Likarolo tsa Aluminium CNC li hlahile e le phetoho ea papali indastering ea tlhahiso, e fetolang tlhahiso ea likarolo tse nepahetseng ka ho tšoarella le ho feto-fetoha ha tsona. Tšebeliso ea theknoloji ea Computer Numerical Control (CNC) hammoho le aluminium e butse menyetla e mecha ea ho theha likarolo tse rarahaneng le tsa boleng bo phahameng ho pholletsa le liindasteri tse fapaneng. E 'ngoe ea melemo ea bohlokoa ea likarolo tsa aluminium CNC ke ho nepahala ha tsona ho ikhethang. Mechini ea CNC e khona ho hlahisa likarolo tse nang le mamello e matla haholo, ho netefatsa hore karolo ka 'ngoe e kopana le litlhaloso tse nepahetseng. Boemo bona ba ho nepahala bo bohlokoa liindastering tse kang sefofane, likoloi le lisebelisoa tsa elektroniki, moo le kheloha e nyane haholo e ka lebisang mathateng a bohlokoa a ts'ebetso.

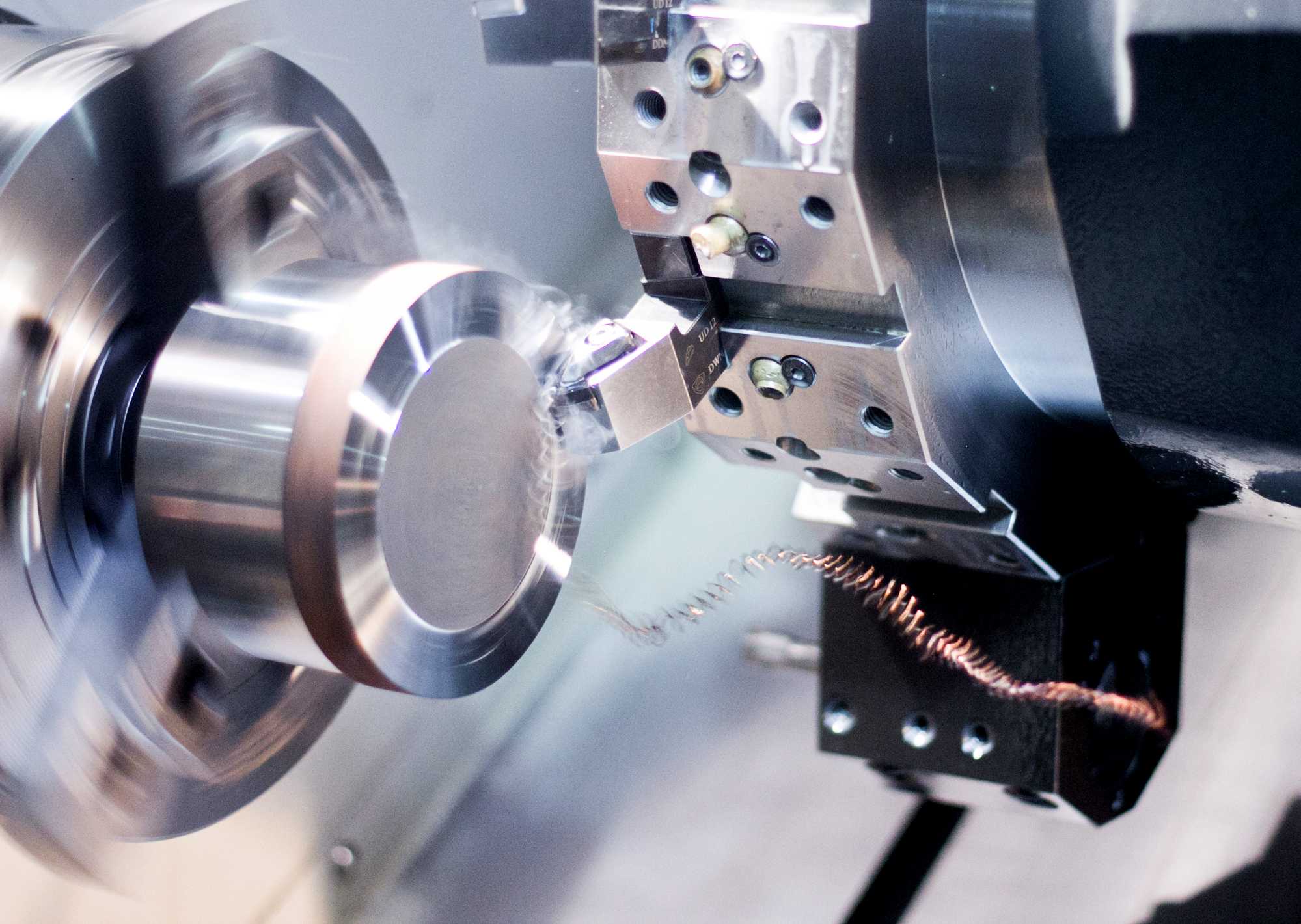

Ho feta moo,likarolo tsa aluminium CNCfana ka nako e telele le matla a ikhethang. Aluminium e tsebahala ka thepa ea eona e bobebe, e etsang hore e be khetho e nepahetseng bakeng sa lits'ebetso moo ho fokotsa boima ba 'mele ho tlang pele. Leha e le bobebe, aluminium e boetse e matla ka mokhoa o tsotehang, e fana ka botšepehi bo hlokahalang bakeng sa mefuta e mengata ea liindasteri le tsa khoebo. Ho feto-fetoha ha likarolo tsa aluminium CNC ke ntho e 'ngoe e susumetsang ho amoheloa ha tsona hohle. Ka theknoloji ea CNC, bahlahisi ba ka etsa lijeometri tse rarahaneng le meralo e rarahaneng e ka bang thata kapa e sa khoneheng ho e fihlela ho sebelisoa mekhoa ea khale ea machining. Ho feto-fetoha ha maemo hona ho lumella tlhahiso ea likarolo tse ikhethileng tse lumellanang le litlhoko tse itseng, ho fa likhoebo monyetla oa tlholisano limmarakeng tsa tsona.

Indastering ea sepakapaka, likarolo tsa aluminium CNC li sebelisoa ha ho etsoa likarolo tsa sefofane, joalo ka likarolo tsa sebopeho, likarolo tsa enjene le lisebelisoa tsa kahare. Sebopeho se bobebe sa aluminium se thusa ho fokotsa boima ba sefofane ka kakaretso, se lebisang ho ntlafatseng ts'ebetso ea mafura le ts'ebetso. Ho feta moo, ho nepahala ha CNCmachininge netefatsa hore likarolo tsena tsa bohlokoa li finyella litekanyetso tse thata tsa tšireletso tse hlokehang bakeng sa likopo tsa lifofane. Lefapheng la likoloi, likarolo tsa aluminium CNC li bapala karolo ea bohlokoa tlhahisong ea likarolo tsa enjene, likarolo tsa phetisetso le likarolo tsa chassis. Tšebeliso ea aluminiamo e thusa ho matlafatsa moruo oa mafura le ho fokotsa mesi, ho kenya letsoho ntlafatsong ea likoloi tse tšoarellang le tse bolokang tikoloho. Ho nepahala ha machining a CNC ho boetse ho netefatsa hore likarolo tsena li hokahane ka mokhoa o sa reroang moralong oa koloi ka kakaretso, ho ntlafatsa ts'ebetso le ts'epahalo.

Indasteri ea lisebelisoa tsa elektroniki le eona e rua molemo ts'ebelisong ea likarolo tsa aluminium CNC, haholo ha ho etsoa liphaello tsa elektroniki, licheso tsa mocheso le likhokahanyo. Aluminium e bobebe empa e tšoarella nako e telele e etsa hore e be thepa e loketseng ho sireletsa lisebelisoa tsa elektronike tse hlokolosi ha e ntse e ntša mocheso hantle. Ho nepahala ha machining a CNC ho lumella hore ho thehoe meralo e rarahaneng e lumellanang le litlhoko tse rarahaneng tsa lisebelisoa tsa sejoale-joale tsa elektroniki. Ho feta moo, makala a bongaka le a bophelo bo botle a sebelisa likarolo tsa aluminium tsa CNC ho hlahisa lisebelisoa tsa bongaka, li-prosthetics le lisebelisoa tsa lisebelisoa. The biocompatibility ea aluminium, e kopantsoeng le ho nepahala ha mechine ea CNC, e nolofalletsa ho theha likarolo tsa boleng bo phahameng, tse entsoeng ka tloaelo tse finyellang litekanyetso tse thata tsa indasteri ea tlhokomelo ea bophelo.

Qetellong, tšebeliso ea likarolo tsa aluminium CNC e fetotse haholo sebaka sa tlhahiso, e fana ka ho nepahala ho ke keng ha bapisoa, ho tšoarella, le ho feto-fetoha ha maemo ho pholletsa le mefuta e mengata ea liindasteri. Ha thekenoloji ea CNC e ntse e tsoela pele, monyetla oa ho theha likarolo tsa aluminium tse rarahaneng le tse ncha ha li na moeli, li bula tsela bakeng sa tsoelo-pele e eketsehileng indastering le boenjiniere.

Nako ea poso: Jul-29-2024