Aluminium alloy machining likarololi fetohile karolo ea bohlokoa ea liindasteri tse fapa-fapaneng ka lebaka la boima ba tsona bo bobebe, bo tšoarellang, le ho ikamahanya le maemo. Likarolo tsena li sebelisoa haholo makaleng a likoloi, sefofane, lisebelisoa tsa elektroniki le likarolo tse ling tsa tlhahiso, moo ho nepahala le ho ts'epahala ho leng bohlokoa. Tlhokahalo ea likarolo tsa machining ea aluminium alloy e ntse e eketseha butle-butle, e tsamaisoa ke tlhokahalo ea likarolo tse sebetsang hantle tse fanang ka tekanyo e phethahetseng ea matla le boima ba 'mele. E 'ngoe ea melemo ea mantlha ea likarolo tsa mochini oa aluminium alloy ke karo-karolelano e ikhethang ea matla ho boima ba 'mele. Sena se ba etsa khetho e nepahetseng bakeng sa lits'ebetso moo ho fokotsa boima ba 'mele ntle le ho sekisetsa botšepehi ba sebopeho ho bohlokoa. Ka mohlala, indastering ea likoloi, tšebeliso ea likarolo tsa mochini oa aluminium alloy e lebisitse ntlafatsong e kholo ea katleho ea mafura le ts'ebetso ea koloi ka kakaretso. Ho feta moo, indasteri ea sepakapaka e boetse e amohetse tšebeliso ea likarolo tsa machining a aluminium alloy kahong ea lifofane, moo ponto e 'ngoe le e' ngoe e bolokiloeng e fetolelang ho eketsa bokhoni ba ho lefa le ho fokotsa tšebeliso ea mafura.

Ho feto-fetoha ha likarolo tsa machining a aluminium alloy ke ntlha e 'ngoe e susumetsang ho amoheloa ha tsona hohle. Likarolo tsena li ka etsoa ka libopeho tse rarahaneng le meralo, e lumellang hore ho thehoelikarolo tsa tloaeloe etselitsoeng litlhoko tse khethehileng. Ho feto-fetoha ha maemo ho etsa hore likarolo tsa machining tsa aluminium alloy li tšoanelehe bakeng sa mefuta e mengata ea lisebelisoa, ho tloha likarolong tsa enjene le likarolo tsa meralo ho ea ho tse rarahaneng tsa elektronike le lijana tsa mocheso. Ho feta moo, likarolo tsa machining tsa aluminium alloy li fana ka khanyetso e ntle ea kutu, e li etsa hore li tšoanelehe ho sebelisoa libakeng tse thata le lits'ebetsong tsa kantle. Thepa ena, e kopantsoeng le ts'ebetso ea eona e phahameng ea mocheso, e etsa hore likarolo tsa machining tsa aluminium alloy e be khetho e nepahetseng bakeng sa li-exchangers tsa mocheso, litsamaiso tse pholileng le litharollo tse ling tsa taolo ea mocheso. Ka lebaka leo, likarolo tsena li ntse li sebelisoa ka ho eketsehileng lits'ebetsong tsa matla a tsosolositsoeng, tse kang liphanele tsa letsatsi le li-turbine tsa moea, moo ho tšepahala le ho phela nako e telele e leng tsa bohlokoa.

Tlhokahalo eamotsoako oa aluminiumlikarolo tsa machining li boetse li tsamaisoa ke mokhoa o ntseng o hola oa mekhoa ea tlhahiso e tšoarellang le e bonolo ea tikoloho. Aluminium ke thepa e ka sebelisoang hape, 'me tlhahiso ea likarolo tsa machining ea aluminium alloy e sebelisa matla a fokolang haholo ha a bapisoa le litšepe tse ling. Sena se etsa hore likarolo tsa machining tsa aluminium e be khetho e ratoang bakeng sa lik'hamphani tse batlang ho fokotsa tšusumetso ea tsona ea tikoloho le ho latela litekanyetso tse tiileng tsa ts'ebetso. Ntle le thepa ea bona ea mochini, likarolo tsa machining tsa aluminium alloy le tsona li ka phekoloa holimo ho ntlafatsa ts'ebetso le ponahalo ea tsona. Ka mohlala, anodizing e ka ntlafatsa ho hanyetsa ha kutu le ho apara likarolo tsa aluminium alloy, ha e ntse e fana ka qetello ea mokhabiso. Sena se holisa le ho feta ts'ebeliso e ka bang teng ea likarolo tsa mochini oa aluminium alloy ho pholletsa le liindasteri tse fapaneng, moo botle le ts'ebetso li tsamaisanang.

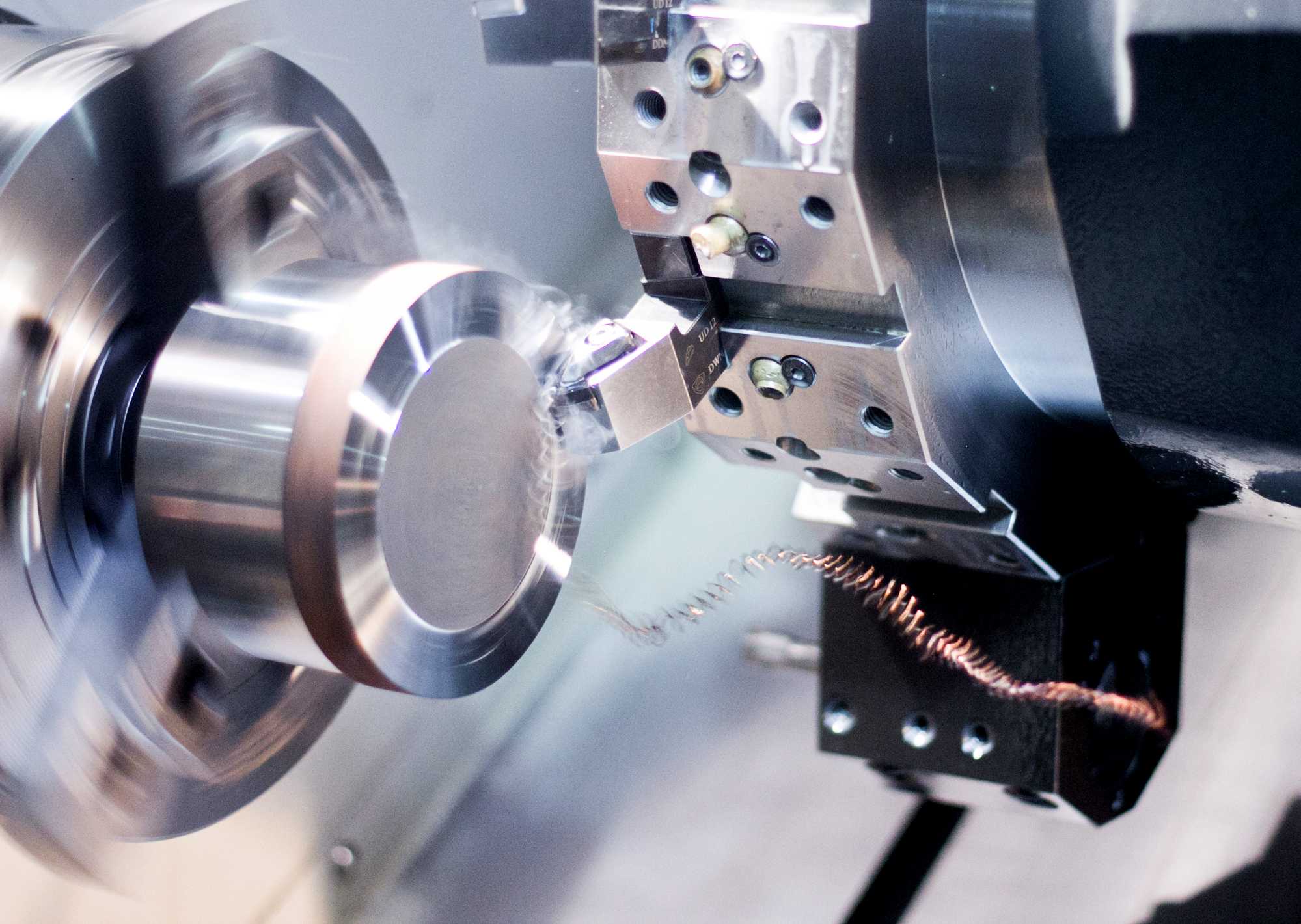

Ha re shebile pele, bokamoso ba likarolo tsa mochini oa aluminium alloy bo bonahala bo ts'episa, ka tsoelo-pele e tsoelang pele ea thepa.mahlale le theknoloji ea tlhahiso.Nts'etsopele ea li-alloys tse ncha tsa aluminium tse nang le thepa e ntlafalitsoeng, joalo ka matla a ntlafalitsoeng le sebopeho, e bula menyetla e mecha ea ts'ebeliso ea likarolo tsa machining tsa aluminium lits'ebetsong tse hlokahalang. Ho feta moo, ho amoheloa ha mekhoa e tsoetseng pele ea machining, joalo ka mochini oa CNC le tlhahiso ea tlatsetso, e nolofalletsa tlhahiso ea likarolo tse rarahaneng tsa aluminium tse nang le litšila tse nyane haholo.

Qetellong, likarolo tsa machining tsa aluminium alloy li hlahile e le motheo oa tlhahiso ea sejoale-joale, e fanang ka motsoako o hapileng oa kaho e bobebe, ho tšoarella le ho ikamahanya le maemo. Ha liindasteri li ntse li tsoela pele ho etelletsa pele ts'ebetso, ts'ebetso le botsitso, tlhoko ea likarolo tsa mochini oa aluminium alloy e lebelletsoe ho hola, ho khanna boqapi le ho sutumelletsa meeli ea se ka fihlellehang ka thepa ena e fapaneng. Ka boiteko bo tsoelang pele ba lipatlisiso le nts'etsopele, likarolo tsa machining tsa aluminium alloy li mothating oa ho bapala karolo ea bohlokoa ho bopeng bokamoso ba boenjiniere le moralo ho pholletsa le mefuta e mengata ea liindasteri.

Nako ea poso: Aug-26-2024