Likarolo tsa tšepe tsa aluminiumli fetohile karolo ea bohlokoa liindastering tse fapaneng ka lebaka la ho feto-fetoha ha tsona, ho tšoarella, le thepa e bobebe. Ho tloha sebakeng sa sefofane le likoloi ho ea ho tsa kaho le tsa elektronike, tlhokahalo ea likarolo tsa tšepe ea aluminium e ntse e eketseha ha baetsi ba lihlahisoa ba batla litharollo tsa boleng bo phahameng, tse bolokang chelete e ngata bakeng sa lihlahisoa tsa bona. Indastering ea sepakapaka, likarolo tsa tšepe tsa aluminium li batloa haholo bakeng sa karo-karolelano ea tsona e ikhethang ea boima ba 'mele, ho hanyetsa kutu, le bokhoni ba ho mamella mocheso o feteletseng. Lintho tsena li etsa hore li tšoanelehe bakeng sa likarolo tsa sefofane, tse kang liphanele tsa fuselage, matlalo a mapheo le likarolo tsa sebopeho. Tšebeliso ea likarolo tsa tšepe ea aluminium lits'ebetsong tsa sefofane ha e thuse feela ho sebetsa hantle ha mafura empa hape e ntlafatsa ts'ebetso le polokeho ea lifofane.

Holefapha la likoloi, likarolo tsa tšepe tsa aluminium li bapala karolo ea bohlokoa tlhahisong ea likoloi tse bobebe tse fanang ka ts'ebetso e ntle ea mafura le ho fokotsa mesi. Ho tloha ho liphanele tsa 'mele le likarolo tsa chassis ho ea ho li-exchange tsa mocheso le likarolo tsa enjene,aluminiumlikarolo tsa sheet metal li sebelisoa haholo ho fihlela tekano e lakatsehang lipakeng tsa matla le boima ba 'mele. Ha indasteri ea likoloi e ntse e tsoela pele ho etelletsa pele botsitso le ts'ebetso ea matla, tlhoko ea likarolo tsa tšepe ea aluminium e lebelletsoe ho nyoloha le ho feta. Indasteri ea kaho e boetse e rua molemo tšebelisong ea likarolo tsa tšepe tsa aluminium, haholo-holo ha ho etsoa lirafshoa tsa meralo, litsamaiso tsa marulelo le likarolo tsa sebopeho. Mofuta o bobebe oa aluminium o etsa hore e be khetho e khahlehang bakeng sa merero ea kaho, kaha e lumella ho tšoara, ho kenya le ho tsamaisa habonolo. Ho feta moo, ho hanyetsa ha kutu ea likarolo tsa tšepe tsa aluminium ho netefatsa bophelo bo bolelele le tlhokomelo e fokolang, e leng se etsang hore e be tharollo e theko e boima bakeng sa lits'ebetso tse fapaneng tsa moaho. Lefapheng la lisebelisoa tsa elektronike, tlhokahalo ea likarolo tsa tšepe ea aluminium e tsamaisoa ke tlhokahalo ea likarolo tse ka tšeptjoang, tse bobebe le tse senyang mocheso.

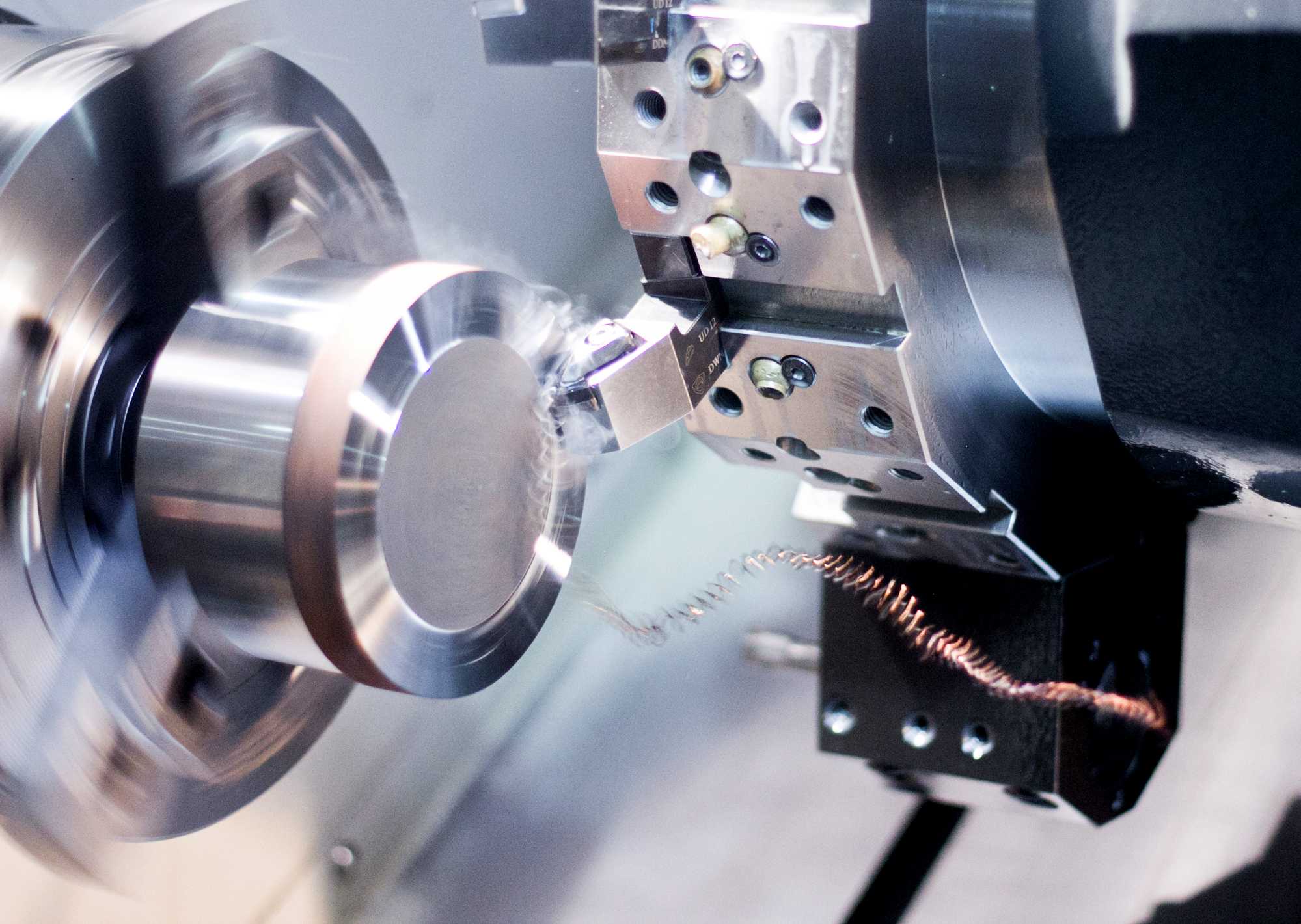

Tšebeliso e ntle ea mocheso oa Aluminium le thepa ea motlakase e e etsa thepa e loketseng bakeng sa likabelo tsa elektroniki, lisinki tsa mocheso, le likarolo tse ling tsa bohlokoa tse hlokang taolo e nepahetseng ea mocheso le tšireletso ea motlakase. Ha indasteri ea lisebelisoa tsa elektroniki e ntse e tsoela pele, tlhokahalo ea likarolo tsa tšepe tsa aluminium tse entsoeng ka nepo e lebelletsoe ho hola ka mokhoa o ts'oanang. Ho feto-fetoha ha likarolo tsa tšepe tsa aluminium ho fetela ka nqane ho liindasteri tsena, ka ts'ebeliso ea likepe, matla a ka nchafatsoang, thepa ea bareki le tse ling. Bokhoni ba ho theha, ho cheselletsa le ho qeta likarolo tsa tšepe tsa aluminium ho latela lintlha tse nepahetseng li li etsa khetho e ratoang bakeng sa bahlahisi ba batlang litharollo tse sebetsang hantle bakeng sa lihlahisoa tsa bona. Ho feta moo, tsoelo-pele ea mahlale a mahlale a tšepe a aluminium, joalo ka ho itšeha ka laser, machining a CNC, le lits'ebetso tsa ho theha, e atolositse menyetla ea moralo le bokhoni ba tlhahiso ea likarolo tsa tšepe tsa aluminium.

Sena se lebisitse ho hlahisoeng ha likaroloana tse rarahaneng, tse bobebe, le tse entsoeng ka mokhoa o rarahaneng tse fihlelang litlhoko tse thata tsa liindasteri tsa morao-rao. Ha tsepamiso ea lefats'e ea ts'ebetso le ts'ebetso ea matla e ntse e eketseha, tlhoko ea likarolo tsa tšepe ea aluminium e lebelletsoe ho tsoela pele ho ea holimo. The recyclability ea aluminium ka ho eketsehileng ntlafatsa boipiletso ba eona e le

Qetellong, ho amoheloa ho pharaletseng ha likarolo tsa tšepe tsa aluminium ho pholletsa le liindasteri tse sa tšoaneng ho hatisa bohlokoa ba tsona e le tharollo e sebetsang, e tšoarellang, le e theko e tlaase bakeng sa mefuta e mengata ea lisebelisoa. Ha thekenoloji le mekhoa e mecha e ntse e tsoela pele ho ntlafatsa tlhahiso ea tšepe ea aluminium, monyetla oa tsoelo-pele e eketsehileng le lisebelisoa tse ncha li ngata haholo, li beha likarolo tsa tšepe tsa aluminium e le lejoe la motheo la tlhahiso ea morao-rao le nts'etsopele ea indasteri.

Nako ea poso: Jul-08-2024