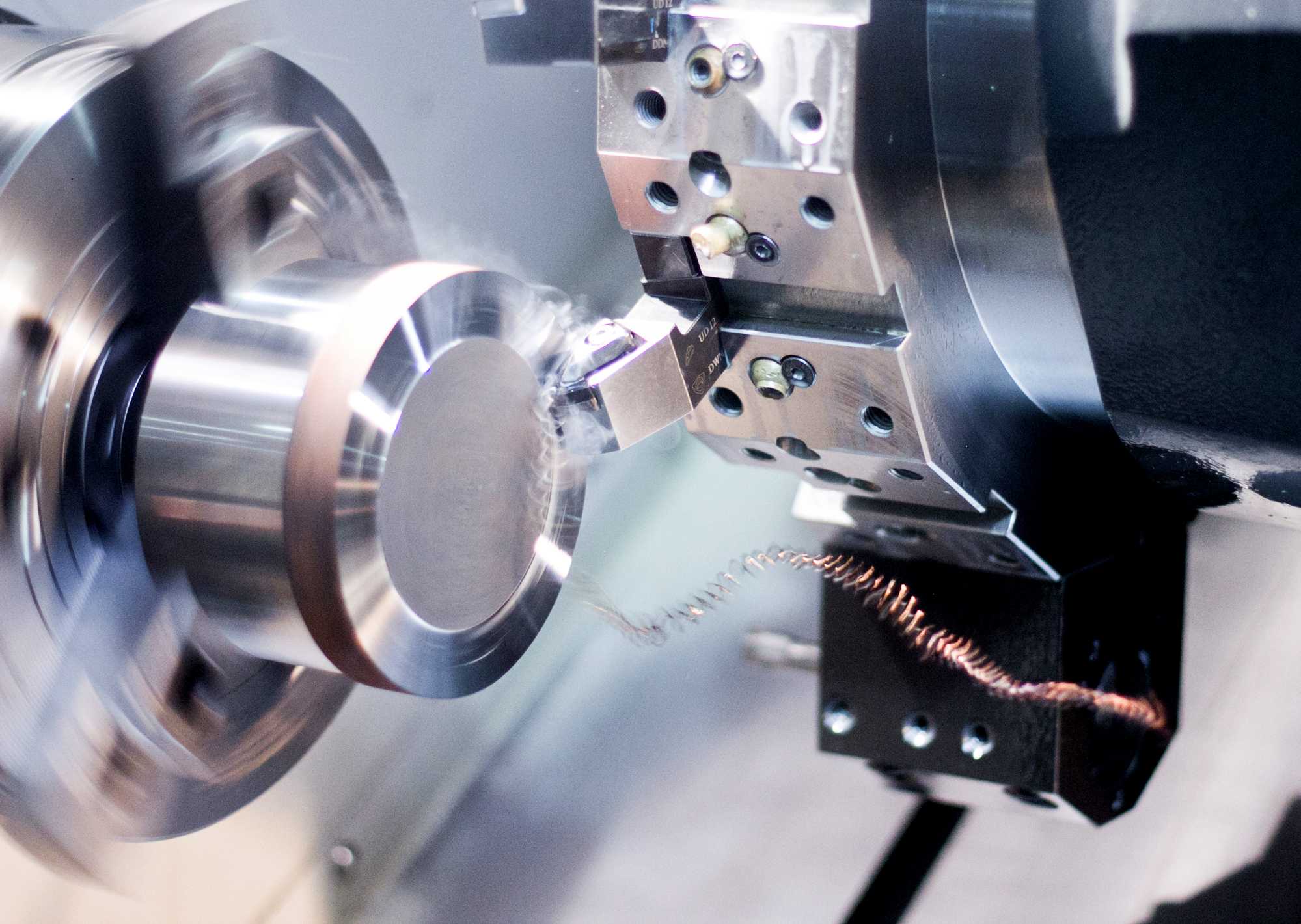

Lefats'eng la tlhahiso, machining a CNC le masela a tšepe ke lits'ebetso tse peli tsa bohlokoa tse bapalang karolo ea bohlokoa ho theheng mefuta e mengata ea lihlahisoa. Ho tloha ho likarolo tse rarahaneng ho ea ho mehaho e meholo, mekhoa ena e 'meli e ka pele ho tlhahiso ea morao-rao. Ha re shebisiseng bohlokoa ba ho etsa mochini oa CNC le masela a tšepe indastering. CNC (Computer Numerical Control) machining ke mokhoa oa tlhahiso o sebelisang lisebelisoa tsa lik'homphieutha le lisebelisoa tsa mochine ho tlosa thepa ho tloha mosebetsing. Mokhoa ona o nepahetseng le o sebetsang o lumella ho hlahisa likarolo tse rarahaneng tse nang le mamello e thata. Ebang ke ho sila, ho phethoha, kapa ho cheka, mochini oa CNC o fana ka ho nepahala ho ke keng ha bapisoa le ho pheta-pheta, ho e etsa khetho e ratoang bakeng sa liindasteri tse fapaneng, ho kenyeletsoa sefofane, likoloi le bongaka.

Ka lehlakoreng le leng, ho etsa lesela la tšepe ho kenyelletsa ho qhekella ha lishiti tsa tšepe ho etsa lihlahisoa tse fapaneng. Ho tloha ho masakaneng a bonolo ho isa libakeng tse koaletsoeng ka thata, ho etsoa ha litšepe ho kenyelletsa ho seha, ho kobeha, le ho kopanya lishiti tsa tšepe ho fihlela litlhoko tse khethehileng tsa moralo. Ka tsoelo-pele ea theknoloji, joalo ka laser cutting le CNC punching, masela a tšepe a se a feto-fetoha le maemo 'me a khona ho hlahisa meralo e rarahaneng ka nepo e phahameng. Ha machining a CNC le masela a tšepe a kopantsoe, phello ke synergy e matla e nolofalletsang ho theha lihlahisoa tse rarahaneng le tse tšoarellang. Bokhoni ba ho etsa likarolo tse nepahetseng tsa mochini le ho li kopanya ka har'a li- sheet metal assemblies bo fetotse indasteri ea tlhahiso, e lumellang tlhahiso ea lihlahisoa tse tsoetseng pele tse nang le boleng bo ikhethang.

E 'ngoe ea melemo ea bohlokoa ea ho sebelisaMechine ea CNCle tlhahiso ea tšepe ea lakane hammoho ke bokhoni ba ho finyella kopanyo e se nang moeli pakeng tsa likarolo tse entsoeng ka mochine le likarolo tsa lakane. Momahano ena ke ea bohlokoa liindastering tseo ho tsona ho nepahetseng le ho tšepahala ha meralo e leng tsona tsa bohlokoahali, tse kang tlhahisong ea likarolo tsa sefofane, lisebelisoa tsa bongaka le likabelo tsa elektroniki. Ho feta moo, motsoako oa machining oa CNC le masela a tšepe a fa bahlahisi monyetla oa ho sebetsa ka mefuta e mengata ea thepa, ho kenyeletsoa aluminium, tšepe e sa hloekang le titanium. Mokhoa ona oa ho feto-fetoha o lumella hore ho thehoe lihlahisoa tse sa tšoarellang feela le tse ka tšeptjoang empa hape le tse bobebe le tse khahlehang.

Ho phaella ho matla a bona ka bomong, CNC machining leletlapa la tšepeboqapi bo boetse bo kenya letsoho mekhoeng e tsitsitseng ea tlhahiso. Ka ho ntlafatsa ts'ebeliso ea thepa le ho fokotsa litšila, lits'ebetso tsena li ikamahanya le melao-motheo ea tlhahiso ea eco-friendly. Ho feta moo, bokhoni ba ho sebelisa le ho sebelisa likhechana tsa tšepe hape ho matlafatsa ts'ireletso ea tikoloho ea machining a CNC le masela a tšepe. Ha thekenoloji e ntse e tsoela pele, ho kopanngoa ha machining a CNC le masela a tšepe ho lebeletsoe hore e se ke ea senyeha le ho sebetsa hantle le ho feta. Tšebeliso ea software e tsoetseng pele bakeng sa moralo le ketsiso, hammoho le nts'etsopele ea mekhoa e mecha ea ho etsa machining le mekhoa ea ho etsa, e tla ntlafatsa le ho feta bokhoni ba sehlopha sena se matla sa tlhahiso.

Qetellong, machining a CNC le masela a tšepe ke likarolo tsa bohlokoa tsa tlhahiso ea sejoale-joale, e fanang ka ho nepahala, ho tenyetseha le ho tšoarella. Ho kopana ha mekhoa ena e 'meli ho fetotse tlhahiso ea mefuta e mengata ea lihlahisoa, ho tloha ho likarolo tse rarahaneng ho ea ho tse kholo. Ha indasteri ea tlhahiso e ntse e tsoela pele ho fetoha, tšebelisano lipakeng tsa mochini oa CNC le masela a tšepe ntle le pelaelo e tla bapala karolo ea bohlokoa ho bopeng bokamoso ba tlhahiso.

Nako ea poso: Jul-23-2024