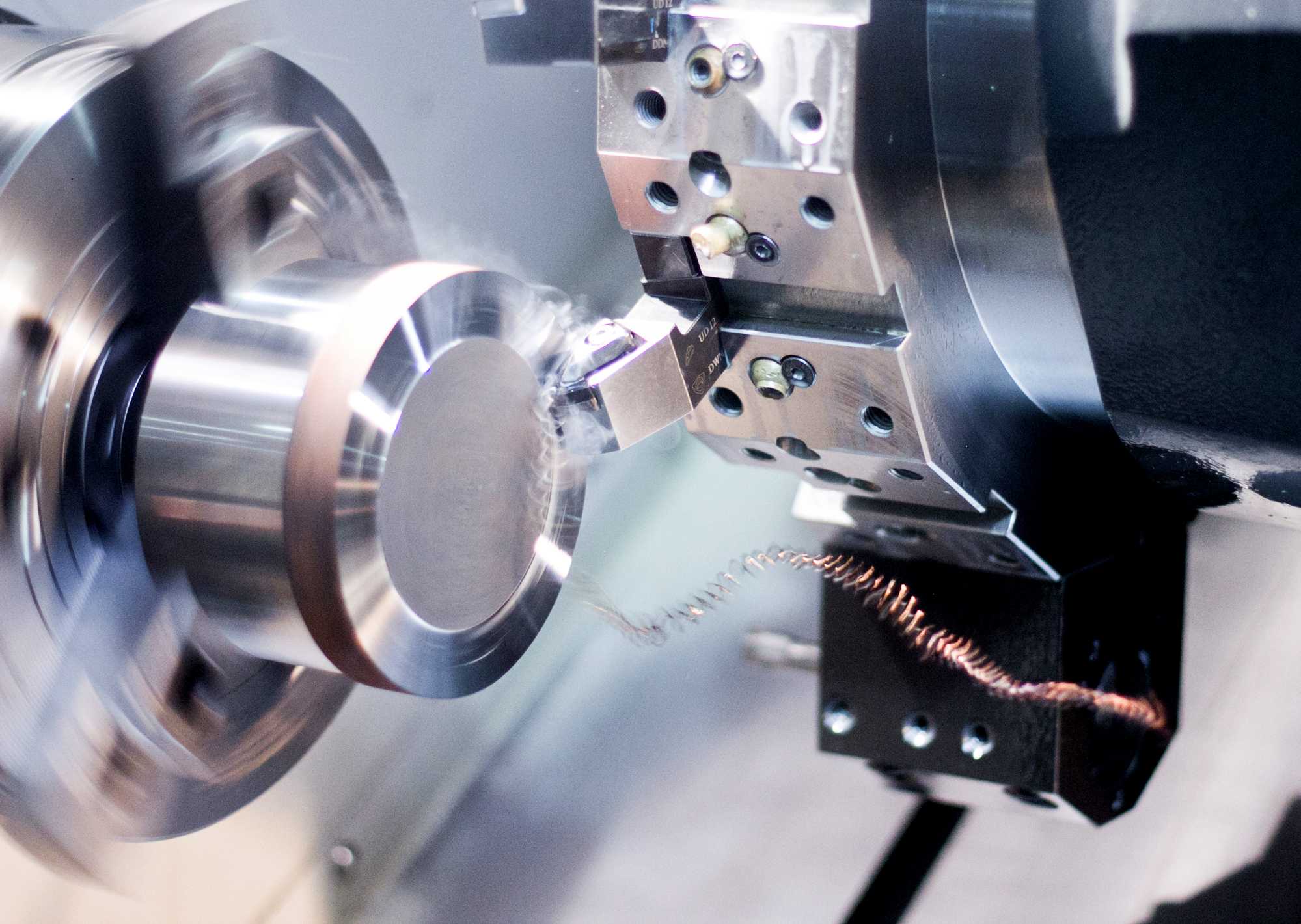

Lefatšeng la tlhahiso,Mechine ea CNClikarolo tse ling li bapala karolo ea bohlokoa ho netefatsa hore liindasteri tse fapaneng li sebetsa ka thelelo le ka bokhabane. Ho tloha ho likoloi ho ea sebakeng sa sefofane, lisebelisoa tsa bongaka ho ea ho lisebelisoa tsa elektroniki tsa bareki, likarolo tsa machining tsa CNC ke mokokotlo oa mekhoa ea sejoale-joale ea tlhahiso. CNC (Computer Numerical Control) machining ke mokhoa oa tlhahiso o sebelisang lisebelisoa tsa lik'homphieutha le lisebelisoa tsa mochine ho tlosa thepa ho tloha mosebetsing, ho etsa likarolo tse entsoeng ka mokhoa o tloaelehileng ka ho nepahala le ho nepahala ho phahameng. Likarolo tsena ke likarolo tsa bohlokoa tsa mochini le lisebelisoa tse sebelisoang liindastering tse fapaneng.

E 'ngoe ea melemo ea mantlha ea machining ea CNClikarolo tsa tlatsetsoke bokhoni ba tsona ba ho hlahisoa ka boemo bo phahameng ba ho tsitsa le ho pheta-pheta. Sena se bohlokoa haholo liindastering tseo ho tsona ho nepahetseng le boleng ba tsona e leng tsa bohlokoa, tse kang ho etsa lifofi le lisebelisoa tsa bongaka. Likarolo tsa lisebelisoa tsa mochini oa CNC li ka etsoa ka mamello e thata haholo, ho netefatsa hore li kopana le lintlha tse hlokahalang bakeng sa ts'ebeliso ea tsona e reriloeng. Ho feta moo, likarolo tsa lisebelisoa tsa mochini oa CNC li ka hlahisoa ho tsoa mefuteng e fapaneng ea lisebelisoa, ho kenyeletsoa litšepe, lipolasetiki le li-composite. Mokhoa ona oa ho feto-fetoha o lumella bahlahisi ho etsa likarolo tse lumellanang le litlhoko tse khethehileng tsa lihlahisoa tsa bona, ebang ke karolo e bobebe bakeng sa sefofane kapa karolo e tšoarellang bakeng sa mochine o boima oa indasteri.

Indasteri ea likoloi ke e 'ngoe ea bareki ba kholo ka ho fetisisa ba lisebelisoa tsa mochini oa CNC. Ho tloha ho likarolo tsa enjene ho ea ho likarolo tsa phetisetso, mochini oa CNC o bapala karolo ea bohlokoa tlhahisong ea likoloi tse sebetsang hantle le tse tšepahalang. Ho nepahala le ho tsitsa ha likarolo tsa mochini oa CNC ho bohlokoa bakeng sa ho netefatsa polokeho le ts'ebetso ea likoloi tsa sejoale-joale. Indastering ea sepakapaka, likarolo tsa machining tsa CNC li sebelisoa ha ho etsoa likarolo tsa sefofane, joalo ka mahare a turbine, lisebelisoa tsa ho lulisa le likarolo tsa meralo. Likarolo tsena li tlameha ho fihlela litekanyetso tse thata tsa boleng le polokeho, 'me machining a CNC a lumella tlhahiso ea likarolo tse rarahaneng le tse rarahaneng ka boemo bo phahameng ka ho fetesisa.

Indasteri ea lisebelisoa tsa bongaka e boetse e itšetleha haholo ka likarolo tse ling tsa mochini oa CNC bakeng sa tlhahiso ea lisebelisoa tsa ho buoa, li-implants le lisebelisoa tsa tlhahlobo. Bokhoni ba ho etsa likarolo tse entsoeng ka mokhoa o ikhethileng ka ho nepahala ho ikhethang ke tsa bohlokoa bakeng sa ho netefatsa katleho le polokeho ea lisebelisoa tsa bongaka tse sebelisoang tlhokomelong ea bakuli. Lefapheng la lisebelisoa tsa elektroniki tsa bareki, likarolo tsa machining tsa CNC li sebelisoa ho hlahisa likarolo tsa li-smartphones, lilaptop le lisebelisoa tse ling tsa elektroniki. Tlhokahalo ea likarolo tse nyane, tse bobebe le tse tšoarellang ho feta e tsamaisitse ts'ebeliso ea machining ea CNC ho theha likarolo tse rarahaneng le tse nepahetseng haholo bakeng sa lihlahisoa tsena.

Ka kakaretso, likarolo tsa lisebelisoa tsa mochini oa CNC ke karolo ea bohlokoahali ea tlhahiso ea sejoale-joale, e nolofalletsang tlhahiso ea likarolo tsa boleng bo holimo tse etselitsoeng liindasteri tse fapaneng. Ha thekenoloji e ntse e tsoela pele, mochini oa CNC o tla bapala karolo ea bohlokoa ho fihlela litlhoko tse ntseng li tsoela pele tsa tlhahiso le ho khanna boqapi makaleng a fapaneng.

Nako ea poso: Jul-15-2024