Lefats'eng latlhahiso, bokhoni ba ho etsa likarolo tsa mochini ho tsoa ho lisebelisoa tse fapaneng bo bohlokoa bakeng sa ho hlahisa lihlahisoa tsa boleng bo holimo. Ho tloha ho litšepe ho isa ho li-composite, tlhokahalo ea machining e nepahetseng ea lisebelisoa tse fapaneng e lebisitse tsoelopeleng e kholo ea mahlale a machining. E 'ngoe ea liphephetso tsa mantlha tsa ho etsa lisebelisoa tse fapaneng ke thepa e fapaneng ea thepa ka' ngoe. Litšepe tse kang aluminium, tšepe le titanium li hloka mekhoa e fapaneng ea machining ka lebaka la ho thatafala ha tsona, ductility le conductivity ea mocheso. Ka mokhoa o ts'oanang, li-composites tse kang carbon fiber le fiberglass li hlahisa mathata a tsona ka tlhaho ea tsona ea abrasive le tšekamelo ea ho senya nakong ea mochine.

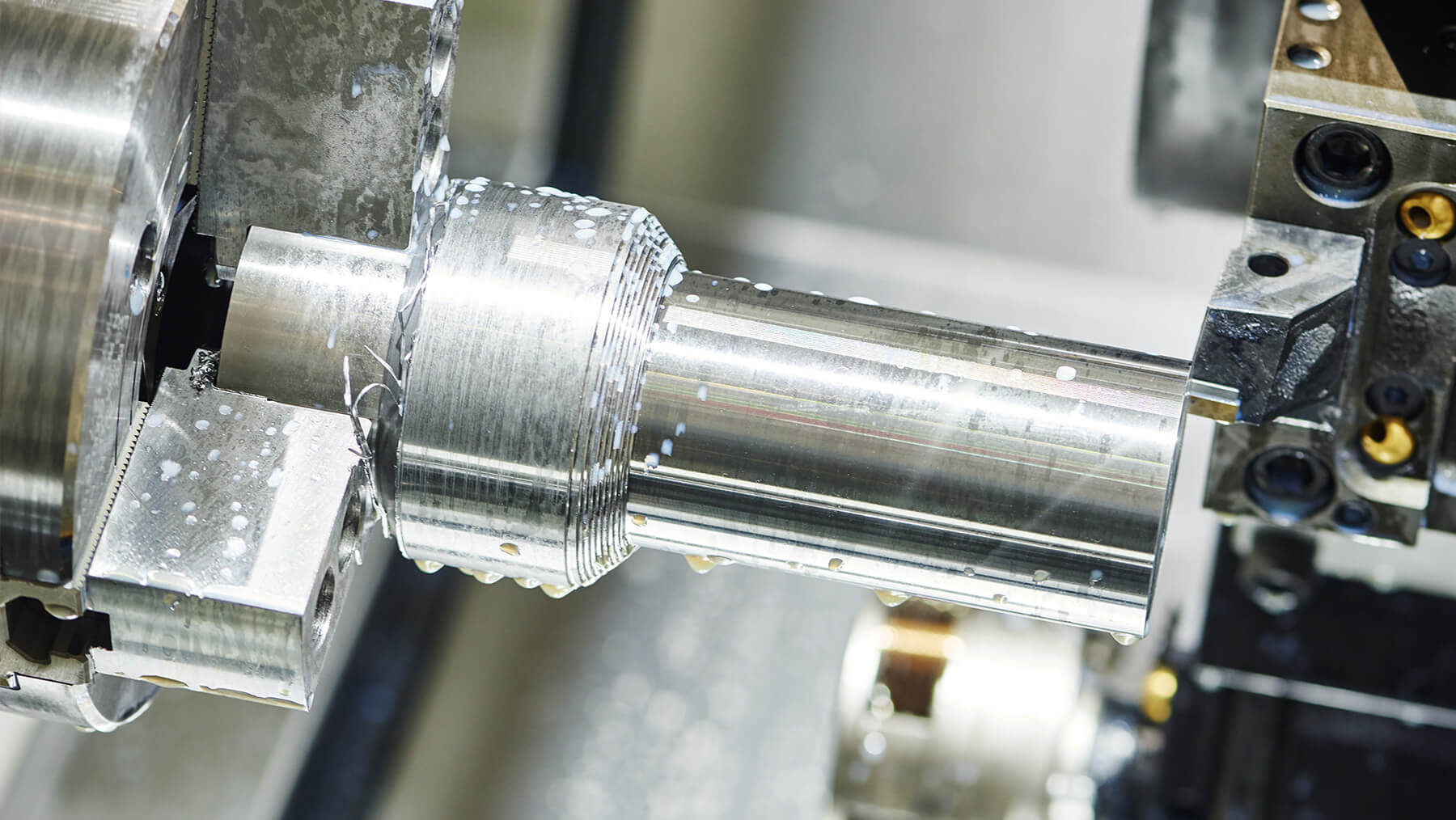

Ho rarolla mathata ana, bahlahisi ba ntse ba tsetela ho theknoloji e tsoetseng pele ea mochini e ka sebetsanang le mefuta e mengata ea lisebelisoa ka nepo le ka bokhabane. E 'ngoe ea theknoloji e joalo kemachining a multi-axis CNC, e lumellang hore li-geometri tse rarahaneng le ho mamellana ho thata ho finyelloe ka thepa e fapaneng. Ka ho sebelisa lisebelisoa tse tsoetseng pele tsa ho itšeha le maano a litsela, mochini oa CNC e se e le tharollo e sebetsang bakeng sa likarolo tsa machining ho tsoa litšepe, li-composites, esita le lisebelisoa tse sa tloaelehang joalo ka lirafshoa le li-alloys tse kholo. Ntle le machining a CNC, tsoelo-pele ea lisebelisoa tsa ho seha le eona e phethile karolo ea bohlokoa ho etseng lisebelisoa tse fapaneng. Lisebelisoa tsa tšepe tse lebelo le phahameng (HSS) le li-carbide e 'nile ea e-ba khetho ea setso bakeng sa lisebelisoa tsa machining, empa ho phahama ha lisebelisoa tsa ceramic le taemane tse koahetsoeng ke daemane ho ekelitse bokhoni ba ho sebetsa ho kenyelletsa lisebelisoa tse thata le tse senyang.

Tsena li tsoetse pelelisebelisoa tsa ho sehafana ka ho ntlafala ha moaparo le botsitso ba mocheso, ho lumella hore ho be le lebelo le phahameng la ho itšeha le bophelo bo bolelele ba lisebelisoa ha ho etsoa lisebelisoa tse kang Inconel, tšepe e thata, le metsoako ea carbon. Ho feta moo, ho kopanngoa ha tlhahiso ea tlatsetso le mekhoa ea ho etsa mechine ea setso ho butse menyetla e mecha ea ho hlahisa likarolo ho tsoa mefuteng e fapaneng ea thepa. Sistimi ea tlhahiso ea li-hybrid, e kopanyang khatiso ea 3D le machining ea CNC, e nolofalelitse ho hlahisa likarolo tse rarahaneng, tse sebetsang hantle tse nang le thepa e hlophisitsoeng. Mokhoa ona o bile molemo ka ho khetheha bakeng sa liindasteri tse kang sefofane le likoloi, moo lisebelisoa tse bobebe, tse matla haholo li hlokahalang haholo.

Tsoelo-pele ea mahlale a machining bakeng sa lisebelisoa tse fapaneng e boetse e susumetsoa ke tlhoko e ntseng e hola ea mekhoa e tsitsitseng ea tlhahiso. Ka ho tsepamisa maikutlo ho fokotsa litšila tsa thepa le tšebeliso ea matla, mekhoa ea machining e fetohile ho sebetsa hantle le ho boloka tikoloho. Mohlala, ts'ebeliso ea lisebelisoa tse pholisang tse nang le khatello e phahameng ea khatello le lubrication ea bonyane ba bongata li ntlafalitse ho ntšoa ha li-chip le ho fokotsa tšebeliso ea maro a sehang, e leng se lebisang ho tšoarelleng le ho feta.mokhoa oa ho sebetsa. Ho feta moo, ho amoheloa ha mahlale a tlhahiso ea dijithale, joalo ka software ea ketsiso le lits'ebetso tsa ho lekola nako ea nnete, ho matlafalitse ponelopele le taolo ea lits'ebetso tsa machining bakeng sa lisebelisoa tse fapaneng. Ka ho etsisa machining a lisebelisoa tse fapaneng, bahlahisi ba ka ntlafatsa maano a lisebelisoa le mekhoa ea ho seha ho fokotsa ho roala ha lisebelisoa le ho eketsa tlhahiso.

Litsamaiso tsa tlhahlobo ea nako ea 'nete li fana ka lintlha tsa bohlokoa mabapi le boemo ba sesebelisoa le botsitso ba ts'ebetso, e lumellang tlhokomelo e potlakileng le netefatso ea boleng nakong ea ts'ebetso ea mochini. Qetellong, tsoelo-pele ea theknoloji ea machining bakeng sa lisebelisoa tse fapaneng e fetotse indasteri ea tlhahiso, e nolofalletsang tlhahiso ea likarolo tsa boleng bo holimo tse nang le lisebelisoa tse kholo.ho nepahala, ho sebetsa hantle, le ho tšoarella. Ka nts'etsopele e tsoelang pele ea machining a multi-axis CNC, lisebelisoa tse tsoetseng pele tsa ho itšeha, tlhahiso e nyalisitsoeng, le theknoloji ea tlhahiso ea dijithale, bahlahisi ba hlometse hantle ho fihlela litlhoko tsa likarolo tsa machining tse tsoang mefuteng e fapaneng ea thepa. Ha indasteri e ntse e tsoela pele ho fetoha, ho kopanngoa ha thepa e ncha le theknoloji ho tla tsoela pele ho atolosa menyetla ea ho sebetsa ka mechine, ho khanna mekhoa e mecha le tsoelo-pele ea tlhahiso.

Nako ea poso: May-06-2024